When exploring the structure of an engine, it becomes essential to grasp how various mechanical elements are interconnected. Each component plays a critical role in ensuring the engine functions efficiently, and understanding their arrangement is key to proper maintenance and repair. By familiarizing yourself with this layout, you can address issues more effectively and keep everything running smoothly.

In this section, we will delve into the positioning and connections of key elements within the system. Recognizing how these parts interact with one another provides valuable insight into the overall operation and performance of the engine. This knowledge can simplify troubleshooting and enhance your ability to make adjustments when necessary.

Whether you’re handling routine maintenance or dealing with more complex challenges, having a clear understanding of how each element fits together is crucial. By the end of this guide, you will have a comprehensive view of the essential components and their relationships within the engine system.

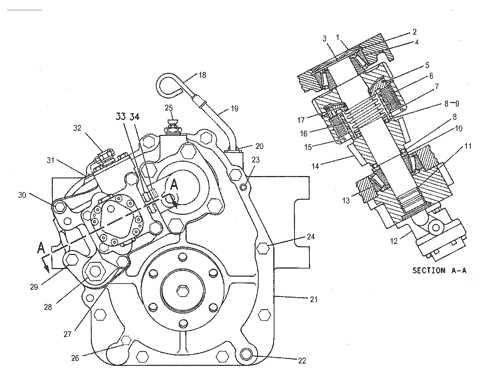

Comprehensive Overview of Cat 3208 Components

This section provides a detailed look at the essential elements found in a well-known heavy-duty engine model. With a focus on the core units and their interaction, the following information will guide you through the key mechanisms that ensure optimal performance.

Core Structural Elements

The main framework includes various mechanical parts responsible for maintaining durability and efficiency during operation. Each piece is designed to withstand high pressure and temperature, ensuring long-term reliability. The internal structure plays a vital role in distributing power and managing fuel effectively.

Mechanical and Hydraulic Systems

Both the mechanical and hydraulic systems work in harmony to deliver consistent power and motion. These interconnected systems allow for smooth operation under different loads, with critical adjustments provided by finely tuned controls. Ensuring regular maintenance of these systems can significantly extend the engine’s lifespan.

Understanding the Key Engine Parts

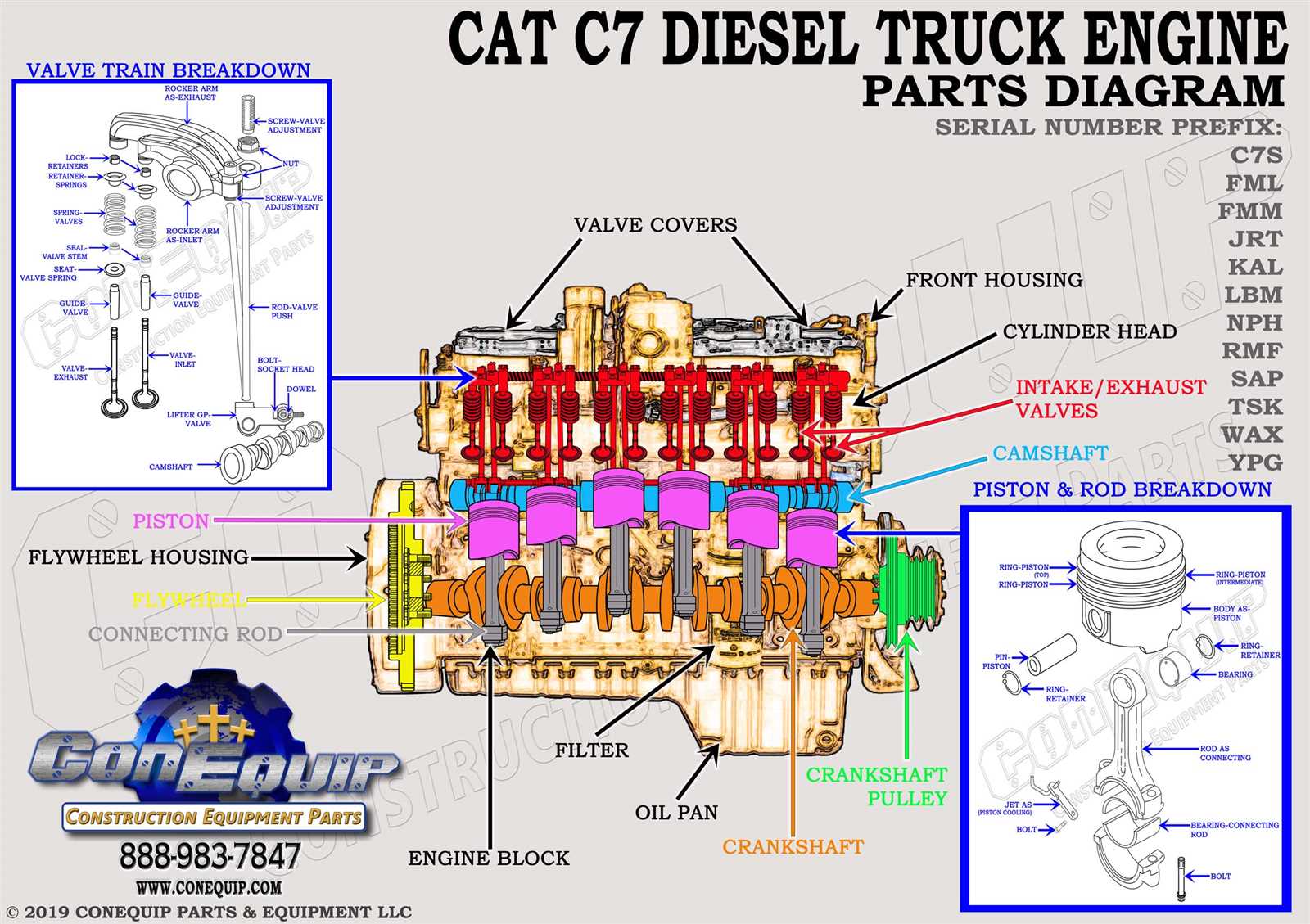

Recognizing the crucial elements of an engine is essential for ensuring its smooth operation and long-term durability. Each component plays a significant role in maintaining the overall function, and understanding these roles can help identify issues before they become serious problems.

Below is an overview of the most important elements you should be familiar with when assessing an engine:

- Cylinder Block: The foundation that houses the engine’s cylinders, providing the structural integrity for all other components.

- Crankshaft: A pivotal element that converts the linear motion of pistons into rotational force, driving the vehicle.

- Pistons: Responsible for compressing the air-fuel mixture, leading to the explosion that powers the engine.

- Camshaft: Controls the opening and closing of valves, synchronizing the intake of air and exhaust gases.

- Connecting Rods: These link the pistons to the crankshaft, transferring the motion effectively.

Familiarity with these parts can lead to a better understanding of how the engine functions and what maintenance it may require over time.

Detailed Breakdown of the Cooling System

The cooling mechanism plays a critical role in maintaining optimal temperature during engine operation. Understanding its various components helps ensure efficient functioning and prevents overheating, which can lead to more significant issues.

The system is composed of several interconnected elements, each performing a specific function to regulate temperature. Below is an overview of the key components involved in this mechanism:

- Radiator: Responsible for dispersing heat from the fluid, ensuring the engine stays within safe operating limits.

- Thermostat: Controls the flow of fluid, allowing the system to reach the correct operating temperature before circulating the coolant.

- Water Pump: Ensures continuous movement of coolant throughout the system, facilitating heat transfer away from the engine.

- Cooling Fan: Assists the radiator by providing additional airflow when necessary, particularly during low-speed or idle conditions.

- Hoses: Serve as conduits for transferring coolant between the different components, connecting all parts of the system.

Maintaining these elements in good condition ensures the cooling system operates efficiently, preventing overheating and ensuring the longevity of the machinery.

Fuel System Elements in the Cat 3208

The fuel system in this engine consists of several interconnected components, each playing a crucial role in ensuring efficient combustion and engine performance. These elements work together to deliver fuel to the cylinders, maintaining proper pressure and flow for optimal operation.

Main Components Overview

The essential parts of the fuel delivery system include pumps, filters, and injectors, all designed to regulate the flow of fuel while keeping it clean and free from contaminants. These components are built for durability and precision, ensuring smooth engine functionality under various conditions.

- Fuel Pump: Responsible for transferring fuel from the tank to the injectors, maintaining the correct pressure.

- Fuel Filter: Keeps impurities out of the system, ensuring clean fuel reaches the engine.

- Fuel Injectors: Precisely deliver the fuel into the combustion chamber for optimal performance.

Supporting Elements

Besides the core components, additional elements assist in maintaining fuel efficiency and performance. These include regulators and return lines, which help manage fuel pressure and recycle unused fuel.

- Pressure

Air Intake and Exhaust Mechanism Components

The air intake and exhaust system is vital for ensuring efficient engine performance. This mechanism controls the entry of fresh air into the engine and the release of exhaust gases, playing a key role in maintaining proper airflow and reducing emissions. Understanding the components involved in this system allows for better maintenance and optimization.

Main Elements of the Air Intake

The air intake section is responsible for bringing clean air into the engine. It consists of several components that ensure the air is filtered and measured before reaching the combustion chambers. These elements work together to provide the engine with the necessary oxygen for the fuel mixture.

Key Exhaust Components

On the exhaust side, the components focus on efficiently removing gases produced during combustion. This system ensures that the exhaust is properly expelled, which not only improves engine efficiency but also helps in reducing harmful emissions.

Component Function Air Filter Removes impurities from the air before it enters the engine. Exhaust Manifold Channels exhaust gases from multiple cylinders into one outlet. Turbocharger Increases the amount of air entering the engine Identifying Internal Engine Parts

Understanding the components within a motor is crucial for effective maintenance and repair. Recognizing these elements can enhance performance and extend the lifespan of the machine. This section will explore key components, their functions, and how to identify them efficiently.

Key Components and Their Functions

- Cylinders: Enclosed spaces where fuel and air mix, igniting to create power.

- Pistons: Moving parts that compress the mixture in the cylinders and transfer energy to the crankshaft.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, driving the output.

- Valves: Regulate the intake of air and fuel as well as the expulsion of exhaust gases.

- Camshaft: Controls the timing of the valve openings and closings, crucial for engine efficiency.

Tips for Identification

- Refer to a comprehensive schematic of the engine layout to locate components easily.

- Use appropriate tools to access and inspect internal parts safely.

- Document any findings for future reference or maintenance needs.

- Consult experts or manuals when uncertain about specific parts or their functions.

Oil Circulation and Filtration Components

The effective functioning of a machinery system heavily relies on the intricate network of components responsible for oil movement and filtration. This network ensures that lubricating fluids are properly circulated throughout the engine, minimizing wear and tear while maintaining optimal performance.

In the realm of lubrication, various elements work synergistically to ensure a seamless flow of oil, safeguarding the internal mechanisms from damage. Key components in this system include the oil pump, filters, and various hoses that facilitate the transport of fluids.

Component Function Oil Pump Responsible for circulating oil throughout the engine, ensuring adequate lubrication. Oil Filter Removes contaminants from the oil, maintaining cleanliness and efficiency in the system. Oil Cooler Regulates the temperature of the oil, preventing overheating and ensuring stable operation. Hoses and Lines Facilitate the movement of oil between components, ensuring a continuous flow within the system. Understanding the role of each of these components is crucial for maintaining the longevity and efficiency of the engine. Regular maintenance and timely replacement of these elements can lead to enhanced performance and reduced risk of failure.

Electrical System Components in the Engine

The electrical system of an engine plays a crucial role in ensuring optimal performance and efficiency. It consists of various elements that work together to facilitate smooth operation, from starting the engine to powering auxiliary systems.

Among the key components are the alternator, which generates electrical energy to recharge the battery and supply power to the electrical systems while the engine is running. The starter motor is essential for initiating the engine’s operation, providing the necessary torque to start the combustion process.

Additionally, the battery serves as a vital energy reservoir, supplying power when the engine is off and supporting various electrical components during operation. Wiring harnesses connect these elements, ensuring efficient communication and power distribution throughout the engine’s electrical network.

Moreover, sensors and control modules monitor and manage various functions, contributing to performance optimization and diagnostics. Understanding these components is essential for maintenance and troubleshooting, enabling effective management of the engine’s electrical system.

Common Wear Points in the Cat 3208

Understanding the typical areas of wear in this engine model is essential for maintaining optimal performance and longevity. Various components can experience degradation over time due to constant use and environmental factors, which may lead to inefficiencies or operational failures.

High-Stress Components

Parts subjected to significant stress are often the first to show signs of wear. These include the pistons, crankshaft, and connecting rods. Regular inspections can help identify any cracks or deformation that may affect functionality.

Cooling System Vulnerabilities

The cooling system is crucial for preventing overheating. Components such as the water pump and radiator can become clogged or corroded, leading to inadequate cooling. Ensuring these parts are in good condition can mitigate risks associated with thermal damage.

Placement of Key Gaskets and Seals

Correct positioning of essential gaskets and seals is vital for ensuring optimal performance and preventing leaks in various machinery components. These components play a crucial role in maintaining integrity and efficiency, as they provide the necessary barrier against fluids and contaminants.

Understanding the arrangement of these sealing elements can help in avoiding potential failures and enhancing the lifespan of the equipment. Each gasket and seal must be installed with precision, taking into account their specific function and the environment in which they operate.

Moreover, regular inspection and maintenance of these components are essential to identify any wear or damage that could lead to malfunctions. Properly placed gaskets and seals not only ensure smooth operation but also contribute to the overall reliability of the system.

Mounting and Support Components in the Engine

The proper arrangement and fixation of various elements within a power unit are crucial for optimal performance. These components not only ensure stability but also absorb vibrations, thereby enhancing the overall efficiency of the engine. A detailed understanding of these elements is essential for effective maintenance and troubleshooting.

Types of Mounting Components

- Engine Mounts: These elements connect the power unit to the chassis, allowing for movement while reducing vibrations.

- Brackets: These supports hold various components in place, ensuring they remain secured during operation.

- Supports: Designed to provide additional stability, these components distribute weight and reduce stress on the assembly.

Importance of Proper Installation

Ensuring that these mounting and support components are installed correctly is vital for the longevity of the engine. Misalignment can lead to excessive wear and potential failure of parts. Regular inspections and maintenance practices are recommended to identify any issues early.