Modern heating solutions incorporate a variety of essential elements that work together to create an efficient and sustainable environment. Each component within these systems plays a crucial role, ensuring proper functionality and maintaining consistent energy output. Exploring the structure and interconnections of these elements is vital for users seeking to optimize their setup for both performance and longevity.

When examining the inner workings of these systems, it becomes clear how crucial proper maintenance and replacement of certain components are. Each part contributes to the overall balance, and understanding their roles can lead to better performance. For those who rely on advanced heating technologies, this knowledge becomes invaluable for ensuring efficiency and safety.

Through a detailed exploration of these components, we gain insight into how various elements interact, ultimately achieving a smooth and reliable operation. This approach allows users to identify potential areas for improvement and make informed decisions about necessary updates or repairs.

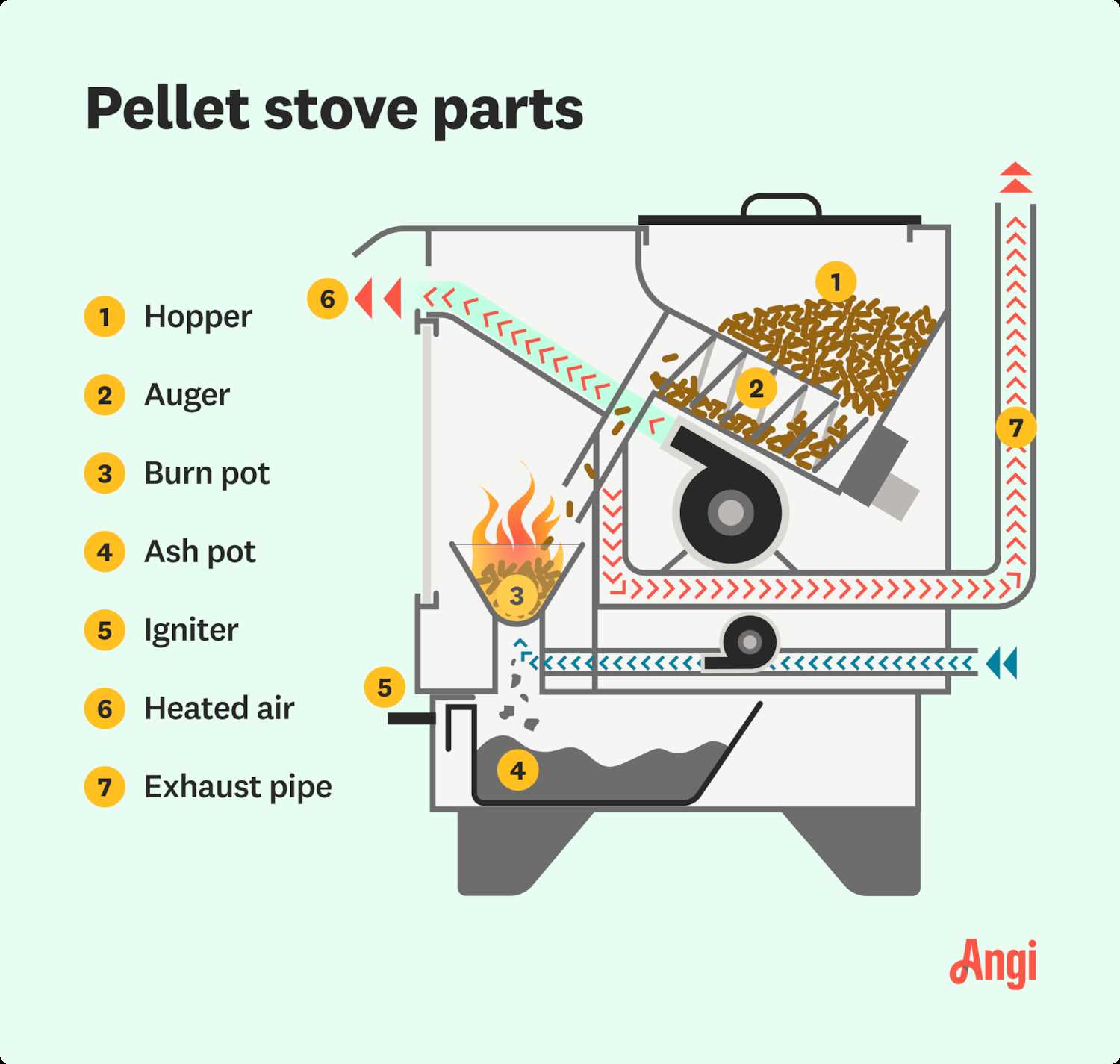

Overview of Heating System Components

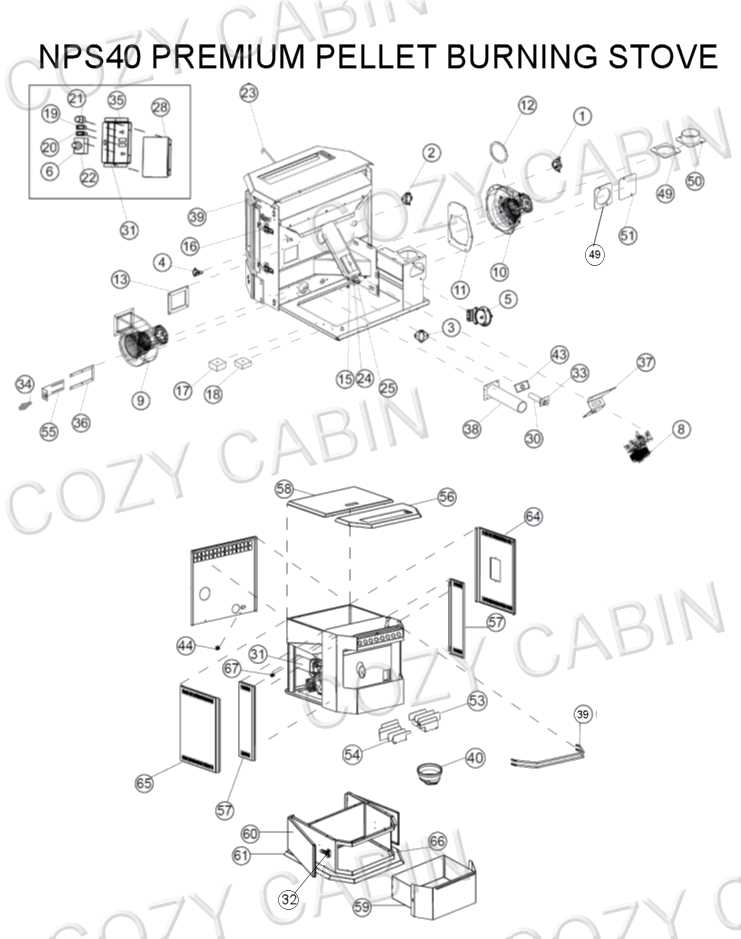

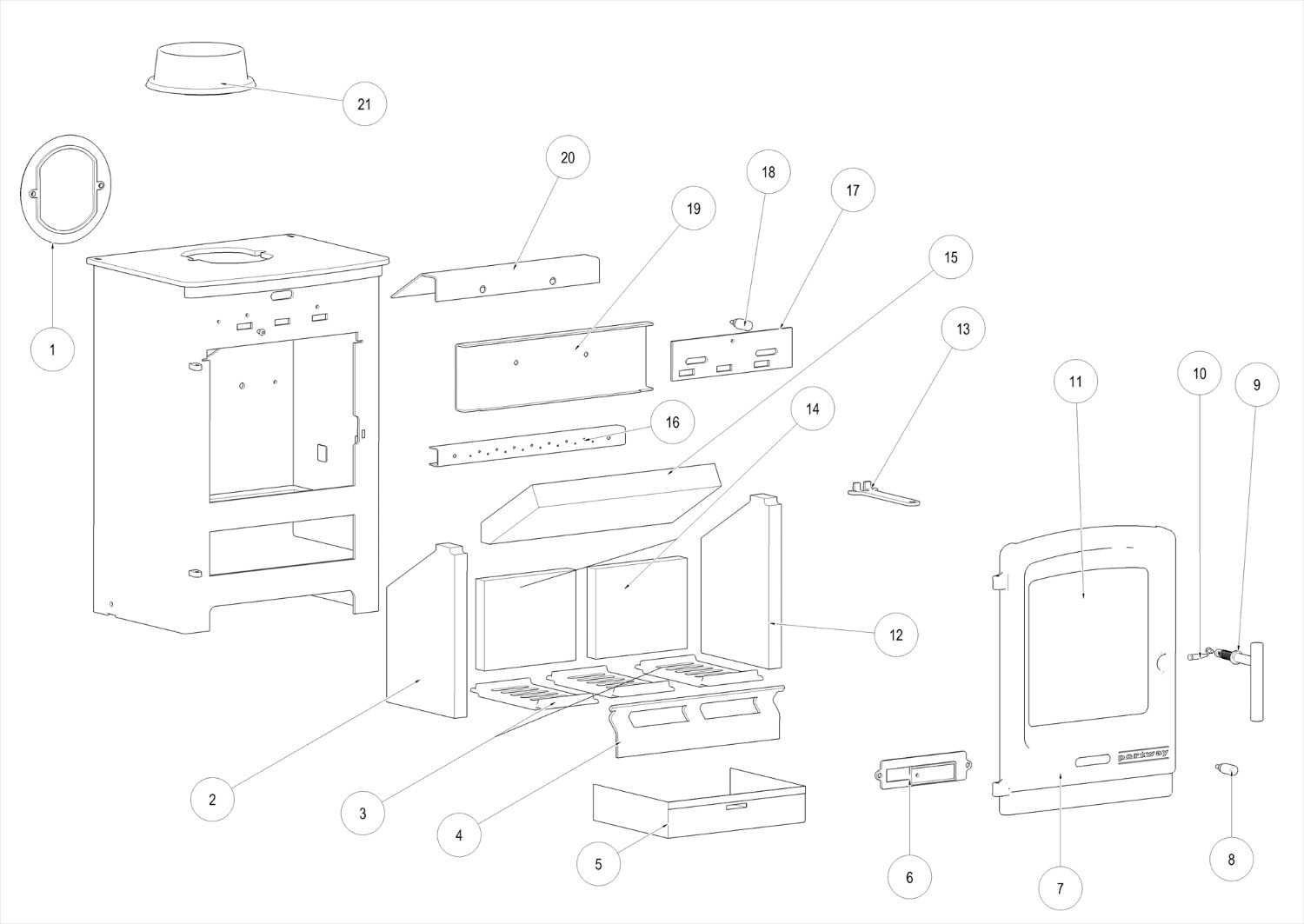

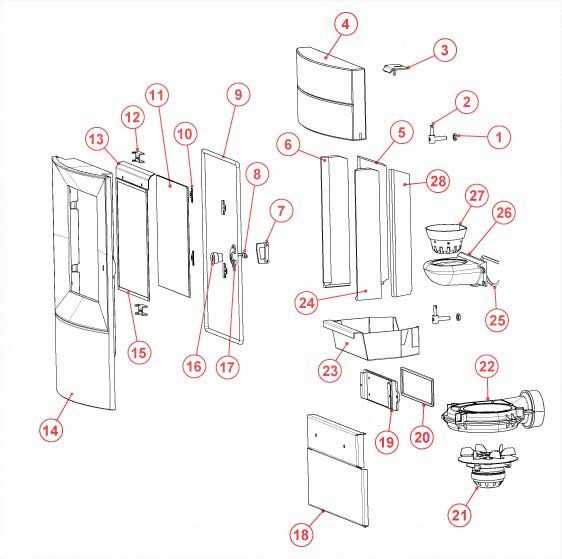

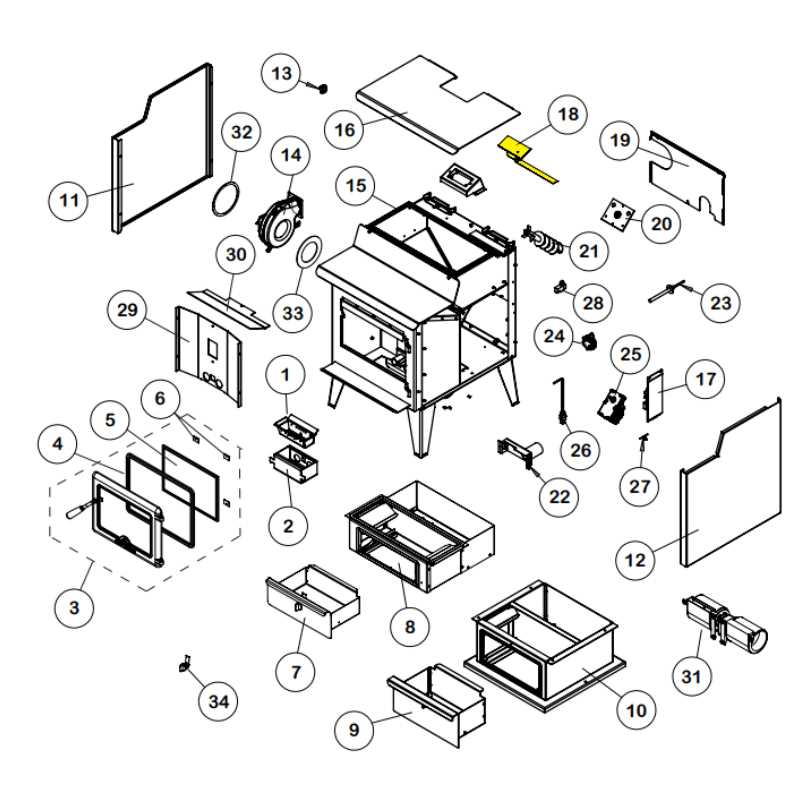

Understanding the elements that contribute to an efficient heating system is essential for maintaining consistent warmth and proper functionality. Each component plays a unique role in ensuring the seamless operation of the system, from generating warmth to regulating air flow and controlling fuel consumption.

Key elements include mechanisms that distribute heated air or liquid throughout the structure, regulators that adjust temperatures, and various safety features designed to prevent overheating or system malfunctions. Recognizing the functions of these individual components can help in troubleshooting issues or improving overall system performance.

Key Elements for Proper Functioning

For any system to operate effectively, each of its components must work in harmony. Ensuring the right balance between mechanical elements and control units is critical to maintaining efficient operation. Regular maintenance and attention to detail will help extend the lifespan of the entire system.

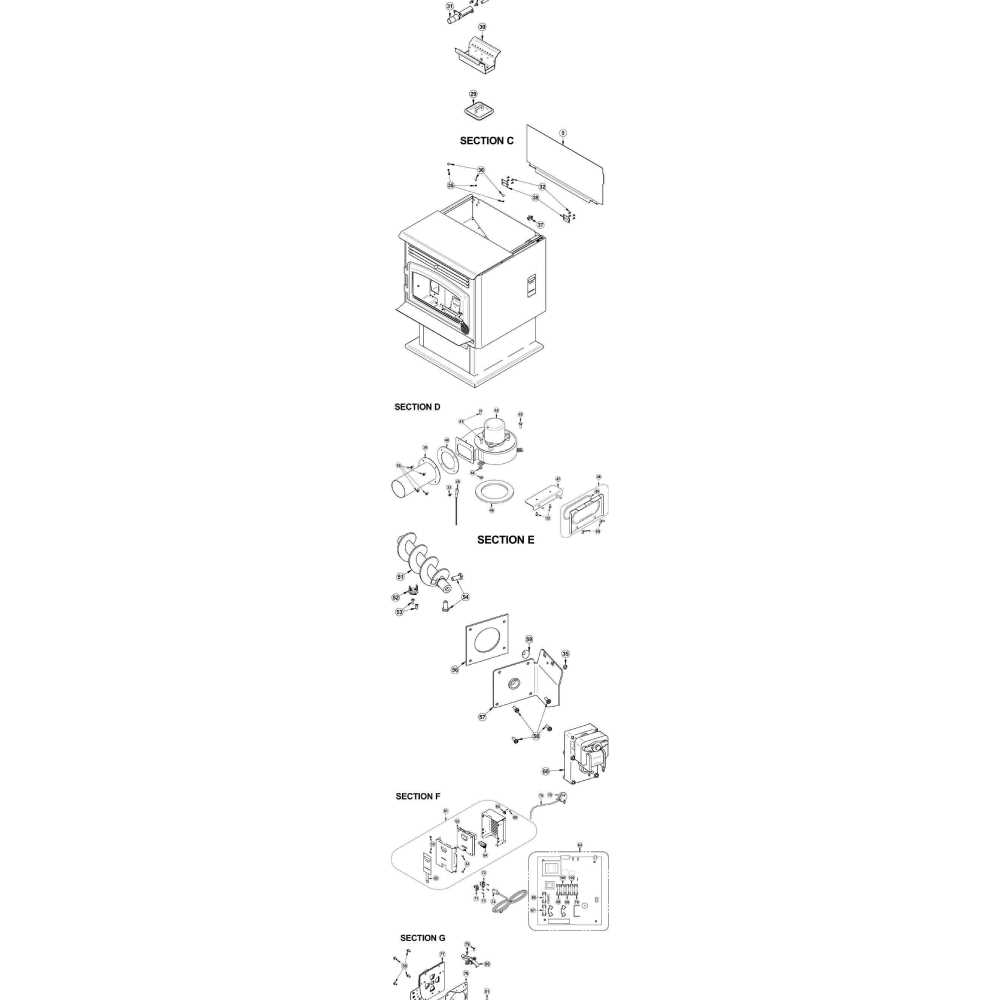

Control Mechanisms

Monitoring and regulating internal processes is essential for smooth performance. Sensors play a crucial role in detecting changes, while controllers adjust settings accordingly. These systems need to be calibrated and checked to prevent disruptions.

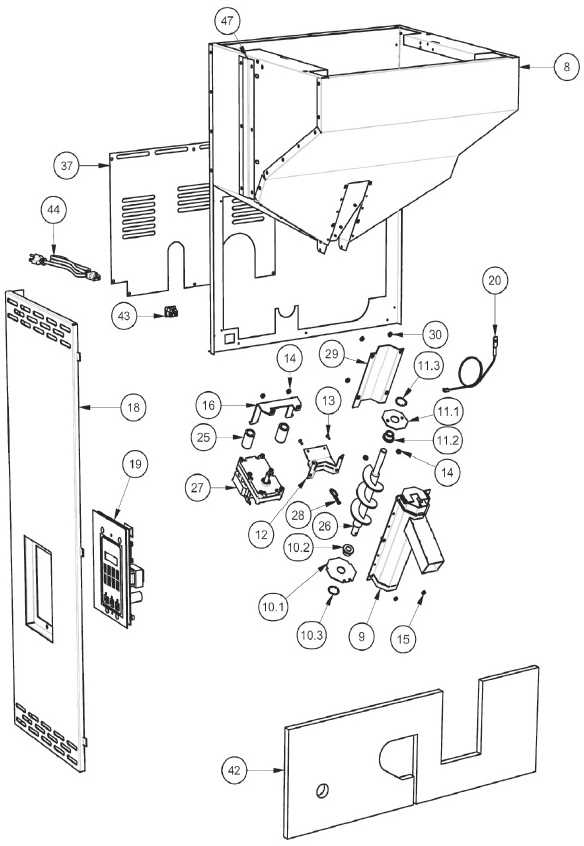

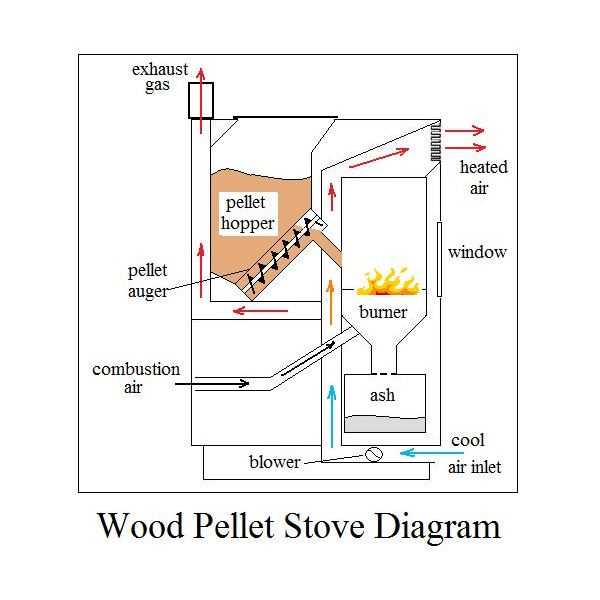

Airflow and Combustion Management

Maintaining a steady flow of air is vital for combustion efficiency. Proper ventilation not only supports optimal function but also enhances safety by preventing buildup in the system. Balancing air intake and exhaust ensures a more consistent operation.

| Component | Function |

|---|

| Component | Function | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Container | Holds the energy material securely for continuous supply | |||||||||||

Transport Mechan

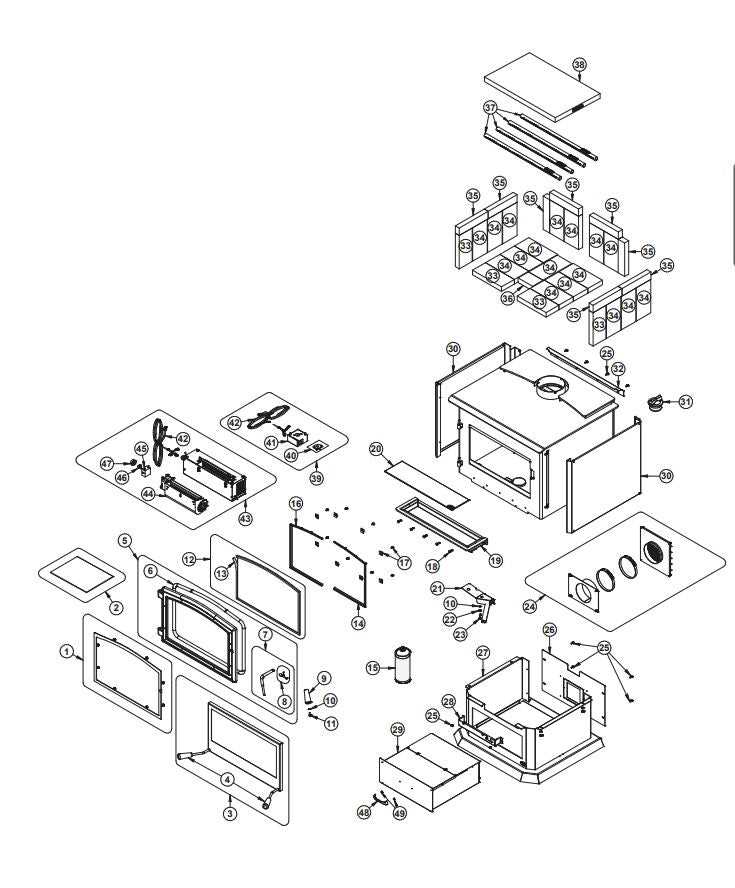

Understanding Air Circulation MechanismsEfficient air movement is essential for maintaining proper functionality and ensuring optimal performance. The flow of air helps distribute heat evenly, prevent overheating, and maintain a consistent temperature throughout the system. By understanding how these systems work, it becomes easier to identify potential issues and improve overall efficiency. Key Components of AirflowThe air circulation system typically includes fans, vents, and ducts designed to manage air intake and output. Each component plays a crucial role in ensuring that the movement of air is smooth and unobstructed. Proper maintenance of these elements is vital for consistent operation and to avoid potential breakdowns. Enhancing Circulation Efficiency

Improving the efficiency of air movement can significantly enhance system per Temperature Regulation and Control DevicesMaintaining a stable and comfortable environment requires precise systems that monitor and adjust heat levels. These devices play a critical role in ensuring safety and energy efficiency by responding to varying conditions and automatically adjusting to keep the environment within the desired temperature range. Thermostatic SensorsThermostatic sensors are essential in detecting changes in heat levels. They continuously monitor the ambient temperature and send signals to the control units, which can then regulate the heating elements accordingly. These sensors ensure that heating systems operate within safe and efficient parameters. Control Panels and Adjustment MechanismsControl panels allow users to manually set and adjust temperature preferences. These panels are often equipped with digital displays and offer a range of settings to suit different needs. Advanced systems may include programmable options, allowing for automatic adjustments based on time of day or external conditions.

|