When maintaining or repairing machinery, having a clear understanding of its internal structure is crucial. Identifying individual elements and understanding their placement within the system allows for more efficient troubleshooting and ensures that the device operates at peak performance. Every piece, no matter how small, plays a significant role in ensuring smooth functionality.

Exploring the arrangement of different mechanical elements offers invaluable insights into how the entire system works. By familiarizing yourself with the layout and the interconnections between components, you can ensure longer operational life and better performance for the device as a whole. This knowledge becomes especially useful when performing regular checks or during necessary replacements.

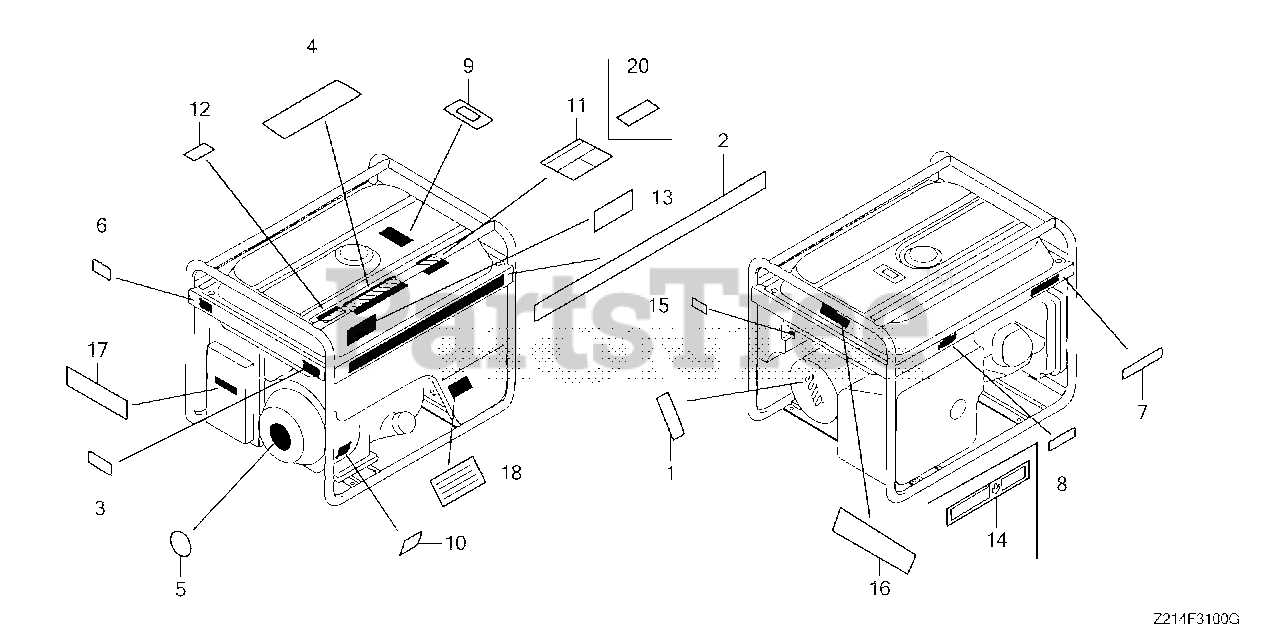

Honda EM5000SX Parts Overview

Understanding the components of a high-performance generator is crucial for ensuring its longevity and smooth operation. Each element plays a role in the overall functionality, contributing to the machine’s ability to deliver reliable energy. Familiarizing yourself with these key elements allows for more efficient maintenance and troubleshooting when needed.

Essential Components

Within this type of power equipment, there are several fundamental pieces that work together to produce electricity. From the engine that drives the mechanism to the control systems that regulate output, every part is designed for optimal performance. Routine inspection of these areas helps to maintain the equipment’s functionality over time.

Maintenance Considerations

Regular care is vital for keeping these machines running smoothly. Ensuring that critical elements, such as the fuel system and electrical wiring, are clean and in good condition can prevent potential issues. Taking proactive steps in monitoring and replacing worn components enhances the overall lifespan of the equipment.

Main Components and Their Functions

Understanding the key elements of a generator and how they operate is essential for maintaining its efficiency and performance. Each component plays a specific role, ensuring the smooth production of electricity and the safe operation of the unit. Below, we’ll explore the primary sections and their responsibilities.

| Component | Function | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Serves as the power source, converting fuel into mechanical energy to drive the alternator. | |||||||||||||||||||||||||

| Alternator | Converts mechanical energy into electrical power, providing the output used by connected devices. | |||||||||||||||||||||||||

| Control Panel | Allows the user to start, monitor, and control the generator’s operation through various switches and displays. | |||||||||||||||||||||||||

Fuel

Electrical System Breakdown

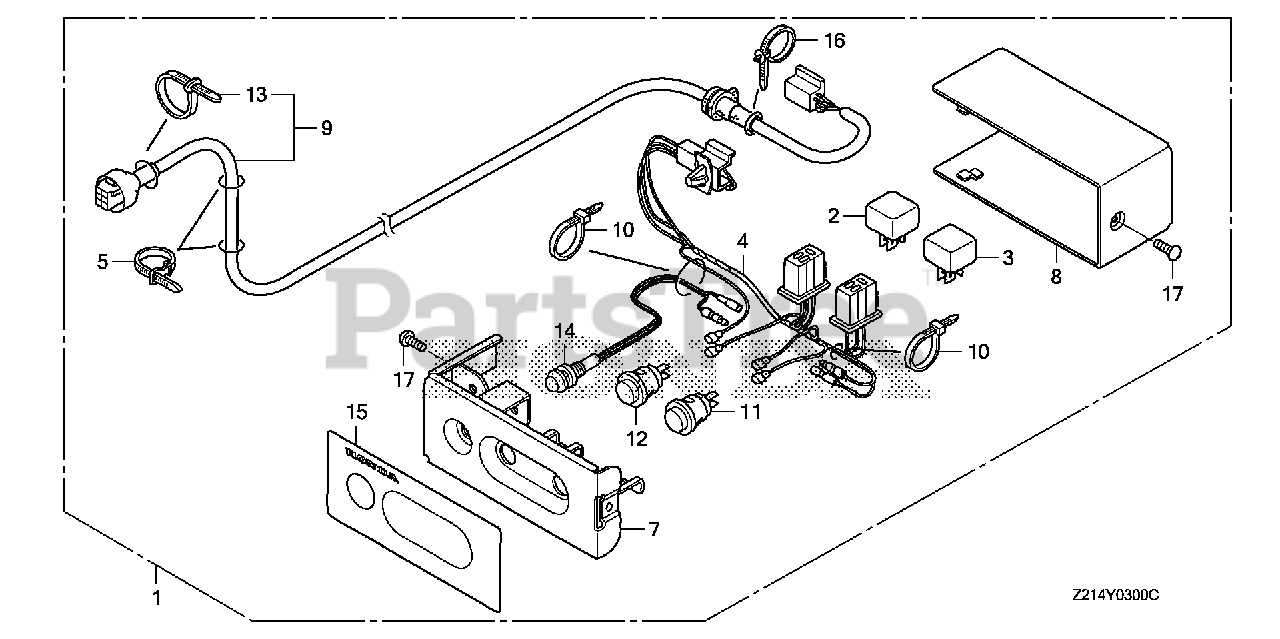

The electrical system plays a crucial role in ensuring the smooth functioning of the entire equipment. It consists of several interconnected components that work together to distribute and regulate electrical power efficiently. Understanding the structure of this system is essential for diagnosing issues and performing maintenance.

By thoroughly understanding each of these components, it becomes easier to troubleshoot and maintain the system, ensuring its longevity and reliable operation. Engine Parts and Specifications

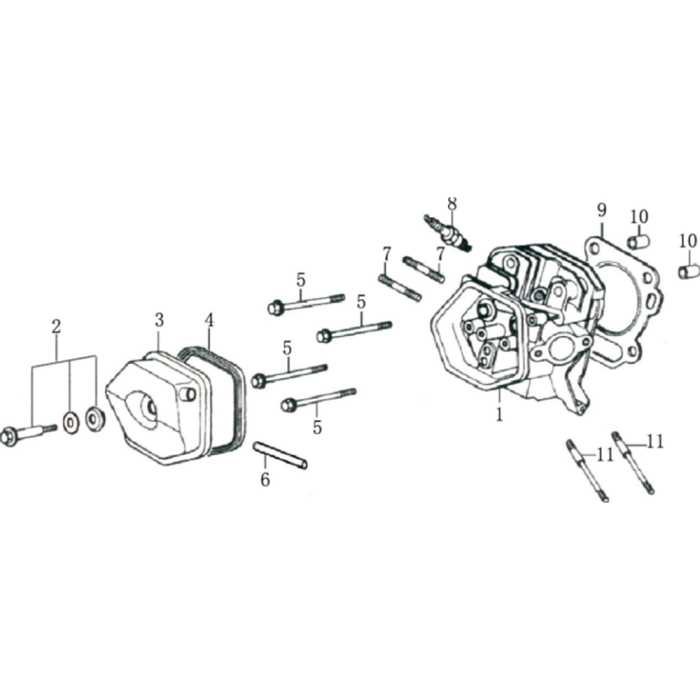

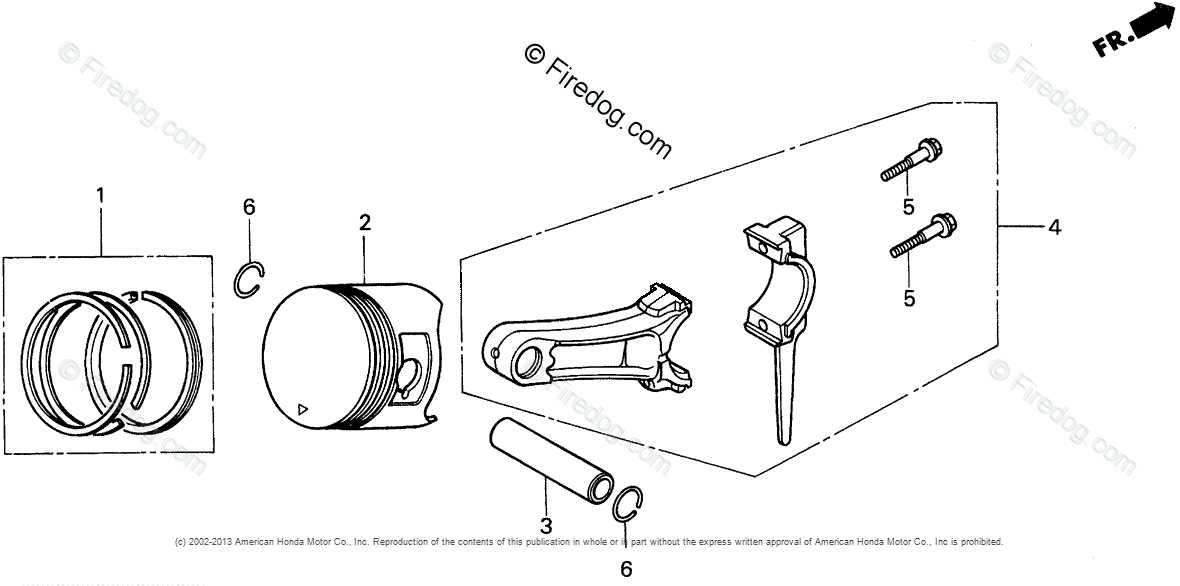

The internal combustion engine consists of multiple essential components that work together to ensure optimal functionality and efficiency. These elements are meticulously designed to convert fuel into mechanical energy, powering various devices and systems. Understanding the structure and characteristics of these components is crucial for maintaining and repairing the unit. Key Components Overview

The engine is made up of several key elements, including mechanical and thermal systems that operate in harmony. Cylinders, pistons, valves, and camshafts form the core, each playing a vital role in energy conversion. The precision of these components directly impacts the performance, lifespan, and reliability of the engine. Performance Specifications

Each engine is designed with specific performance parameters in mind, such as power output, fuel efficiency, and heat tolerance. These specifications define how well the engine can handle demanding conditions and its overall durability. Regular assessment of these metrics helps in ensuring optimal functionality over time. Fuel System Structure

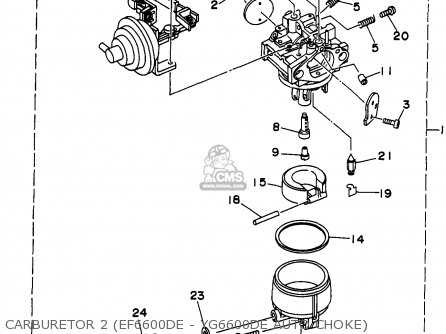

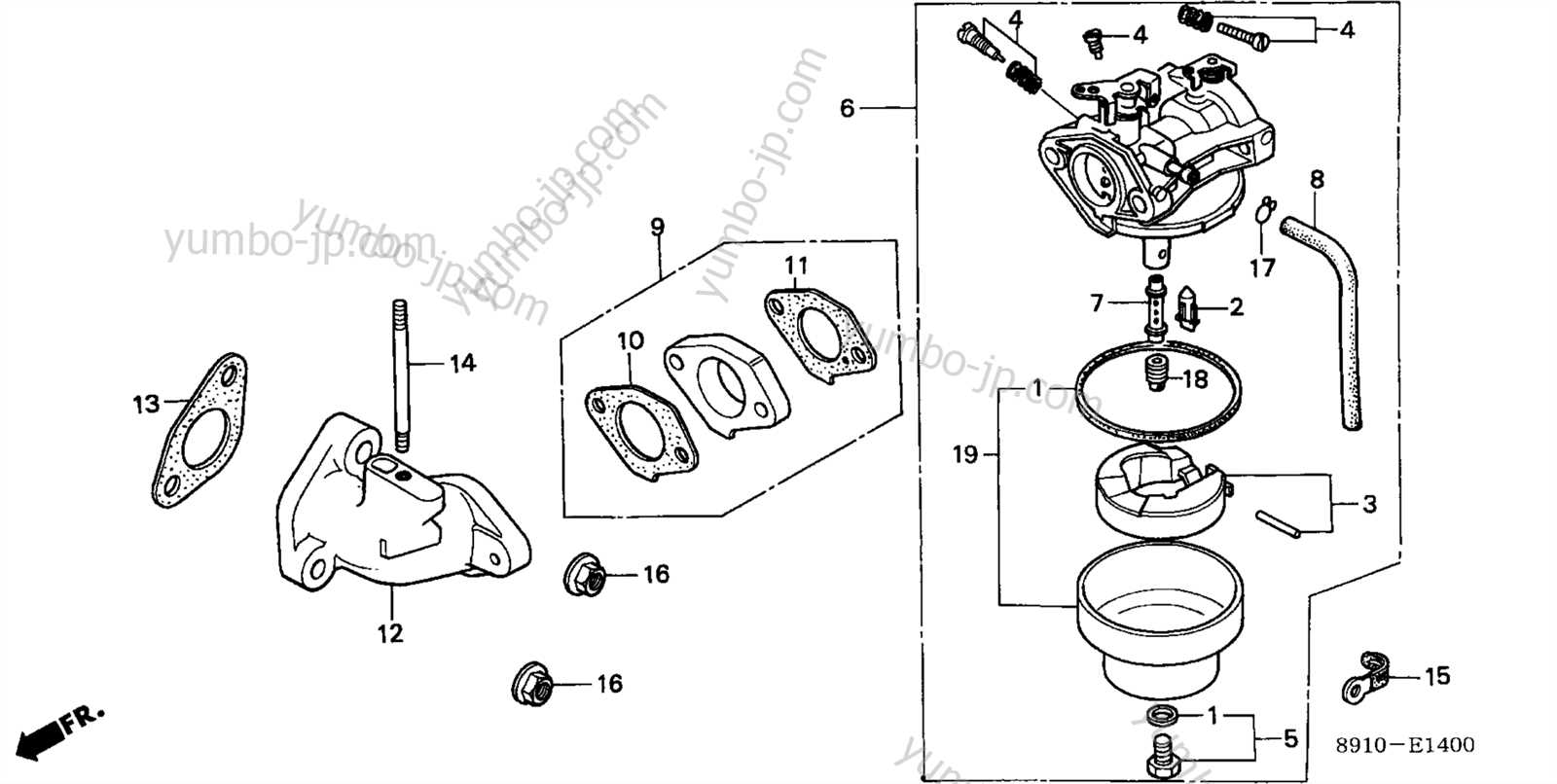

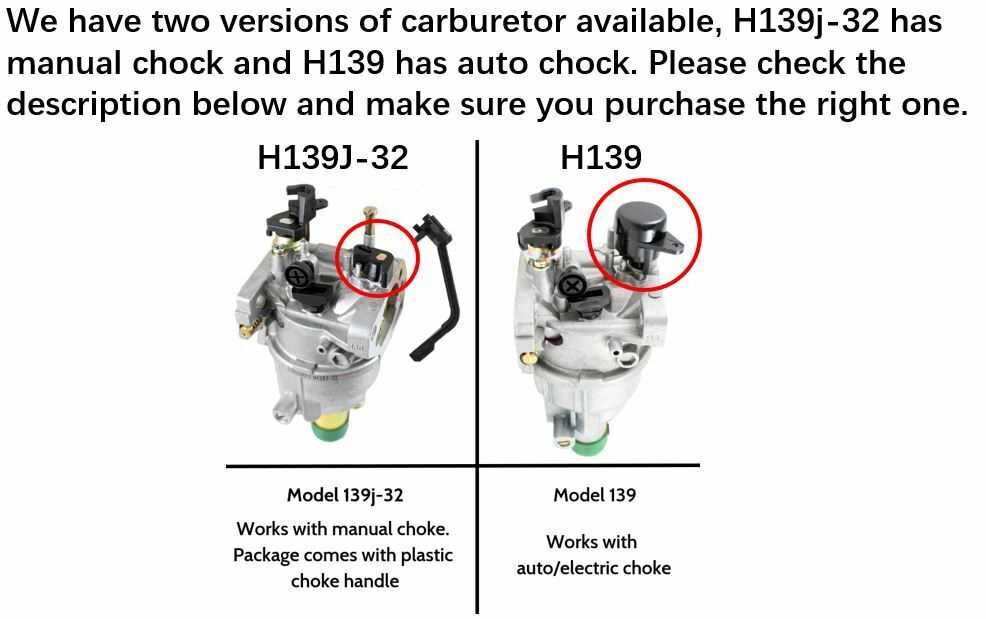

The fuel system plays a critical role in ensuring efficient operation by delivering the necessary amount of fuel to the engine. It involves multiple interconnected components that work together to regulate the flow of fuel, ensuring smooth and reliable performance. This section covers the key elements of the system, focusing on how each part contributes to maintaining functionality and fuel efficiency.

Understanding how these components function together is essential for maintaining the overall efficiency of the engine, minimizing malfunctions, and optimizing fuel consumption. Starter Mechanism ComponentsThe starter mechanism is a crucial part of many electrical devices, serving as the initial point of engagement to activate the engine. It comprises various elements that work together to ensure a reliable and efficient start. Understanding these components can aid in troubleshooting and maintenance tasks. Key Elements

Several essential components contribute to the effective functioning of the starter mechanism:

Functionality OverviewThe starter mechanism operates by drawing electrical energy from the battery through the wiring harness to the solenoid. Once activated, the solenoid closes a circuit, allowing current to flow to the starter motor. This motor then engages the pinion gear with the flywheel, enabling the engine to start. Cooling System Diagram

The cooling mechanism in generators is crucial for maintaining optimal performance and longevity. It ensures that the engine operates within a safe temperature range, preventing overheating and potential damage. This section will explore the various components involved in this essential system, illustrating how they work together to dissipate heat effectively. The primary element of the cooling assembly is typically the radiator, which allows coolant to release heat into the atmosphere. The coolant circulates through the engine, absorbing heat generated during operation before returning to the radiator. A fan may assist in enhancing airflow, promoting more efficient heat exchange. In addition, hoses connect the radiator and the engine, facilitating the movement of coolant. A thermostat regulates the flow of coolant, ensuring it circulates at the appropriate temperature. Understanding these elements is vital for proper maintenance and troubleshooting of the cooling mechanism. Control Panel Parts ExplanationThe control interface of a generator is essential for managing its operation effectively. Understanding the various components is crucial for ensuring optimal performance and ease of use. Each element plays a specific role, contributing to the overall functionality of the machine. Main Components

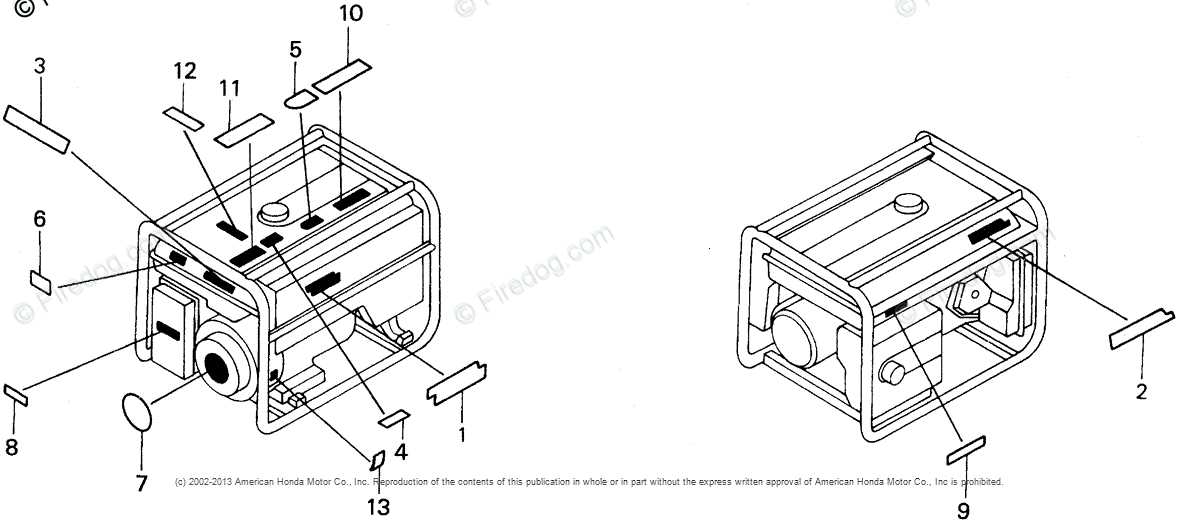

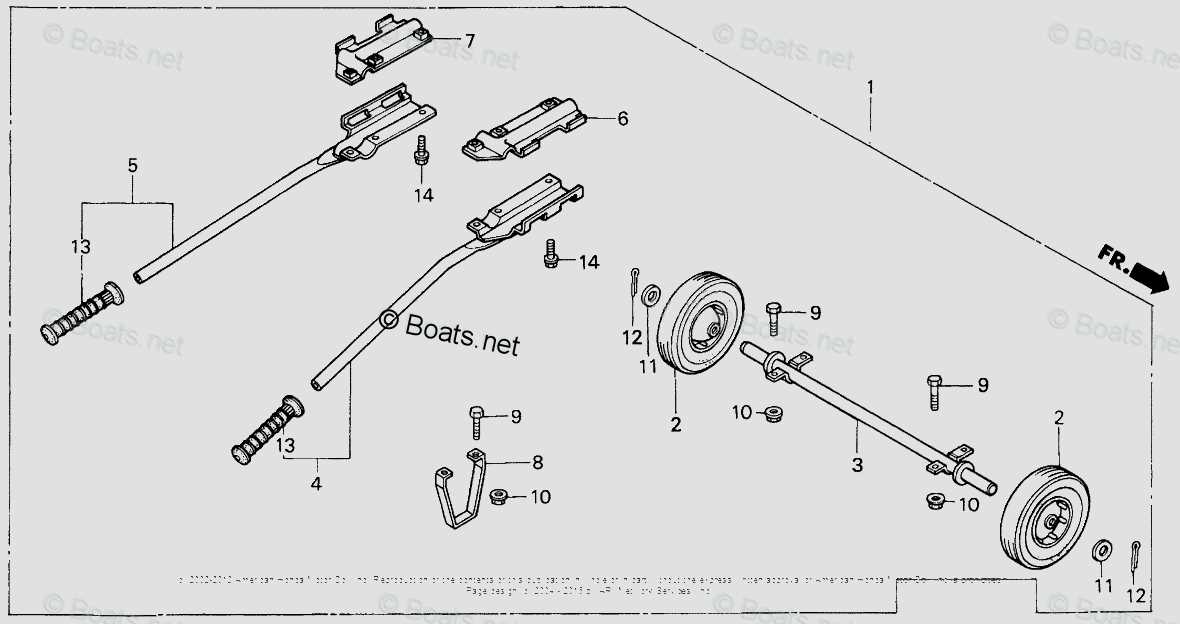

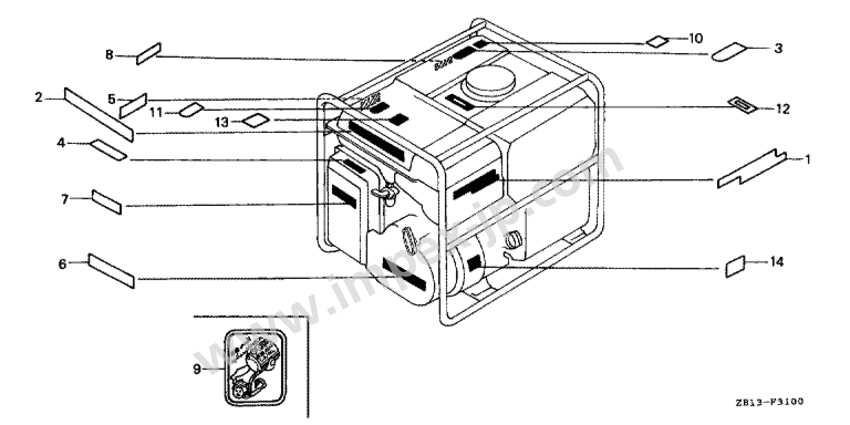

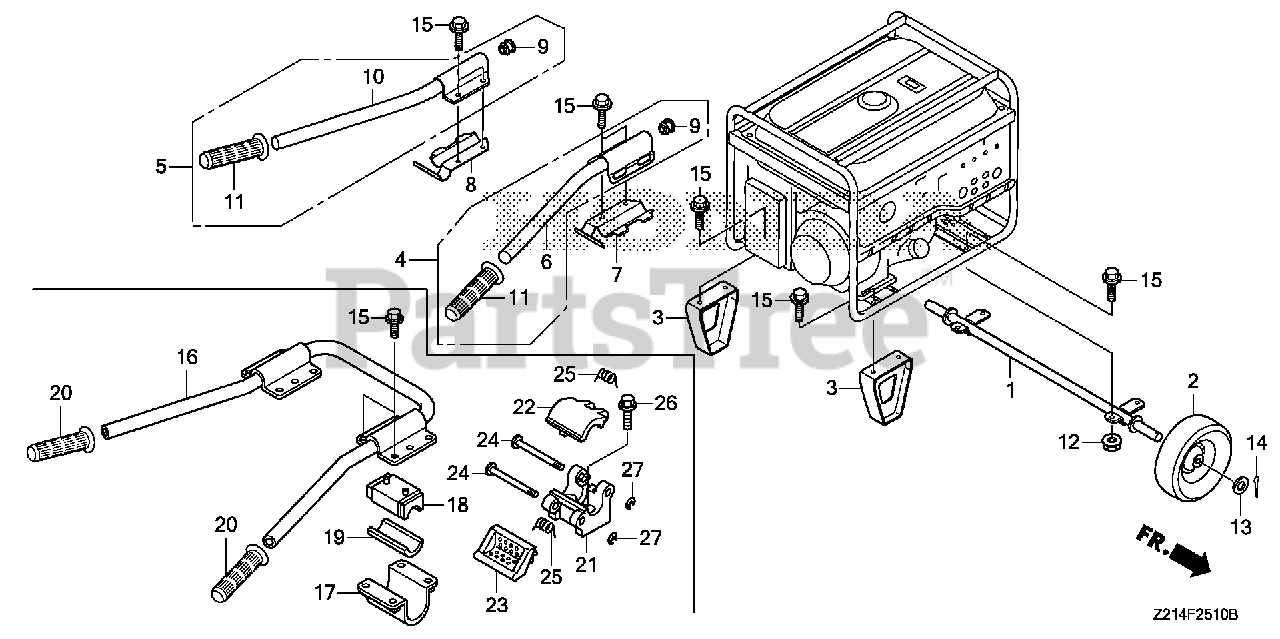

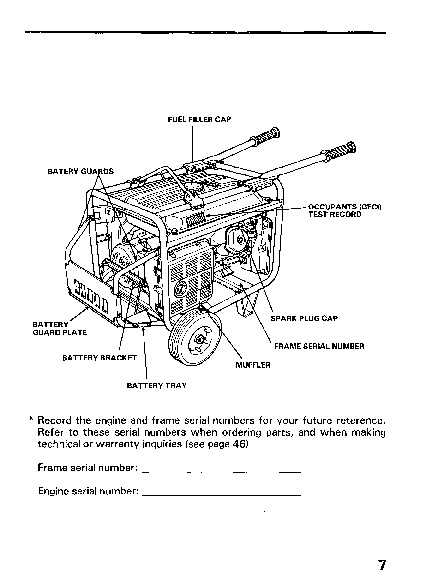

Functionality OverviewThe interaction between these elements ensures that the generator operates smoothly. The power switch is the primary control point, while indicator lights serve as a quick reference for the operational state. The voltage selector and control knobs allow users to tailor performance to their requirements, enhancing versatility. Frame and Exterior Elements

The framework and external components of a generator play a crucial role in its overall functionality and durability. These elements not only provide structural integrity but also contribute to the aesthetic appeal and usability of the device. Understanding the different parts involved is essential for maintenance and efficient operation. The frame serves as the backbone, supporting the internal mechanisms while protecting them from external damage. Typically constructed from robust materials, it ensures stability during operation. The exterior elements, including the housing and covers, are designed to shield vital components from environmental factors such as dust, moisture, and impacts. Additionally, features like handles and wheels enhance portability, making the unit easier to transport and maneuver. Regular inspection of the frame and external elements is vital to identify any signs of wear or damage. Ensuring that these parts remain intact not only extends the lifespan of the equipment but also guarantees safe operation. Maintenance practices should focus on cleaning, tightening screws, and addressing any rust or corrosion to maintain the integrity of the structure. Maintenance and Replaceable PartsRegular upkeep and timely substitution of components are vital for ensuring optimal functionality and longevity of the equipment. A well-maintained machine operates more efficiently and is less prone to unexpected failures, which can disrupt its performance and lead to costly repairs. Here are some essential aspects to consider when performing maintenance:

In addition to these routine checks, certain components may require periodic replacement:

Implementing these maintenance practices and being proactive about replacing essential components will significantly enhance the reliability and performance of the equipment. Exhaust System Breakdown

The exhaust system plays a critical role in the overall performance and efficiency of any internal combustion engine. It is designed to direct harmful gases away from the engine and reduce emissions, ensuring that the unit operates smoothly and safely. Understanding the components of this system is essential for maintenance and troubleshooting. Components of the Exhaust SystemThe exhaust system typically consists of several key elements, including the exhaust manifold, catalytic converter, muffler, and exhaust pipes. Each of these parts serves a specific function, contributing to the effective management of engine byproducts. The manifold collects gases from the engine cylinders and channels them into the exhaust stream, while the catalytic converter transforms harmful pollutants into less harmful emissions. Maintenance ConsiderationsRegular inspection and maintenance of the exhaust system are vital to ensure optimal performance. Common issues may include leaks, corrosion, or blockages, which can hinder the efficiency of gas flow. Prompt attention to these problems can prevent more severe damage to the engine and improve overall functionality. Wiring Diagram and Connections

This section provides an overview of the electrical layout and interconnections essential for ensuring optimal functionality of the equipment. Understanding the wiring setup is crucial for maintenance and troubleshooting, allowing users to identify and resolve potential issues effectively. Understanding Electrical LayoutFamiliarity with the electrical arrangement helps in recognizing various components and their respective connections. Key elements include:

Essential Connection Points

To ensure proper operation, it is vital to pay attention to specific connection points. Below are the critical aspects to consider:

By following these guidelines, users can maintain a reliable electrical system and enhance the overall efficiency of the equipment. Generator Mechanism Components

The operation of an electrical generator relies on a variety of essential elements working together seamlessly. Each component plays a vital role in the overall functionality, ensuring that electrical energy is produced efficiently and reliably. Understanding these components is crucial for effective maintenance and troubleshooting.

|