Navigating the complexities of marine machinery can be a daunting task for both seasoned sailors and newcomers alike. Having a clear grasp of the various elements that comprise essential equipment is crucial for ensuring efficient operation and maintenance. This section delves into the intricate components that play vital roles in marine anchoring systems.

By examining the individual elements involved in these systems, one can better appreciate their functions and how they contribute to overall performance. A thorough understanding not only aids in troubleshooting issues but also enhances the ability to make informed decisions when it comes to repairs and upgrades.

In the following segments, we will break down the various constituents of these anchoring devices, presenting a visual representation that facilitates easier comprehension. With this knowledge, mariners can confidently navigate the challenges that come with maintaining their equipment, ensuring safe and successful voyages on the open waters.

Understanding Lofrans Windlass Functionality

The operation of marine anchoring systems is crucial for ensuring safety and stability when vessels are at rest. These systems are designed to streamline the process of deploying and retrieving anchors, enhancing both efficiency and ease of use for sailors. By examining the inner workings of these mechanisms, one can gain insights into their effectiveness and reliability in various maritime conditions.

Key Components and Their Roles

At the heart of these systems lie several essential components that work in concert to perform anchoring tasks. The motor serves as the powerhouse, driving the mechanism that controls the cable. Additionally, gears and clutches play a pivotal role in managing the torque and speed, ensuring a smooth operation during deployment and retrieval. Understanding the function of each element is vital for troubleshooting and maintenance.

Operational Mechanism

The functionality of these systems is typically initiated via a control panel, allowing users to manage the anchoring process with precision. When engaged, the motor activates the gears, causing the anchor to descend or ascend. The incorporation of safety features, such as overload protection, further enhances reliability, reducing the risk of malfunctions during critical moments. Regular maintenance and familiarity with the system are essential for optimal performance, enabling sailors to navigate with confidence.

Essential Components of Windlass Systems

Understanding the critical elements of anchoring mechanisms is vital for ensuring efficient operation and safety at sea. Each component plays a significant role in the overall functionality, working together to manage the deployment and retrieval of anchors seamlessly.

- Drum: This is the central part that houses the anchor chain or rope, providing the necessary surface for winding and unwinding.

- Motor: A powerful electric or hydraulic unit that drives the system, enabling swift and controlled movement of the anchor.

- Gypsy: A wheel or cone that grips the chain or rope, facilitating its movement and preventing slippage during operation.

- Control Unit: The interface that allows the operator to manage the system’s functions, often equipped with remote capabilities for added convenience.

- Clutch: A mechanism that enables the user to disengage the motor from the drum, allowing manual operation when needed.

Additional components also enhance functionality:

- Base Plate: Provides stability and secure mounting to the vessel’s deck.

- Chain Stopper: A device that secures the chain, preventing it from moving when not in use.

- Sheave: A pulley that aids in guiding the anchor line smoothly during deployment and retrieval.

Each of these elements contributes to the reliable operation of anchoring systems, ensuring safety and efficiency while navigating waters.

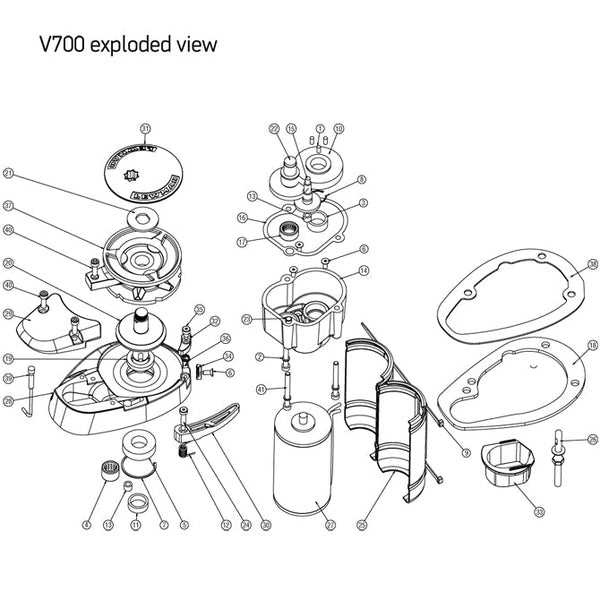

How to Interpret Parts Diagrams

Understanding visual representations of mechanical components is crucial for effective maintenance and repair. These illustrations serve as a guide, helping users identify various elements and their relationships within a system. By familiarizing yourself with the layout and symbols used, you can streamline troubleshooting and ensure proper assembly.

Start by examining the overall layout. Look for the main components highlighted in the illustration, as they often provide context for the supporting parts. This holistic view allows you to grasp how everything fits together.

Next, pay attention to the labels and legends. Each symbol or number typically corresponds to a specific component. Understanding these references is essential for locating and ordering the right items. Cross-referencing these with a parts list can further enhance your comprehension.

Additionally, take note of the directional arrows. These often indicate the movement or orientation of specific parts, which is vital for proper installation and operation. Understanding how components interact helps prevent common errors during assembly.

Finally, practice makes perfect. The more you engage with these illustrations, the more intuitive they will become. Regularly referencing them during maintenance tasks will deepen your understanding and improve your efficiency in handling repairs.

Common Lofrans Models Overview

This section provides an overview of popular models commonly used in maritime applications, highlighting their unique features and specifications. Each model is designed to enhance efficiency and reliability, catering to various vessel types and operational needs.

| Model Name | Type | Maximum Load (kg) | Voltage (V) |

|---|---|---|---|

| Model A | Horizontal | 1000 | 12/24 |

| Model B | Vertical | 1500 | 12/24 |

| Model C | Self-Loading | 2000 | 230 |

| Model D | Electric | 1200 | 12/24 |

Understanding the differences among these models aids in selecting the right option for specific needs, ensuring optimal performance and durability in various marine environments.

Maintenance Tips for Windlass Parts

Proper upkeep of your anchoring equipment is essential for ensuring smooth operation and longevity. Regular attention can prevent minor issues from escalating into major repairs, ultimately saving time and money. By following a few key practices, you can keep your system in optimal condition and enhance its reliability.

Firstly, it’s crucial to inspect components regularly for signs of wear and corrosion. Look for rust or pitting on metal parts, which can compromise their integrity. Cleaning these areas with a suitable solvent can help maintain their function and appearance.

Lubrication is another vital aspect. Use high-quality marine grease to treat moving elements, ensuring they operate smoothly without friction. Be cautious not to over-lubricate, as this can attract dirt and debris.

Moreover, check electrical connections for any signs of corrosion or loose wiring. Secure connections are vital for the efficient operation of the system. Consider using dielectric grease to protect against moisture intrusion and prevent corrosion.

Lastly, ensure that all fasteners are tightened to the manufacturer’s specifications. Vibrations from operation can loosen bolts and screws over time, leading to potential failure. Regular checks and adjustments will ensure everything remains secure.

Identifying Wear and Tear Indicators

Recognizing the signs of degradation in marine equipment is crucial for maintaining functionality and safety. Various components can exhibit specific indicators that suggest they may require inspection or replacement. Understanding these signs can help prevent more significant issues and extend the lifespan of your apparatus.

Common Signs of Degradation

Several key indicators can point to wear and tear in marine devices. Regular inspection for these signs is essential:

| Indicator | Description |

|---|---|

| Corrosion | Rust or discoloration on metal surfaces indicating potential structural weakness. |

| Fraying | Worn or damaged cables that can lead to failure under stress. |

| Cracks | Visible splits or fractures in components, signaling the need for immediate attention. |

| Excessive Play | Looseness in moving parts that can affect performance and safety. |

Monitoring Performance

Regularly assessing the functionality of your equipment can also reveal potential issues. If you notice unusual noises, reduced efficiency, or inconsistent operation, these could be signs that maintenance is required. Timely attention to these indicators can help ensure safe and reliable operation.

Replacing Worn Components Safely

Ensuring the reliability of marine equipment is crucial for safety and performance. When components begin to show signs of wear, it’s essential to approach their replacement with caution. Understanding the right procedures and utilizing the correct tools can make the process efficient and safe.

Assessment and Preparation

Before starting the replacement, a thorough assessment of the components is necessary. Identify any parts that are damaged or excessively worn. Make a checklist of the tools and replacement items needed for the task. Safety gear, such as gloves and goggles, should be worn at all times to protect against injury during the procedure.

Safe Replacement Techniques

When replacing any worn items, ensure the equipment is properly secured to prevent any unexpected movements. Follow manufacturer guidelines closely to guarantee correct installation. Double-check all connections and fittings after replacing components to maintain optimal performance and reduce the risk of future issues. Properly dispose of the old parts to prevent hazards and promote environmental responsibility.

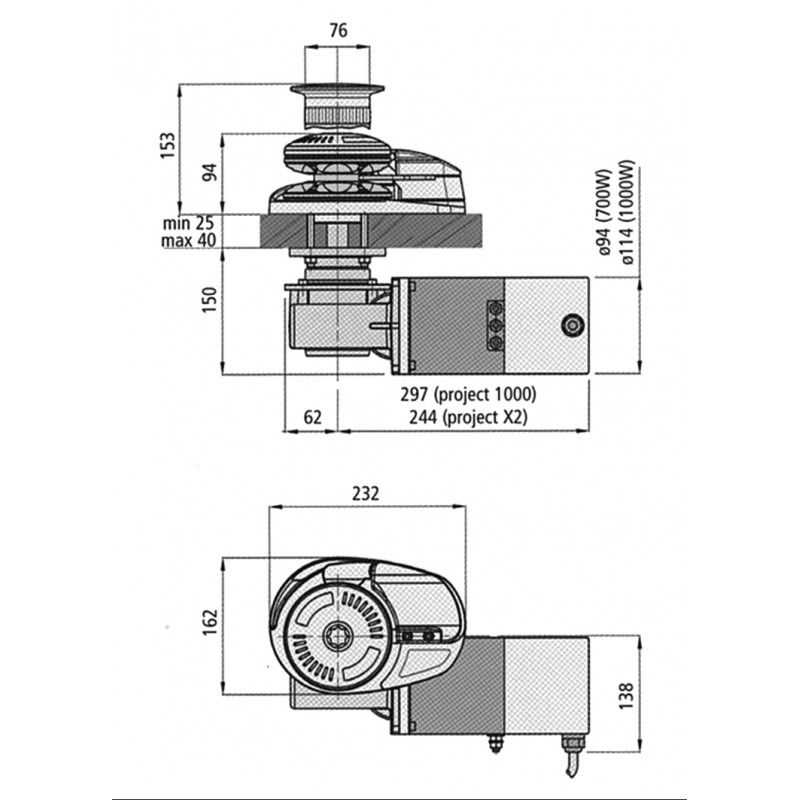

Installation Guidelines for Windlass Units

Proper installation of marine anchoring systems is crucial for ensuring reliability and safety during maritime operations. Adhering to detailed guidelines will help achieve optimal performance and longevity of the equipment. This section outlines essential steps and considerations for the effective setup of these devices.

1. Preparation and Planning: Before commencing installation, it is vital to assess the vessel’s deck structure and design. Ensure that the location chosen can accommodate the unit’s dimensions and that the deck is sturdy enough to support the weight and operational forces involved.

2. Tools and Equipment: Gather all necessary tools and materials beforehand. This may include drilling equipment, fasteners, sealants, and safety gear. Having everything on hand will facilitate a smoother installation process.

3. Follow Manufacturer’s Instructions: Always refer to the specific guidelines provided by the manufacturer. These instructions typically include detailed diagrams and specifications for installation, ensuring compatibility and functionality of the system.

4. Securing the Unit: When placing the device onto the deck, ensure that it is aligned correctly. Use appropriate fasteners to secure it firmly. Adequate sealing around the mounting area is essential to prevent water ingress, which could lead to corrosion and system failure.

5. Electrical Connections: If the equipment requires electrical integration, follow safety protocols. Connect wiring carefully, ensuring proper insulation and secure fittings to prevent short circuits and damage.

6. Testing and Maintenance: After installation, conduct a thorough test of the system to confirm its functionality. Regular maintenance checks are essential to identify any potential issues early and to ensure continued safe operation.

By following these guidelines, users can achieve a successful installation that enhances the safety and efficiency of their anchoring equipment.

Electrical Systems in Lofrans Windlasses

The functionality of marine equipment heavily relies on their electrical systems, which serve as the backbone for operational efficiency and safety. These systems ensure smooth performance by managing power distribution, control, and feedback mechanisms necessary for various functions. A thorough understanding of these components is crucial for effective maintenance and troubleshooting.

Key Components of Electrical Systems

- Power Source: Typically a battery or generator that supplies the necessary energy.

- Control Panel: An interface that allows users to operate the equipment and monitor performance.

- Wiring Harness: A network of wires that connects all electrical components, ensuring proper communication.

- Motor: Converts electrical energy into mechanical energy to perform the required tasks.

- Sensors: Monitor various parameters such as load and position, providing feedback to the control system.

Maintenance Considerations

- Regularly inspect wiring for signs of wear or corrosion.

- Test battery capacity and connections to ensure reliable power supply.

- Check control panel functionality to prevent operational failures.

- Monitor motor performance and look for unusual sounds or vibrations.

- Keep sensors clean and calibrated for accurate readings.

Understanding these elements helps to ensure that marine operations remain safe and efficient, contributing to the overall reliability of the equipment in various conditions.

Upgrading Windlass Features and Options

Enhancing the capabilities of your anchoring system can significantly improve your boating experience. With various advanced features and customization options available, you can tailor the equipment to better suit your needs and preferences. This section will explore potential upgrades that can optimize performance and usability.

Modern Features to Consider

Investing in new technologies can bring a range of benefits, including increased efficiency and ease of use. Consider the following enhancements:

- Remote Control Systems: Allow for operation from a distance, providing greater convenience.

- Automatic Freefall: Facilitates quick and efficient deployment of the anchor.

- Integrated GPS: Enables precise positioning and management of anchoring.

- Power Options: Upgrading to higher voltage systems for improved lifting capabilities.

Customization Options

Personalizing your equipment can improve both functionality and aesthetics. Explore these customization possibilities:

- Finishes: Choose from various materials and coatings to match your vessel’s design.

- Capacity Enhancements: Adjust specifications to accommodate larger anchors for bigger boats.

- Accessory Add-ons: Consider installing features such as additional safety mechanisms or lighting.

By focusing on these upgrades, you can enhance both the performance and the overall enjoyment of your maritime adventures.

Choosing the Right Accessories

When it comes to optimizing your marine equipment, selecting the appropriate add-ons is crucial for enhancing performance and safety. The right accessories not only improve functionality but also contribute to a smoother overall experience on the water. Understanding your specific needs and the compatibility of available options will guide you in making the best choices.

Assess Your Needs

Start by evaluating the type of activities you plan to undertake. Whether you are focusing on leisure sailing or serious offshore adventures, the accessories you choose should align with your usage patterns. Consider factors such as the weight of your vessel, the weather conditions you might encounter, and the overall duration of your journeys. This assessment will help you identify essential items that can elevate your experience.

Quality and Compatibility

It is essential to prioritize quality when selecting additional equipment. Investing in durable and reliable accessories will pay off in the long run. Furthermore, ensure that any items you choose are compatible with your existing setup. Consult product specifications and user reviews to confirm that the add-ons will integrate seamlessly. Remember, well-matched accessories enhance both safety and efficiency while you’re navigating the waters.

Frequently Asked Questions about Lofrans

This section aims to address common inquiries related to the equipment and components produced by a well-known manufacturer in the marine industry. Here, you will find answers to some of the most frequently posed questions, providing clarity on usage, maintenance, and compatibility.

- What types of marine equipment does this brand offer?

- Anchor handling devices

- Deck machinery

- Electrical systems

- How can I find the right components for my device?

Consult the manufacturer’s website or user manual for detailed specifications. Additionally, you may reach out to authorized distributors for assistance in identifying suitable parts.

- What maintenance is required to ensure longevity?

Regular inspection and cleaning, lubrication of moving parts, and timely replacement of worn components are essential practices for upkeep.

- Are there any troubleshooting tips for common issues?

- Check the power supply and connections.

- Inspect for mechanical obstructions.

- Ensure that controls are functioning correctly.

- Where can I find replacement components?

Replacement items are available through authorized dealers, online marketplaces, and specialized marine supply stores.