Understanding the structure of modern coffee brewing systems can greatly enhance both maintenance and overall performance. Each element plays a vital role in ensuring that the machine operates efficiently, from heating to brewing.

Whether you are replacing a single element or performing more extensive repairs, knowing the placement and functionality of individual components is crucial. This guide helps to clarify how various parts of the system connect and work together to deliver the best results.

In the following sections, we will explore the specific breakdown of different system elements, helping you navigate the inner workings of your brewing device with ease.

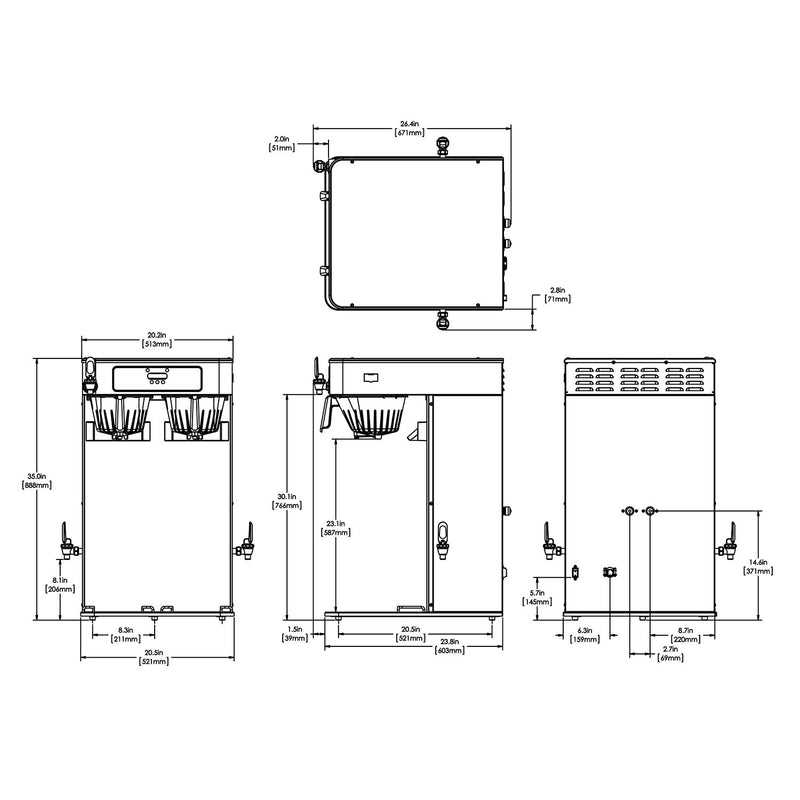

Components of the Bunn ThermoFresh System

This system consists of several key elements that work together to maintain optimal brewing performance and temperature retention. Each component plays a crucial role in delivering high-quality beverages efficiently and reliably.

Main Elements of the Brewing Unit

The brewing unit includes parts that control the flow of water and ensure even distribution over the grounds. These elements are designed to handle high volumes while maintaining consistent performance.

Thermal Retention Features

Thermal retention is achieved through specialized components that help maintain the temperature of the brewed beverage for extended periods. These include insulated vessels and temperature control mechanisms.

Understanding the Brewer’s Internal Structure

The internal configuration of a modern coffee maker is designed to ensure efficient brewing, combining several key components that work in harmony. Each element within the machine plays a crucial role in the overall process, from heating the water to delivering the perfect cup of coffee.

Water Reservoir: This section holds the water that will be heated and passed through the machine. It’s essential for maintaining a consistent flow during the brewing cycle.

Heating Element: Located at the core, this component ensures the water reaches the optimal temperature for extraction. It’s typically insulated to retain heat and support energy efficiency.

Pump System: The pump is responsible for moving the water through the system, ensuring a steady pressure for even distribution over the coffee grounds.

Dispensing Mechanism: Once the water has passed through the grounds, it flows into the final section, where the brewed coffee is delivered to the carafe or mug.

Understanding these main elements provides insight into the complexity and precision of the brewing process, highlighting the thoughtful engineering behind creating the ideal coffee experience.

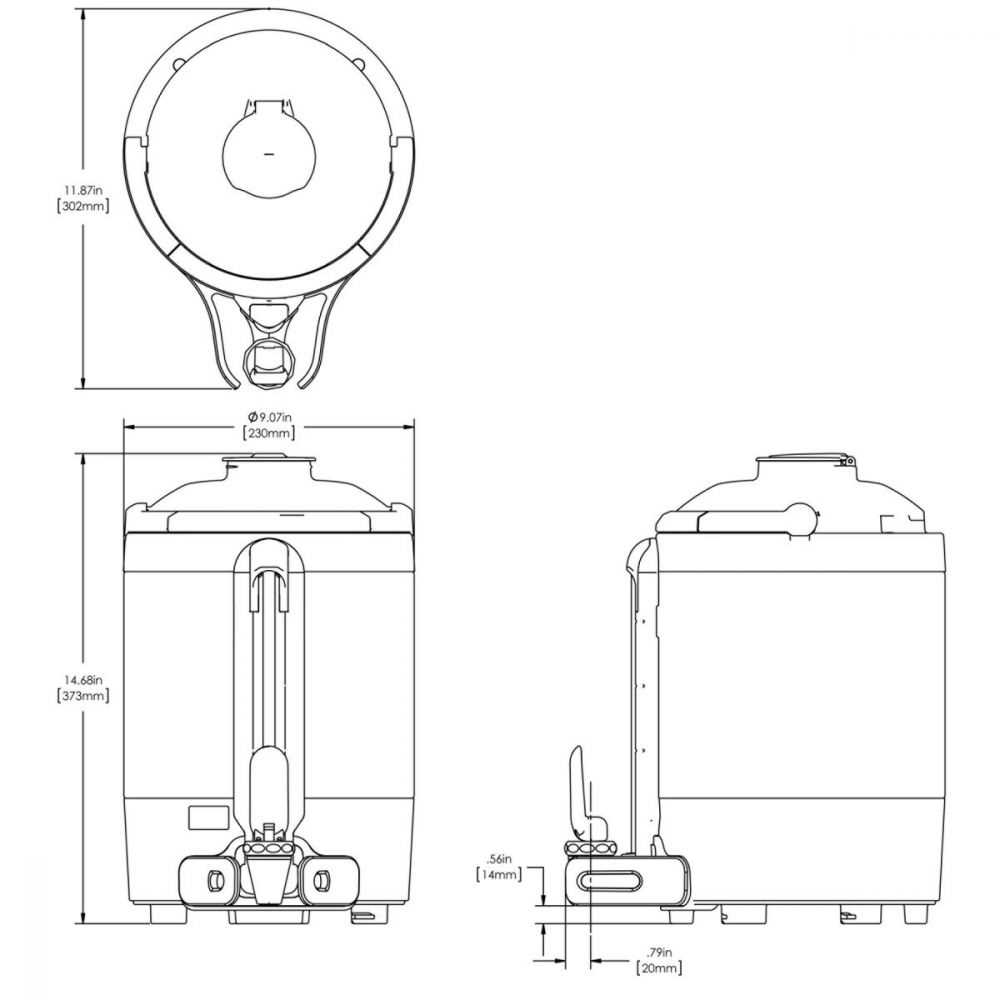

Thermal Carafe and Its Key Functions

The thermal carafe plays a central role in preserving the temperature of brewed beverages for extended periods, ensuring that the drink remains hot without the need for continuous heating. Its construction and design are aimed at maintaining optimal insulation and ease of use, enhancing the overall experience of serving and enjoying warm drinks.

Key Features of the Thermal Carafe

- Insulation Technology: The carafe uses double-wall insulation to retain heat efficiently, keeping beverages warm for hours without the need for external heat sources.

- Durable Construction: Made from stainless steel or other sturdy materials, the carafe is designed to resist wear and maintain its thermal performance over time.

- Spill-Resistant Lid: The lid is crafted to prevent spills while pouring, making it both practical and easy to handle.

Practical Advantages

- Energy Efficiency: With no continuous heating required, the carafe saves energy while maintaining the desired beverage temperature.

- Convenience for Serving: Its ergonomic handle and lightweight design make it simple to pour and serve, even in large gatherings.

- Vers

Water Reservoir Features and Maintenance

The water reservoir is a key component that ensures the proper flow and heating of water. Its design helps manage water distribution efficiently, making it essential for optimal operation. Regular upkeep of this part is crucial to maintaining overall performance and extending the lifespan of the system.

Key Features of the Reservoir

The water container is built to hold a sufficient amount of liquid, ensuring that the system works continuously without interruptions. It is designed with easy access for refilling and cleaning, which enhances convenience. Additionally, the material used for the reservoir is durable, resisting wear from frequent use.

Maintenance Tips

To ensure the longevity of the water tank, it is recommended to clean it regularly and inspect for any signs of buildup or debris. Avoid using harsh chemicals during cleaning, as this can damage the interior surface. Proper cleaning and care will help prevent blockages and ensure smooth operation.

| Component | Function |

|---|---|

| Water Heater | Ensures water reaches the optimal brewing temperature. |

| Carafe | Keeps the beverage hot after brewing through insulation. |

| Spray Head | Distributes water evenly over coffee grounds. |

| Filter Basket |

Drip Tray Design and Importance

The structure of a drip tray plays a crucial role in the overall efficiency of any brewing system. Designed to collect excess liquid during the brewing or dispensing process, it ensures that no spillage occurs, maintaining cleanliness in the working environment. Additionally, the tray’s design helps prevent messes that could lead to accidents or product waste.

| Maintenance Task | Frequency |

|---|---|

| Clean the reservoir | Weekly |

| Inspect for buildup | Monthly |

| Feature | Benefit |

|---|---|

| Removable tray | Easy cleaning and maintenance |

| Wide surface | Prevents overflow and splashes |

| Durable material | Long-lasting performance and resistance to wear |

The tray’s role extends beyond simple spill containment, contributing to the durability of the machine by reducing wear and tear on other components. A well-designed drip tray enhances the user experience, ensuring that the brewing or dispensing process remains smooth and efficient.

Control Panel Layout and Operation

The control panel is designed to provide intuitive access to all the essential functions of the machine. Each button and indicator light has a specific purpose, allowing users to interact with the system easily. The arrangement ensures that the most frequently used features are readily accessible, optimizing convenience during operation.

Main Function Buttons

The panel includes primary function buttons for starting and stopping the brewing process, adjusting settings, and selecting specific modes. These controls are positioned for quick access, making the brewing experience seamless. The user can quickly switch between modes or customize settings with minimal effort.

Status Indicators

LED lights are positioned to indicate the current status of the system. Whether it’s showing the water temperature, brewing progress, or any potential issues, these indicators provide real-time feedback. This ensures that users can monitor operations at a glance and make adjustments if necessary.

Spray Head and Water Distribution

The spray head plays a crucial role in evenly distributing water over the coffee grounds to ensure optimal extraction. Its design allows for a controlled flow of water, which is essential for achieving balanced flavor during brewing. The water distribution process ensures that the coffee grounds are fully saturated, leading to a consistent and flavorful brew.

- The spray head helps control the water flow and pressure.

- Water is evenly distributed across the coffee grounds to avoid dry spots.

- Proper water saturation leads to a more consistent and balanced coffee flavor.

- Efficient water distribution prevents over-extraction in certain areas.

Heating Plate and Temperature Control

The heating plate is a crucial component in maintaining the ideal temperature of brewed liquids. Its design ensures consistent heat distribution, which is essential for preserving flavor and aroma over time. Understanding how the heating element works and how to adjust the temperature is key to optimal use.

- Heating Plate Function: The plate transfers heat evenly to the container, ensuring the liquid remains at a stable temperature.

- Temperature Control: A built-in thermostat allows users to modify the heat settings, providing flexibility depending on the type of beverage.

- Safety Features: Many heating plates include automatic shutoff mechanisms to prevent overheating and ensure safe operation.

Proper maintenance of the heating system is important for extending the life of the equipment and ensuring consistent performance.

Filter Basket Role in Brewing Process

The filter basket plays a crucial part in the coffee brewing experience, ensuring that the extraction of flavors occurs smoothly and efficiently. This component is designed to hold the ground coffee while allowing water to flow through, extracting essential oils and aromas that contribute to the overall taste of the beverage.

When hot water passes through the coffee grounds contained within the basket, it activates the soluble compounds, leading to a flavorful infusion. The design and material of the filter basket can significantly impact the brewing process. A well-structured basket allows for optimal flow rate and even saturation, which enhances the extraction quality.

Moreover, the filter basket also serves to prevent unwanted particles from entering the final brew. This separation is vital for achieving a clean cup, free from sediments. Regular maintenance and cleaning of the filter basket are essential to preserve its functionality and ensure that each brewing cycle delivers the best possible flavor profile.

In summary, the filter basket is not merely a passive container but an active participant in the coffee brewing process, influencing both flavor and clarity in the final product.

Handle Assembly and User Interaction

The handle assembly plays a crucial role in the functionality and user experience of brewing equipment. It serves as the primary interface between the user and the machine, allowing for efficient operation and control. Understanding the components involved in this assembly can enhance the overall experience and ensure optimal performance.

Key elements of the handle assembly include the grip, locking mechanisms, and adjustment features. Each component is designed to provide comfort and ease of use, facilitating seamless interaction during the brewing process. Below is a detailed overview of these components:

| Component | Description | Functionality |

|---|---|---|

| Grip | A contoured surface designed for easy handling. | Ensures a secure and comfortable hold during operation. |

| Locking Mechanism | A system that secures the handle in place. | Prevents accidental disengagement during use. |

| Adjustment Features | Settings that allow for customization based on user preference. | Facilitates individual control over the brewing process. |

Lid Mechanism and Sealing Performance

The effectiveness of a lid system in maintaining temperature and freshness hinges on its design and sealing capabilities. A well-engineered mechanism ensures that heat retention is maximized, while preventing any undesired leakage or evaporation of contents.

Key factors contributing to the efficiency of the lid system include:

- Material Quality: High-quality materials provide durability and contribute to better sealing.

- Design Precision: An accurately designed mechanism ensures a snug fit, enhancing the overall sealing effect.

- Seal Integrity: The presence of a robust sealing element prevents leaks and maintains internal temperature.

- Ease of Use: A user-friendly design allows for easy operation while ensuring effective sealing.

Regular maintenance and checks on the lid mechanism are essential to ensure optimal performance over time. Users should look for signs of wear or damage that may compromise the sealing efficiency.

Power Cord and Electrical Connections

The power supply and electrical linkages are vital components that ensure the smooth operation of any brewing device. Understanding these elements is essential for maintaining optimal functionality and safety during usage. Proper installation and regular checks of these connections can prevent operational failures and enhance the longevity of the appliance.

Importance of a Quality Power Cord

A reliable power cord is crucial for providing a consistent electrical supply to the machine. It should be capable of handling the required voltage and current to ensure efficient performance. Regular inspection for wear and tear, as well as ensuring secure connections, helps prevent potential hazards.

Connecting to Electrical Sources

When linking the device to electrical outlets, it is essential to use compatible connections that meet safety standards. Ensuring that the voltage rating matches the appliance specifications will prevent malfunctions and protect against electrical risks. Users should always adhere to the manufacturer’s guidelines when connecting the appliance.

| Connection Type | Description |

|---|---|

| Plug Type | Defines the configuration of the power plug used for the electrical outlet. |

| Cord Length | Indicates the distance from the device to the nearest power source, affecting placement flexibility. |

| Voltage Rating | Specifies the electrical voltage that the device can safely operate under. |

| Amperage | Denotes the current the appliance will draw during operation. |

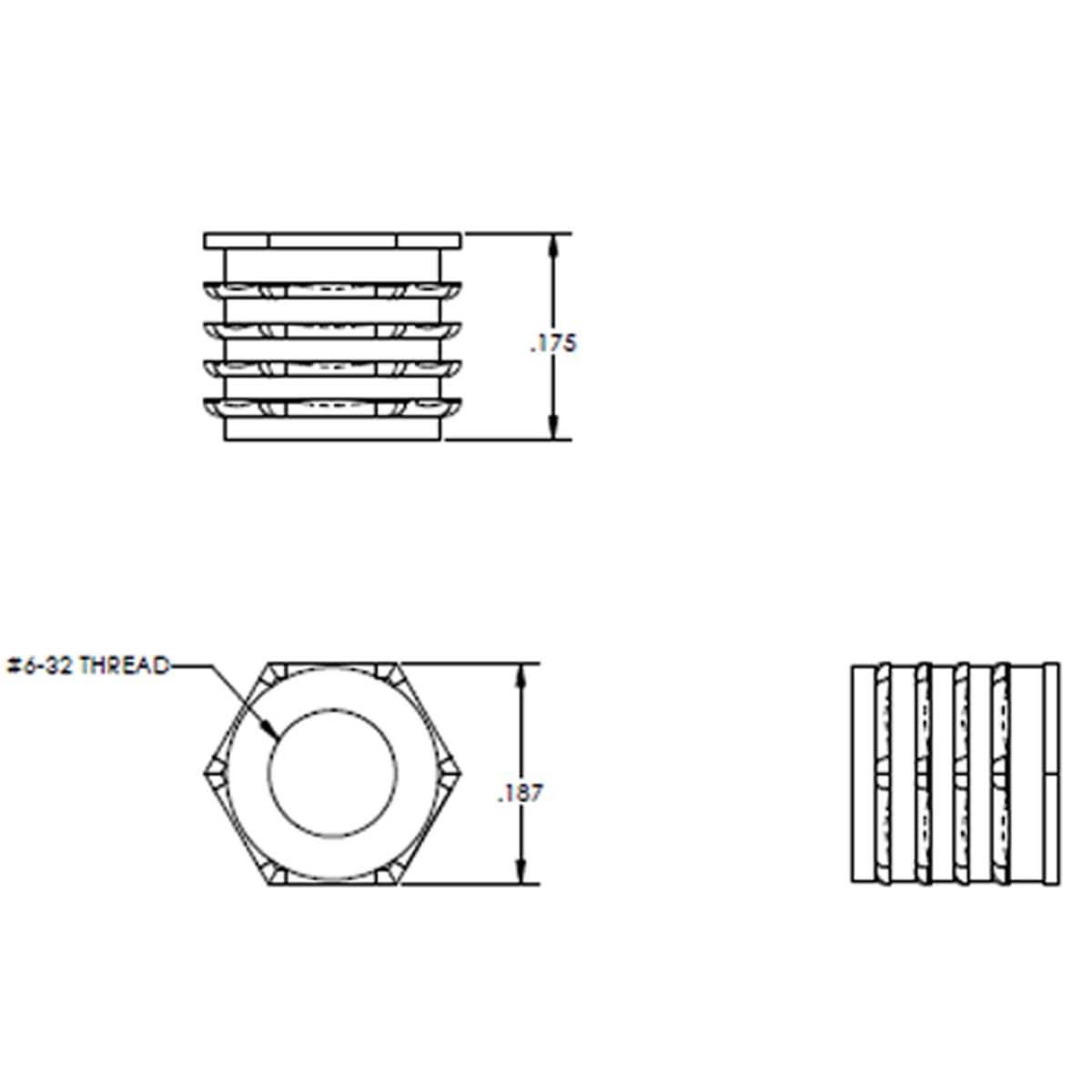

Common Replacement Parts and Availability

Understanding the typical components that may require substitution in brewing equipment is essential for maintaining optimal performance. Various elements can wear out over time, affecting the efficiency and quality of the brewing process. Knowing which components are most commonly replaced and their availability can help users make informed decisions about maintenance and repairs.

Frequently Needed Components

Among the commonly needed components are heating elements, water reservoirs, and filtration systems. These components play crucial roles in ensuring the brewing process runs smoothly. Users often find that replacing these parts not only extends the life of their equipment but also improves the overall quality of the beverages produced.

Finding Replacement Options

Replacement components can typically be sourced through authorized retailers, online marketplaces, or directly from manufacturers. Availability may vary, so it’s advisable to check multiple sources to find the best options and prices. Ensuring compatibility with the specific model is also essential when selecting new components.