This section aims to provide a comprehensive overview of the assembly and individual elements of a specific model. By examining the configuration, users can gain insights into how various components interact within the overall structure.

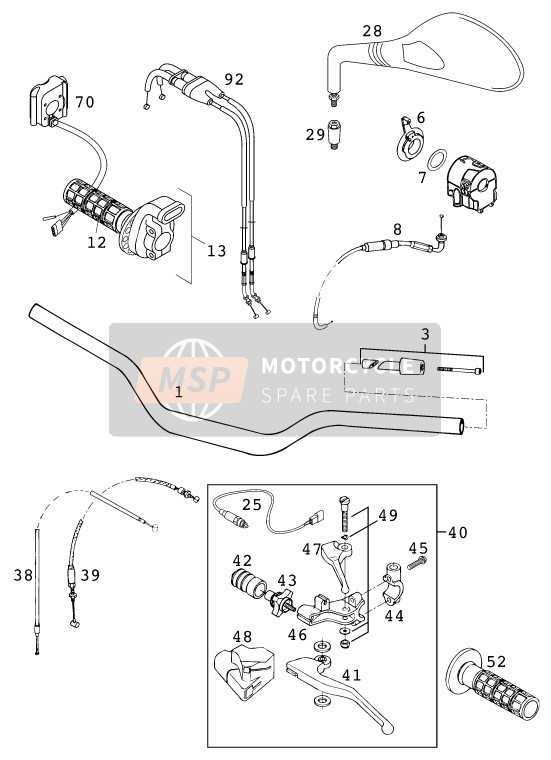

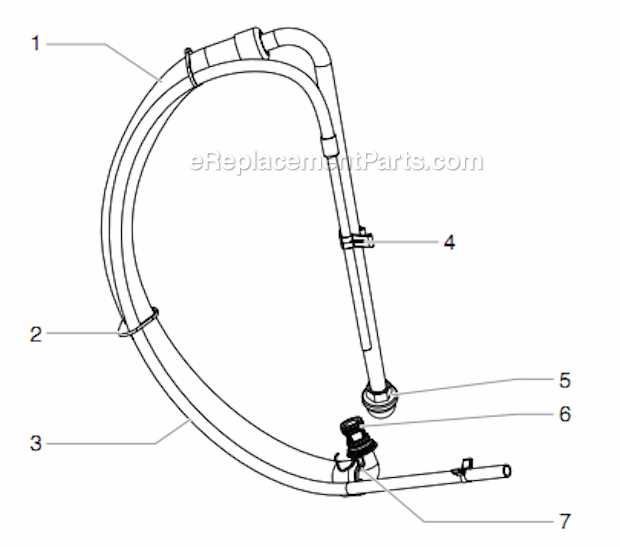

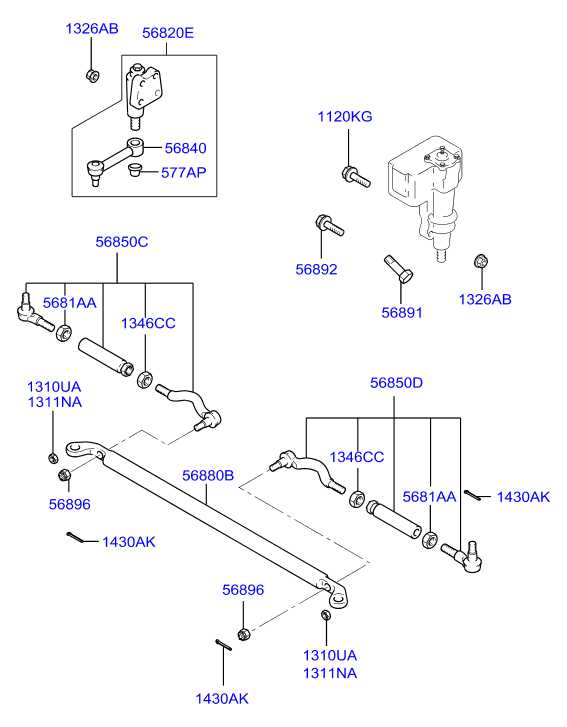

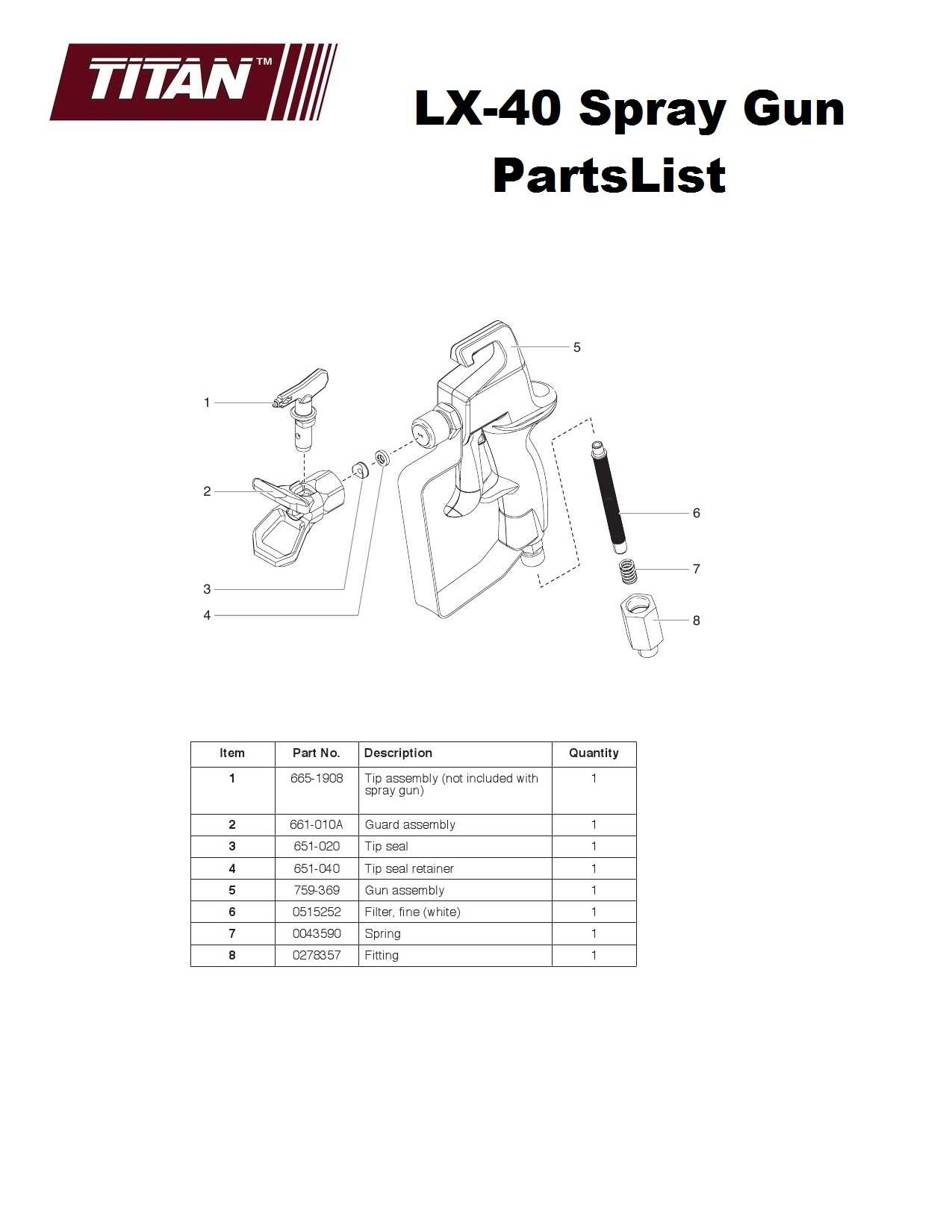

Detailed illustrations play a crucial role in enhancing comprehension. They serve to clarify the relationships between different segments, ensuring that individuals can navigate through the complexities of the setup with ease. Familiarity with these representations fosters a deeper understanding of functionality and maintenance.

Ultimately, grasping the arrangement of these elements empowers users to make informed decisions regarding repairs and enhancements. Informed choices lead to improved performance and longevity of the equipment.

Diagram Overview

This section provides a comprehensive understanding of the essential components of a specific machinery model. By exploring the various elements and their functions, users can gain insights into the overall design and operational capabilities.

- Key Components:

- Engine assembly

- Transmission unit

- Hydraulic system

- Chassis structure

- Maintenance Tips:

- Regular inspections of each component

- Timely replacements of worn-out parts

- Proper lubrication to ensure smooth operation

- Assembly Guidance:

- Step-by-step assembly instructions

- Recommended tools for efficient setup

- Safety precautions during assembly

Understanding the Component Layout

The arrangement of elements within a mechanical assembly plays a crucial role in its overall functionality and efficiency. A clear comprehension of how each piece interacts contributes significantly to effective maintenance and troubleshooting. By familiarizing oneself with the layout, users can optimize performance and ensure longevity.

Key Elements of the Assembly

Primary components serve as the backbone of the system, each fulfilling specific roles that facilitate smooth operations. Identifying these essential parts is vital for any effective analysis or repair.

Interaction and Integration

Understanding how individual pieces connect and work together enhances the user’s ability to manage any operational issues. Each element’s placement is carefully designed to maximize efficiency, ensuring that all components function seamlessly as part of a unified whole.

Key Parts Identification Guide

This section aims to enhance your understanding of essential components found in various machinery. By recognizing these vital elements, you can ensure optimal performance and efficient maintenance, leading to a longer lifespan for your equipment.

Understanding Component Functions

Each element plays a crucial role in the overall operation. Familiarizing yourself with their functions allows for better troubleshooting and informed decision-making when repairs or replacements are necessary.

Common Features and Characteristics

Identifying key features of these components can simplify the process of selection and replacement. Pay attention to sizes, shapes, and connection types, as these characteristics are critical in achieving compatibility and functionality.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding in any technical field. These illustrations serve as a guide, ensuring that users can easily identify components and their relationships. When clarity is achieved, it enhances efficiency and reduces the likelihood of errors during assembly or maintenance processes.

Enhancing User Experience

Accurate visuals significantly improve the user experience by providing clear instructions. Users can quickly reference the illustrations, leading to a smoother workflow. This not only saves time but also boosts confidence in handling complex tasks.

Reducing Mistakes

By relying on precise visual guides, the chances of mistakes diminish. When components are accurately depicted, it minimizes confusion, ensuring that each part is utilized correctly. This attention to detail fosters reliability and longevity in equipment performance.

How to Use the Diagram Effectively

Utilizing a visual reference can greatly enhance your understanding of complex machinery components. This tool serves as an essential guide for identifying various elements and their interconnections, streamlining maintenance or repairs. By mastering its layout, users can quickly locate specific sections and make informed decisions.

Begin by familiarizing yourself with the overall structure, noting key areas that are frequently referenced. Cross-reference each part with accompanying documentation for a deeper comprehension. Pay attention to any annotations that highlight important details, as these can provide valuable insights into functionality and maintenance tips.

When working on a project, keep the visual aid accessible. Refer back to it regularly to ensure accuracy in your tasks. This practice not only minimizes errors but also builds confidence in handling the equipment effectively.

Common Issues and Solutions

In the realm of machinery, users often encounter typical challenges that may hinder performance. Recognizing these issues and understanding effective resolutions can greatly enhance operational efficiency.

One frequent problem is unexpected noise during operation. This may indicate wear or misalignment of components. Regular maintenance and timely replacements can mitigate this issue.

Another common concern involves decreased efficiency. This can stem from blockages or faulty mechanisms. Thorough cleaning and inspections are essential to restore optimal functionality.

Additionally, users may face difficulties with connectivity or control systems. Ensuring all connections are secure and updating software can resolve these connectivity issues.

Maintenance Tips for Each Component

Regular upkeep of machinery elements is essential for optimal performance and longevity. This section provides valuable insights into best practices for maintaining various components, ensuring smooth operation and preventing potential issues.

General Maintenance Practices

- Inspect components regularly for wear and tear.

- Clean all parts to remove dust and debris that may hinder functionality.

- Lubricate moving parts to reduce friction and prevent overheating.

Specific Component Care

- Engine: Ensure proper oil levels and replace filters as needed.

- Wheels: Check for air pressure and inspect treads for wear.

- Hydraulic System: Monitor fluid levels and look for leaks in hoses and connections.

Parts Replacement Procedures Explained

Understanding how to efficiently substitute components is crucial for maintaining optimal functionality of your equipment. This section outlines essential steps and considerations to ensure a smooth replacement process, minimizing downtime and enhancing performance.

Initial Assessment and Preparation

Before initiating the replacement, conduct a thorough evaluation of the current state of the equipment. Identify which elements require substitution and gather all necessary tools and new components. Proper preparation not only streamlines the process but also reduces the likelihood of errors.

Replacement Steps and Best Practices

Start by carefully disassembling the relevant sections, ensuring that you follow the recommended procedures for each component. As you proceed, keep track of screws and fittings, utilizing containers to organize them. When installing new elements, pay close attention to alignment and secure them properly. Documenting each step can also aid future replacements and maintenance tasks.

Finally, once the installation is complete, conduct a thorough inspection to confirm that everything is in place. Testing the functionality before resuming regular use will ensure that the replacements have been executed correctly and that the equipment operates as intended.

Where to Find Genuine Parts

For those seeking authentic components for their machinery, it is essential to know reliable sources that provide high-quality replacements. Ensuring the authenticity of these items not only enhances performance but also prolongs the lifespan of your equipment.

Authorized Dealers

One of the most reliable methods to acquire genuine components is through authorized dealers. These suppliers are certified to offer original items, ensuring that you receive exactly what your equipment requires. Visiting their websites or physical locations can provide a wealth of options tailored to your needs.

Manufacturer Websites

Another excellent resource is the official website of the manufacturer. Here, you can find comprehensive listings of available items along with detailed specifications. Often, these sites offer direct purchasing options, which can simplify the acquisition process. Always verify the authenticity of the components before making a purchase to ensure you are receiving quality products.

Upgrading Titan 640 Components

Enhancing the functionality of your equipment can significantly improve its performance and longevity. Upgrades may involve replacing older elements with newer, more efficient ones, ensuring that your device operates at its peak. Careful selection of components can lead to better efficiency and an overall enhanced user experience.

When considering upgrades, it is crucial to assess the compatibility of new parts with existing systems. Researching options and understanding the specific needs of your setup will guide you in making informed decisions. Consulting manuals and technical specifications can provide valuable insights, allowing for seamless integration of new elements into your current configuration.

Additionally, investing in high-quality components can yield long-term benefits, including reduced maintenance costs and increased reliability. Prioritize reputable brands and verify the durability of the products you choose. By focusing on quality and compatibility, you can achieve a significant enhancement in overall functionality.

FAQs About Parts and Diagrams

This section addresses common inquiries regarding components and their visual representations. Understanding these elements is essential for effective maintenance and repair.

What Should I Consider When Looking for Components?

When searching for specific components, it’s vital to ensure compatibility with your model. Check dimensions, specifications, and manufacturer guidelines to avoid mismatches.

How Can Visual Representations Aid in Maintenance?

Visual guides provide clarity in identifying and locating components, making the maintenance process more straightforward. Utilizing these resources can significantly enhance your understanding and execution of repair tasks.

Resources for Further Learning

Expanding knowledge on machinery components and their functionalities is essential for both enthusiasts and professionals. Numerous resources are available to enhance understanding and facilitate deeper insights into equipment maintenance and repair.

Online Tutorials and Courses

Many platforms offer detailed tutorials and courses focused on machinery operation and component identification. These resources often include video demonstrations and interactive content.

Books and Manuals

Comprehensive books and manuals can serve as valuable references. They typically cover various aspects of machinery, from basic operations to advanced troubleshooting techniques.

| Resource Type | Examples |

|---|---|

| Online Courses | Coursera, Udemy, Skillshare |

| Books | Maintenance Guides, Technical Handbooks |

| Websites | Forums, Manufacturer Sites |