In the world of agricultural machinery, comprehending the intricate relationships between various elements is essential for efficient operation and maintenance. These machines consist of numerous components, each playing a vital role in ensuring optimal performance. Familiarity with these parts not only aids in troubleshooting but also enhances the ability to perform necessary repairs and upgrades.

For anyone involved in the operation or servicing of these machines, a detailed exploration of the different sections and their functionalities is indispensable. By analyzing the layout and connections of these crucial elements, operators can better understand how each part interacts with the others, leading to improved productivity and reduced downtime.

Moreover, having a clear visual representation of the machinery’s structure can greatly assist in training new personnel, enabling them to grasp the mechanics of the equipment quickly. This foundational knowledge serves as a springboard for more advanced skills, making it easier to tackle more complex challenges that may arise during usage.

Understanding the Jinma 254 Parts Diagram

This section provides an overview of the key components and their relationships in a specific agricultural machine. Understanding the layout and organization of these elements is crucial for effective maintenance and repair. A well-structured visual representation aids users in identifying parts and their functions, enhancing operational efficiency.

Key Components

Familiarity with the essential elements can greatly facilitate troubleshooting and repair. Here are some of the primary components to consider:

- Engine assembly

- Transmission unit

- Hydraulic system

- Electrical connections

- Chassis framework

Interconnections

Recognizing how these components interact is vital for proper functionality. Understanding these interconnections helps in diagnosing issues and optimizing performance:

- Power transfer from the engine to the transmission

- Hydraulic flow to operational elements

- Electrical signals between control units

- Structural support provided by the chassis

By mastering the layout and relationships among these components, users can ensure optimal operation and longevity of the machinery.

Overview of Jinma 254 Components

This section provides a comprehensive examination of the essential elements that comprise a popular compact utility tractor. Understanding these components is vital for effective maintenance and operational efficiency.

Key Elements

The tractor is equipped with various integral systems that contribute to its performance. Each element, from the engine to the transmission, plays a crucial role in ensuring smooth operation. Regular inspection and familiarity with these components can significantly enhance longevity and reliability.

Functional Importance

Every part serves a distinct function, whether it’s power generation, mobility, or hydraulic operations. Familiarity with the configuration of these systems allows operators to diagnose issues swiftly and perform necessary repairs, ensuring that the machine operates at peak performance. Understanding these vital components is essential for both novice and experienced users alike, as it empowers them to optimize their machinery’s capabilities and address potential concerns proactively.

Importance of Accurate Parts Identification

Precise identification of components is crucial for the smooth operation and maintenance of machinery. Understanding the specific elements that make up a system allows for effective repairs, minimizes downtime, and ensures optimal performance. When individuals are equipped with the correct knowledge, they can efficiently troubleshoot issues, order replacements, and implement upgrades.

In the context of mechanical systems, recognizing each individual element and its specifications contributes to overall efficiency and reliability. The following table highlights the key reasons why accurate identification is essential:

| Reason | Description |

|---|---|

| Enhanced Efficiency | Correctly identifying components ensures that repairs and replacements are executed swiftly, reducing downtime. |

| Cost-Effectiveness | Accurate identification prevents the unnecessary purchase of incorrect items, saving both time and money. |

| Improved Safety | Understanding the function and specification of each component can help avoid mishaps during operation and maintenance. |

| Optimal Performance | Using the right components ensures that machinery operates at its best, enhancing productivity. |

In conclusion, meticulous attention to detail in component identification is vital for achieving long-lasting functionality and efficiency in any mechanical system.

Key Features of Jinma 254 Design

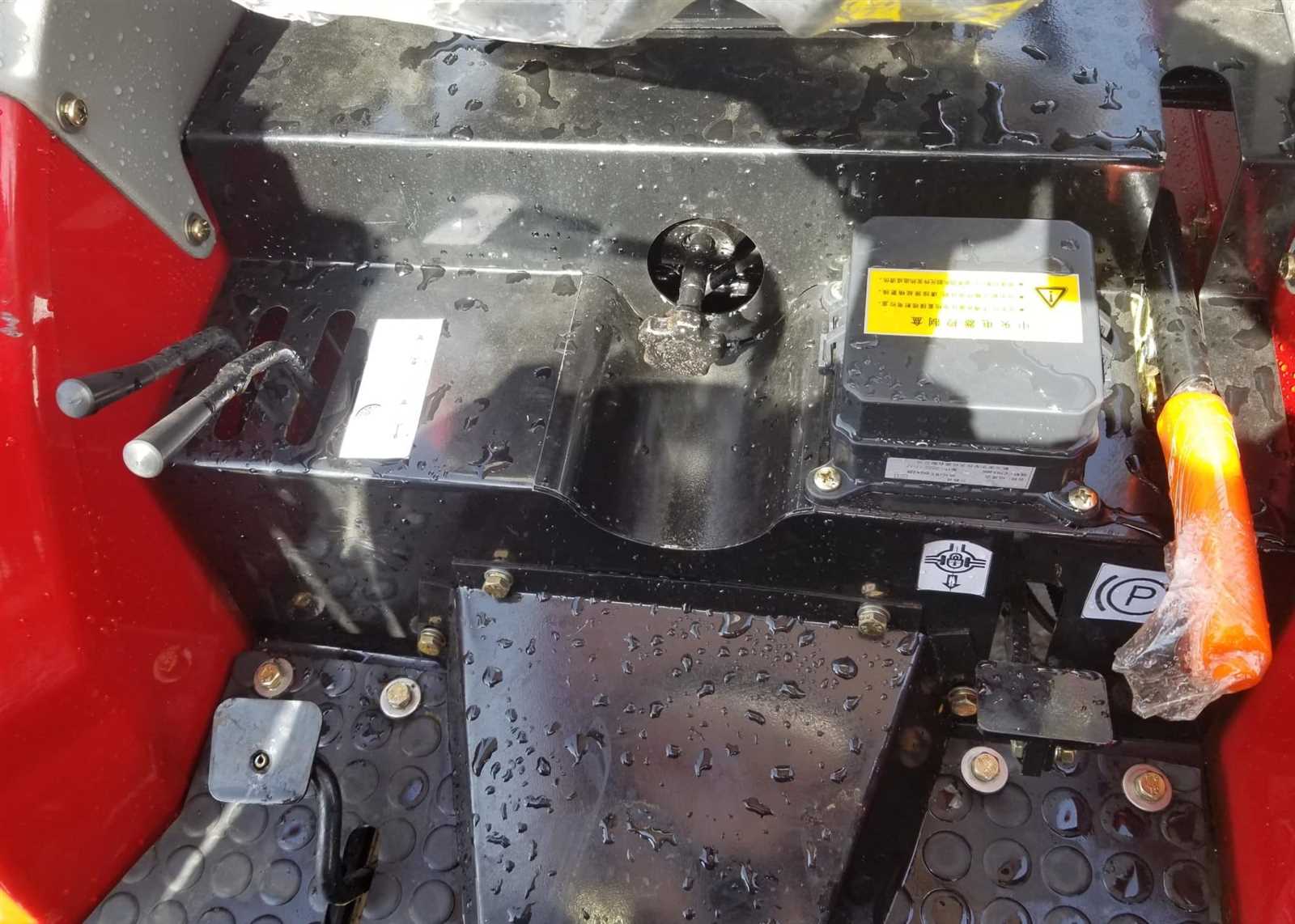

The design of this compact agricultural machine emphasizes functionality and efficiency, catering to the diverse needs of modern farming. Its innovative structure combines robust construction with advanced engineering principles, resulting in a reliable vehicle capable of tackling various tasks on the field.

One notable aspect of this model is its powerful engine, which delivers impressive torque and horsepower, ensuring high performance even in challenging conditions. The incorporation of a versatile transmission system allows for smooth operation across different terrains, enhancing the overall user experience.

Additionally, the ergonomic layout of controls and seating contributes to operator comfort, making long hours of work more manageable. Safety features are thoughtfully integrated into the design, ensuring that operators can perform tasks with confidence while minimizing risks.

Furthermore, maintenance is made straightforward, with easily accessible components that simplify servicing and repairs. This thoughtful engineering approach ensures longevity and reduces downtime, making it an excellent choice for agricultural professionals.

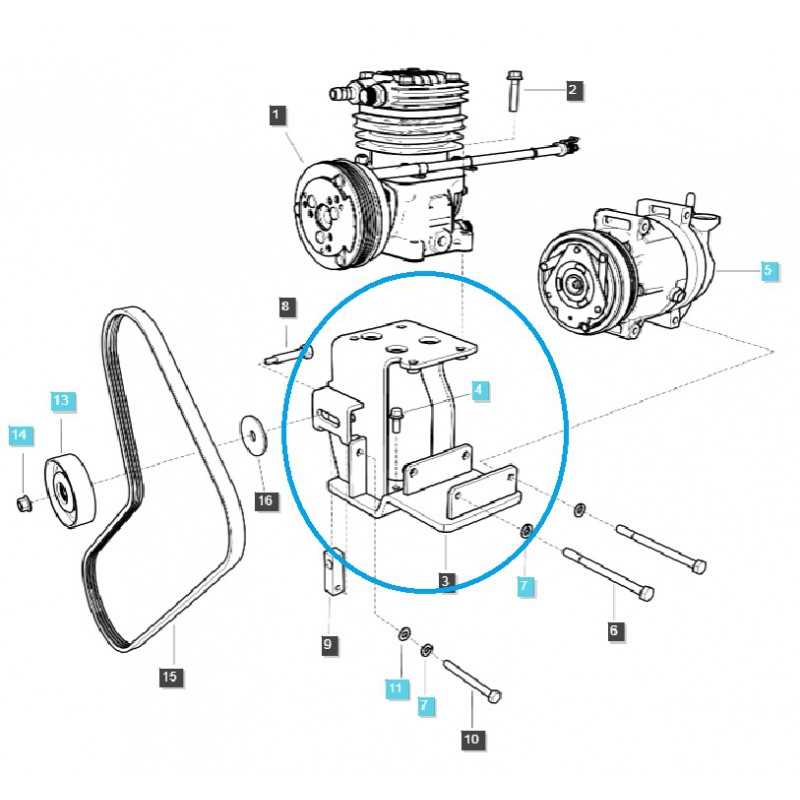

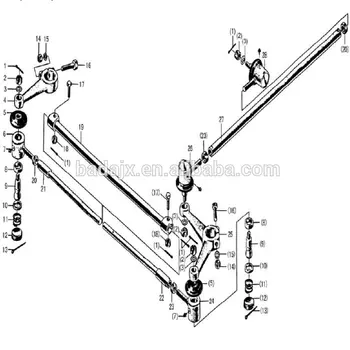

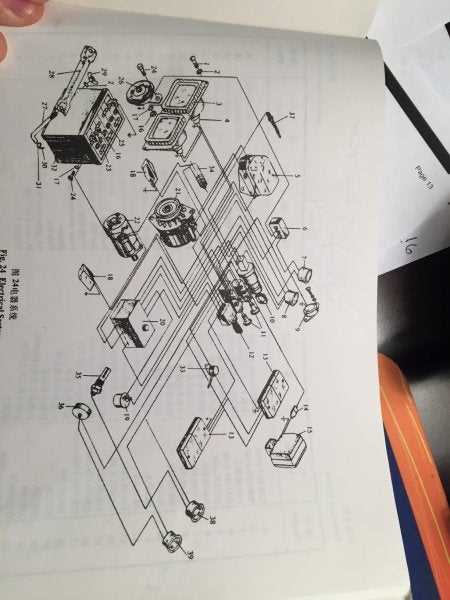

How to Read the Parts Diagram

Understanding a component illustration is essential for effective maintenance and repair of machinery. This visual representation provides vital information about the various elements of the system, their arrangement, and how they interact with one another. Mastering the ability to interpret these visuals can significantly streamline the troubleshooting process.

When approaching a component illustration, consider the following steps:

- Familiarize Yourself with the Legend: Most illustrations include a legend or key that explains the symbols and notations used. Take the time to study this section to understand what each symbol represents.

- Identify Major Components: Start by locating the primary elements highlighted in the visual. Recognizing these will help you grasp the overall structure and function of the assembly.

- Trace Connections: Follow the lines or arrows that indicate how different elements are connected. This will provide insight into the flow of energy or materials through the system.

- Note Specific Details: Pay attention to any numbers or labels associated with each component. These often refer to part numbers or specifications that can aid in sourcing replacements.

- Cross-Reference with Manuals: If available, consult the machinery’s manual for additional context. Manuals often provide detailed explanations and can enhance your understanding of the illustration.

By following these steps, you will enhance your ability to effectively interpret component illustrations, facilitating better maintenance practices and informed decision-making during repairs.

Common Issues with Jinma 254 Parts

When working with machinery components, various challenges can arise that may impact performance and efficiency. Understanding these common complications is crucial for effective maintenance and troubleshooting. Below are some prevalent issues that operators may encounter with their equipment.

1. Wear and Tear

Over time, mechanical components can experience significant wear. This deterioration can lead to:

- Reduced efficiency and performance

- Increased noise and vibration

- Potential for failure in critical operations

2. Compatibility Issues

When replacing or upgrading components, compatibility can become a major concern. Operators should be aware of:

- Differences in size and fit that may prevent proper installation

- Variations in material quality affecting durability

- Incompatibility with existing systems leading to operational inefficiencies

Addressing these common problems can greatly enhance the reliability and functionality of your machinery.

Replacement Options for Damaged Components

When dealing with the repair or maintenance of machinery, it is crucial to consider viable alternatives for any compromised elements. These options not only ensure the efficient operation of the equipment but also contribute to its longevity. Here, we will explore various strategies for sourcing replacements, including aftermarket choices, OEM parts, and refurbished components.

Aftermarket Components

Aftermarket parts are often designed to meet or exceed original specifications while typically being more cost-effective. These options can provide excellent performance and durability, making them a popular choice among users looking to save money without sacrificing quality.

OEM Parts

Original Equipment Manufacturer components guarantee compatibility and reliability, as they are made by the same manufacturer as the original. While these parts may come at a higher price, they often provide peace of mind regarding quality and fit.

| Type of Component | Advantages | Disadvantages |

|---|---|---|

| Aftermarket | Cost-effective, varied options | Potential compatibility issues |

| OEM | Guaranteed fit, high reliability | Higher price point |

| Refurbished | Environmentally friendly, lower cost | May have limited warranties |

Maintenance Tips for Jinma 254

Regular upkeep is essential for ensuring optimal performance and longevity of your agricultural machinery. By following a few straightforward guidelines, you can keep your equipment running smoothly and efficiently.

- Routine Inspections: Regularly check for any signs of wear and tear, including hoses, belts, and filters. Early detection can prevent costly repairs.

- Fluid Levels: Ensure that all fluids, including engine oil, coolant, and hydraulic fluid, are at the proper levels. Change them according to the manufacturer’s recommendations.

- Cleanliness: Keep the engine compartment clean and free of debris. A clean environment helps in identifying leaks and other issues more easily.

- Tire Maintenance: Check tire pressure and tread regularly. Proper inflation and tread depth are crucial for traction and fuel efficiency.

- Electrical System: Inspect the battery and wiring connections for corrosion or damage. Clean connections as needed to ensure reliable performance.

- Storage Conditions: If the machinery is not in use, store it in a dry and sheltered area to protect it from the elements and extend its lifespan.

By adhering to these maintenance tips, you can enhance the reliability and efficiency of your agricultural equipment, ensuring it meets your operational needs effectively.

Resources for Jinma 254 Parts

When it comes to maintaining and upgrading machinery, having access to reliable information is essential. This section provides valuable references for sourcing components and understanding their functionalities. Whether you’re looking for manuals, catalogs, or online forums, a wealth of resources is available to help you make informed decisions.

Online Forums and Communities: Engaging with fellow enthusiasts can offer insights and recommendations for various suppliers and components. Many online platforms provide discussions, troubleshooting tips, and reviews of different products.

Manufacturer Websites: Directly visiting the official websites of manufacturers can yield technical specifications, user manuals, and warranty information. These resources often have dedicated sections for aftermarket accessories and replacements.

Retail Outlets: Local and online retailers often stock a wide range of components. Checking reviews and product ratings can ensure you select high-quality items that meet your needs.

Technical Manuals: Detailed guides and schematics are invaluable for understanding the assembly and disassembly of machinery. They typically include part numbers and specifications, making it easier to locate replacements.

Utilizing these resources can streamline the process of finding necessary components and enhance your overall experience in equipment maintenance and repair.

Comparative Analysis with Other Models

This section delves into a comparative examination of various machinery models, focusing on their components and functionalities. By assessing similarities and differences, we aim to provide insights into their operational efficiencies and design philosophies.

Key Differences

When evaluating different machinery options, several critical factors emerge, including performance metrics, maintenance requirements, and compatibility with attachments. Understanding these aspects helps users make informed decisions based on their specific operational needs.

Performance Metrics Comparison

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 25 HP | 30 HP | 28 HP |

| Weight | 1200 lbs | 1350 lbs | 1250 lbs |

| Fuel Capacity | 6 gallons | 7 gallons | 6.5 gallons |

This comparison highlights the distinct characteristics that can influence user experience and operational efficiency. Evaluating these differences is essential for selecting the right machinery for specific applications.

Customer Experiences and Feedback

Understanding user experiences and opinions is essential for enhancing the quality and reliability of agricultural machinery. Feedback from operators provides valuable insights into performance, durability, and usability, helping manufacturers make informed improvements.

Positive Insights

Many users express satisfaction with the reliability and efficiency of their equipment. Operators often highlight how these machines simplify various tasks, improving overall productivity. Users appreciate the ease of maintenance, which contributes to longer operational lifespans.

Areas for Improvement

While there are numerous positive remarks, some feedback points to specific areas where enhancements could be made. For instance, certain operators mention challenges with component accessibility, suggesting that improved design could facilitate easier repairs. Addressing these concerns would likely lead to even greater customer satisfaction.