Understanding the various elements of a utility vehicle is crucial for effective maintenance and repair. This section provides a comprehensive overview of the vehicle’s components, allowing owners to familiarize themselves with each part’s function and importance. By exploring the intricate layout of the system, users can better navigate their vehicle’s mechanics and ensure optimal performance.

In this guide, you’ll find detailed representations that showcase the arrangement and relationship between different elements. This information is essential for troubleshooting issues and performing necessary upkeep. Emphasizing clarity and precision, the provided visuals aim to support vehicle enthusiasts and operators alike in their maintenance endeavors.

By equipping yourself with knowledge of the various components, you can approach repairs with confidence and understanding. Whether you’re a seasoned mechanic or a new owner, this resource will aid in enhancing your experience and ensuring the longevity of your utility vehicle.

This section provides an overview of the essential elements that make up the vehicle’s structure and functionality. Understanding these components is crucial for effective maintenance and repairs, ensuring optimal performance.

Main Components Overview

The vehicle consists of various integral parts, each playing a significant role in its overall operation. Familiarity with these elements aids in diagnosing issues and facilitating repairs.

| Component | Description |

|---|---|

| Engine | The power unit that drives the vehicle. |

| Transmission | System that transmits power from the engine to the wheels. |

| Chassis | The frame that supports all vehicle components. |

| Suspension | System that absorbs shocks and provides stability. |

| Brakes | Components that slow down or stop the vehicle. |

Importance of Component Knowledge

Recognizing the specific roles and interconnections of these elements enhances the ability to troubleshoot and maintain the vehicle effectively. This knowledge can prevent potential failures and extend the lifespan of the equipment.

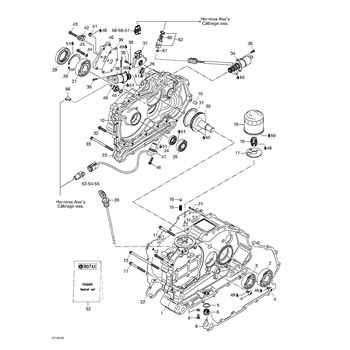

Engine Assembly and Specifications

This section outlines the construction and key details of the power unit, emphasizing its role within the overall machinery. Understanding the assembly process and technical specifications is crucial for effective maintenance and performance enhancement.

Key Components of the Engine

- Cylinder Head

- Piston and Connecting Rod

- Crankshaft

- Oil Pan

- Timing Chain and Gears

Technical Specifications

- Displacement: 500cc

- Number of Cylinders: 1

- Cooling System: Liquid cooled

- Fuel Type: Unleaded gasoline

- Maximum Power Output: 38 horsepower

Transmission and Drive System Details

The transmission and drive mechanism is crucial for the efficient operation of any all-terrain vehicle. It encompasses a variety of components working in harmony to deliver power from the engine to the wheels, ensuring optimal performance in diverse terrains. Understanding these elements can enhance maintenance and improve overall functionality.

Key Components of the Drive System

Among the primary components are the gearbox, drive belt, and differential. The gearbox regulates the engine’s output, allowing for smooth acceleration and deceleration. The drive belt transfers power effectively, while the differential enables the wheels to turn at different speeds, essential for cornering and stability.

Maintenance Tips for Longevity

Regular inspection and maintenance of these components are vital. Ensure that the drive belt is not worn or frayed, and check the fluid levels in the gearbox to avoid overheating. Keeping these elements in optimal condition will lead to improved reliability and performance.

Suspension and Steering Mechanisms

The suspension and steering systems play a crucial role in enhancing the ride quality and handling of an all-terrain vehicle. These components are designed to absorb shocks and provide stability, ensuring a smooth driving experience over various terrains.

- Suspension Components:

- Shock absorbers

- Coil springs

- Control arms

- Stabilizer bars

- Steering System Parts:

- Steering wheel

- Steering column

- Rack and pinion assembly

- Linkages

- Functionality:

- Improved traction on uneven surfaces

- Enhanced maneuverability

- Increased comfort for passengers

- Stability during turns

Maintaining the integrity of these systems is essential for optimal performance and safety. Regular inspections and timely replacements of worn-out components can prevent potential issues and enhance the longevity of the vehicle.

Electrical System Layout and Wiring

The electrical framework of an all-terrain vehicle plays a crucial role in its overall functionality. Understanding the layout of the electrical components is essential for efficient operation and maintenance. This section outlines the arrangement and interconnections of various electrical parts, highlighting their significance in the vehicle’s performance.

Key Components: The primary elements include the battery, ignition system, wiring harness, and lighting systems. Each component has a specific function, contributing to the reliable operation of the vehicle. The battery serves as the energy source, while the ignition system initiates the engine’s power. The wiring harness connects these elements, ensuring proper communication and flow of electricity.

Wiring Configuration: Proper wiring is essential to avoid short circuits and ensure safety. Color coding is typically employed to distinguish different wires, facilitating easier troubleshooting and repairs. Understanding the wiring configuration can help users diagnose electrical issues effectively.

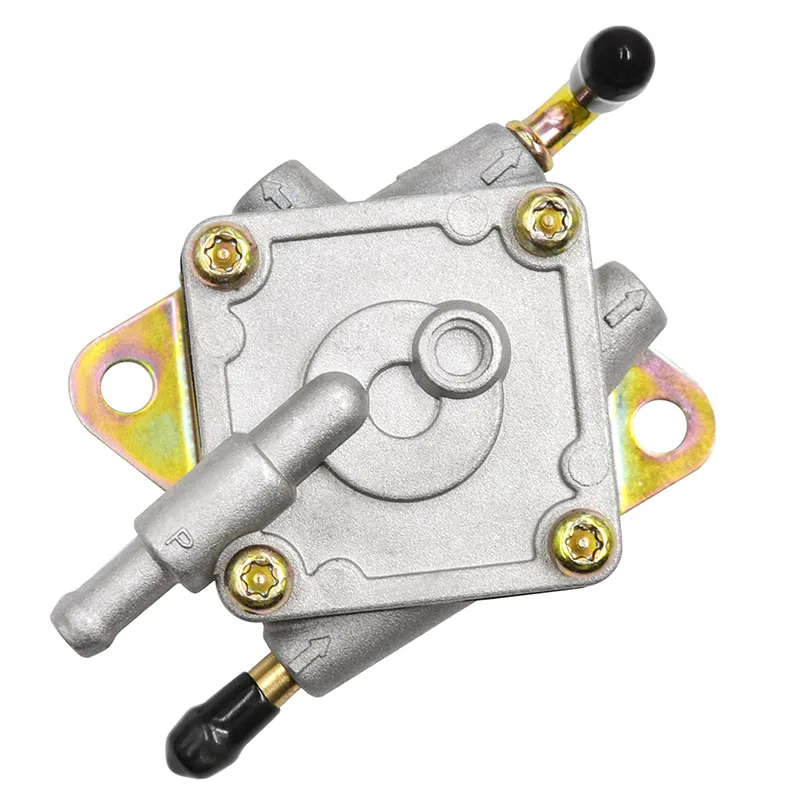

Fuel System Parts and Configuration

The fuel system is crucial for ensuring the efficient operation of the engine. It is designed to deliver the appropriate amount of fuel to the combustion chamber while maintaining optimal pressure and flow. Understanding the various components and their configuration is essential for effective maintenance and troubleshooting.

Components Overview

The main components include the fuel tank, fuel pump, fuel filter, and fuel injectors. Each element plays a specific role in the fuel delivery process. The fuel tank stores the fuel, while the pump transports it to the engine. The filter ensures that impurities are removed, preventing damage to the injectors.

Configuration Details

Proper configuration of the fuel system is vital for performance. The alignment of the fuel lines and the positioning of the components can significantly affect efficiency. Regular inspections and adjustments are recommended to maintain the integrity of the system and to ensure that it operates smoothly.

Braking System Components Explained

The braking system is crucial for ensuring the safety and control of any vehicle. It comprises various elements that work together to slow down or stop the motion effectively. Understanding these components helps in maintaining optimal performance and addressing any potential issues that may arise.

Brake Pads: These are essential for generating friction against the brake discs. They come in different materials, each affecting performance and longevity. High-quality pads enhance stopping power and reduce wear on the rotors.

Brake Discs: Also known as rotors, these components serve as the surface against which the brake pads clamp down. The material and design of the discs play a vital role in heat dissipation, which is critical for maintaining braking efficiency.

Calipers: The calipers house the brake pads and are responsible for applying pressure to them against the brake discs. They can be either fixed or floating and significantly influence the overall braking performance.

Brake Lines: These hydraulic lines connect the brake master cylinder to the calipers. They transport brake fluid, allowing for the transfer of force when the brake pedal is pressed. Proper maintenance of these lines is essential to avoid leaks and ensure responsive braking.

Master Cylinder: This component generates the hydraulic pressure needed to activate the braking system. When the brake pedal is pressed, the master cylinder pushes brake fluid through the lines to the calipers, initiating the braking action.

Understanding the various components of the braking system is essential for effective maintenance and ensuring vehicle safety. Regular inspections and timely replacements of worn parts can greatly enhance braking performance and prolong the lifespan of the system.

Body and Frame Assembly Insights

The construction and assembly of the chassis and body play a crucial role in the overall performance and durability of any vehicle. A well-designed frame provides the necessary support and stability, ensuring that all components work harmoniously. Understanding the intricacies of these assemblies can greatly enhance maintenance and repair processes, leading to improved longevity and efficiency.

Structural Components

Key elements of the chassis include the main frame, subframes, and reinforcement sections. Each part is engineered to withstand various stresses while maintaining optimal weight distribution. Proper installation of these components is essential for achieving the desired handling characteristics and ride quality.

Maintenance Considerations

Regular inspections of the body and frame assembly are vital for identifying wear and tear. Attention to corrosion protection and the integrity of welds can prevent significant issues down the line. Ensuring all parts are secure and functioning as intended contributes to safety and performance, enhancing the overall driving experience.

Maintenance Tips for Traxter 500

Regular upkeep is essential for ensuring the longevity and optimal performance of your vehicle. By adhering to a consistent maintenance schedule, you can prevent potential issues and enhance the overall driving experience. Here are some practical suggestions to keep in mind for effective maintenance.

Regular Oil Changes

Changing the engine oil at regular intervals helps maintain engine health and efficiency. Ensure to use the recommended oil type for optimal performance. Check the oil level frequently and top up as needed to avoid any damage.

Tire Inspection and Pressure

Frequent tire checks are vital for safety and handling. Inspect for wear and tear, and ensure that the tire pressure is within the recommended range. Properly inflated tires not only enhance safety but also improve fuel efficiency.

Where to Find Replacement Parts

Finding suitable components for your utility vehicle can be a straightforward process if you know where to look. Numerous resources are available to help you locate the necessary items, ensuring your vehicle remains in optimal condition.

Start by checking with authorized dealers and service centers that specialize in off-road vehicles. They often have access to genuine components and can provide guidance on installation. Additionally, online marketplaces and auction sites can offer a wide selection of aftermarket alternatives. It’s essential to compare prices and read customer reviews to ensure quality.

Another option is to visit local salvage yards or specialty shops that focus on recreational vehicles. These places can be treasure troves for used parts, often at a fraction of the original price. Engaging with online forums and communities dedicated to utility vehicles can also yield valuable recommendations and resources for sourcing components.