In the realm of machinery and equipment, a clear visual representation is crucial for effective maintenance and repair. Such illustrations serve as invaluable tools, guiding users through the intricate components and their interconnections. By comprehending these schematics, operators can ensure the longevity and optimal performance of their systems.

The significance of these visual aids cannot be overstated, as they offer a comprehensive overview of the various elements at play. Each symbol and line provides insight into the relationships between components, simplifying complex tasks. This clarity enables technicians to swiftly identify issues and implement solutions with confidence.

Moreover, possessing a thorough understanding of these representations empowers users to perform regular inspections and necessary adjustments. By becoming familiar with the layout and functionality of the individual elements, one can enhance the overall efficiency and reliability of the machinery in question.

This section will explore the fundamental components and their relationships within a specific type of machinery. By breaking down each element, we aim to provide a clear overview that enhances the understanding of how these components interact to ensure optimal performance. A comprehensive approach will allow enthusiasts and users to appreciate the design and functionality of the entire system.

The following headings will guide the reader through various aspects of this subject:

- Overview of the Machinery

- Key Components and Their Functions

- Assembly and Disassembly Process

- Common Issues and Troubleshooting

- Maintenance Tips for Longevity

- Upgrades and Modifications

- Safety Considerations

- Expert Recommendations

- Comparison with Other Models

- Resources for Further Learning

- Conclusion and Final Thoughts

Overview of Key Components

This section delves into the essential elements that form the foundation of the system. Understanding these fundamental aspects is crucial for grasping how the entire mechanism operates effectively and efficiently.

Essential Elements

- Control Unit: This component manages the operations and ensures the proper functioning of various functions.

- Power Supply: It provides the necessary energy required for all other components to operate seamlessly.

- Connector Interface: Facilitates communication between different segments of the system, ensuring smooth data flow.

- Sensor Module: Gathers real-time information, allowing for responsive adjustments based on environmental conditions.

Supporting Structures

- Frame: Provides physical support and houses all components securely.

- Mounting Brackets: Used to attach various parts to the frame, ensuring stability and accessibility.

- Wiring Harness: Organizes electrical connections, reducing clutter and preventing potential issues.

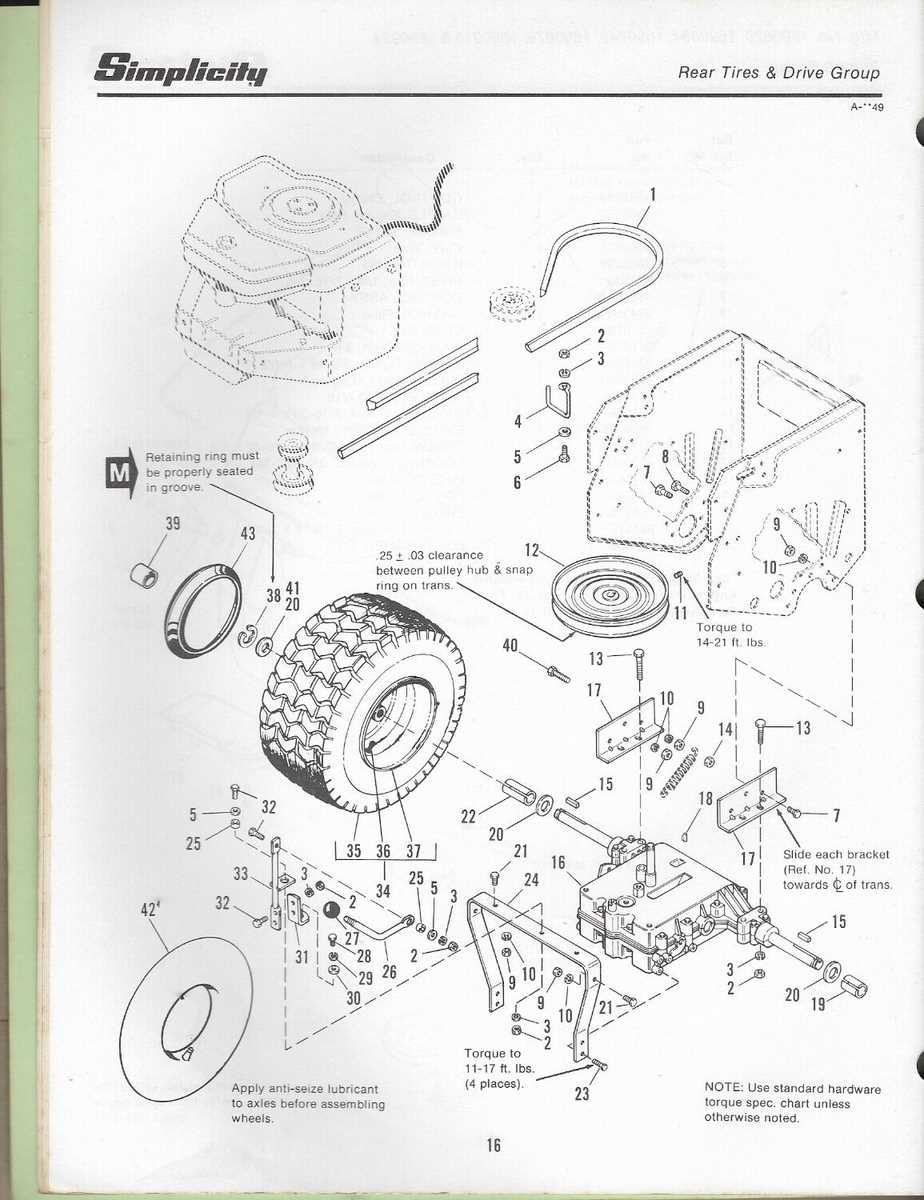

Importance of Accurate Diagrams

Having precise illustrations is crucial for effective understanding and communication in various fields. These visual representations serve as essential tools that facilitate comprehension, ensuring that users can grasp the relationships and functions of different components. When designed correctly, they enhance learning and efficiency by providing a clear reference point.

Enhancing Clarity

Accurate illustrations contribute significantly to clarity. When individuals refer to well-crafted visuals, they can easily identify specific elements and their interconnections. This clarity reduces the likelihood of misunderstandings and mistakes, fostering a more streamlined process whether in assembly, maintenance, or analysis.

Supporting Troubleshooting Efforts

Detailed visuals play a vital role in troubleshooting and repair processes. When issues arise, having a reliable reference allows technicians to pinpoint problems quickly. This efficiency not only saves time but also minimizes the risk of further complications, ultimately leading to more effective resolutions.

Common Issues with Assembly

When putting together various components of machinery, certain challenges may arise that can hinder the overall functionality. Recognizing these potential pitfalls is essential for achieving a seamless assembly process and ensuring optimal performance.

Frequent Challenges Encountered

- Mismatched Components: Using elements that are not compatible can lead to malfunctioning systems.

- Incomplete Instructions: Lack of clear guidance often results in errors during the assembly process.

- Quality of Materials: Inferior materials can compromise durability and functionality.

- Improper Tools: Using incorrect tools can lead to damage and ineffective assembly.

Preventative Measures

- Ensure all components are verified for compatibility before starting.

- Review assembly instructions thoroughly and seek clarification if needed.

- Use high-quality materials to enhance longevity and efficiency.

- Select appropriate tools tailored for the specific task at hand.

Tools Required for Maintenance

Proper upkeep of machinery is essential for optimal performance and longevity. To ensure effective servicing, a selection of tools is necessary to address various tasks. Each tool plays a vital role in facilitating repairs and maintenance, making it easier to tackle issues as they arise.

Basic Hand Tools are fundamental for any maintenance job. A reliable set of wrenches, screwdrivers, and pliers are indispensable for loosening or tightening components. These tools allow for efficient access to internal mechanisms, ensuring that any adjustments or replacements can be performed seamlessly.

Specialized Equipment may also be required, depending on the complexity of the tasks at hand. Tools such as torque wrenches, alignment gauges, and diagnostic instruments are essential for ensuring precision and accuracy in repairs. These instruments help technicians monitor performance and identify potential issues before they escalate.

Safety Gear should never be overlooked during maintenance procedures. Protective eyewear, gloves, and appropriate clothing are crucial for safeguarding against potential hazards. Using the right safety equipment not only protects the individual but also ensures that maintenance activities can be conducted without unnecessary risk.

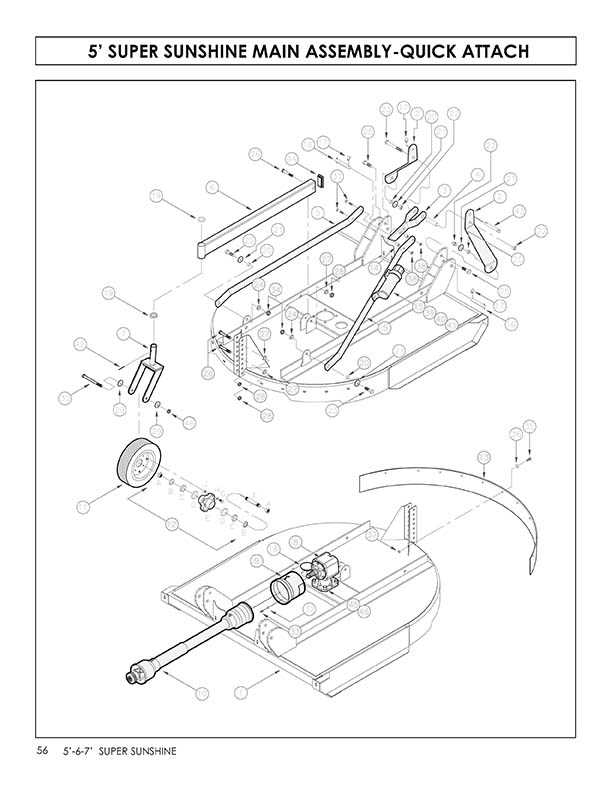

Step-by-Step Assembly Instructions

Assembling components can be a straightforward task when approached with clear guidance. This section will provide detailed instructions that will help you piece together the various elements effectively. By following these steps, you will ensure that each part fits seamlessly, resulting in a well-constructed unit.

Step 1: Begin by organizing all the components in a designated workspace. Make sure you have all necessary tools at hand to facilitate the process.

Step 2: Start with the foundational element. Align it properly and secure it in place, ensuring it is level and stable before proceeding to the next stage.

Step 3: Gradually introduce additional components, connecting them as specified in the provided guidelines. Pay attention to the orientation of each piece to avoid confusion later on.

Step 4: Once all elements are joined, conduct a thorough inspection to confirm that everything is securely attached. Make adjustments if needed to enhance stability and functionality.

Step 5: Finally, test the assembled unit to ensure it operates correctly. Troubleshoot any issues that may arise, making the necessary modifications to achieve optimal performance.

By adhering to these straightforward steps, you will successfully assemble the unit, ready for use or further enhancement.

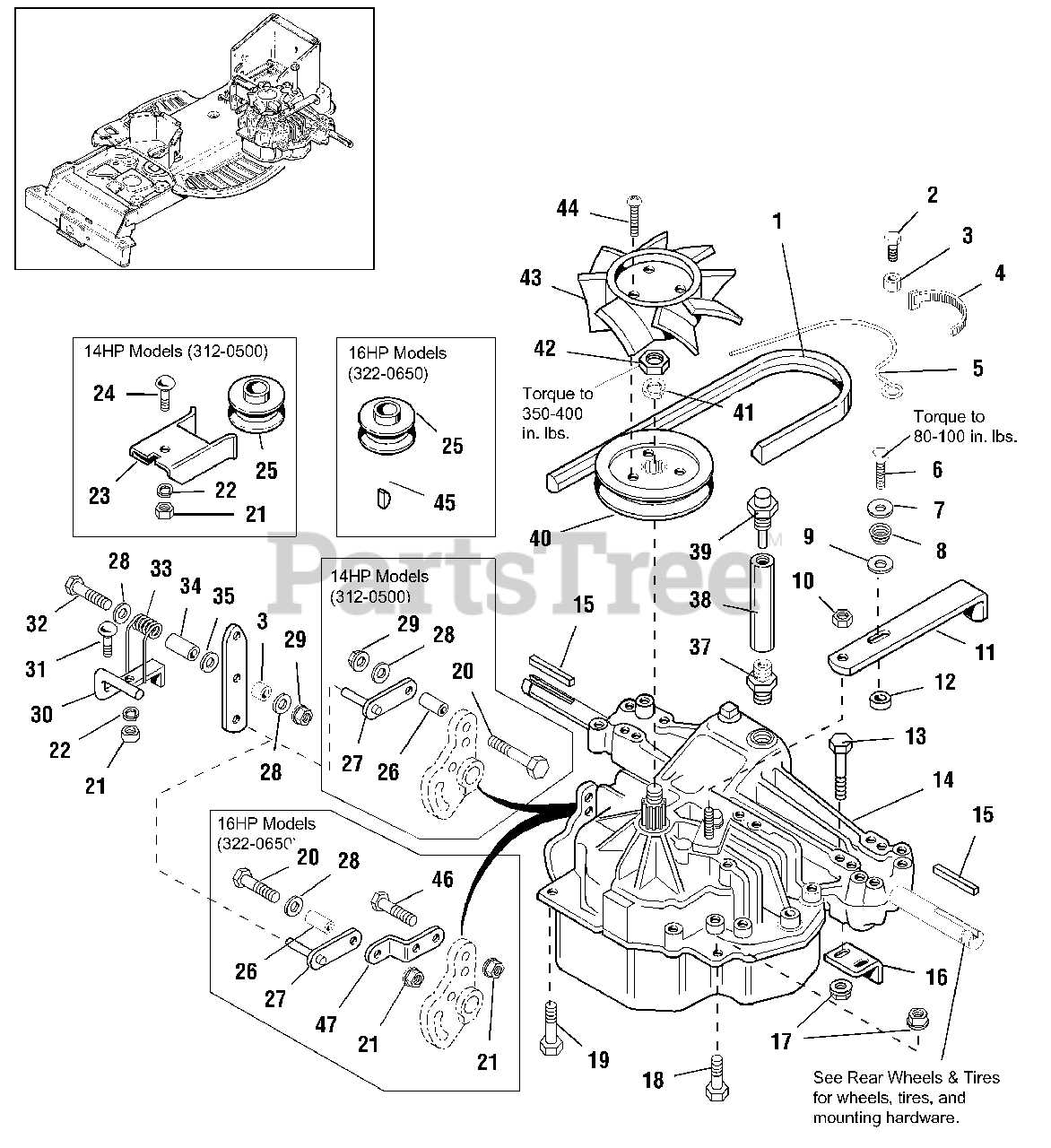

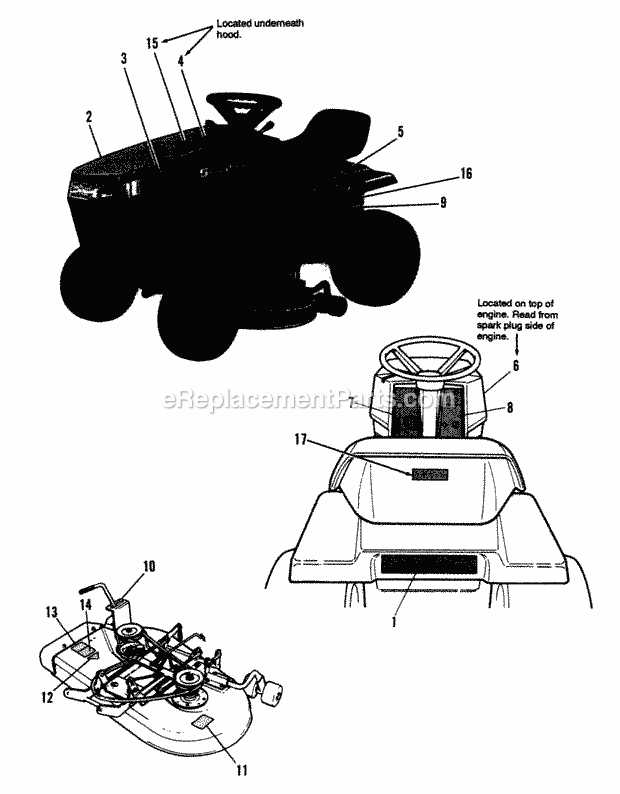

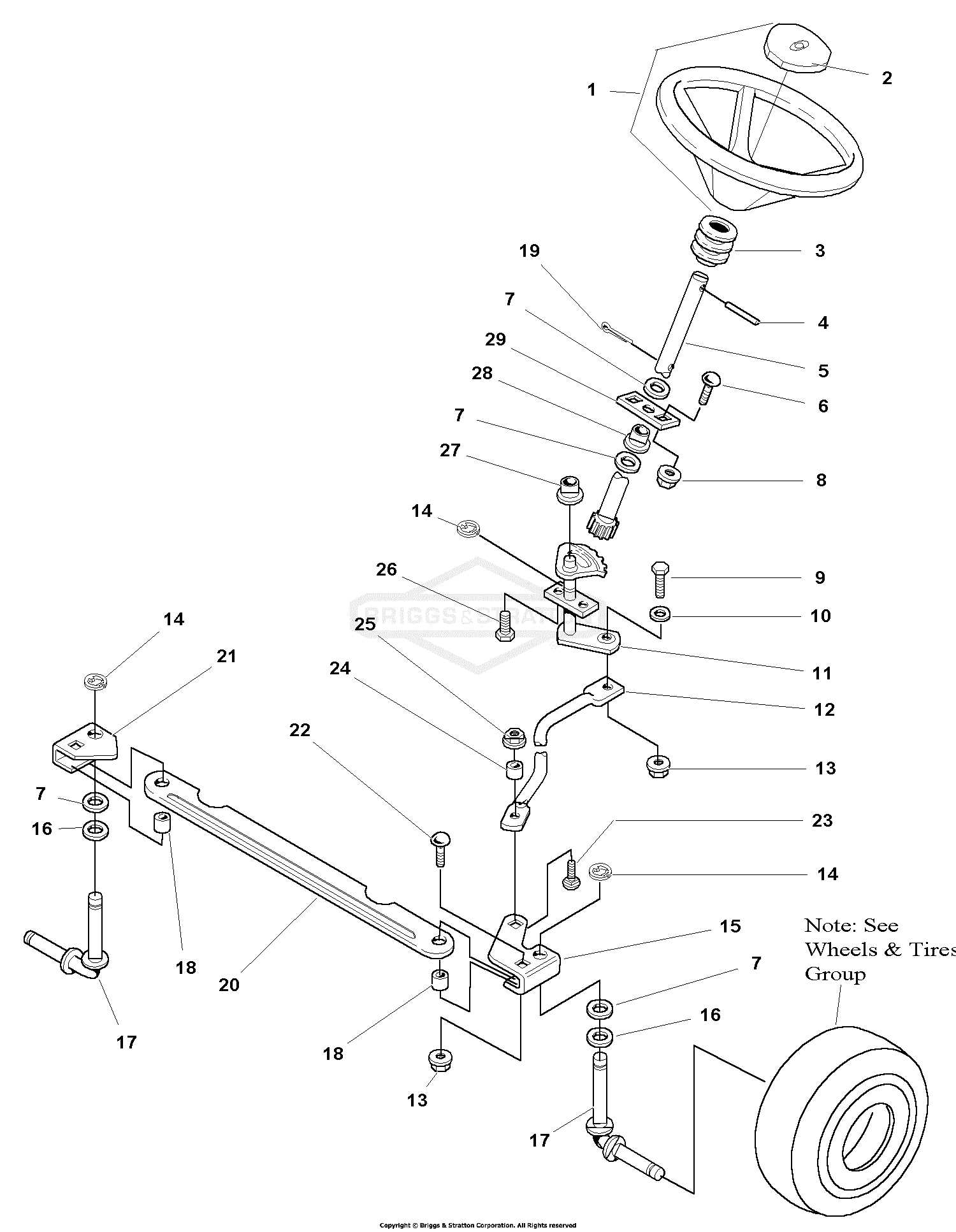

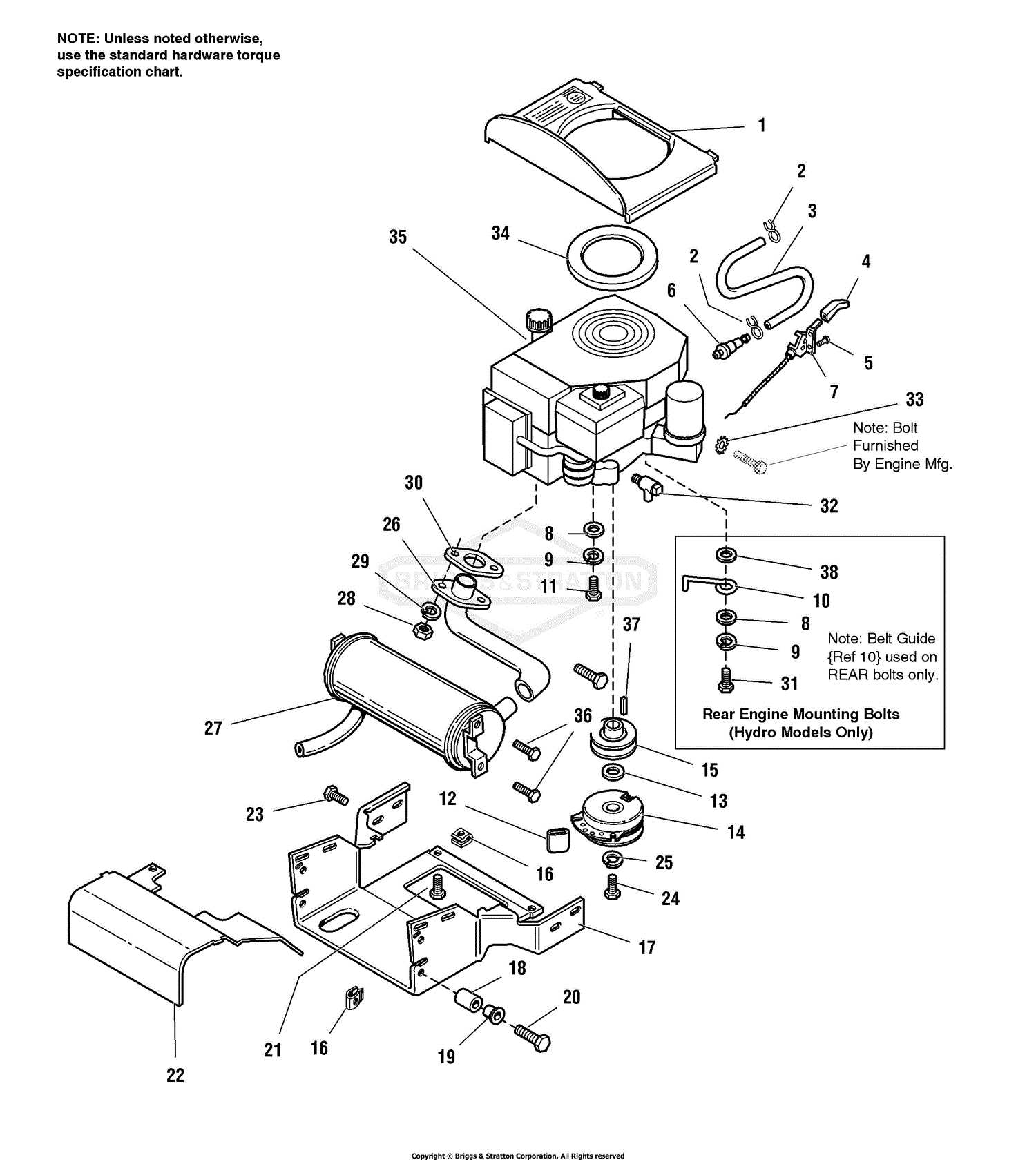

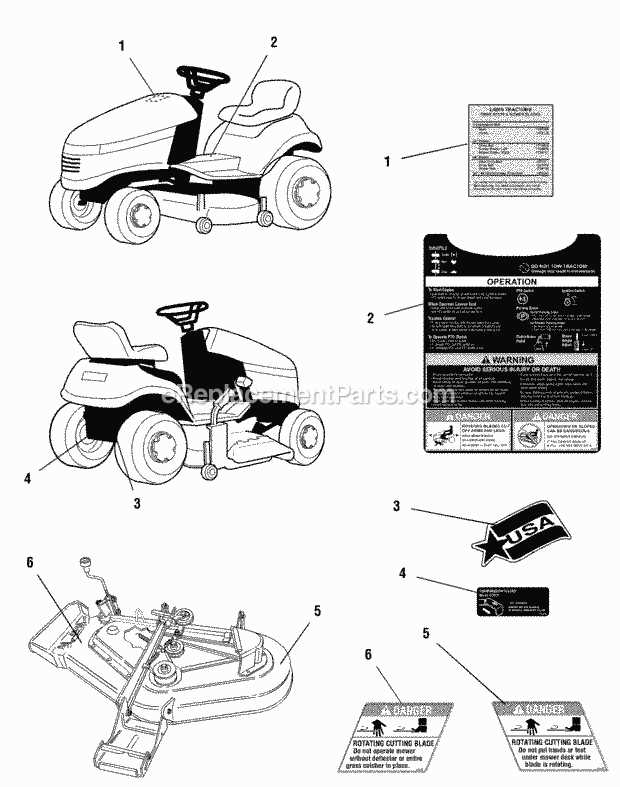

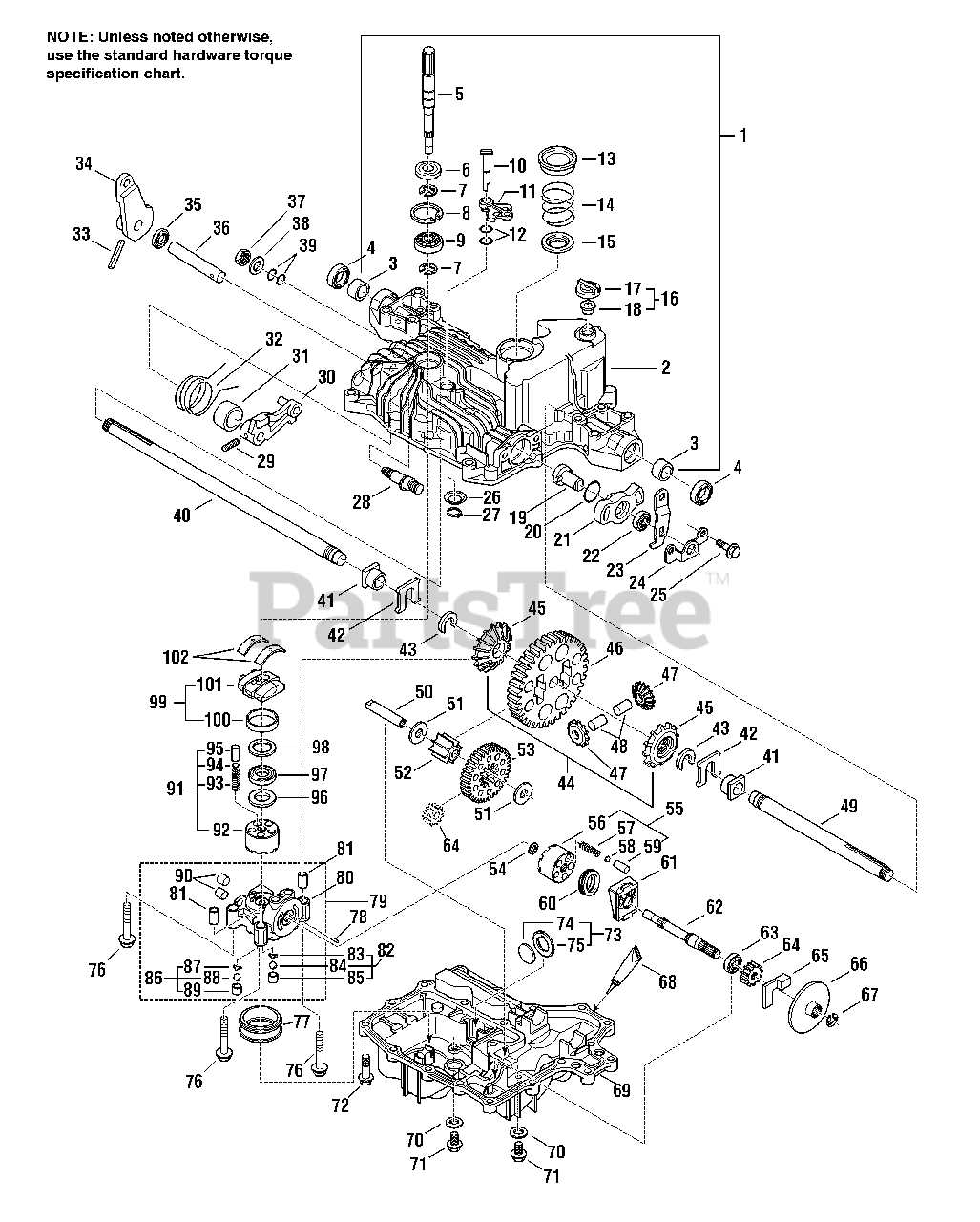

Identifying Parts by Diagram

Understanding the various components of a system is crucial for effective maintenance and repair. Visual representations play an essential role in this process, allowing individuals to familiarize themselves with different elements and their respective functions. By analyzing these illustrations, one can easily locate and identify necessary components, facilitating more efficient troubleshooting and repairs.

Importance of Visual References

Visual aids serve as a valuable tool for technicians and enthusiasts alike. They simplify complex systems, breaking them down into manageable sections. This approach enhances comprehension and ensures that all essential components are accounted for during inspections or repairs.

Common Components Overview

| Component Name | Description | Function |

|---|---|---|

| Housing | The outer shell that protects internal elements | Provides structural support and shields from external damage |

| Drive Assembly | The mechanism responsible for motion | Transfers energy to facilitate movement |

| Control Unit | The central hub for operations | Manages functionalities and coordinates actions |

Best Practices for Maintenance

Regular upkeep is essential for ensuring the longevity and optimal performance of mechanical systems. Implementing effective strategies not only enhances reliability but also minimizes potential failures. A proactive approach to maintenance can significantly reduce downtime and associated costs, promoting overall efficiency in operations.

Establish a Routine Schedule

Creating a consistent maintenance schedule is vital. This should include regular inspections, cleaning, and necessary adjustments to components. By adhering to a timetable, operators can identify and address issues before they escalate, thus preserving the functionality of the equipment.

Utilize Quality Materials

Using high-quality components and lubricants is crucial for the smooth operation of any machinery. Investing in superior materials ensures better performance and reduces wear and tear over time. Additionally, sourcing parts from reputable suppliers can enhance the reliability and safety of the overall system.

Troubleshooting Common Problems

When working with mechanical systems, various issues may arise that impede their optimal performance. Identifying these challenges promptly can save time and resources. This section provides insights into frequent complications and their potential solutions, ensuring a smooth operational process.

Understanding the symptoms of malfunctioning components is crucial. Below is a table that outlines common issues, their signs, and recommended actions to resolve them:

| Issue | Symptoms | Recommended Actions |

|---|---|---|

| Inconsistent Operation | Erratic performance, frequent stopping | Check for loose connections and ensure all components are properly aligned. |

| Unusual Noises | Grinding, squeaking, or rattling sounds | Inspect moving parts for wear and tear; lubricate or replace as necessary. |

| Overheating | Excessive heat, smoke, or burning smell | Examine cooling mechanisms and clean any obstructed vents; allow the system to cool down. |

| Leakage | Visible fluid pooling or dripping | Identify the source of the leak and replace seals or gaskets as needed. |

By systematically addressing these issues, users can enhance the longevity and reliability of their mechanical systems.

Replacing Worn Components

As time passes, certain elements of machinery can become worn and less effective, leading to decreased performance and potential failures. Timely replacement of these deteriorating components is crucial to maintain optimal functionality and prolong the lifespan of the equipment.

Identifying worn components typically involves inspecting for visible signs of wear, such as cracks, corrosion, or unusual noises during operation. Once identified, it is essential to source high-quality replacements that match the original specifications to ensure compatibility and performance. Proper installation is equally important; following manufacturer guidelines can help prevent future issues and ensure reliable operation.

Regular maintenance checks can significantly aid in early detection of wear. Keeping a maintenance log can also help track component lifespans and predict when replacements will be necessary, ultimately leading to improved efficiency and reduced downtime.

Safety Precautions During Repair

Engaging in repair tasks demands a thorough understanding of essential safety measures to ensure a secure working environment. Awareness and adherence to these precautions can significantly reduce the risk of accidents and injuries during the process.

1. Disconnect Power Supply: Before starting any maintenance, always ensure that the electrical source is disconnected. This prevents unexpected activations that could lead to electric shocks or equipment damage.

2. Use Personal Protective Equipment: Wearing appropriate protective gear such as gloves, goggles, and masks is crucial. This gear shields against potential hazards like sharp objects, flying debris, and harmful substances.

3. Maintain a Clean Workspace: A tidy work area minimizes the risk of slips, trips, and falls. Keep tools organized and remove any unnecessary clutter to enhance safety and efficiency.

4. Follow Manufacturer Instructions: Always consult the provided manuals or guidelines. These documents contain vital information on safe handling and specific procedures, ensuring that repairs are carried out correctly.

5. Be Mindful of Chemical Safety: If the repair involves chemicals, ensure proper ventilation and follow handling instructions carefully. Store chemicals in labeled containers away from heat sources.

6. Seek Assistance When Needed: If uncertain about a procedure or feeling overwhelmed, do not hesitate to ask for help. Collaborating with a knowledgeable individual can prevent mistakes and enhance safety.

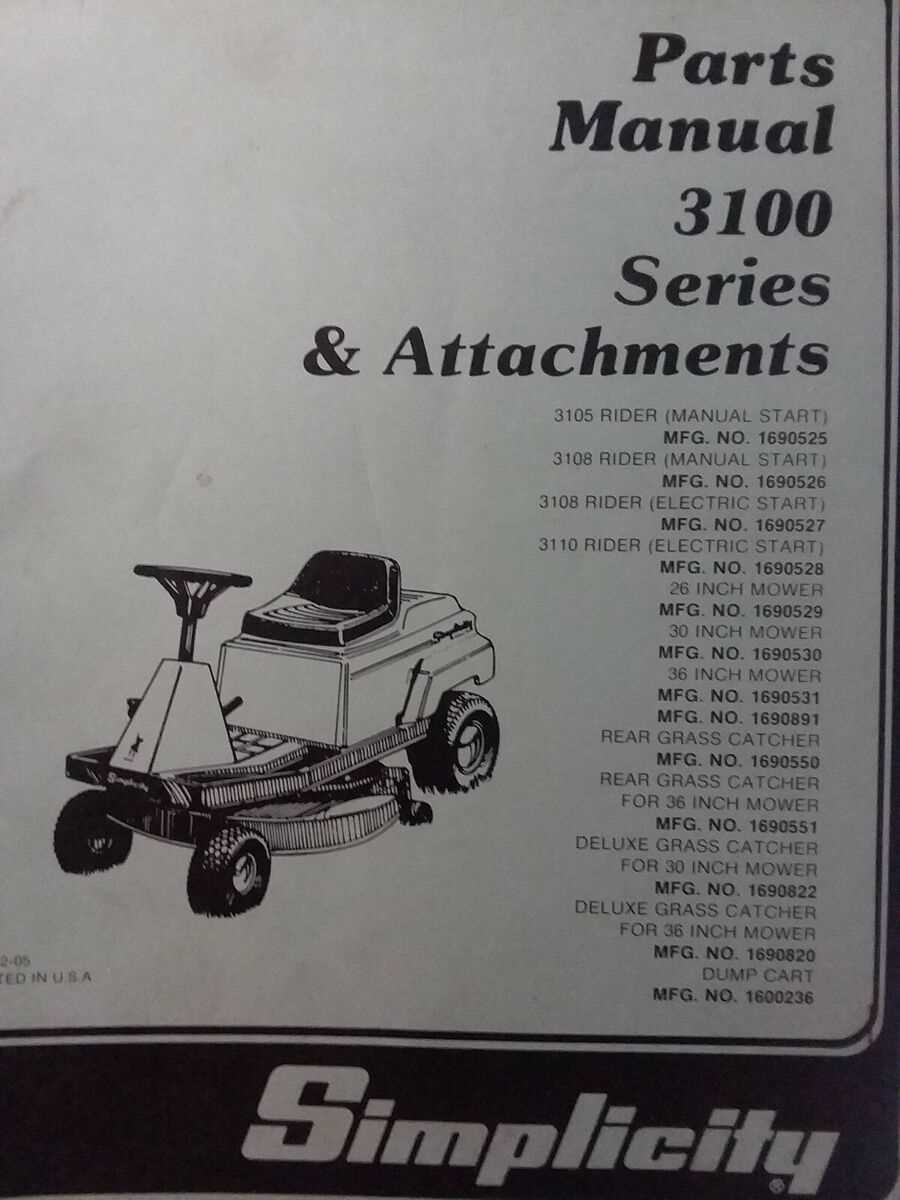

Resources for Further Learning

To deepen your understanding of agricultural machinery and its components, a variety of resources are available. These materials can enhance your knowledge and provide practical insights into machinery maintenance, troubleshooting, and efficient operation.

Consider exploring the following avenues:

- Online Courses: Numerous platforms offer specialized courses focused on agricultural equipment and maintenance practices.

- Books and Manuals: Reference materials can provide in-depth information on specific models and general operational guidelines.

- Webinars and Workshops: Engaging with industry experts through live sessions can offer valuable real-time insights and hands-on demonstrations.

- Forums and Community Groups: Joining online communities allows for sharing experiences, asking questions, and gaining tips from fellow enthusiasts and professionals.

Utilizing these resources can greatly enhance your skills and knowledge in managing agricultural equipment.