In the world of modern kitchen appliances, maintaining optimal functionality is essential for efficiency and convenience. Understanding the various elements that make up a refrigerator can empower users to troubleshoot issues and perform maintenance with confidence. This section aims to provide a clear and informative overview of the different components found in LG refrigerators, helping users grasp how each part contributes to the overall operation.

From the cooling system to the shelving and storage arrangements, every aspect plays a vital role in ensuring your appliance meets your needs. By familiarizing yourself with the inner workings, you can identify potential problems more easily and understand the significance of each section. With a comprehensive guide, you’ll be better equipped to manage your refrigerator and maximize its lifespan.

Whether you are a new owner or have been using your appliance for years, gaining insight into its structure can enhance your experience. Recognizing how different features interact will enable you to utilize your refrigerator more effectively. Let’s delve into the essential components and explore their functionalities to elevate your understanding and maintenance skills.

Understanding the LFXS24623S Components

In any complex appliance, the individual elements play a crucial role in ensuring smooth operation and functionality. Each component contributes to the overall performance and reliability, making it essential to understand how they interact and function together.

Here are the key elements found in this particular model:

- Refrigeration System: This includes the compressor, evaporator, and condenser, which work together to keep food at optimal temperatures.

- Cooling Mechanisms: These components ensure even temperature distribution throughout the unit, preventing hot spots.

- Control Board: This acts as the brain of the unit, managing various functions and settings based on user input and sensor feedback.

- Water Dispenser System: Comprising the water inlet valve and filters, this setup allows for clean water access and ice production.

- Lighting: LED lights are incorporated for energy efficiency and better visibility inside the appliance.

Understanding these components not only helps in effective troubleshooting but also aids in making informed decisions regarding maintenance and repairs.

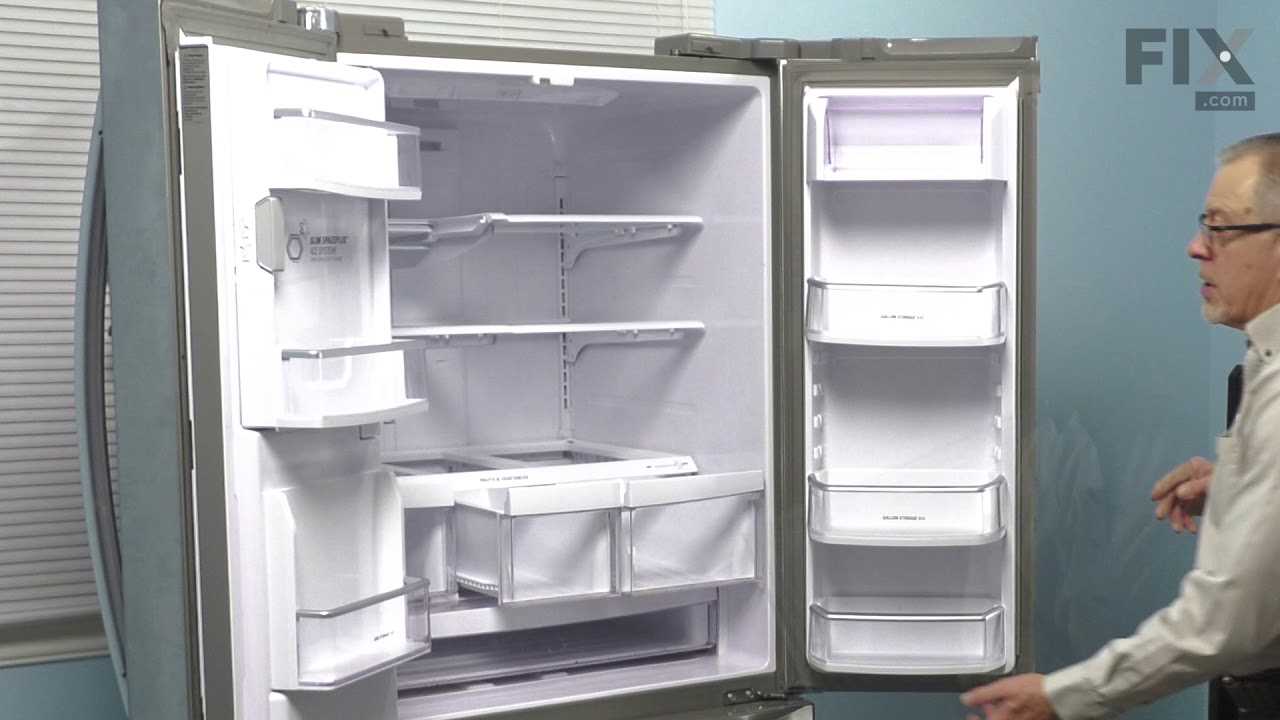

Identifying Key Refrigerator Parts

Understanding the essential components of a cooling unit is crucial for effective maintenance and troubleshooting. Each element plays a significant role in ensuring optimal performance and longevity. By familiarizing oneself with these fundamental elements, users can enhance their ability to identify issues and carry out necessary repairs.

Compressor: This vital component is responsible for circulating refrigerant throughout the system. It compresses the refrigerant, raising its pressure and temperature, allowing it to flow and absorb heat from the interior.

Evaporator Coils: Located inside the appliance, these coils are where the refrigerant absorbs heat, resulting in a drop in temperature. Proper functioning of the evaporator coils is essential for maintaining the desired cool environment.

Condenser Coils: Found on the back or bottom of the appliance, these coils release heat absorbed by the refrigerant. Ensuring they remain clean and free of debris is vital for efficient operation.

Thermostat: This control device regulates the temperature within the cooling unit. It monitors the internal conditions and adjusts the compressor’s operation accordingly to maintain the set temperature.

Door Seals: Often overlooked, these seals are essential for preventing warm air from entering the cooling space. Damaged or worn seals can lead to inefficiency and increased energy consumption.

Recognizing and understanding these critical elements enables users to effectively maintain their cooling appliances and address potential issues before they escalate.

Exploring the Cooling System Layout

The cooling mechanism of a refrigerator plays a crucial role in maintaining optimal temperatures for food preservation. Understanding the configuration of this system can provide insights into its efficiency and functionality. By examining the various components involved, one can appreciate how they work together to regulate temperature and enhance overall performance.

Key Components of the Cooling System

- Compressor: This device compresses refrigerant gas, increasing its pressure and temperature.

- Condenser: Located on the back or bottom, it dissipates heat from the refrigerant, allowing it to transition into a liquid state.

- Expansion Valve: This component regulates the flow of refrigerant into the evaporator, facilitating a drop in pressure.

- Evaporator: This unit absorbs heat from the interior, cooling the air within the appliance.

How the Cooling System Works

- The compressor circulates the refrigerant through the system.

- As the refrigerant moves to the condenser, it releases heat, turning into a liquid.

- The expansion valve reduces the pressure of the refrigerant, allowing it to enter the evaporator.

- In the evaporator, the refrigerant absorbs heat from the interior, thus cooling the air.

Functions of the Ice Maker Assembly

The ice maker assembly plays a crucial role in providing a convenient source of frozen water for various uses, enhancing the overall functionality of the appliance. Understanding its operations can help users appreciate its importance in daily tasks.

Here are the primary functions of the ice maker:

- Water Filtration: The assembly typically includes a filtration system that ensures the water used for ice production is clean and free from impurities.

- Ice Production: This component is responsible for freezing water into ice cubes, which are then stored for use.

- Automated Dispensing: Many ice makers are designed to automatically dispense ice into a designated compartment, making it easily accessible.

- Temperature Regulation: The assembly maintains the optimal temperature to ensure that ice forms properly and remains frozen until needed.

- Self-Cleaning Feature: Some models have a self-cleaning mechanism that helps maintain hygiene by removing any built-up residue or mold.

In summary, the ice maker assembly is essential for ensuring a consistent supply of ice, enhancing the user experience by combining efficiency and convenience in everyday use.

Examining the Door Seal Mechanism

The door seal is a crucial component in maintaining the efficiency of a refrigeration unit. This mechanism plays a significant role in preventing the escape of cold air and the ingress of warm air, thereby ensuring optimal performance and energy efficiency. Understanding how this mechanism operates can aid in troubleshooting and maintaining the appliance effectively.

Functionality of the Door Seal

The door seal functions by creating a barrier between the internal environment and the external surroundings. Here are its key functions:

- Energy Efficiency: By minimizing temperature fluctuations, it helps reduce energy consumption.

- Preservation of Food Quality: A well-functioning seal keeps the internal temperature stable, preserving food freshness.

- Reduction of Moisture: It prevents excess humidity from entering, which can lead to ice buildup.

Common Issues with Door Seals

Over time, door seals may experience wear and tear. Some common issues include:

- Cracks or Tears: Physical damage can compromise the seal’s integrity.

- Loss of Adhesion: The adhesive can weaken, leading to gaps.

- Deformation: Exposure to extreme temperatures can cause the material to warp.

Regular inspection and maintenance of the door seal mechanism can significantly enhance the appliance’s overall functionality and longevity.

Role of the Control Board

The control board serves as the central nervous system of the appliance, orchestrating its various functions and ensuring smooth operation. It is responsible for managing the communication between different components, monitoring performance, and executing commands from user inputs. This pivotal element plays a crucial role in maintaining efficiency and reliability.

Functions and Responsibilities

Among its key duties, the control board regulates temperature settings, initiates cooling cycles, and oversees defrost functions. It processes signals from sensors and makes real-time adjustments to optimize performance. Additionally, it safeguards the system by detecting anomalies and activating alerts, which helps prevent potential malfunctions.

Impact on Appliance Performance

A well-functioning control board enhances the overall effectiveness of the appliance. Its ability to adapt to changing conditions ensures consistent performance, contributing to energy savings and prolonged lifespan. When the control board operates optimally, users experience improved functionality and reduced maintenance needs, highlighting its importance in daily usage.

Overview of the Water Filter System

The water filtration mechanism in refrigerators plays a crucial role in providing clean and safe drinking water. This system effectively removes impurities and contaminants, ensuring that the water dispensed is both fresh and healthy. Understanding how this system functions is essential for proper maintenance and optimal performance.

This filtration setup generally consists of several key components:

- Filter Cartridge: The primary element that traps harmful substances, providing clean water.

- Water Inlet: The entry point for water into the filtration unit.

- Water Reservoir: A storage area that holds filtered water before it is dispensed.

- Dispensing Mechanism: The system that allows users to access the filtered water easily.

Regular replacement of the filter cartridge is vital to maintain the efficiency of this system. Manufacturers often recommend changing the cartridge every six months, depending on usage and water quality. This practice not only ensures the quality of drinking water but also prolongs the lifespan of the entire filtration system.

In conclusion, understanding the water filtration system’s components and their functions is essential for users. Proper maintenance and timely replacements can significantly enhance the quality of water provided by the refrigerator.

Understanding the LED Lighting Setup

The illumination system in modern appliances plays a vital role in enhancing visibility and providing functional lighting. By integrating energy-efficient light sources, manufacturers can create a pleasant environment while minimizing energy consumption. Understanding the arrangement and functionality of this lighting setup can significantly enhance user experience and aid in troubleshooting potential issues.

The LED lighting is designed to offer longevity and efficiency, contributing to the overall performance of the appliance. Below is a brief overview of the essential components and their roles in the lighting setup:

| Component | Description |

|---|---|

| LED Bulb | The primary source of light, providing brightness while using less energy compared to traditional bulbs. |

| Light Diffuser | A component that helps spread light evenly, reducing glare and enhancing visual comfort. |

| Control Circuit | Manages the power supply to the LED bulb, ensuring consistent performance and functionality. |

| Heat Sink | A part that dissipates heat generated by the LED, preventing overheating and extending the lifespan of the light source. |

By familiarizing oneself with these components, users can better understand the lighting setup and how to maintain its efficiency, leading to a more effective and enjoyable appliance operation.

Components of the Temperature Sensors

Temperature sensors play a crucial role in maintaining the optimal functioning of refrigeration units. Understanding the various elements that comprise these sensors is essential for diagnosing issues and ensuring accurate temperature readings. The components work together to monitor and regulate the temperature inside the appliance, contributing to its overall efficiency and performance.

Main Components

- Sensing Element: This is the core component responsible for detecting temperature changes. It converts thermal energy into a measurable signal.

- Transmitter: This part transmits the signal generated by the sensing element to the control system for further analysis.

- Protective Housing: Encloses the sensing element and transmitter, shielding them from environmental factors that could affect their performance.

- Wiring: Connects the components, allowing for the transfer of electrical signals necessary for the sensor’s operation.

Additional Elements

- Calibration Mechanism: Ensures that the sensor provides accurate readings by adjusting the output according to known standards.

- Display Unit: Often included in modern sensors to show real-time temperature data for user convenience.

- Power Source: Supplies energy to the sensor components, which is vital for their functioning.

Each of these components plays a vital role in ensuring that temperature sensors operate efficiently and effectively, providing accurate data that is crucial for the proper functioning of refrigeration systems.

Details on the Compressor Unit

The compressor unit serves as a crucial component in refrigeration systems, playing an essential role in maintaining optimal temperature levels. Its primary function revolves around circulating refrigerant throughout the system, ensuring effective cooling performance.

This unit typically consists of various integral parts that work in harmony to achieve efficient operation. Understanding these components can enhance maintenance practices and prolong the lifespan of the appliance.

- Motor: Powers the compressor, facilitating the movement of refrigerant.

- Compressor Housing: Encloses the internal mechanisms and provides structural support.

- Refrigerant Inlet and Outlet: Pathways for the refrigerant to enter and exit the compressor.

- Valves: Control the flow of refrigerant, ensuring proper circulation during the cooling cycle.

- Electrical Connections: Facilitate power supply to the motor, enabling operation.

Regular inspection and maintenance of the compressor unit are vital for ensuring its efficiency and preventing potential issues. Keeping the unit clean and checking for signs of wear can help maintain optimal performance.

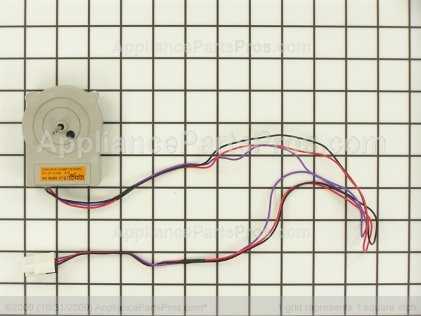

Examining the Fan Assembly Features

The fan assembly plays a crucial role in maintaining optimal operating conditions within the appliance. This section delves into the key characteristics and functionalities of this essential component, highlighting its design and operational aspects that contribute to effective airflow management.

Key Characteristics

- Design: The assembly is engineered for efficient airflow, facilitating proper cooling of internal components.

- Durability: Crafted from robust materials, it ensures long-lasting performance even in demanding environments.

- Noise Levels: Advanced engineering minimizes operational noise, contributing to a quieter user experience.

Operational Functionality

- Air Circulation: The assembly promotes effective circulation, preventing overheating and maintaining consistent temperatures.

- Energy Efficiency: Designed to consume minimal power while delivering optimal performance.

- Maintenance: Easily accessible for cleaning and servicing, ensuring prolonged lifespan and reliable operation.

Evaluating the Defrost System Parts

Understanding the components of the defrost mechanism is crucial for maintaining optimal performance and efficiency in refrigeration appliances. This evaluation focuses on the key elements involved in the process, ensuring that the system functions effectively to prevent frost buildup and maintain appropriate temperatures. Identifying these elements can aid in troubleshooting and enhance the overall reliability of the cooling unit.

Key Components of the Defrost Mechanism

The defrost mechanism consists of several integral components, each playing a vital role in the overall function. Here is a breakdown of these essential elements:

| Component | Description |

|---|---|

| Defrost Heater | Heats the evaporator coils to melt any accumulated frost, facilitating efficient operation. |

| Defrost Timer | Controls the timing of the defrost cycles, ensuring that they occur at appropriate intervals. |

| Defrost Thermostat | Monitors the temperature of the evaporator coils, signaling when to initiate or terminate the defrost process. |

| Drain Pan | Collects and directs melted water away from the evaporator to prevent flooding. |

Assessing System Functionality

Regular assessment of the defrost components is essential to ensure they are functioning properly. Routine checks can help identify issues such as inadequate heating or malfunctioning timers, allowing for timely repairs. By monitoring these elements, users can enhance the longevity and efficiency of their refrigeration system.

Maintenance Tips for Major Components

Ensuring the longevity and efficiency of essential appliances involves regular attention and care. By understanding the key elements and implementing straightforward maintenance practices, users can prevent potential issues and enhance overall performance. Below are some effective strategies to keep the main components in optimal condition.

| Component | Maintenance Tip |

|---|---|

| Cooling System | Regularly clean the condenser coils to improve efficiency and prevent overheating. |

| Doors and Seals | Inspect and clean door seals to ensure a tight closure, preventing energy loss. |

| Water Filter | Replace the water filter as recommended to maintain clean water and ice quality. |

| Control Panel | Keep the control panel free of dust and moisture to ensure responsive operation. |

| Interior Surfaces | Regularly clean the interior with mild soap and warm water to prevent odor buildup. |