In the realm of heavy machinery, comprehending the individual elements that constitute a machine is essential for maintenance and repair. This knowledge not only aids in effective troubleshooting but also enhances the overall efficiency of the equipment. Each component plays a vital role, contributing to the seamless operation of the machine.

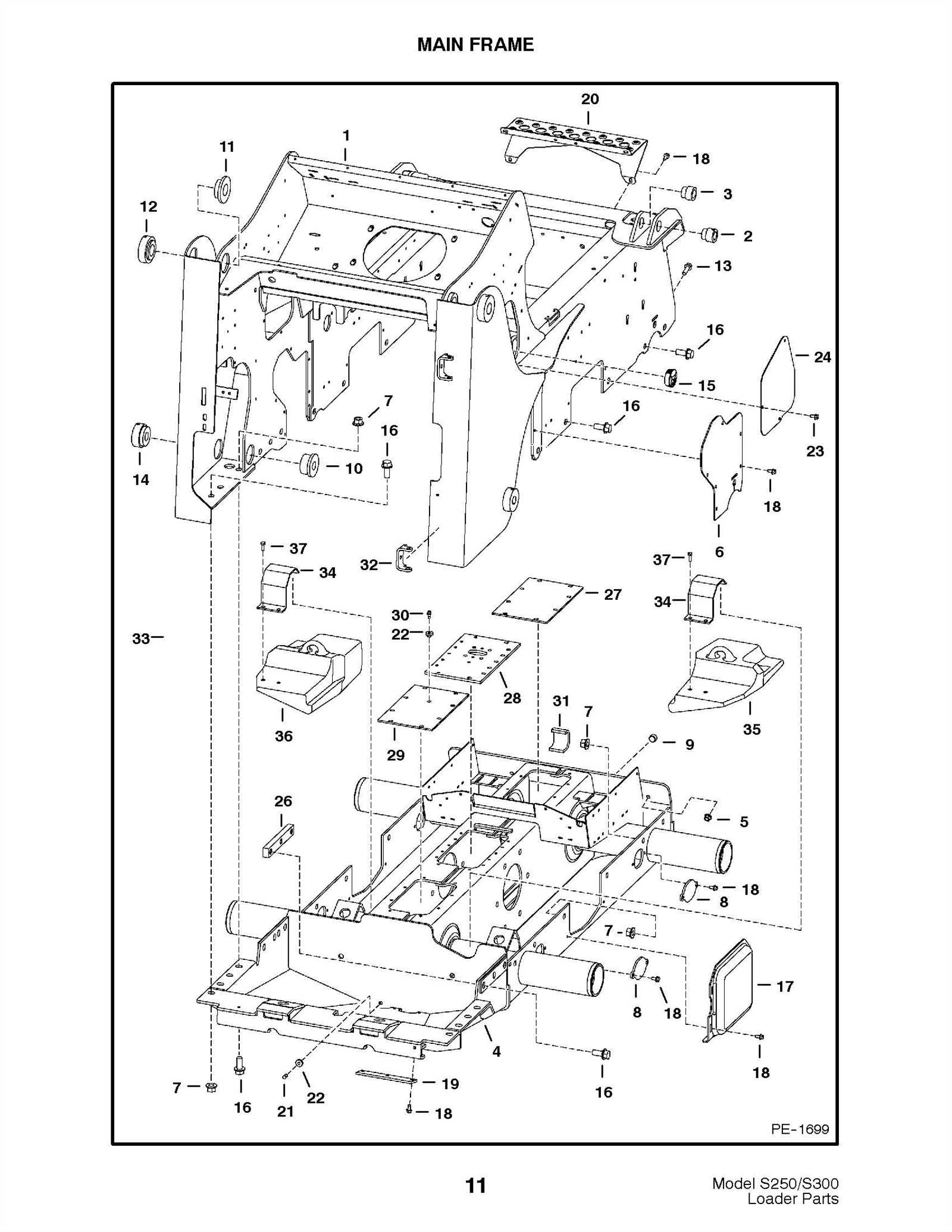

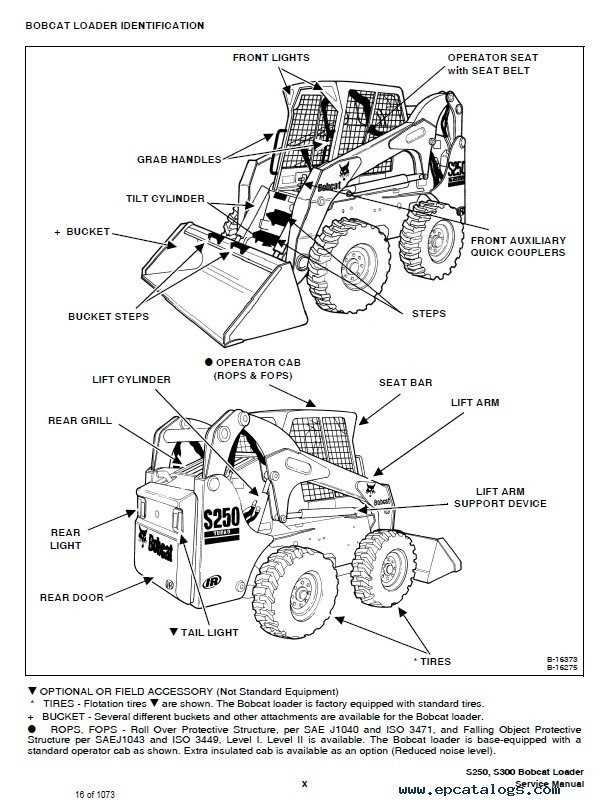

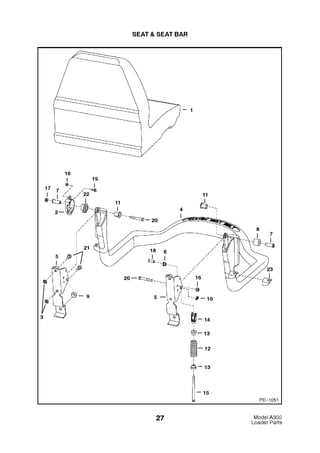

Visual representations of the assembly allow operators and technicians to identify specific sections and understand how various parts interact. Such illustrations serve as invaluable resources for anyone looking to delve deeper into the functionality of machinery. By familiarizing oneself with these components, users can ensure proper upkeep and prolong the lifespan of their equipment.

Furthermore, grasping the intricate design of the machinery promotes confidence during repair tasks. Understanding the arrangement and connection of different elements enables more effective diagnostic procedures, facilitating a quicker resolution of issues. This foundational knowledge ultimately leads to enhanced performance and reliability of the machine.

Overview of Bobcat S300 Parts

This section provides a comprehensive examination of essential components related to the compact loader model. Understanding these elements is crucial for maintenance, repair, and optimal performance. Each component plays a significant role in the overall functionality and efficiency of the machine, contributing to its versatility in various applications.

Key Components and Their Functions

Several critical elements are vital for the effective operation of this equipment. The engine serves as the powerhouse, converting fuel into mechanical energy. Additionally, the hydraulic system is responsible for lifting and maneuvering loads, while the chassis provides structural integrity and stability. Each part works in harmony, ensuring that the loader performs efficiently under various working conditions.

Importance of Regular Maintenance

Routine inspections and maintenance of these components are essential to prolonging the lifespan of the machine. Identifying wear and tear early on can prevent significant issues down the line. By understanding the role of each element, operators can ensure that their equipment remains in optimal working condition, enhancing productivity and safety on the job site.

Importance of Parts Diagrams

Understanding the various components of machinery is crucial for effective maintenance and repair. Visual representations that detail individual elements serve as invaluable resources for technicians and operators alike. These illustrations not only enhance comprehension but also streamline the identification process during troubleshooting.

Utilizing such resources offers several benefits:

- Improved clarity regarding the function of each component.

- Facilitated ordering of necessary replacements.

- Streamlined repair processes through visual guidance.

- Enhanced training for new personnel on equipment specifics.

Incorporating these visual aids into maintenance practices can significantly reduce downtime and improve overall efficiency. By leveraging detailed visual tools, users can ensure optimal operation and longevity of their machinery.

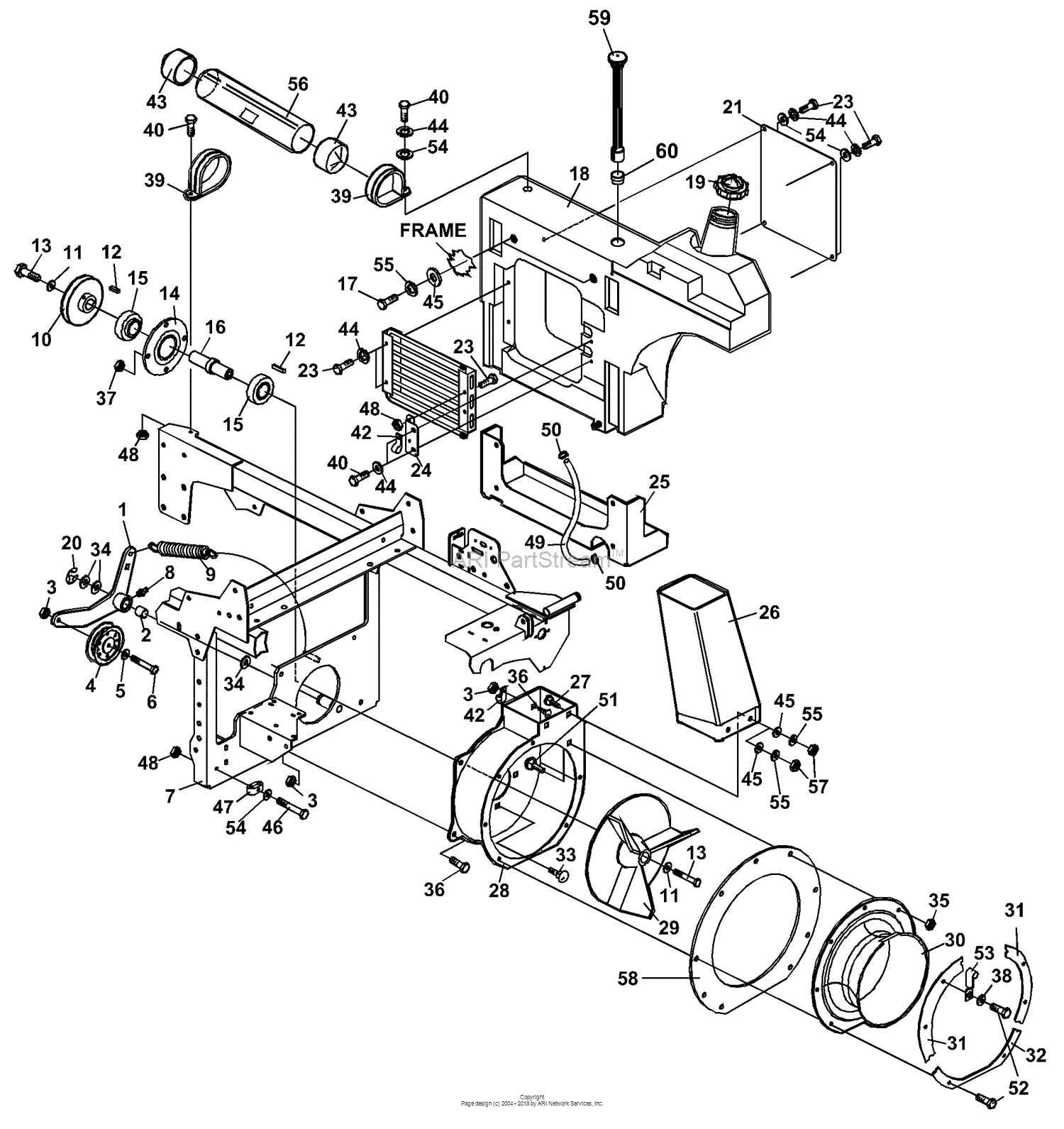

Key Components of S300 Model

This section highlights the essential elements that contribute to the functionality and efficiency of the specified machinery. Understanding these critical components can enhance operational knowledge and maintenance practices.

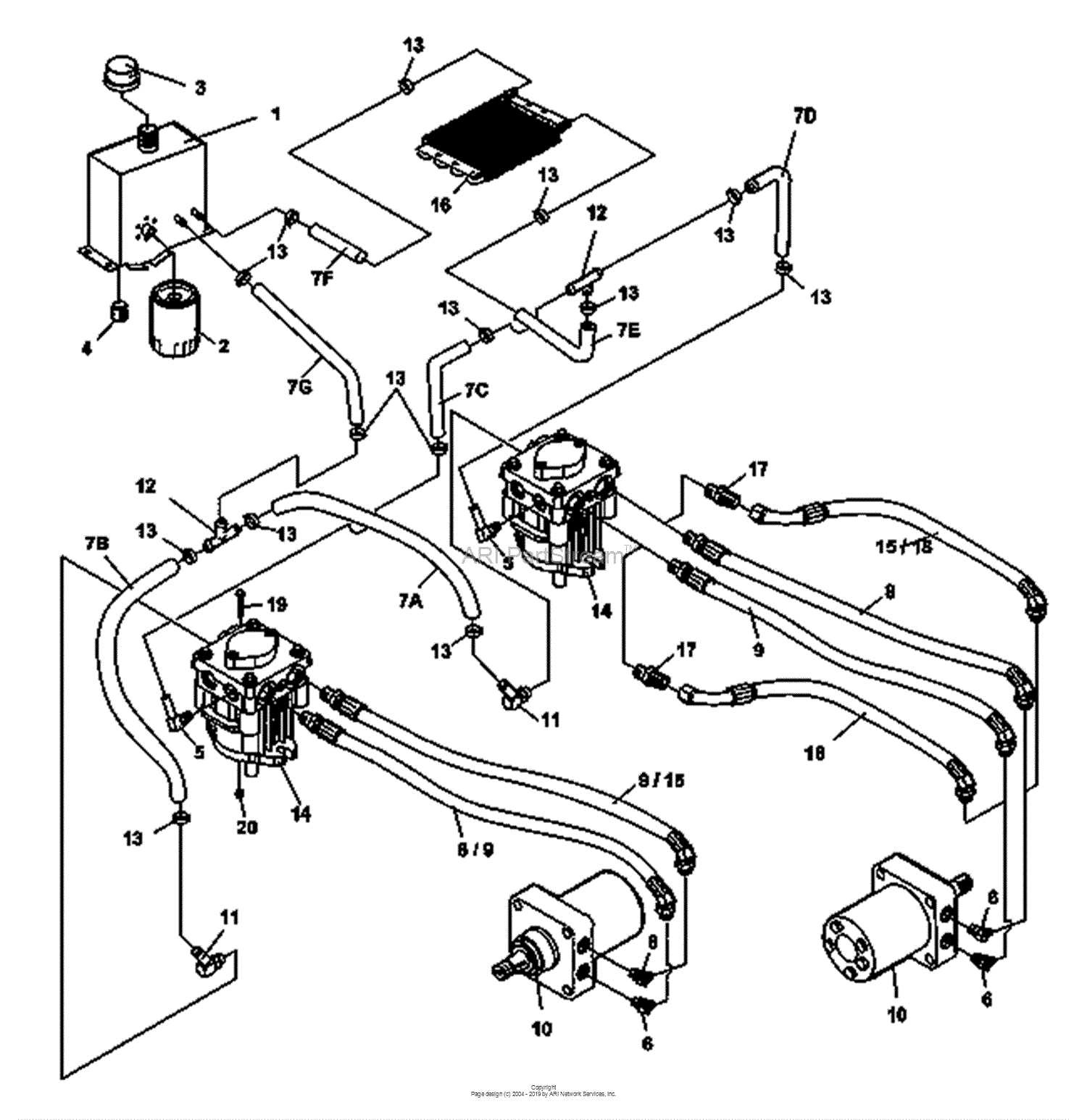

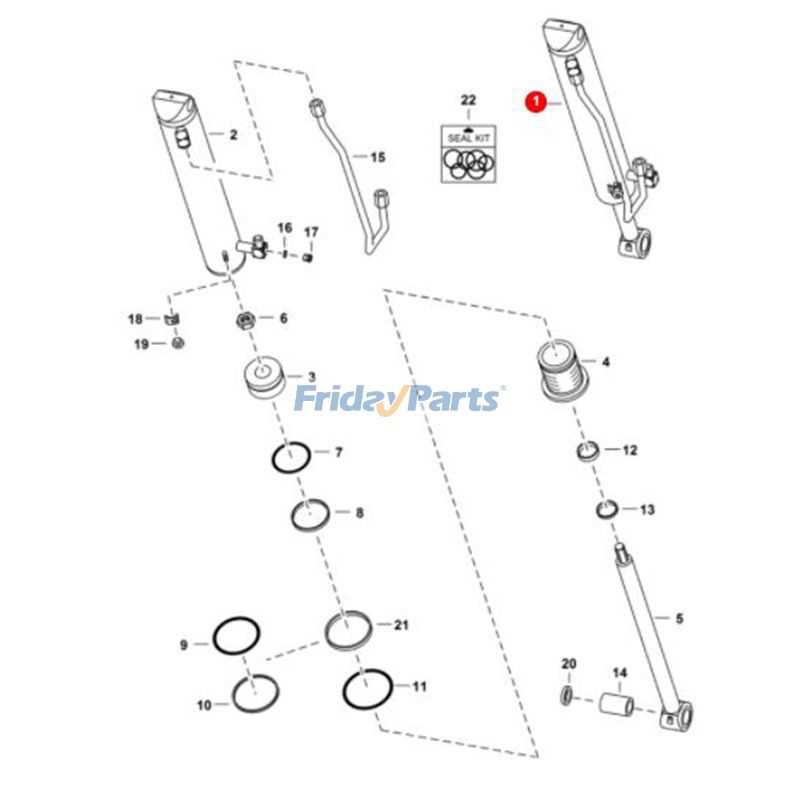

Hydraulic System

The hydraulic system plays a vital role in the operation of the equipment, enabling it to perform various tasks effectively. Key features include:

- Hydraulic Pump: Responsible for generating the hydraulic fluid pressure necessary for movement.

- Control Valves: Direct the flow of hydraulic fluid to different parts of the machine.

- Cylinders: Facilitate lifting and lowering actions through hydraulic pressure.

Engine and Powertrain

The powertrain system is crucial for providing the necessary power to operate the machinery. Important aspects include:

- Engine: The heart of the machinery, converting fuel into mechanical energy.

- Transmission: Transfers power from the engine to the wheels, ensuring smooth movement.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

Understanding Hydraulic System Layout

The hydraulic system is a crucial component of heavy machinery, providing the necessary power to perform various tasks efficiently. Its layout plays a significant role in ensuring optimal performance and reliability. By examining the arrangement of components, operators can gain insights into the functionality and maintenance of the system.

Key Components of the Hydraulic System

At the heart of the hydraulic mechanism are several essential elements, including the pump, cylinders, and valves. The pump generates the hydraulic fluid flow, while cylinders convert that flow into mechanical force. Valves regulate the pressure and direction of the fluid, enabling precise control over movements.

Benefits of an Efficient Layout

An effectively organized hydraulic system enhances the overall efficiency of the equipment. Proper placement of components minimizes fluid resistance and reduces wear, resulting in longer service life and lower maintenance costs. Understanding the layout not only aids in troubleshooting but also contributes to better training for operators.

Engine Specifications and Parts

This section delves into the fundamental attributes and components of the power unit, essential for the efficient operation of the machinery. Understanding these specifications helps ensure optimal performance and longevity of the equipment.

The engine is typically characterized by its horsepower rating, displacement, and configuration, which influence the overall capability of the unit. Various elements such as the cooling system, fuel delivery components, and exhaust system play a crucial role in maintaining efficiency and effectiveness during operation.

Additionally, components like the ignition system, filters, and lubricants are vital for the smooth functioning of the power unit. Regular maintenance and timely replacement of these parts can prevent potential issues, thereby enhancing reliability and productivity in various applications.

Transmission and Drive System Details

The efficiency of a machine’s movement relies heavily on its transmission and drive mechanisms. Understanding the intricacies of these systems is essential for optimal performance and maintenance. This section delves into the components and functionalities that contribute to effective power transfer and mobility.

Key Components

- Transmission Unit: This element is responsible for altering gear ratios to suit various operational requirements, ensuring the machine can tackle different terrains.

- Drive Axles: These components transmit power from the transmission to the wheels, playing a crucial role in traction and stability.

- Hydraulic Pumps: Integral for powering various system functions, these pumps facilitate smooth operation and control.

- Gearbox: This mechanism houses various gears that facilitate the required speed and torque adjustments.

Maintenance Considerations

- Regularly check fluid levels in the transmission and hydraulic systems to prevent overheating and ensure proper operation.

- Inspect drive belts and hoses for signs of wear or damage, replacing them as necessary to avoid breakdowns.

- Monitor the performance of the hydraulic pumps and drive axles for any irregularities that could indicate a need for maintenance.

- Conduct periodic servicing of the gearbox to ensure gears engage smoothly and maintain optimal performance.

Maintenance Tips for S300 Parts

Proper upkeep of machinery components is essential for optimal performance and longevity. Regular attention to key elements ensures smooth operation and minimizes the risk of unexpected failures. Implementing effective maintenance practices can significantly enhance efficiency and reduce repair costs.

Regular Inspections

Conducting frequent examinations of critical components helps identify wear and tear before it leads to major issues. Pay close attention to signs of damage, such as cracks or unusual wear patterns, which may indicate underlying problems. Regular checks can prevent costly breakdowns and extend the life of the equipment.

Lubrication and Cleaning

Maintaining cleanliness and proper lubrication of moving parts is crucial. Ensure that all relevant components are free from dirt and debris, which can hinder performance. Applying the correct type of lubricant at recommended intervals will reduce friction, enhance functionality, and promote smoother operation.

Common Replacement Parts for S300

The maintenance and repair of machinery often require specific components to ensure optimal performance. Understanding the essential elements that typically need to be replaced can enhance longevity and efficiency. This section highlights frequently substituted items that are crucial for keeping equipment running smoothly.

Among the most essential components are the hydraulic filters, which play a vital role in maintaining fluid cleanliness and preventing contamination. Regularly replacing these ensures that the hydraulic system operates efficiently.

Another critical item is the engine oil filter, essential for keeping the engine in good condition by removing impurities from the oil. Replacing it at regular intervals can significantly improve engine performance and reliability.

Additionally, wear parts such as belts and hoses require periodic replacement due to their exposure to stress and environmental factors. Keeping these components in check helps to prevent breakdowns and enhances overall operational safety.

Lastly, undercarriage components, including rollers and tracks, are often subject to wear and tear. Timely replacement of these parts not only ensures smoother operation but also prolongs the life of the entire unit.

Identifying Electrical System Components

The electrical system of a machine plays a crucial role in its overall functionality. Understanding the various elements within this system is essential for effective maintenance and troubleshooting. This section aims to provide insights into the different components that make up the electrical system, enabling operators to recognize and address issues efficiently.

Several key elements constitute the electrical infrastructure, each serving a distinct purpose. These components work together to ensure smooth operation and reliable performance. Familiarizing oneself with these parts can greatly enhance an operator’s ability to manage the machine effectively.

| Component | Description |

|---|---|

| Battery | Stores electrical energy to power the system and start the engine. |

| Alternator | Generates electricity while the engine is running, charging the battery. |

| Starter Motor | Initiates the engine’s operation by turning it over during startup. |

| Wiring Harness | Connects various electrical components, facilitating communication and power distribution. |

| Fuses | Protect the electrical system from overloads by breaking the circuit when necessary. |

| Relays | Control high-current devices by allowing low-current signals to operate them. |

| Sensors | Monitor various parameters and send signals to the control system for adjustments. |

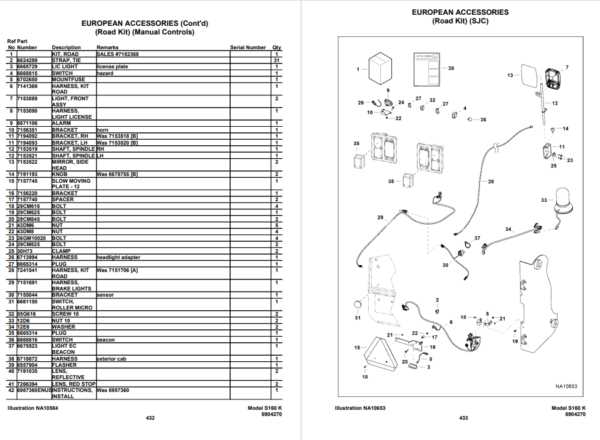

Accessing Bobcat Parts Catalogs

Finding the appropriate components for machinery can often be a complex task. Accessing comprehensive catalogs is crucial for identifying the required items, understanding their specifications, and ensuring compatibility. These resources are designed to assist users in navigating through various options efficiently.

Several platforms offer digital catalogs that provide detailed information on available items. Users can explore these resources to discover the necessary components, including diagrams and part numbers. Additionally, many manufacturers maintain updated online databases, making it easier to locate specific items based on model and type.

For those who prefer printed materials, hard copies of catalogs are often available through authorized dealers or repair shops. These physical resources can be beneficial for quick reference during repairs or maintenance tasks. Engaging with knowledgeable professionals in the industry can also enhance the search process, ensuring access to accurate information.

Utilizing these catalogs effectively can significantly streamline the process of sourcing components. Whether opting for digital or printed formats, users should prioritize finding reliable sources that offer the most current information on available items.

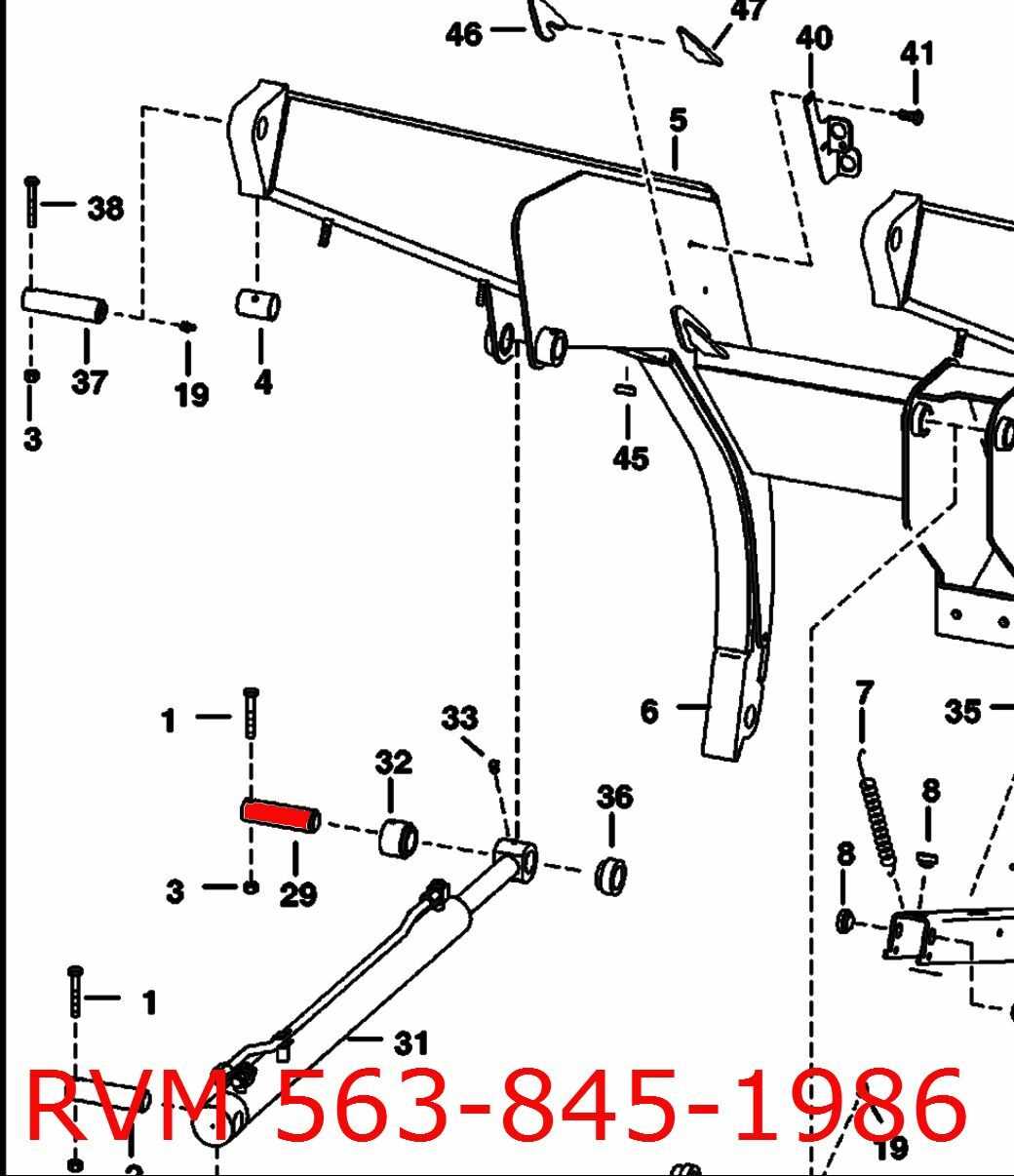

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for effective maintenance and repair tasks. These visual representations provide an organized overview of components, enabling users to identify, locate, and replace specific elements within a machine. By grasping the fundamentals of these graphics, you can enhance your troubleshooting skills and ensure the longevity of your equipment.

Identifying Components

Each element in the illustration is typically labeled with a unique identifier or reference number. Familiarize yourself with the legend or key that accompanies the image, as it will clarify the meanings behind the symbols used. This knowledge is essential for accurately locating and ordering the necessary items.

Understanding Assembly Relationships

The arrangement of components in the visual guide often reflects their actual positioning within the machinery. Pay attention to how parts connect and interact, as this will assist in comprehending the overall structure. Recognizing these relationships is vital for effective disassembly and reassembly processes.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance the overall performance and longevity of machinery. These elements are designed to meet the specific requirements of the equipment, ensuring optimal functionality and reliability.

- Quality Assurance: OEM components are manufactured to the highest standards, guaranteeing superior quality compared to aftermarket alternatives.

- Perfect Fit: These parts are engineered to precisely match the specifications of the machinery, resulting in seamless integration and reduced risk of malfunction.

- Enhanced Performance: Using original components can improve the overall efficiency of the equipment, leading to better performance and productivity.

- Warranty Protection: Many manufacturers provide warranties for their original components, offering peace of mind and protection against defects.

- Increased Resale Value: Equipment maintained with original components often retains a higher resale value due to the assurance of quality and reliability.

In summary, choosing OEM components is a wise investment that promotes efficiency, durability, and overall satisfaction in machinery operation.