Maintaining the performance of your cleaning device requires a thorough understanding of its internal structure and individual elements. Knowing how the parts work together allows for better troubleshooting, efficient repairs, and ultimately a longer lifespan for the machine. Whether you are replacing a worn-out piece or attempting to identify an issue, having a clear overview of the various components is essential.

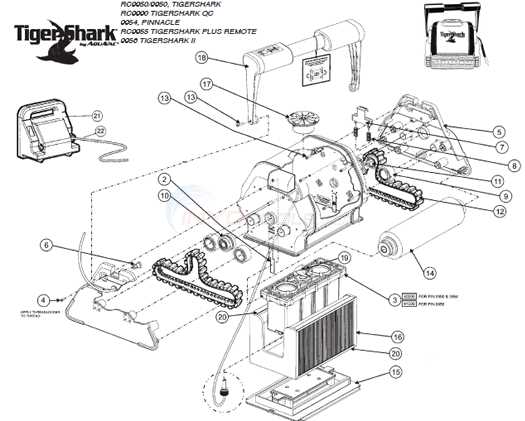

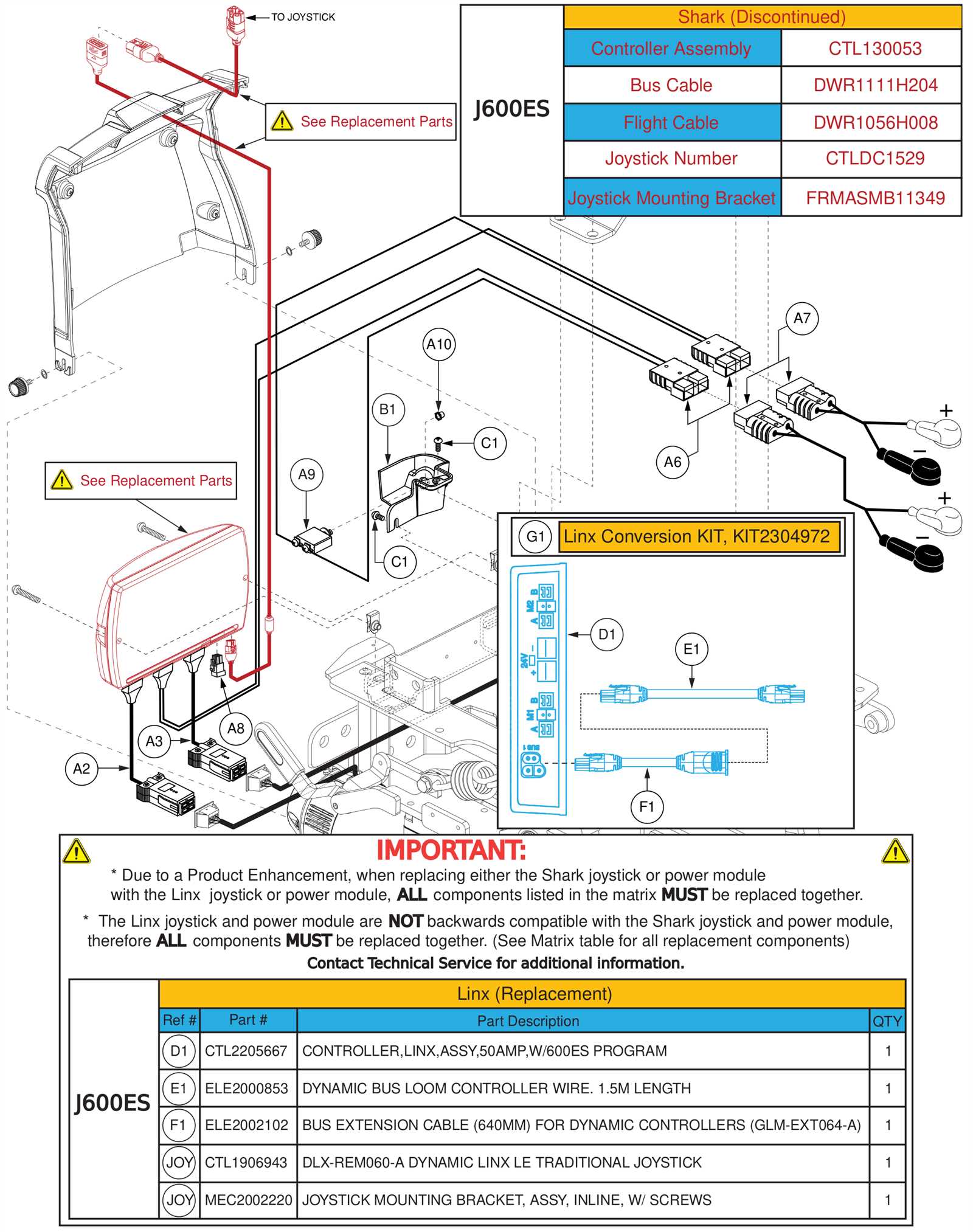

Detailed reference charts can be incredibly helpful when disassembling or servicing your cleaner. These visual guides provide an organized view of each segment, showing how every part connects and functions within the larger system. Such resources can assist in pinpointing the exact piece that requires attention, saving both time and effort.

In this section, we’ll explore an in-depth breakdown of the various segments found in typical vacuum models, focusing on their roles, how they interact, and how to identify potential issues. Understanding this structure will ensure you are well-prepared for maintenance or repair tasks.

Shark NV355 Parts Overview

This section provides a detailed look at the key components that make up a high-performance vacuum cleaner model. Understanding the individual elements that work together can help users identify and address maintenance needs, as well as improve the overall longevity of the machine. By familiarizing yourself with these core components, you can ensure the optimal functioning of your device, preventing unnecessary repairs and enhancing its efficiency.

Essential Components Breakdown

The unit consists of several integral parts, each playing a significant role in the vacuum’s performance. These elements include the motor, filtration system, brushes, and other accessories that contribute to its versatile cleaning capabilities. Identifying any wear or damage in these areas allows users to take proactive steps to maintain the device, ensuring it continues to operate at peak efficiency.

Component Identification and Function

Each section below highlights the function of specific parts and their importance in maintaining the overall functionality of the device. Regular checks can prevent larger issues from arising and ensure that all parts remain in working order, contributing to an uninterrupted cleaning experience.

| Component | Function |

|---|---|

| Motor | Provides the suction power necessary for effective cleaning. |

| Brush Roll | Helps dislodge dirt and debris from carpets and upholstery. |

| Filter System | Traps fine dust particles, ensuring cleaner air output. |

| Dust Canister | Collects and stores debris until it is emptied. |

| Hose | Allows for flexible cleaning of hard-to-reach areas. |

Understanding Key Components of Shark NV355

To properly maintain and troubleshoot a cleaning device, it’s crucial to understand the primary elements that enable it to function effectively. Each component plays a unique role, working together to ensure optimal performance. By familiarizing yourself with these key parts, you can easily identify issues, carry out repairs, or even upgrade certain features to improve efficiency.

Major Functional Elements

Various components within the device contribute to its overall capability. Motors, filters, and brushes are just a few critical elements that directly impact cleaning efficiency. Understanding their design and purpose is essential for proper maintenance and maximizing the appliance’s lifespan. Below is a breakdown of some of the most important components:

| Component | Function |

|---|---|

| Motor | Generates suction power to lift dirt and debris from surfaces. |

| Filter | Traps dust and allergens, ensuring cleaner air during use. |

| Brush Roll | Dislodges dirt and debris from carpets or hard floors, aiding in a deeper clean. |

| Hose | Facilitates extended reach for cleaning tight spots or upholstery. |

| Dust Canister | Collects dirt and debris as the device operates, which is then emptied for reuse. |

Ensuring Longevity and Performance

By regularly inspecting and maintaining these components, users can prevent unnecessary wear and tear. Replacing worn-out parts, cleaning filters, and ensuring the motor is functioning correctly will extend the life of the unit and maintain its high-performance standards. Understanding each element’s function is the first step toward efficient and hassle-free operation.

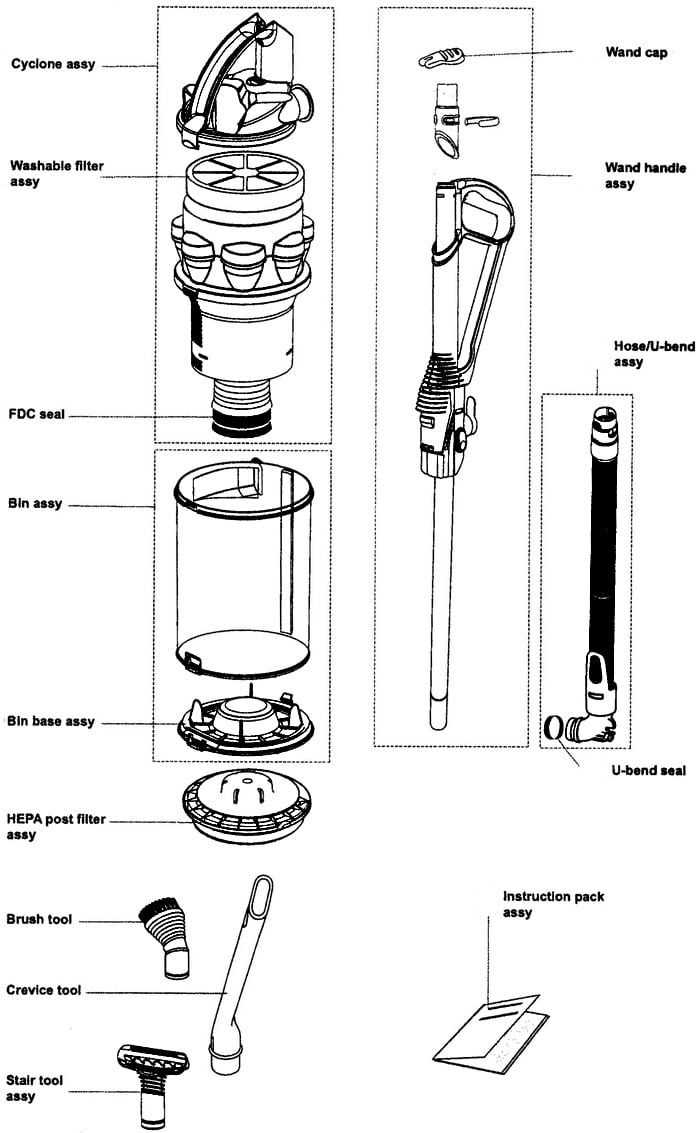

How to Locate Parts in the Diagram

Finding specific components in a technical illustration can be challenging without proper guidance. These schematics are designed to simplify the process by clearly labeling each element, but understanding how to read and navigate the details is essential. This section will explain how to efficiently identify and locate individual elements within a complex visual representation.

Step-by-Step Process

Begin by identifying the overall structure or category that the part belongs to. Typically, the drawing will group similar components together, making it easier to narrow down your search. Once you have an idea of the general area, look for corresponding numbers, letters, or symbols next to each item. These labels often correspond to a list or key, which will provide more specific information about each item, including its function and availability.

Utilizing the Index or Key

The key or index is a critical resource for interpreting the illustration. It will usually be found alongside or beneath the visual representation and will match the labels from the diagram with their descriptions. By cross-referencing these details, you can pinpoint the exact part you’re looking for with precision, whether for replacement, maintenance, or troubleshooting.

Common Shark NV355 Repair Parts

When it comes to maintaining and fixing your vacuum cleaner, understanding the common replacement components can make a huge difference. Over time, certain elements of the appliance wear down and need attention to ensure optimal performance. Whether it’s a worn-out brush, a broken hose, or a clogged filter, knowing which parts are most prone to damage helps streamline the repair process and ensures a smoother cleaning experience.

Frequently Replaced Components

- Brush Roll: The rotating brush is essential for deep cleaning, but it often becomes clogged with hair or debris. A damaged or worn brush roll can reduce the effectiveness of the vacuum.

- Filters: Over time, filters can become clogged with dust and dirt, making them less effective. Regular replacement helps maintain airflow and suction power.

- Hose: Cracks or blockages in the hose can cause a loss of suction. Replacing a damaged hose restores efficiency.

- Belts: A broken or stretched belt can cause the brush roll to stop spinning, which reduces the vacuum’s ability to pick up debris.

Where to Find These Items

- Authorized service centers often provide genuine replacements for all the necessary components.

- Online retailers and specialty vacuum part websites are convenient sources for purchasing compatible parts.

- Local hardware stores sometimes carry essential components like filters and hoses.

Step-by-Step Guide to Replacing Parts

When it comes to maintaining or repairing your home cleaning device, knowing how to replace worn or damaged components is essential for optimal performance. Following a structured approach ensures that the process is smooth, minimizes downtime, and restores functionality efficiently. This guide will walk you through the necessary steps to get your equipment up and running again.

Preparation and Safety

Before starting any repair, ensure that the device is powered off and unplugged from the outlet. This will prevent any risk of electric shock or accidental activation. Lay out all the tools you might need, such as screwdrivers, pliers, or replacement components, in an organized manner. Having everything ready before you begin will streamline the process and avoid interruptions.

Disassembly and Removal

Begin by carefully disassembling the unit. Depending on the type of device, you may need to remove screws or unlock latches to access internal components. Take your time with each step to avoid damaging any parts. It’s a good idea to take photos or note the order in which components are removed for easier reassembly later. Once the necessary components are exposed, proceed to remove the damaged or worn-out part, ensuring that no other components are disturbed in the process.

Tip: Keep track of any small screws or fasteners to avoid losing them. Using a small container or magnetic tray can help with this.

Installing the New Component

Now that the faulty part has been removed, it’s time to install the replacement. Make sure that the new component is the correct size and shape for the device. Carefully place it in position and secure it using the appropriate fasteners. Double-check that everything is firmly in place and aligned correctly to avoid operational issues once the unit is reassembled.

Note: Ensure all connections, such as electrical plugs or clips, are properly secured to avoid malfunctions.

Once the new component is installed, begin reassembling the device in the reverse order of disassembly. Tighten all screws or locks to ensure stability and that no parts are left loose. Finally, test the device to make sure it functions as expected.

Maintenance Tips for Long-lasting Performance

To ensure the prolonged efficiency and optimal functioning of your vacuum cleaner, regular care and attention are essential. Proper upkeep not only extends the lifespan of the appliance but also maintains its powerful suction and cleaning abilities. Adopting a few simple maintenance practices can go a long way in preserving its performance.

Regular filter cleaning is one of the most crucial steps. Over time, filters accumulate dust and debris, which can reduce airflow and suction power. Clean or replace the filters as recommended by the manufacturer to maintain peak performance.

Another important aspect is emptying the dust canister or bag regularly. Letting the container get too full can obstruct airflow and place unnecessary strain on the motor. Ensure it’s emptied frequently to allow the vacuum to operate smoothly.

Inspecting and cleaning the brush roll is equally significant. Hair, debris, and fibers often get tangled around the brush, which can cause the motor to overheat or the brush to lose its effectiveness. Regularly check and clear any obstructions to keep the brush functioning at its best.

Additionally, checking for clogs in hoses and tubes should be done routinely. Blockages can hinder airflow, decreasing suction and efficiency. Clear any blockages promptly to prevent damage to the internal components.

By adhering to these simple maintenance tips, you can ensure that your vacuum operates at its peak, providing reliable and consistent cleaning power for years to come.

Troubleshooting by Component

When your vacuum cleaner begins to malfunction, it’s essential to focus on individual components to identify the cause of the problem. Whether you’re facing a loss of suction, strange noises, or motor issues, narrowing down the problem to specific parts can help you perform efficient diagnostics. By understanding the common issues that affect each part of the device, you can either fix the issue yourself or know exactly what to ask for when seeking professional repair services.

Common Issues and Solutions

Each component in your cleaning device plays a crucial role in its overall performance. If one part fails, it can lead to a range of symptoms that make it seem as though the entire unit is broken. Understanding how each part functions and recognizing the signs of a malfunction can save time and effort. The table below highlights the main components, typical issues, and possible solutions:

| Component | Common Problems | Suggested Fixes |

|---|---|---|

| Motor | Overheating, lack of power | Clean air vents, check for blockages, ensure the motor is not clogged with debris |

| Filter | Reduced suction, poor air flow | Wash or replace the filter; ensure it is properly positioned |

| Brush Roll | Brush not spinning, tangled debris | Clear the brush of hair or debris, check for belt wear |

| Hose | Clogs, loss of suction | Inspect for blockages, clean the hose thoroughly, check for holes or cracks |

| Battery (if cordless) | Short battery life, failure to charge | Replace the battery, check charging contacts for dirt |

Performing Basic Checks

To begin troubleshooting, start with the simplest checks. Make sure the vacuum is plugged in (or charged, in the case of cordless models) and that all parts are securely connected. If the vacuum isn’t turning on, check the power button, cord, and fuse. If the suction is weak, focus on the hose and filter. Cleaning and maintaining each of these components regularly will help extend the life of your equipment and reduce the chances of encountering major issues.

Where to Buy Replacement Parts

When a device begins to malfunction or certain components wear out, finding the right items to restore it to full functionality becomes essential. Whether you’re looking to repair a household appliance or a specialized machine, the proper replacement components can often be sourced from various reputable vendors. Knowing where to look and what options are available can save both time and money, ensuring your equipment operates as it should for an extended period.

There are several trusted outlets where consumers can find quality replacement components. These include online retailers, local repair shops, and the manufacturer’s official store. It’s important to consider factors such as product compatibility, customer service, and delivery times when selecting a supplier.

| Option | Description | Pros | Cons |

|---|---|---|---|

| Official Website | Directly from the manufacturer, often offering genuine components. | Guaranteed compatibility, easy returns, often fast shipping. | May be more expensive compared to third-party sellers. |

| Online Marketplaces | Sites like Amazon, eBay, and others where third-party vendors sell items. | Wide selection, competitive prices, customer reviews. | Risk of counterfeit products, varying quality standards. |

| Specialized Repair Shops | Local stores focused on repairs and parts replacement. | Personalized service, expert advice, in-person support. | Limited selection, prices can vary. |

| Third-Party Retailers | Major chain stores and smaller shops offering a broad range of replacement items. | Affordable, convenient locations. | May not always carry the exact part needed, quality concerns. |

Choosing the right source depends on your individual needs. If you prioritize reliability and exact matches, the official website is often the best choice. However, for those looking to explore alternatives or find lower prices, online marketplaces and third-party retailers can offer valuable options. Just ensure you research the vendor’s reputation and verify product details before making a purchase.

Identifying Faulty Parts in Shark NV355

Maintaining optimal performance of your vacuum cleaner often requires identifying and replacing damaged or malfunctioning components. Over time, certain elements of your device may degrade, leading to reduced efficiency or complete failure. Understanding how to recognize these issues can significantly extend the lifespan of your appliance and restore its full functionality. The process involves careful observation, diagnostic techniques, and sometimes a bit of disassembly to pinpoint the root cause of performance problems.

Signs of Malfunction

When a vacuum begins to show signs of poor suction, unusual noises, or intermittent operation, it’s typically an indicator that something within the internal mechanism is not functioning correctly. Clogs in the airflow system, damaged seals, or faulty electrical connections are common culprits. Additionally, if the cleaner starts to emit strange odors or vibrates excessively, these may also signal an issue with the motor or rotating brush system.

Key Components to Inspect

Some of the most common areas to examine include the motor, filters, brush roll, and belts. A weak motor can struggle to produce adequate suction, while clogged filters impede airflow. If the brush roll is jammed or worn out, it can prevent debris from being effectively lifted from the floor. Likewise, a broken belt will halt the rotation of the brush, rendering the cleaner less effective. Taking the time to check these critical components can help in pinpointing the exact issue, allowing for a quicker and more cost-effective repair.

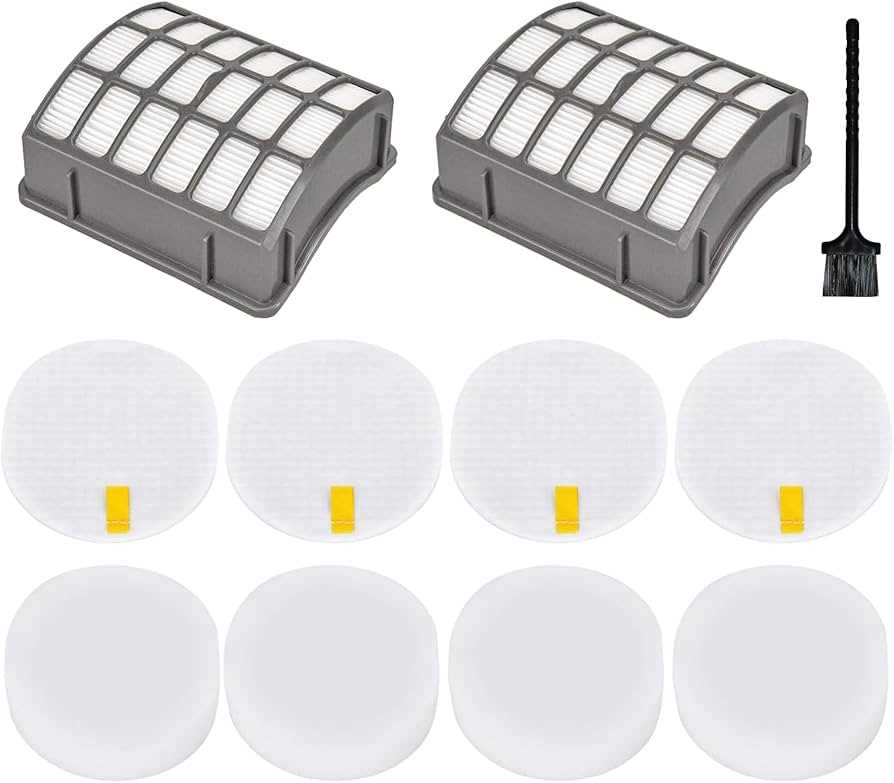

Shark NV355 Filter and Brush Assembly

The filtration system and brush components of a vacuum cleaner play a crucial role in ensuring optimal cleaning performance and maintaining air quality. Proper maintenance of these parts enhances the vacuum’s efficiency and prolongs its lifespan. This section provides a detailed look into the filter and brush setup, offering essential information for their care and replacement.

The filter traps dust, debris, and allergens, preventing them from being released back into the air. Regular cleaning or replacing the filter ensures the vacuum continues to work effectively. The brush assembly, on the other hand, is responsible for agitating and lifting dirt from various surfaces, making it an integral part of the cleaning process. Keeping the brush free from tangles and in good condition is equally important for smooth performance.

- Filter Maintenance: The filter should be cleaned regularly to avoid blockages. For optimal performance, it’s recommended to replace it at intervals based on usage.

- Brush Care: Remove hair, dirt, and debris from the brush to prevent it from becoming clogged. Regularly check the bristles for wear and tear to maintain their effectiveness.

- Signs of Damage: If either the filter or the brush becomes severely damaged or worn out, replacement is necessary to ensure continued efficient operation.

Regular maintenance of these two key elements can significantly improve the vacuum cleaner’s ability to capture dirt and allergens, as well as enhance its longevity. Proper care ensures a cleaner home environment and more reliable performance over time.

Why Regular Maintenance Matters for NV355

Proper upkeep of your cleaning device ensures it operates at peak efficiency, prolonging its lifespan and preventing unexpected malfunctions. Regular attention to essential components helps maintain smooth performance and avoids unnecessary repairs. Without consistent care, even the most durable machines can experience reduced efficiency and more frequent breakdowns.

Consistent servicing is vital for keeping internal systems running smoothly. When dust, debris, or wear and tear build up, the overall function of the machine can degrade, leading to less effective cleaning. Routine maintenance identifies small issues before they become significant problems, allowing for timely interventions.

Timely maintenance also contributes to better energy efficiency. Devices that are well-maintained use less power to perform the same tasks, ultimately saving on energy costs. By investing a little time in regular check-ups, users can avoid larger, more costly repairs and improve the overall performance of the machine.