When it comes to maintaining the efficiency of restroom fixtures, a thorough comprehension of their inner workings is essential. Each element within the system plays a crucial role, and recognizing how they interconnect can enhance both functionality and longevity. This knowledge empowers homeowners to troubleshoot issues and perform necessary repairs without the need for professional assistance.

In this section, we will explore the various components that contribute to the seamless operation of a toilet system. By examining their structure and function, readers will gain insight into how these mechanisms work together to manage water flow effectively. Understanding these details not only demystifies the process but also facilitates informed decision-making during maintenance or upgrades.

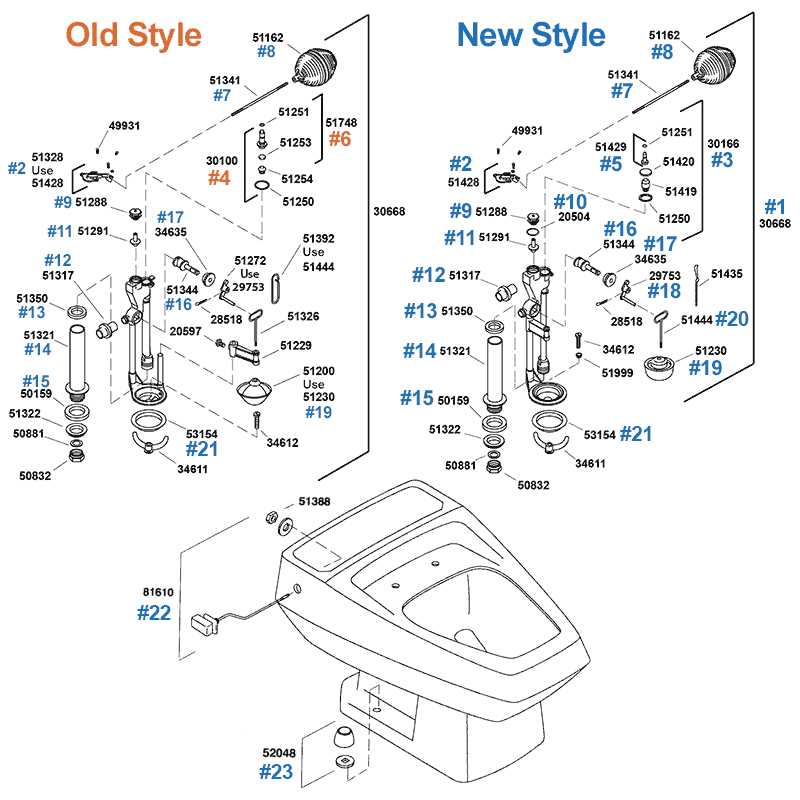

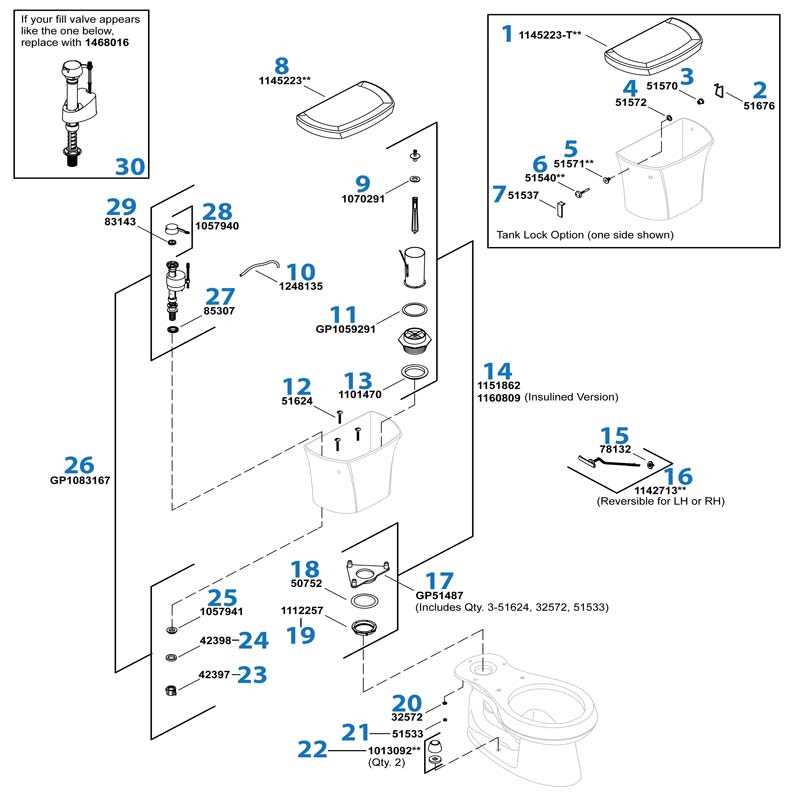

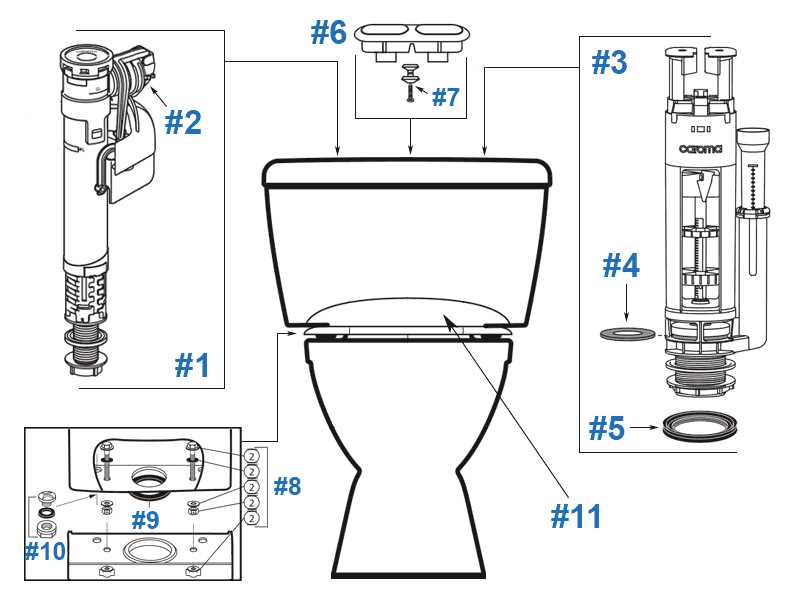

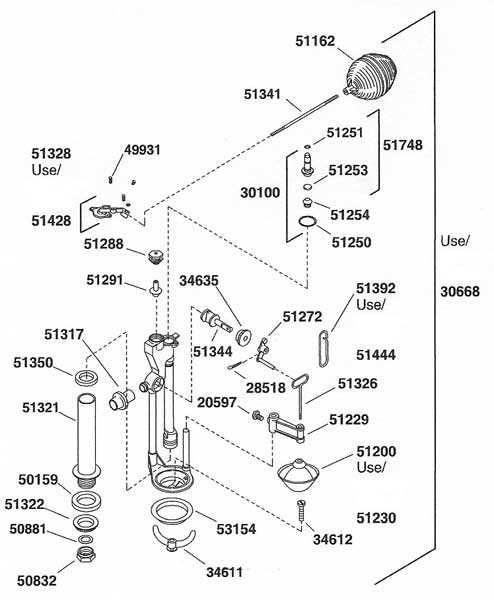

Additionally, visual aids can significantly enhance comprehension. Diagrams highlighting the specific elements can serve as valuable references, allowing for easier identification and replacement of components when needed. With this knowledge, you can confidently approach any repair tasks, ensuring your restroom fixtures remain in optimal condition.

Understanding Kohler Flush Valve Components

The components that make up a toilet’s flushing mechanism play a crucial role in ensuring efficient operation and longevity. By gaining insight into these essential elements, users can better maintain their systems and troubleshoot potential issues, leading to improved performance and reduced water waste.

Key Elements of the Mechanism

At the heart of the flushing system lies a series of interconnected components. The primary mechanism involves a discharge assembly that regulates the release of water from the tank into the bowl. This is typically controlled by a lift chain and a flapper, which work in unison to create a proper seal when not in use and to allow for a powerful flush when activated.

Importance of Regular Maintenance

Regular inspection and maintenance of these elements are vital for preventing leaks and ensuring optimal functionality. Components such as seals and gaskets may degrade over time, leading to inefficiencies. Replacing worn parts promptly can save water and enhance overall performance, making it essential for homeowners to familiarize themselves with these critical components.

Overview of Flush Valve Functionality

The mechanism responsible for water discharge in sanitary fixtures plays a crucial role in maintaining efficiency and cleanliness. Understanding its operation is essential for effective maintenance and troubleshooting.

Basic Operation Principles

This system primarily controls the release of water into the bowl, creating a powerful flow that facilitates waste removal. When activated, it ensures an optimal amount of liquid is utilized, balancing performance and conservation.

Components Involved

Key elements include the actuator, which initiates the flow, and the sealing mechanism, responsible for preventing leaks. Each component must function harmoniously to achieve the ultimate goal of effective waste management and user satisfaction.

Key Parts of Kohler Flush Valves

This section will explore the essential components that contribute to the effective operation of water discharge systems in toilets. Understanding these elements is crucial for maintenance and troubleshooting.

- Seal: Ensures a tight closure to prevent leaks.

- Actuator: Triggers the release of water during use.

- Chamber: Holds the water until it is needed for flushing.

- Lift Arm: Connects the actuator to the mechanism that lifts the seal.

- Overflow Tube: Prevents water from spilling over by directing excess water back into the tank.

By delving into each component’s function, users can gain insight into how to optimize performance and address potential issues.

Common Issues with Flush Valves

In many households, the mechanisms responsible for water release often encounter various challenges that can disrupt their functionality. Understanding these common problems is essential for maintaining optimal performance and ensuring efficient water usage.

1. Leaks: One of the most prevalent issues is the presence of leaks, which can occur due to worn-out seals or improperly fitted components. These leaks not only waste water but can also lead to further damage if left unaddressed.

2. Weak Flushing Action: Insufficient force during the flushing process may result from mineral buildup or damaged internal elements. This can lead to ineffective waste removal, causing frustration and potential sanitation issues.

3. Noisy Operation: Unusual sounds during operation can indicate air trapped within the system or malfunctioning parts. This can be bothersome and may signal the need for inspection and repair.

4. Continuous Running: If the mechanism doesn’t stop running after use, it often points to a faulty float or a malfunction in the control mechanism. This can lead to increased water bills and unnecessary strain on the system.

5. Corrosion: Over time, exposure to water and minerals can lead to corrosion of components, which compromises their integrity and efficiency. Regular maintenance can help mitigate this issue.

Addressing these common challenges promptly can enhance the longevity of the system and improve overall efficiency, ultimately contributing to a more sustainable household environment.

Maintenance Tips for Flush Valves

Regular upkeep of your toilet’s mechanism is essential for ensuring optimal performance and longevity. A well-maintained system not only enhances efficiency but also helps prevent common issues such as leaks and clogs. Here are some effective strategies to keep your toilet’s components in top condition.

1. Inspect Regularly: Conduct routine checks to identify any signs of wear or damage. Look for corrosion, cracks, or any unusual noises that may indicate a problem.

2. Clean Components: Accumulation of minerals and debris can hinder performance. Use a gentle cleaner to wipe down the internal components and remove buildup. Avoid harsh chemicals that can cause damage.

3. Adjust Water Level: Ensure that the water level in the tank is set correctly. An improper level can lead to inefficient flushing and water wastage. Refer to the manufacturer’s guidelines for optimal settings.

4. Replace Worn Parts: If you notice any damaged components during your inspections, replace them promptly. Using original replacements ensures compatibility and reliable operation.

5. Monitor for Leaks: Regularly check for leaks around the base and connections. Early detection can save you from costly repairs and excessive water bills.

6. Professional Servicing: Consider scheduling periodic professional maintenance to address any issues that may not be visible during routine checks. Experts can provide insights and repairs that enhance functionality.

By following these maintenance tips, you can ensure that your toilet operates efficiently and effectively for years to come.

Replacing Flush Valve Parts Effectively

When it comes to maintaining your toilet’s functionality, understanding how to efficiently swap out its internal components is crucial. This task not only enhances performance but also extends the lifespan of the fixture. With the right approach and knowledge, you can achieve optimal results.

| Component | Function | Replacement Tips |

|---|---|---|

| Seal | Prevents leaks | Ensure proper fit; lubricate before installation. |

| Handle | Controls flushing mechanism | Check for secure attachment; replace if wobbly. |

| Chain | Connects handle to the flushing mechanism | Avoid tangles; adjust length for efficiency. |

| Flapper | Regulates water flow | Ensure it closes completely; check for wear. |

Tools Needed for Valve Repair

Repairing a water control mechanism requires specific implements to ensure a smooth and efficient process. Having the right tools at hand can significantly reduce the time and effort needed to complete the task, making it essential to prepare beforehand.

Essential Implements

Basic hand tools such as wrenches, screwdrivers, and pliers are crucial for disassembling components. Additionally, a bucket or towel can be helpful for managing any residual water during the repair.

Specialized Equipment

For more intricate tasks, items like a replacement kit or sealant may be necessary. Utilizing a tape measure can also aid in ensuring precise installations, ultimately leading to better functionality.

Identifying Valve Model Variations

Understanding the distinctions between various models is crucial for effective maintenance and repair. Each design may feature unique characteristics that impact functionality and compatibility. By recognizing these differences, users can ensure they select the appropriate components for their specific installation.

Key factors to consider include the shape, size, and material of each element. For instance, some models may incorporate a different sealing mechanism or actuator design, which can influence performance. Visual inspection of these components can provide significant insights into identifying the right variation.

Furthermore, consulting manufacturer documentation can enhance your ability to discern between similar designs. This information can guide users in making informed decisions, ultimately leading to improved system efficiency and longevity.

DIY vs. Professional Installation

When it comes to home improvements, the choice between tackling a project yourself or hiring an expert can be crucial. Each option presents distinct advantages and challenges that can impact the overall outcome and experience.

DIY enthusiasts often appreciate:

- Cost savings, as they eliminate labor fees.

- The opportunity to learn new skills and gain satisfaction from completing a project.

- Flexibility in scheduling, allowing for work at their own pace.

On the other hand, hiring a professional can provide:

- Expertise and experience, ensuring high-quality results.

- Access to specialized tools and equipment that may be costly to purchase.

- A guarantee of work, providing peace of mind against future issues.

Ultimately, the decision hinges on personal comfort with the task, the complexity of the job, and budget considerations.

How to Read Flush Valve Diagrams

Understanding schematics related to toilet mechanisms can greatly simplify repairs and maintenance. These visual representations provide essential information on component arrangement, function, and troubleshooting techniques. Familiarity with the symbols and layout can empower users to address issues efficiently.

Key Elements to Recognize

- Symbols: Each component is represented by a specific symbol. Familiarizing yourself with these can save time.

- Connections: Lines indicate how components are linked. Pay attention to the flow direction.

- Labels: Components are often labeled with numbers or letters for easy reference.

Steps to Interpret the Schematic

- Identify the main components and their symbols.

- Trace the connections to understand the overall function.

- Refer to the accompanying legend or key for clarification.

- Use the diagram to troubleshoot specific issues.

Understanding Water Flow Mechanisms

Comprehending the dynamics of water movement is crucial for optimizing system efficiency and functionality. Various components work together to regulate the passage and control of liquid, ensuring a seamless experience in daily applications. A deeper insight into these mechanisms reveals the intricacies of their design and operation.

| Component | Function |

|---|---|

| Inlet | Regulates the entry of water into the system. |

| Outlet | Facilitates the exit of water, ensuring proper drainage. |

| Seals | Prevents leaks and maintains pressure within the system. |

| Float | Controls water levels and activates the inlet mechanism. |

By examining these essential elements, one can grasp how water is effectively managed within a variety of environments, leading to enhanced performance and longevity of systems.

Where to Find Replacement Parts

Finding the right components for your plumbing fixtures is essential for maintaining their functionality and longevity. Whether you are in need of a specific item or looking to upgrade your system, there are several reliable sources where you can locate these necessary components.

Here are some options to consider:

- Local Hardware Stores: Many neighborhood hardware shops carry a selection of plumbing items and can assist you in identifying the right components for your needs.

- Specialty Plumbing Supply Stores: These stores typically have a wider range of options, including specialized items that may not be available elsewhere.

- Online Retailers: Websites such as Amazon, eBay, and dedicated plumbing supply websites offer a vast inventory. Ensure to check customer reviews for quality assurance.

- Manufacturer’s Website: Often, the official site of the brand will provide a catalog of their products and a list of authorized sellers.

- DIY Repair Shops: Some stores focus on repairs and may have a selection of components as well as knowledgeable staff to help you make the right choice.

Before making a purchase, it’s advisable to double-check the specifications and dimensions of the items you need to ensure a perfect fit for your existing setup.