The intricate world of engine mechanics is essential for maintaining performance and efficiency in outdoor power equipment. Every machine comprises a myriad of elements that work harmoniously to achieve optimal functionality. By grasping the layout and relationship between these components, one can enhance troubleshooting and repair processes.

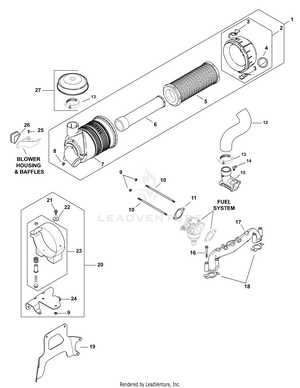

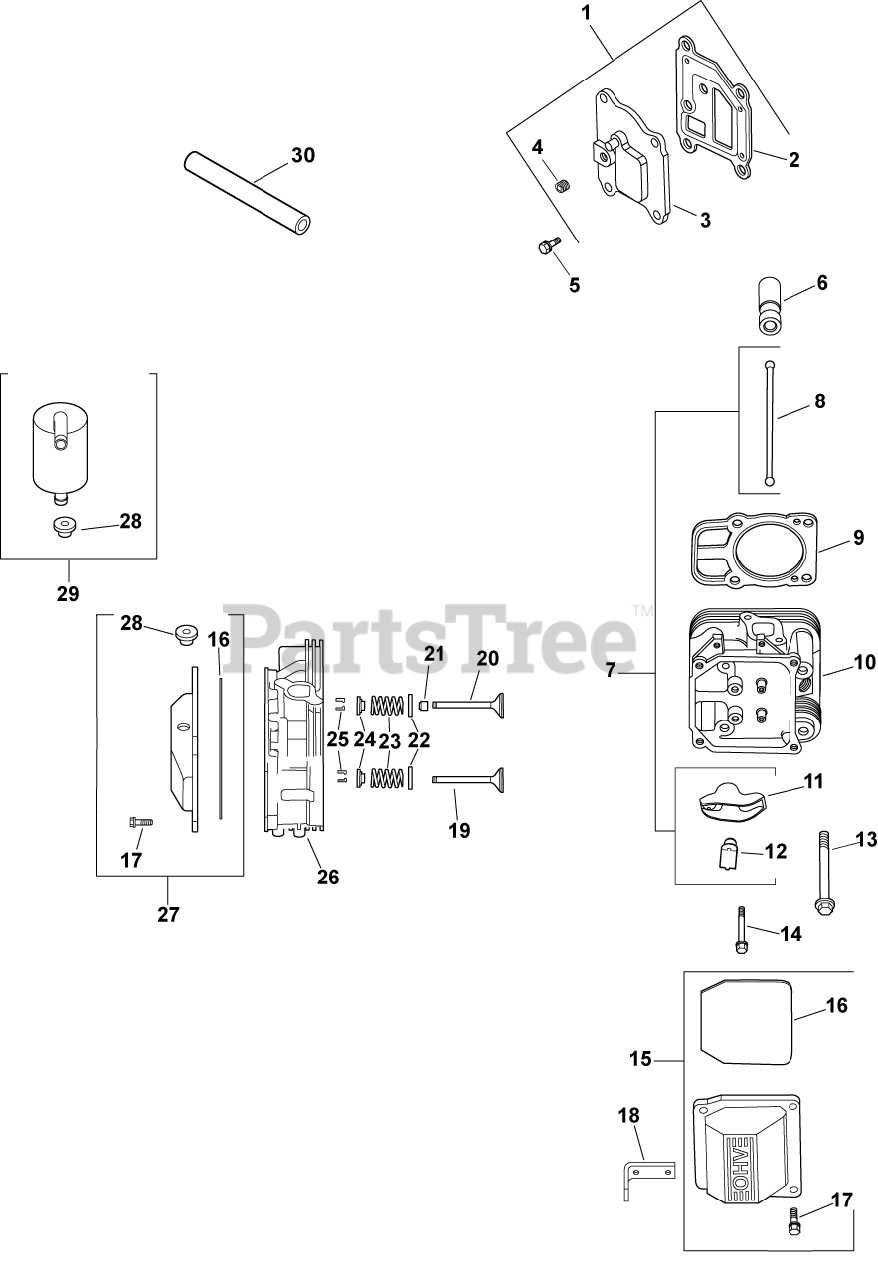

Visual representations of these assemblies provide invaluable insights into the intricate workings of engines. These schematics serve as a guide, illustrating the arrangement and interaction of various parts, allowing enthusiasts and technicians alike to delve deeper into their understanding of mechanical systems.

Familiarity with these representations not only aids in effective maintenance but also empowers users to make informed decisions regarding repairs and upgrades. Ultimately, having access to detailed illustrations of engine configurations streamlines the journey towards ensuring longevity and reliability in outdoor machinery.

Kohler CV23S Overview

This section provides a comprehensive look at a popular engine model known for its reliability and performance. Understanding its features and components can enhance maintenance and functionality.

- Engine Type: V-twin configuration for smooth operation.

- Power Output: Designed for high torque and efficiency.

- Cooling System: Air-cooled, reducing overheating risks.

- Fuel System: Equipped with a carburetor for optimal fuel management.

Regular maintenance is crucial for longevity. Key practices include:

- Checking oil levels frequently.

- Replacing air and fuel filters as needed.

- Inspecting spark plugs for wear.

By understanding the intricacies of this engine, users can ensure peak performance and durability in various applications.

Essential Components of CV23S Engine

The intricate design of this power unit comprises various critical elements that work in harmony to ensure optimal performance. Understanding these essential components can enhance maintenance efforts and promote longevity.

Key Elements

- Combustion Chamber: Where fuel mixes with air for ignition.

- Piston: Transforms combustion energy into mechanical motion.

- Cylinder Head: Houses the valves and enhances airflow.

- Crankshaft: Converts linear motion into rotational force.

- Valves: Regulate air and fuel intake, as well as exhaust.

Supporting Components

- Fuel System: Supplies the engine with necessary fuel.

- Cooling System: Maintains optimal operating temperature.

- Lubrication System: Reduces friction between moving parts.

- Electrical System: Powers ignition and other accessories.

Understanding Kohler Engine Diagrams

Engine schematics serve as invaluable resources for anyone looking to maintain or repair small power units. These illustrations provide a visual representation of the various components, their connections, and the overall layout. By interpreting these visuals, users can gain insights into how the engine operates and how different parts interact with one another.

Deciphering the Components involves identifying key elements such as the fuel system, ignition system, and lubrication mechanisms. Each section of the illustration often highlights critical features and functions, enabling users to troubleshoot issues more effectively. Familiarity with these elements allows for a more comprehensive understanding of the unit’s performance and maintenance needs.

Understanding Connections is another crucial aspect of these schematics. Lines and symbols often depict pathways for fuel, air, and electrical currents. Recognizing how these systems intertwine can help diagnose problems related to flow or energy transfer, ultimately aiding in efficient repairs. By analyzing the layout, users can prioritize their maintenance tasks and ensure optimal engine functionality.

Lastly, the importance of maintenance schedules can often be inferred from these illustrations. Many diagrams include indicators for routine checks and replacements, reminding users of necessary upkeep to prolong the engine’s lifespan. Utilizing these resources effectively can enhance both performance and durability.

Common Issues with CV23S Parts

When dealing with small engines, various components can experience wear and tear over time, leading to common problems that can affect performance. Understanding these typical issues is crucial for maintenance and repairs, as it helps in identifying which elements might need attention or replacement.

| Component | Common Issue | Symptoms |

|---|---|---|

| Ignition System | Faulty spark plug | Hard starting, engine misfires |

| Fuel System | Clogged fuel filter | Loss of power, stalling |

| Oil System | Low oil levels | Unusual noises, overheating |

| Cooling System | Dirty air filter | Engine overheating, reduced efficiency |

| Exhaust System | Leaking exhaust gasket | Excessive noise, strong fumes |

Addressing these frequent problems promptly can enhance the longevity and functionality of the engine, ensuring smooth operation in various applications. Regular inspection and maintenance can help in mitigating these issues before they escalate.

Importance of Regular Maintenance

Consistent upkeep of machinery is crucial for ensuring optimal performance and longevity. Regular inspections and servicing can prevent unexpected breakdowns, enhance efficiency, and ultimately save costs over time. By prioritizing maintenance, owners can protect their investments and ensure smooth operation.

Benefits of Preventive Care

Engaging in routine maintenance allows for the early detection of potential issues, which can be addressed before they escalate into major problems. This proactive approach not only extends the life of the equipment but also improves safety and reliability, providing peace of mind for users.

Cost-Effectiveness

Investing time and resources in regular maintenance often results in significant savings. Avoiding costly repairs and minimizing downtime contributes to a more efficient operation, ultimately enhancing the overall productivity of the machinery.

How to Read Engine Diagrams

Understanding engine schematics is essential for effective maintenance and repair. These visual representations provide a clear view of various components and their relationships, enabling users to grasp complex systems easily.

Here are key steps to effectively interpret these illustrations:

- Familiarize with Symbols: Each component has a unique symbol. Learn the most common ones to enhance comprehension.

- Identify Components: Look for major parts such as the engine block, fuel system, and ignition system. Recognizing these will help you follow the flow of operations.

- Follow Connections: Pay attention to lines that connect components. These often indicate pathways for fluids or electrical signals.

- Note Annotations: Descriptive notes or labels provide additional information about functions and specifications, making it easier to understand the schematic.

- Practice with Examples: Use sample illustrations to practice your skills. Familiarity builds confidence in reading more complex designs.

By applying these strategies, you can delve deeper into the intricacies of engine designs and enhance your repair capabilities.

Top Replacement Parts for CV23S

Ensuring optimal performance in your engine requires awareness of key components that may need replacement over time. This section highlights essential items that are critical for maintaining efficiency and reliability, helping you keep your machine running smoothly.

Essential Components

Understanding which elements frequently require attention can save both time and resources. Below are some vital items you should consider when looking to refresh your engine’s functionality.

| Component | Description |

|---|---|

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean airflow. |

| Oil Filter | Removes contaminants from engine oil, enhancing lubrication and performance. |

| Spark Plug | Ignites the air-fuel mixture, critical for engine combustion and efficiency. |

| Fuel Pump | Delivers fuel from the tank to the engine, essential for proper operation. |

Conclusion

Regularly checking and replacing these crucial components can significantly improve the longevity and performance of your engine. Investing in high-quality replacements is the ultimate way to ensure your equipment operates at its best.

DIY Repair Tips for Kohler Engines

When it comes to maintaining small engines, understanding basic repair techniques can save both time and money. Tackling minor issues yourself not only boosts confidence but also enhances your knowledge of how these machines function. With the right tools and a bit of guidance, you can address common problems effectively.

Start by gathering essential tools like wrenches, screwdrivers, and pliers. A reliable service manual can be invaluable, offering insights into specific models and common issues. Always ensure that the engine is off and cooled down before beginning any work to avoid injuries.

Regular maintenance is key to longevity. Change the oil regularly and check the air filter for clogs. Keeping fuel fresh and using the correct grade can prevent performance issues. If you notice decreased power or unusual sounds, inspecting the spark plug is a good first step.

For fuel-related problems, clean or replace the carburetor as necessary. Be sure to check for any leaks in fuel lines. If the engine won’t start, examine the ignition system and battery connections. Addressing these elements can often resolve starting issues.

Finally, don’t hesitate to reach out to online forums or local repair shops for advice. Many enthusiasts are willing to share their experiences and solutions, making it easier for you to navigate your repair journey. With patience and persistence, many repairs can be completed right at home.

Finding Quality Parts Suppliers

Identifying reliable sources for essential components is crucial for maintaining the efficiency and longevity of equipment. The right suppliers can significantly impact performance and cost-effectiveness.

- Research and Reviews: Look for suppliers with positive feedback from customers.

- Certification and Standards: Ensure they meet industry standards for quality.

- Product Range: A diverse selection indicates a comprehensive understanding of your needs.

- Customer Support: Reliable communication and assistance are key factors.

Comparing multiple sources can help you make informed decisions. Take your time to delve into options to find the ultimate supplier for your requirements.

Innovations in Kohler Engine Design

The evolution of small engine technology has led to remarkable advancements, enhancing efficiency, reliability, and performance. This section explores groundbreaking developments that have revolutionized engine functionality and user experience.

One key innovation is the integration of advanced materials, which not only reduce weight but also improve durability. These materials help in resisting corrosion and wear, thereby extending the lifespan of the engine.

Another significant advancement involves the implementation of electronic fuel injection systems. This technology optimizes fuel delivery, leading to better fuel efficiency and reduced emissions, aligning with environmental standards while maintaining power output.

Moreover, the incorporation of smart technology, such as diagnostic tools and maintenance alerts, has transformed the way users interact with their engines. This allows for timely upkeep and enhances overall performance.

In summary, these innovations represent the ultimate commitment to quality and sustainability in engine design, setting new benchmarks in the industry.