For anyone looking to maintain or repair their cutting equipment, having a clear visual reference of its various elements is essential. Knowing how each part interacts can greatly enhance the efficiency of the device, ensuring it operates smoothly and effectively. A comprehensive guide that showcases these components can provide valuable insight into how to keep your machinery in top condition.

By exploring the layout of the different elements, users can better understand the assembly and disassembly processes involved. This knowledge is crucial for performing repairs or replacements when necessary. Additionally, recognizing the function of each piece can help in troubleshooting common issues that may arise during operation.

Equipped with this information, users can approach maintenance tasks with confidence, ensuring their equipment remains reliable for all gardening and landscaping activities. Investing time in learning about these components not only prolongs the life of the device but also improves its overall performance, making each task easier and more efficient.

The FS 40 is a well-designed machine that relies on various key elements to function efficiently. Understanding these components is crucial for proper maintenance and optimal performance.

- Engine: The heart of the equipment, responsible for powering the entire unit and driving the cutting mechanism.

- Fuel Tank: Holds the necessary fuel mixture, ensuring the engine receives the right amount of energy to operate.

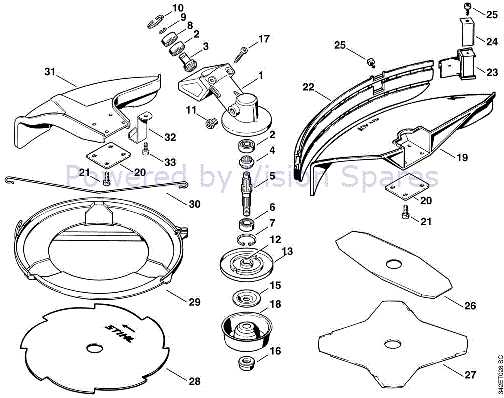

- Cutter Head: The component that houses the cutting line or blade, allowing for effective trimming and mowing.

- Handlebar: Provides stability and control, enabling the operator to maneuver the machine with ease.

- Throttle Trigger: Regulates the engine speed, giving the user control over cutting performance.

- Guard: A safety feature that protects the operator from debris and potential injuries during operation.

Each of these essential elements plays a vital role in ensuring the equipment operates smoothly and safely. Regular inspection and maintenance of these components contribute to the longevity and effectiveness of the machine.

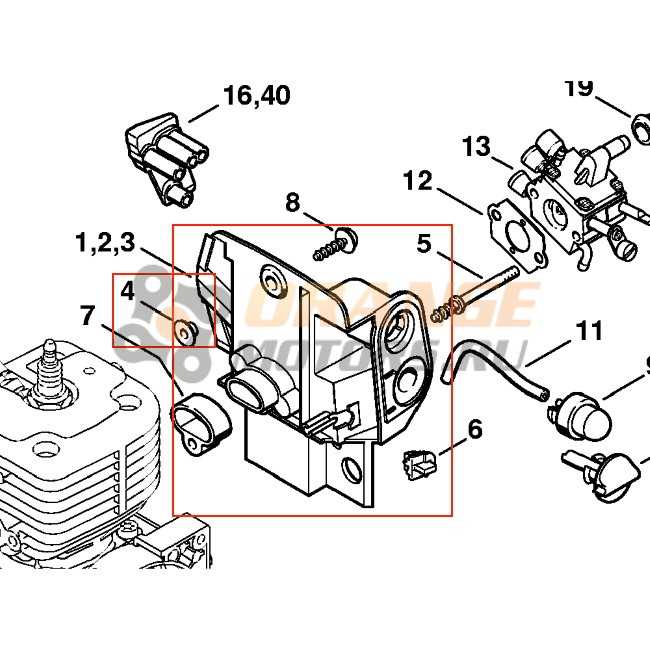

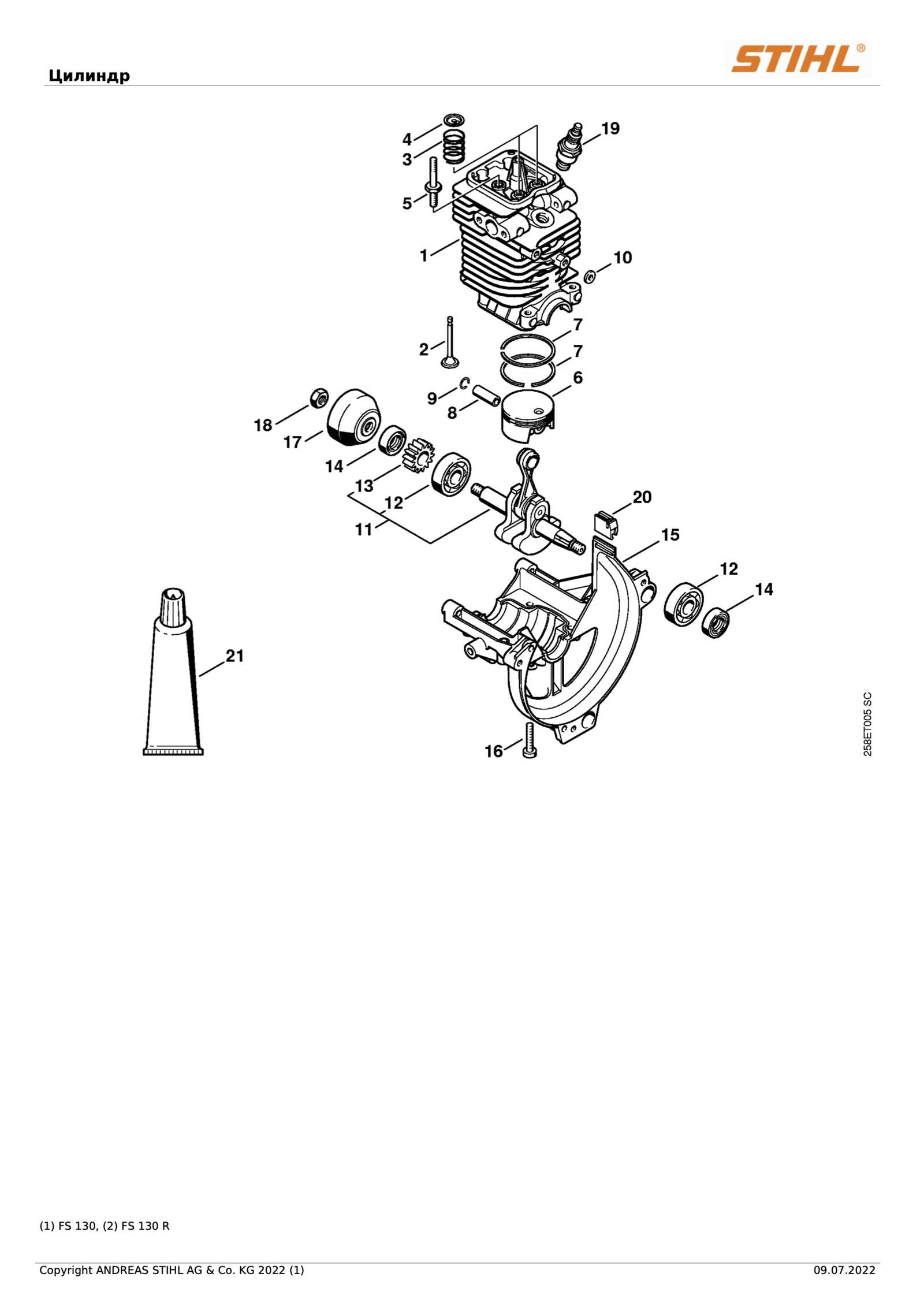

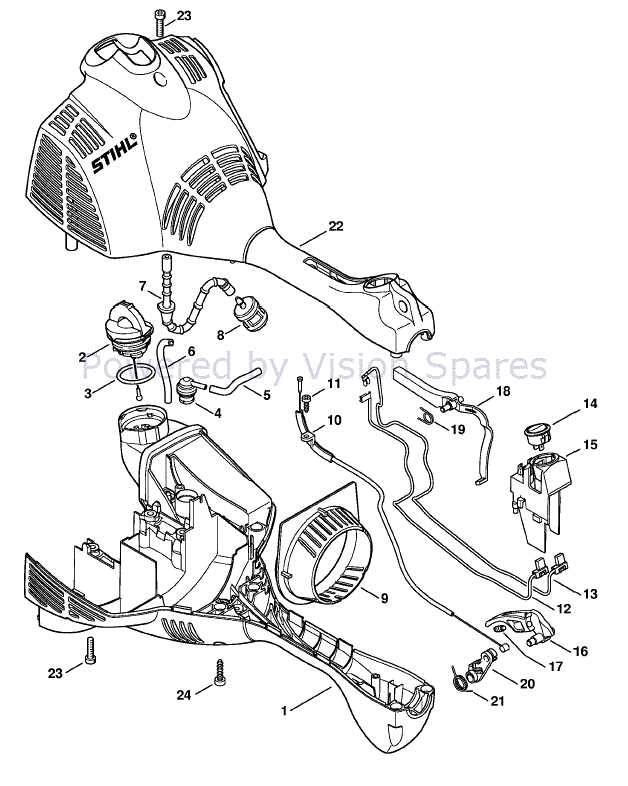

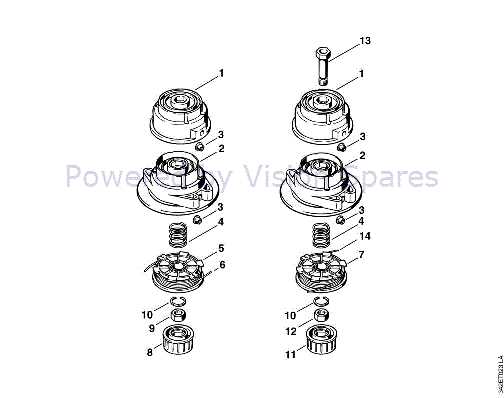

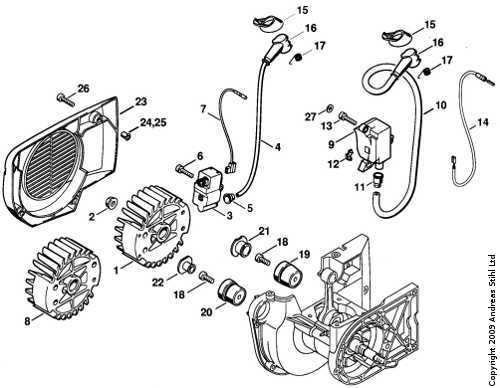

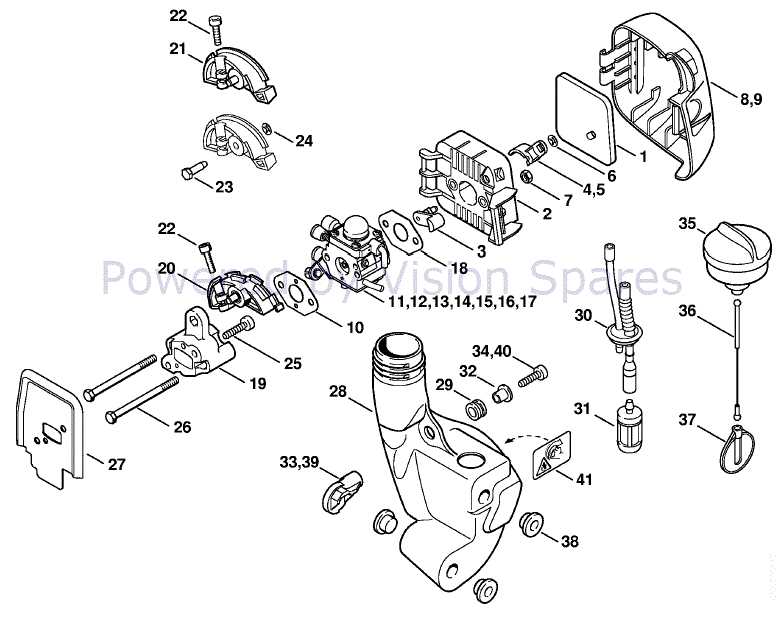

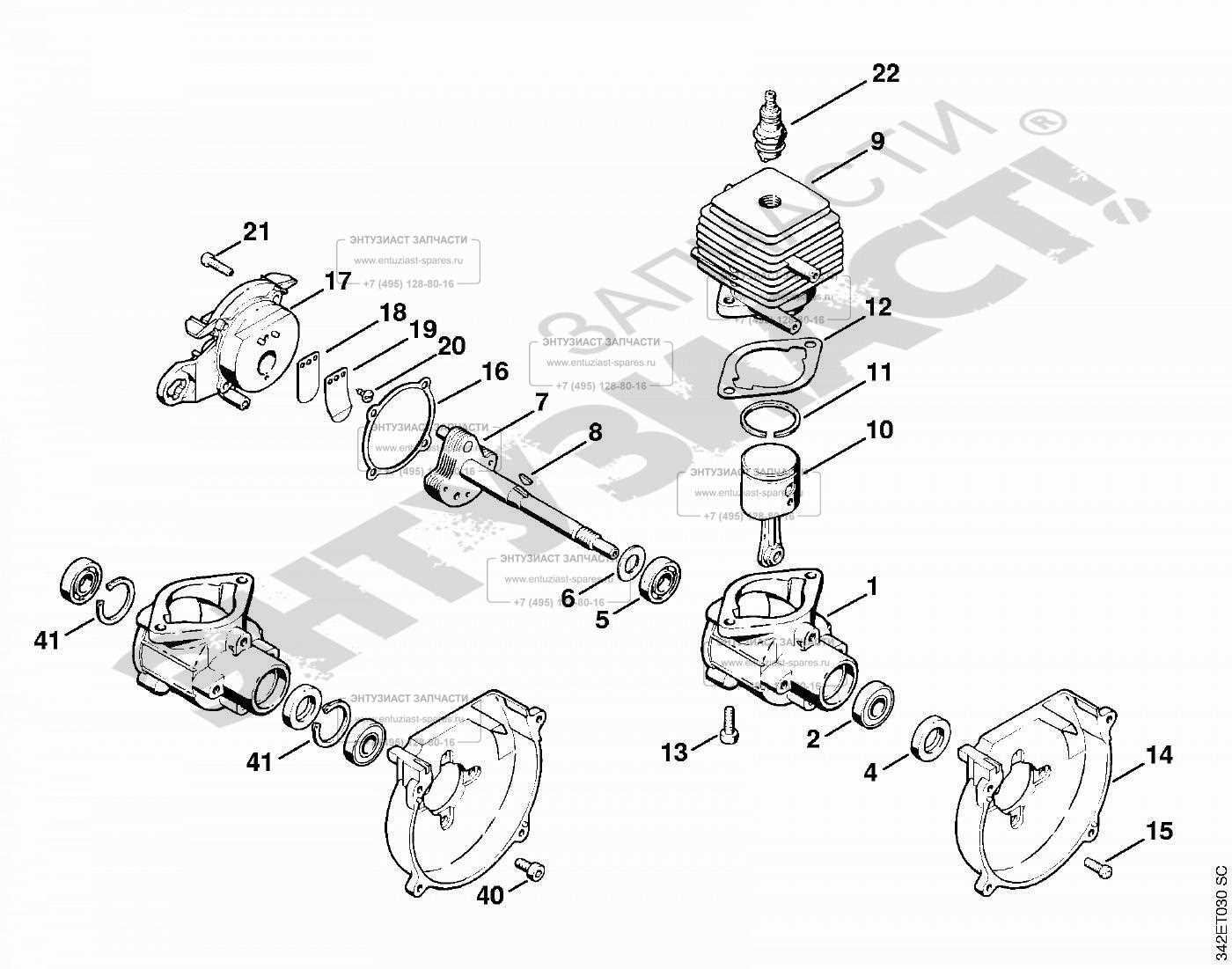

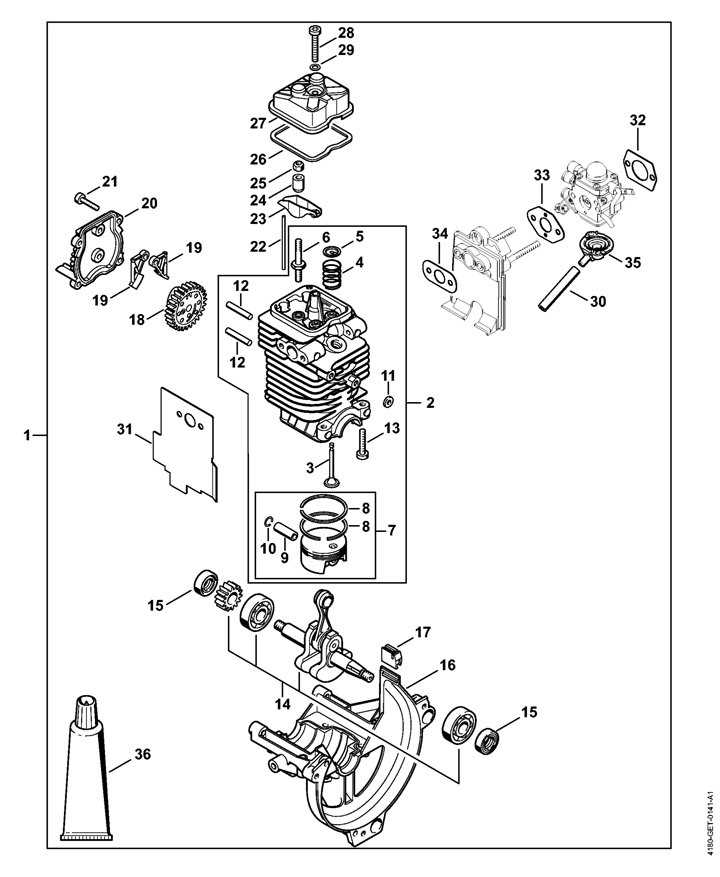

Understanding the Parts Diagram

Gaining a clear insight into the assembly layout is crucial for maintaining and repairing your equipment. This visual representation serves as a guide, detailing each component’s relationship and placement within the entire system. By familiarizing yourself with this layout, you can effectively troubleshoot issues and identify necessary replacements.

Key Components are typically illustrated in a systematic manner, making it easier to locate specific elements. Each item is numbered or labeled, providing clarity on their function and connection points. Understanding these references can significantly enhance your efficiency when performing maintenance tasks.

Assembly Relationships are also highlighted, showing how individual parts interact with one another. This context helps users understand not just where a part fits, but how it contributes to the overall performance of the machinery. By recognizing these connections, you can approach repairs and upgrades with greater confidence.

How to Identify Each Part

Understanding the components of your tool is essential for effective maintenance and repair. Each segment plays a specific role in the overall functionality, and recognizing them can simplify tasks such as assembly, disassembly, or troubleshooting.

Recognizing Key Components

Start by familiarizing yourself with the primary sections of your equipment. Look for the main body, which houses the engine, and examine the attachments that connect to it. Common elements include the cutting mechanism and the handle assembly. Identifying these fundamental parts will provide a solid foundation for further exploration.

Utilizing Visual Aids

Reference visuals that illustrate the various elements. Diagrams and labeled images can serve as helpful guides. Pay close attention to each part’s shape and position; this can aid in distinguishing similar components. Additionally, consulting user manuals can provide detailed descriptions and specifications for further clarification.

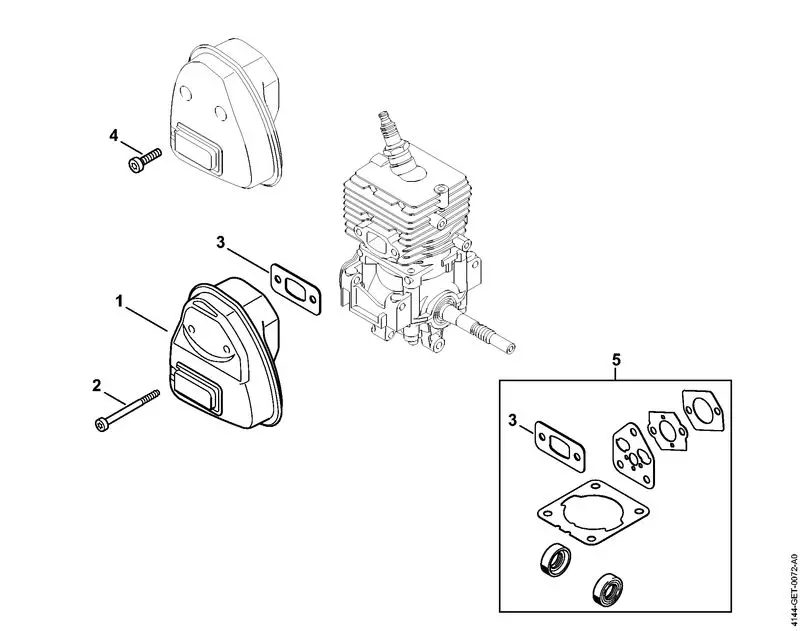

Common Issues and Solutions

When operating a garden tool, users may encounter several common challenges that can affect performance and efficiency. Understanding these issues and their potential fixes can help ensure smooth operation and prolong the lifespan of the equipment.

1. Engine Won’t Start

This is a frequent issue that can stem from various causes. Here are some possible reasons and their corresponding solutions:

- Fuel Problems: Ensure that the fuel is fresh and mixed correctly. Old or improperly mixed fuel can prevent the engine from starting.

- Dirty Air Filter: A clogged air filter can restrict airflow. Clean or replace the air filter as needed.

- Spark Plug Issues: Check the spark plug for wear or fouling. Replace it if necessary to ensure proper ignition.

2. Poor Performance or Lack of Power

When the tool struggles to operate effectively, several factors might be involved:

- Clogged Muffler: A blockage in the exhaust can limit engine performance. Inspect and clean the muffler regularly.

- Worn Cutting Line: A dull or damaged cutting line can hinder cutting efficiency. Replace the line to restore optimal performance.

- Incorrect Idle Speed: If the idle speed is too low, it may stall. Adjust the idle speed to the manufacturer’s specifications.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment involves a combination of regular care and mindful practices. By implementing a few straightforward maintenance strategies, you can significantly enhance its performance and durability over time.

Regular Cleaning: Keeping the exterior and internal components free from debris and dirt is crucial. After each use, wipe down the surfaces and check for any residue that could affect operation.

Frequent Inspections: Schedule periodic checks to identify any wear and tear. Look for signs of damage or unusual wear on essential components, and address issues promptly to avoid further complications.

Proper Lubrication: Ensure that all moving parts are adequately lubricated. This helps reduce friction and prevents overheating, contributing to smoother operation and extended lifespan.

Correct Fuel Usage: Always use the recommended fuel type, as improper fuel can lead to performance issues and potential damage. Additionally, consider using fuel stabilizers to maintain fuel quality over time.

Storage Practices: Store your equipment in a dry, sheltered area when not in use. Protecting it from the elements will prevent rust and other environmental damage, ensuring it remains in optimal condition.

By adhering to these maintenance tips, you can help ensure your equipment operates efficiently for many years, allowing you to get the most out of your investment.

Ordering Replacement Parts

When it comes to maintaining your outdoor equipment, acquiring the right components is essential for optimal performance. Whether you’re facing wear and tear or need upgrades, knowing how to efficiently order these items can save time and ensure your machine runs smoothly.

Identifying the Required Components: Before placing an order, it’s important to pinpoint exactly what you need. Consult your user manual or the manufacturer’s website to find a list of recommended replacements. This will help you avoid unnecessary purchases and ensure compatibility.

Where to Purchase: Components can be sourced from various retailers, including local shops and online platforms. Online marketplaces often provide a wider selection and competitive pricing. Always opt for reputable sellers to guarantee the quality of the items.

Checking Availability: After identifying the necessary components, check their availability. Many retailers offer stock updates on their websites, allowing you to see if the items are in stock or if they need to be ordered from the supplier.

Placing Your Order: Once you’ve confirmed the items you need and their availability, proceed to place your order. Make sure to double-check your selections and confirm the shipping details. Keep in mind that some sellers may offer expedited shipping options for quicker delivery.

After the Order: After receiving your components, inspect them for any damage or discrepancies. If everything is in order, you can proceed with the installation process. Should you encounter any issues, contact the supplier for support or replacement.

Tools Needed for Repairs

When it comes to maintaining and fixing your equipment, having the right tools is essential for effective repairs. Proper tools not only ensure efficiency but also contribute to achieving the best results while minimizing the risk of damage to the device.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for removing and securing screws.

- Wrenches: Adjustable wrenches or socket sets are necessary for loosening or tightening bolts.

- Plier Set: Needle-nose and slip-joint pliers assist in gripping and bending components as needed.

- Torque Wrench: This tool is vital for applying the correct amount of force when securing fasteners to avoid over-tightening.

- Hex Keys: A set of Allen wrenches is important for working with hexagonal screws commonly found in various assemblies.

- Cutting Tools: Sharp blades or cutting shears are useful for trimming or replacing damaged parts.

- Measuring Tools: A ruler or caliper can help in measuring dimensions for replacements or adjustments.

Having these essential tools on hand can significantly streamline the repair process, ensuring that tasks are completed efficiently and correctly. Always remember to use the appropriate tool for each job to maintain safety and the integrity of your equipment.

Assembly Instructions for FS 40

This section provides essential guidance for the proper assembly of your trimming tool. Following these instructions will ensure that all components are correctly fitted, allowing for optimal performance and longevity of the device.

Gather Required Tools

Before you begin the assembly process, make sure you have all necessary tools at hand. Common tools may include a screwdriver, wrench, and any additional items specified in your instruction manual. Having everything ready will facilitate a smoother assembly experience.

Step-by-Step Assembly Process

Begin by laying out all components in an organized manner. Start with the main body and carefully attach the handle. Ensure that all screws are tightened securely but avoid over-tightening, which may cause damage. Next, install the cutting head according to the guidelines, ensuring it is aligned correctly for efficient operation. After all components are connected, conduct a visual inspection to confirm that everything is in place.

Tip: Always refer to the manufacturer’s manual for specific instructions related to your model, as variations may exist.

Safety first: Wear appropriate protective gear during assembly to avoid injuries.

Safety Precautions During Maintenance

Performing maintenance on outdoor power equipment requires careful attention to safety. Following proper precautions helps prevent accidents and ensures a smooth and effective maintenance process.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes and dust.

- Keep your workspace clean and organized to minimize the risk of trips and falls.

- Ensure that the equipment is turned off and disconnected from power sources before starting any maintenance task.

Handling Tools and Equipment

- Use tools that are specifically designed for the tasks at hand.

- Inspect tools before use to ensure they are in good condition and free from defects.

- Handle sharp components with care to avoid cuts and injuries.

- Store tools safely when not in use to prevent accidents.

Benefits of Genuine Stihl Parts

Choosing authentic components for your equipment is essential for ensuring optimal performance and longevity. High-quality replacements provide reliability and efficiency, making them a wise investment for any user.

Here are some key advantages of utilizing original components:

- Quality Assurance: Genuine items are manufactured to strict standards, ensuring durability and superior performance.

- Compatibility: These components are designed specifically for your machine, guaranteeing a perfect fit and seamless operation.

- Extended Lifespan: Using authentic replacements helps prevent premature wear and tear, extending the overall life of your equipment.

- Safety: Original components meet safety regulations, reducing the risk of malfunctions and accidents during operation.

- Manufacturer Support: Purchasing genuine items often includes access to customer support and warranties, providing peace of mind.

Investing in authentic components not only enhances performance but also contributes to the safety and reliability of your equipment, ensuring that it operates at its best for years to come.

FAQs about Stihl FS 40

This section addresses common inquiries related to the specific model of outdoor power equipment. Users often seek guidance on various aspects, including maintenance, functionality, and troubleshooting.

One frequent question is about the optimal maintenance schedule for ensuring longevity. Regular cleaning and timely replacement of essential components are crucial for peak performance.

Another common concern involves the proper use of the device. Understanding how to adjust settings and utilize accessories can enhance efficiency and effectiveness during operation.

Users also frequently ask about compatibility with different attachments. It is vital to ensure that accessories are suitable for the model to achieve the best results.

Finally, many individuals seek advice on resolving common issues that may arise during use. Familiarity with troubleshooting techniques can help users quickly address and rectify minor problems, ensuring uninterrupted functionality.

Customer Reviews and Feedback

This section aims to provide insights into the experiences and opinions of users regarding a specific model of outdoor power equipment. Feedback from customers is essential for understanding the strengths and weaknesses of the product, allowing potential buyers to make informed decisions.

Positive Experiences

- Many users appreciate the lightweight design, making it easy to maneuver for extended periods.

- Customers frequently highlight the efficiency of the engine, noting its powerful performance on various tasks.

- Numerous reviews commend the user-friendly controls, which facilitate ease of operation, even for beginners.

Areas for Improvement

- Some users have reported challenges with assembly instructions, suggesting that clearer guidance would be beneficial.

- A few customers mentioned that the fuel consumption could be optimized for longer usage between refills.

- Some feedback indicated that the durability of certain components could be enhanced to withstand rigorous use.