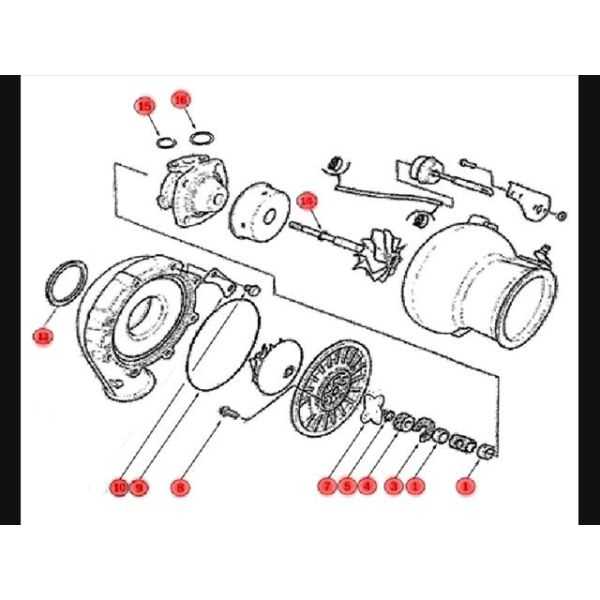

In the realm of automotive engineering, comprehending the intricate layout of engine components is essential for effective maintenance and repair. Each segment plays a pivotal role in the overall functionality of the engine, ensuring optimal performance and longevity. A well-organized schematic serves as a valuable resource for both novice mechanics and seasoned professionals alike.

Visual representations of engine assemblies provide insights into how various elements interact within the system. By examining these illustrations, one can identify the placement and connection of critical components, facilitating a deeper understanding of their respective functions. This knowledge not only enhances repair efficiency but also aids in diagnosing potential issues that may arise during operation.

Utilizing detailed blueprints can significantly streamline the troubleshooting process. Recognizing how different parts relate to one another allows for quicker identification of faults, ultimately saving time and resources. Furthermore, these visuals foster a greater appreciation for the complexity and engineering marvel that modern engines embody, reinforcing the importance of meticulous attention to detail in automotive craftsmanship.

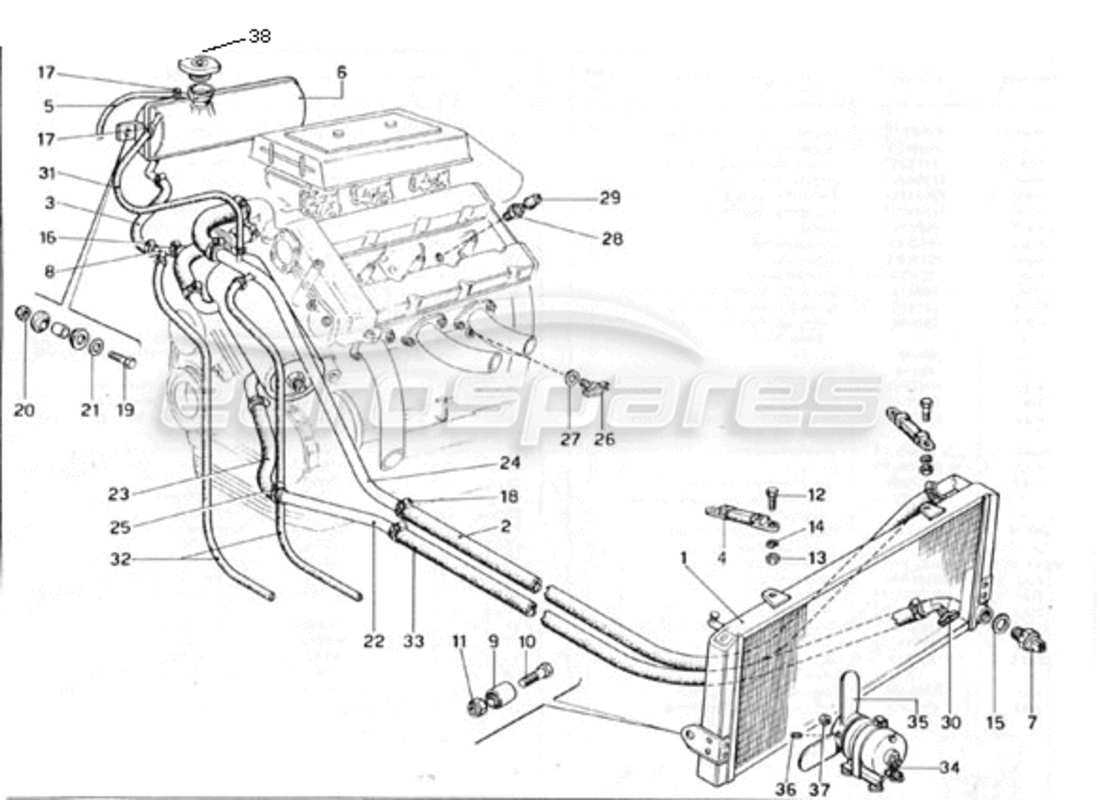

The configuration of a vehicle’s fuel delivery mechanism plays a crucial role in its overall performance and efficiency. A comprehensive understanding of this arrangement allows for better maintenance, troubleshooting, and enhancements to ensure optimal functioning of the engine. Each component within the system has a specific function that contributes to the effective management of fuel supply.

Key Components of the Fuel System

- Fuel Tank: Stores the fuel until it is needed by the engine.

- Fuel Pump: Transfers fuel from the tank to the engine at the required pressure.

- Fuel Filter: Removes impurities and contaminants from the fuel before it reaches the engine.

- Fuel Injectors: Atomize the fuel and deliver it into the combustion chamber.

- Pressure Regulator: Maintains the correct fuel pressure for optimal performance.

Importance of Each Element

Each part of the fuel system is integral to the vehicle’s operation. The fuel tank not only holds the necessary fuel but also serves as a reservoir that influences the pump’s efficiency. The fuel pump’s reliability determines how effectively the fuel is delivered, while the filter’s performance ensures that only clean fuel enters the engine. Fuel injectors are critical for mixing fuel with air, and the pressure regulator ensures that the engine receives the right amount of fuel for different operating conditions.

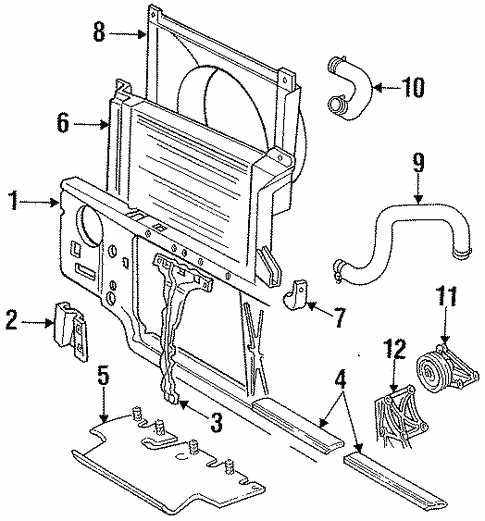

Cooling System Parts Explained

The cooling mechanism in a vehicle is crucial for maintaining optimal operating temperatures and preventing overheating. This system comprises several components that work in unison to regulate the engine’s temperature effectively, ensuring efficient performance and longevity.

Understanding these elements helps in troubleshooting issues and performing maintenance tasks effectively.

| Component | Description |

|---|---|

| Radiator | A heat exchanger that dissipates heat from the coolant before it returns to the engine. |

| Water Pump | A pump that circulates coolant through the engine and radiator, maintaining flow. |

| Thermostat | A valve that regulates coolant flow based on temperature, ensuring the engine warms up efficiently. |

| Coolant Reservoir | A tank that holds excess coolant and allows for expansion as temperatures rise. |

| Hoses | Flexible tubes that transport coolant between the engine, radiator, and other components. |

| Cooling Fans | Fans that assist in drawing air through the radiator to enhance cooling efficiency. |

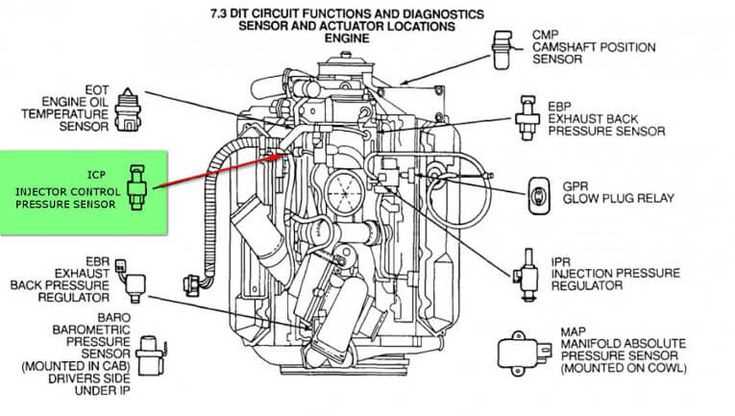

Common Electrical Components Overview

Understanding the essential electrical elements is crucial for efficient operation and maintenance of modern vehicles. These components play a significant role in ensuring proper functionality, reliability, and performance of various systems. This overview focuses on the most prevalent electrical elements found in vehicles, their roles, and interactions within the system.

Key Electrical Components

| Component | Description | Function |

|---|---|---|

| Batteries | Energy storage units | Provide electrical power for starting the engine and powering electrical systems |

| Alternators | Charging devices | Convert mechanical energy into electrical energy to recharge batteries |

| Relays | Electromechanical switches | Control high-current circuits with low-power signals |

| Sensors | Measurement devices | Monitor various parameters such as temperature and pressure for optimal performance |

| Fuses | Protective devices | Prevent overcurrent by breaking the circuit when excessive current flows |

Importance of Electrical Components

The reliability of a vehicle heavily relies on the functionality of its electrical components. Regular checks and maintenance of these elements can prevent failures, enhance performance, and ensure a safe driving experience. Awareness of the different types and their specific roles contributes to better troubleshooting and efficient repairs.

Exhaust System Configuration Details

The configuration of the exhaust system plays a critical role in optimizing engine performance and emissions. A well-designed exhaust pathway enhances the engine’s ability to expel gases efficiently, thereby improving overall functionality. This section outlines the various components and their interrelations within the exhaust assembly.

Key Components of the Exhaust Setup

- Exhaust Manifold: Collects exhaust gases from the engine cylinders and directs them into the exhaust system.

- Downpipe: Connects the exhaust manifold to the rest of the exhaust system, facilitating the flow of gases away from the engine.

- Catalytic Converter: Reduces harmful emissions by converting toxic gases into less harmful substances.

- Muffler: Minimizes noise produced by the engine, ensuring a smoother sound profile.

- Tailpipe: The final section of the exhaust system that expels gases into the atmosphere.

Installation and Maintenance Considerations

- Ensure all connections are tight to prevent leaks.

- Regularly inspect components for signs of wear or corrosion.

- Consider upgrading to high-performance parts for enhanced efficiency.

- Follow manufacturer specifications for installation to maintain warranty coverage.

Importance of Oil System Elements

The oil system is crucial for maintaining the optimal performance and longevity of an engine. Each component plays a specific role in ensuring that the lubricating fluid circulates efficiently, reducing friction and wear among moving parts. A well-functioning oil system prevents overheating and helps maintain appropriate operating temperatures, contributing to overall reliability.

Role of the Oil Pump

The oil pump is a vital element responsible for circulating oil throughout the engine. By creating pressure, it ensures that the lubricating fluid reaches all necessary components, providing adequate protection and cooling. Without a functional oil pump, the engine would suffer from increased friction and potential damage.

Significance of Oil Filters

Oil filters are essential for maintaining oil cleanliness. They remove impurities and contaminants from the lubricating fluid, ensuring that only clean oil circulates within the engine. This process not only extends the life of the engine but also enhances overall performance. Regular replacement of oil filters is crucial for sustaining engine health.

Turbocharger and Intercooler Insights

The efficiency and performance of an engine can be significantly enhanced through the integration of specific components designed to optimize air intake and temperature management. This section explores the critical roles played by forced induction systems and heat exchangers in elevating engine capabilities.

Forced Induction Technology is a crucial element that boosts engine output by compressing incoming air. This process allows for a greater amount of air and fuel to be mixed, resulting in increased power generation. Understanding the mechanics behind this technology is essential for those looking to enhance performance.

Heat Management is equally important in maintaining optimal engine temperatures. An efficient heat exchanger helps cool the compressed air before it enters the combustion chamber. By reducing air temperature, the engine can operate more effectively, minimizing the risk of knocking and ensuring longevity.

In conclusion, the synergy between forced induction systems and heat exchangers plays a pivotal role in optimizing engine performance. Knowledge of these components enables enthusiasts to make informed decisions about modifications and maintenance.

Transmission and Drivetrain Overview

The transmission and drivetrain play a crucial role in delivering power from the engine to the wheels, ensuring optimal performance and efficiency. Understanding these components is essential for maintaining and enhancing vehicle functionality.

Key Components

- Transmission: Converts engine torque into usable power for driving.

- Driveshaft: Transfers power from the transmission to the differential.

- Differential: Distributes torque to the wheels, allowing for smooth turns.

- Axles: Connect the wheels to the drivetrain, enabling rotation and support.

Functionality and Importance

Each element within the drivetrain works harmoniously to ensure smooth operation. Regular maintenance of these components can prevent issues such as slipping, noise, or vibration, leading to improved driving experience and longevity.

Maintenance Considerations for Key Parts

Regular upkeep of essential components is crucial for optimal performance and longevity of your vehicle. Neglecting these areas can lead to reduced efficiency and costly repairs over time. By focusing on specific elements, you can ensure a smooth operation and prevent potential issues.

- Fluid Checks: Regularly inspect and replace engine fluids, including oil and coolant, to maintain optimal function.

- Filter Replacement: Change air and fuel filters periodically to ensure proper airflow and fuel delivery.

- Belt and Hose Inspection: Check belts and hoses for wear and tear, replacing them as necessary to avoid breakdowns.

- Battery Maintenance: Keep battery terminals clean and ensure proper connections to prevent starting issues.

By adhering to these maintenance tips, vehicle owners can significantly enhance the reliability and efficiency of their machines. Establishing a routine maintenance schedule helps in early detection of problems and contributes to overall performance improvement.

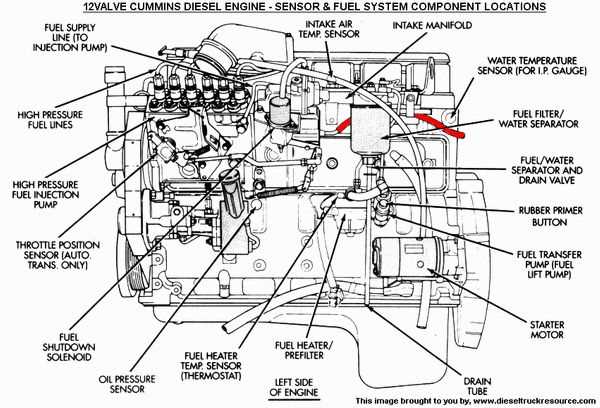

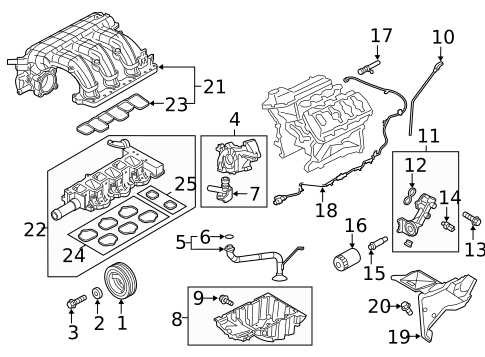

Visual Representation of Component Relationships

This section aims to illustrate the interconnectedness of various elements within a specific system. By providing a clear depiction of how these components interact, it enhances understanding and facilitates better maintenance and troubleshooting practices.

A comprehensive visual guide can effectively convey the arrangement and linkage of each part, enabling users to quickly identify potential issues and areas for improvement. Utilizing detailed graphics helps in recognizing how alterations in one component may influence others, fostering a holistic perspective on the overall functionality.

Through such representations, users gain valuable insights into the operational dynamics, leading to improved efficiency and effectiveness in managing the system. This approach not only simplifies complex concepts but also serves as a crucial resource for both novice and experienced individuals engaged with the technology.