The intricate assembly of any machinery plays a crucial role in its functionality and efficiency. By exploring the individual elements that contribute to the overall performance, users can enhance their maintenance practices and ensure longevity.

Familiarizing oneself with the various segments allows for more informed decisions regarding repairs and upgrades. Each component, while small, serves a specific purpose, collectively ensuring the machine operates smoothly.

Additionally, having a clear reference for these elements can facilitate troubleshooting and facilitate easier replacements. This knowledge empowers users to tackle issues with confidence and improve their operational experience.

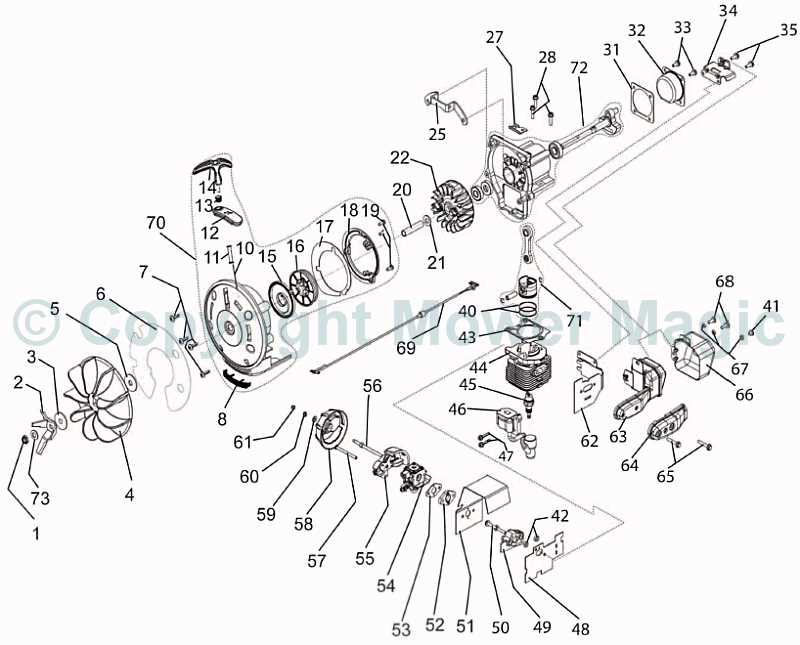

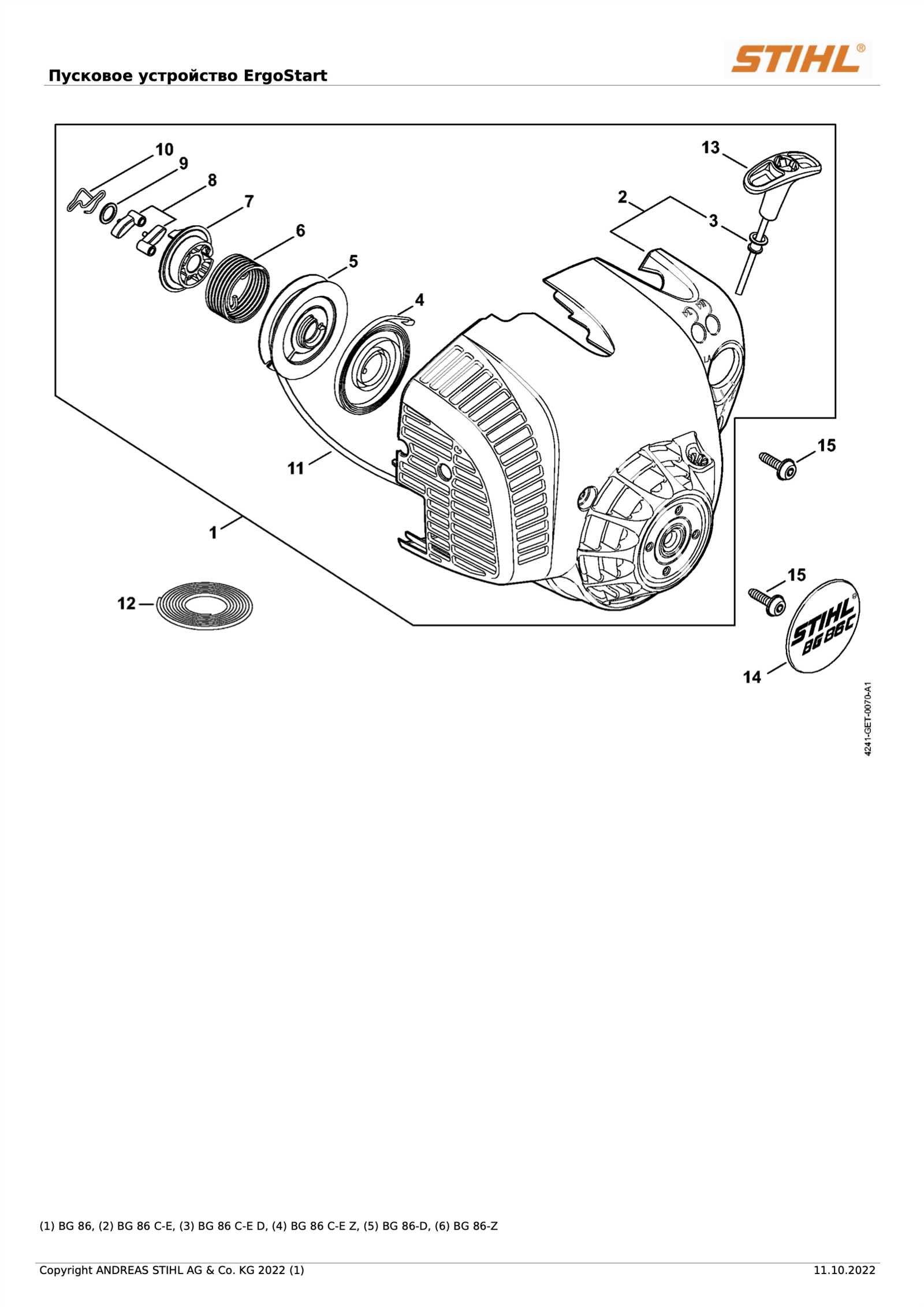

Importance of Parts Diagrams

Understanding the layout of components in machinery is crucial for effective maintenance and repair. Visual representations help users identify each element, ensuring that replacements and repairs are executed accurately. This knowledge not only saves time but also enhances the overall functionality and longevity of the equipment.

Enhanced Maintenance Efficiency

When users are familiar with the arrangement of components, they can quickly locate issues and perform necessary adjustments. This streamlined process minimizes downtime, allowing for uninterrupted usage of the machine.

Improved Troubleshooting

Having a clear visual reference aids in diagnosing problems more effectively. By pinpointing specific areas, users can address faults systematically, reducing the likelihood of overlooking critical elements during inspection.

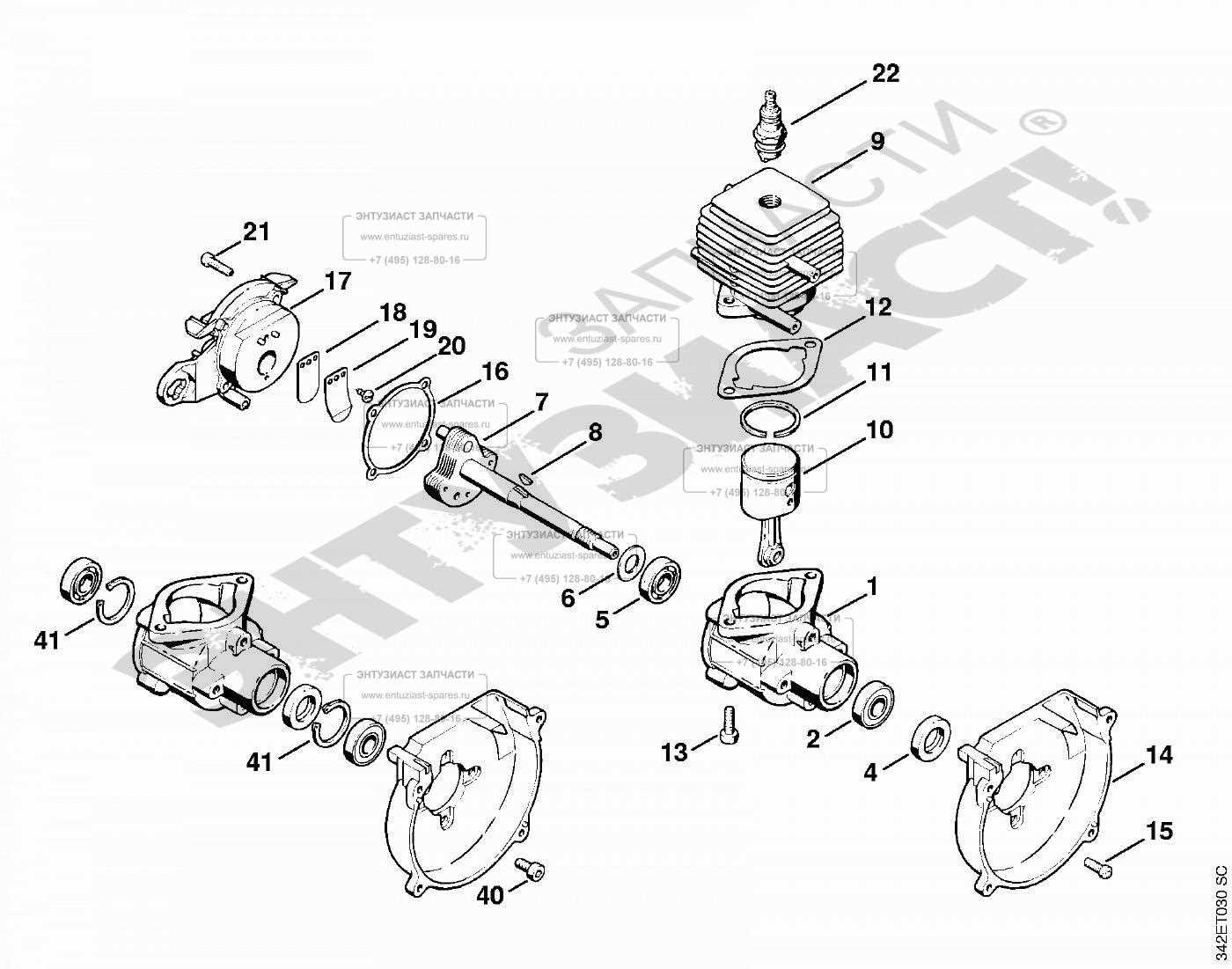

Overview of FS 86 Components

The FS 86 model consists of various integral elements that work in unison to ensure optimal performance. Each component plays a crucial role in the functionality and efficiency of the device, contributing to its overall reliability and effectiveness in operation.

Key Functional Elements

Essential components include the engine assembly, cutting mechanism, and control systems. These parts are engineered to deliver power while maintaining user comfort and safety. Understanding the role of each element allows for better maintenance and troubleshooting.

Maintenance Considerations

Regular inspections and servicing of these components are vital for prolonged lifespan and consistent performance. Familiarity with each part’s function aids users in identifying potential issues early, ensuring the device remains in peak condition.

How to Read a Parts Diagram

Understanding the layout of components in machinery is essential for effective maintenance and repair. This guide provides insights into interpreting visual representations that showcase the various elements and their relationships within a mechanical system.

| Element | Description |

|---|---|

| Key | A legend that explains the symbols and markings used in the illustration. |

| Labels | Identifications for each component, often including part numbers or descriptions. |

| Connections | Lines or arrows that indicate how components are linked or interact with each other. |

| Views | Different angles or perspectives that provide a comprehensive understanding of the assembly. |

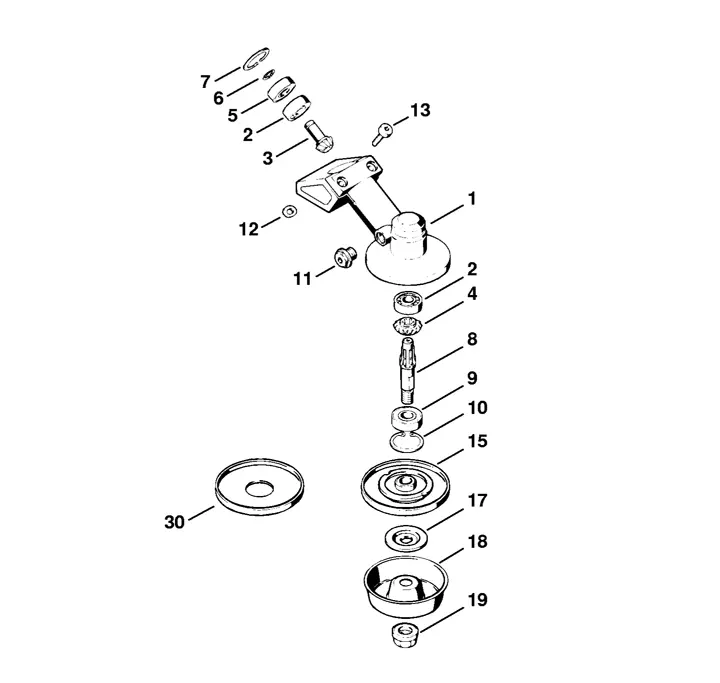

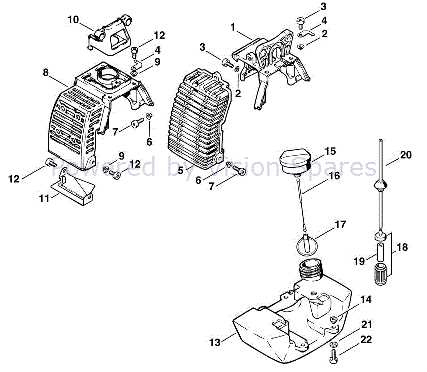

Main Assembly of FS 86

The primary structure of the FS 86 is crucial for its overall functionality and performance. This section explores the essential components that contribute to the efficient operation of the device, ensuring durability and reliability in various tasks.

| Component | Description |

|---|---|

| Engine | Powers the unit, providing the necessary energy for operation. |

| Gearbox | Transmits power from the engine to the cutting tools, ensuring optimal performance. |

| Handle | Offers stability and control, allowing for comfortable operation. |

| Cutting Head | Houses the cutting mechanism, crucial for executing tasks efficiently. |

| Fuel Tank | Stores the fuel needed for engine operation, designed for easy refueling. |

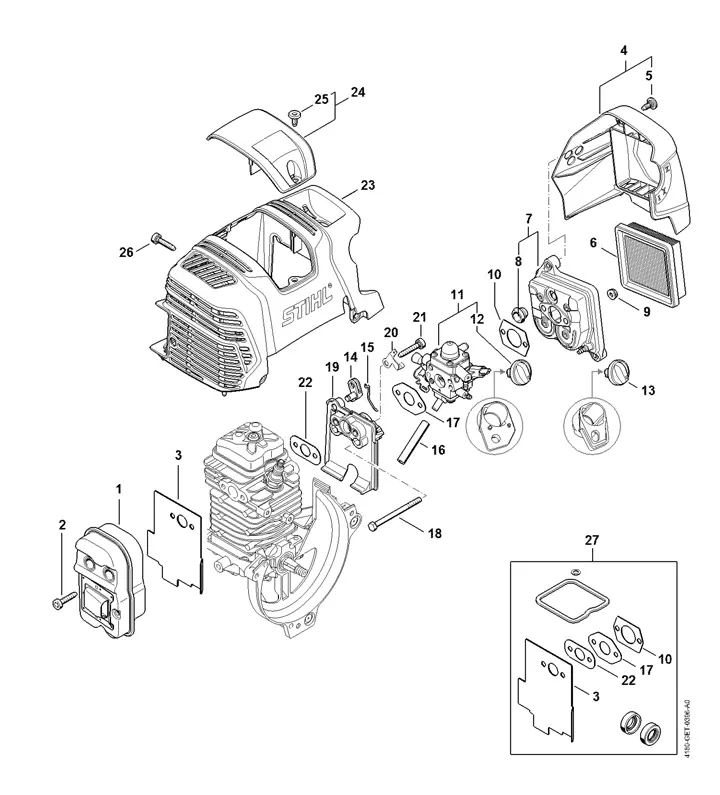

Common Replacement Parts Explained

Understanding the essential components of outdoor power equipment is crucial for maintaining its performance and longevity. Various elements may wear out over time, necessitating timely replacements to ensure efficient operation. Here, we will delve into some of the most frequently substituted components that contribute to the overall functionality of these machines.

Ignition Systems

One of the key systems to consider is the ignition, which plays a vital role in starting the engine. Common issues can arise from faulty spark plugs or ignition coils, leading to performance problems. Regular checks and replacements can enhance reliability and efficiency.

Fuel Delivery Components

Another critical area is the fuel delivery mechanism, including filters and lines that transport fuel to the engine. Over time, these parts can become clogged or damaged, affecting the flow and overall engine performance. Replacing these elements is essential for optimal functionality.

Identifying Part Numbers Easily

Understanding the identification of components is essential for effective maintenance and repair tasks. By familiarizing yourself with the relevant identifiers, you can streamline your workflow and ensure you have the correct items on hand.

- Consulting Manuals: Always refer to the official manuals available for your equipment. They often include comprehensive lists of identifiers for each component.

- Online Resources: Utilize websites that specialize in equipment details, where you can search for your model to find specific component numbers.

- Community Forums: Engage with online communities where experienced users share their insights and tips on identifying components efficiently.

- Visual Guides: Look for visual references that can help you recognize parts quickly based on their appearance.

By employing these strategies, you can enhance your ability to locate the right identifiers swiftly, reducing downtime during maintenance and repairs.

Maintenance Tips for FS 86

Regular upkeep of your equipment is essential for optimal performance and longevity. Implementing a consistent maintenance routine can help prevent issues and ensure smooth operation.

Routine Checks

- Inspect fuel levels regularly to avoid running out during use.

- Examine the cutting line for wear and replace as necessary.

- Check for loose screws or bolts and tighten them to maintain stability.

Cleaning and Storage

- Clean the exterior after each use to prevent dirt buildup.

- Store in a dry, cool place to avoid corrosion and damage.

- Keep the air filter clean to ensure proper airflow and engine performance.

Tools Needed for Assembly

When undertaking the assembly of outdoor power equipment, having the right tools is essential for ensuring a smooth and efficient process. Utilizing the correct implements not only simplifies the task but also enhances the overall outcome, making it crucial to be well-prepared before starting.

Basic Hand Tools

Commonly required hand tools include screwdrivers, wrenches, and pliers. These items play a vital role in securing components and making necessary adjustments during the assembly phase. Choosing the right sizes for screws and bolts will facilitate a more effective assembly experience.

Specialized Tools

In addition to basic hand tools, certain specialized implements may be necessary to achieve optimal results. For instance, a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications. Having a multimeter can also be beneficial for checking electrical connections, if applicable, ensuring all parts function properly once assembled.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and components of various equipment. It aims to provide clarity on essential aspects that users often seek assistance with.

Common Queries

Here are some frequently asked questions regarding the upkeep and functionality of the device:

| Question | Answer |

|---|---|

| What should I do if the equipment doesn’t start? | Check the fuel levels and ensure the spark plug is functioning properly. Regular maintenance can help prevent starting issues. |

| How often should I replace the cutting line? | The cutting line should be replaced as needed, typically after several uses, depending on the density of the vegetation being cut. |

Additional Resources

For more detailed information, consider consulting user manuals or professional maintenance guides that can provide comprehensive insights into operational efficiency.

Where to Find Diagrams Online

Locating technical illustrations for equipment can greatly assist in understanding its components and maintenance requirements. Numerous resources are available online that provide detailed visuals and information for various models. Here are some effective methods to find these resources.

Official Manufacturer Websites

Many manufacturers offer comprehensive resources on their official websites. Here, you can often find:

- User manuals

- Technical guides

- Maintenance resources

Online Forums and Communities

Engaging with online communities can provide valuable insights and resources. Consider exploring:

- Specialized forums dedicated to gardening tools

- Social media groups focused on machinery

- DIY enthusiast websites

Utilizing these sources can help you access the information you need for proper equipment maintenance and repairs.

Purchasing Authentic Stihl Parts

Ensuring the longevity and optimal performance of your equipment is crucial. To achieve this, sourcing genuine components is essential. Authentic items not only guarantee compatibility but also uphold the quality standards set by the manufacturer, ultimately enhancing the functionality of your machinery.

When searching for reliable sources, consider the following aspects:

| Criteria | Description |

|---|---|

| Authorized Dealers | Always opt for licensed vendors who are recognized by the manufacturer. They are more likely to offer genuine products. |

| Online Marketplaces | Be cautious when shopping online. Look for sellers with high ratings and positive reviews to minimize the risk of counterfeit goods. |

| Warranty and Return Policy | Check for warranties on the items. Authentic suppliers often provide guarantees and flexible return options. |

Investing in original components is a wise decision that pays off in the long run. By ensuring the integrity of your equipment through trusted sources, you can maintain its performance and reliability.