The intricate design of a premium coffee brewing apparatus ensures optimal performance and flavor extraction. Each element plays a critical role in the overall functionality, contributing to the machine’s ability to produce exquisite beverages. Understanding these individual components is essential for both enthusiasts and professionals alike.

From the heating systems that maintain precise temperatures to the pressure mechanisms that facilitate extraction, the complexity of these machines is evident. Familiarity with these mechanisms enhances maintenance and troubleshooting efforts, ensuring a seamless brewing experience. Knowledge of how each piece interacts within the system can significantly impact the quality of the final product.

Whether you are a seasoned barista or a coffee lover aiming to deepen your understanding, exploring the various elements involved in the operation of a sophisticated espresso machine opens doors to greater appreciation and expertise. Delving into the specifics of these components will empower users to achieve the best possible results in their coffee-making endeavors.

This section provides an overview of the essential elements that contribute to the functionality and performance of a premium espresso brewing device. Understanding these components is crucial for anyone looking to maintain, repair, or optimize their equipment for the perfect brew.

Essential Elements

- Boiler: A critical component that holds water and heats it to the optimal temperature for brewing.

- Pump: Responsible for generating the pressure needed to extract flavor from the coffee grounds.

- Group Head: The part where the coffee is brewed, ensuring even distribution of water over the grounds.

- Portafilter: A handle with a basket that holds the coffee grounds during extraction.

- Steam Wand: Used to froth milk for beverages like lattes and cappuccinos.

Additional Features

- Pressure Gauge: Displays the current pressure in the brewing system, aiding in optimal extraction.

- Water Reservoir: The container that supplies fresh water to the boiler.

- Temperature Control: A system that maintains the ideal brewing temperature, crucial for flavor extraction.

Understanding the Boiler System

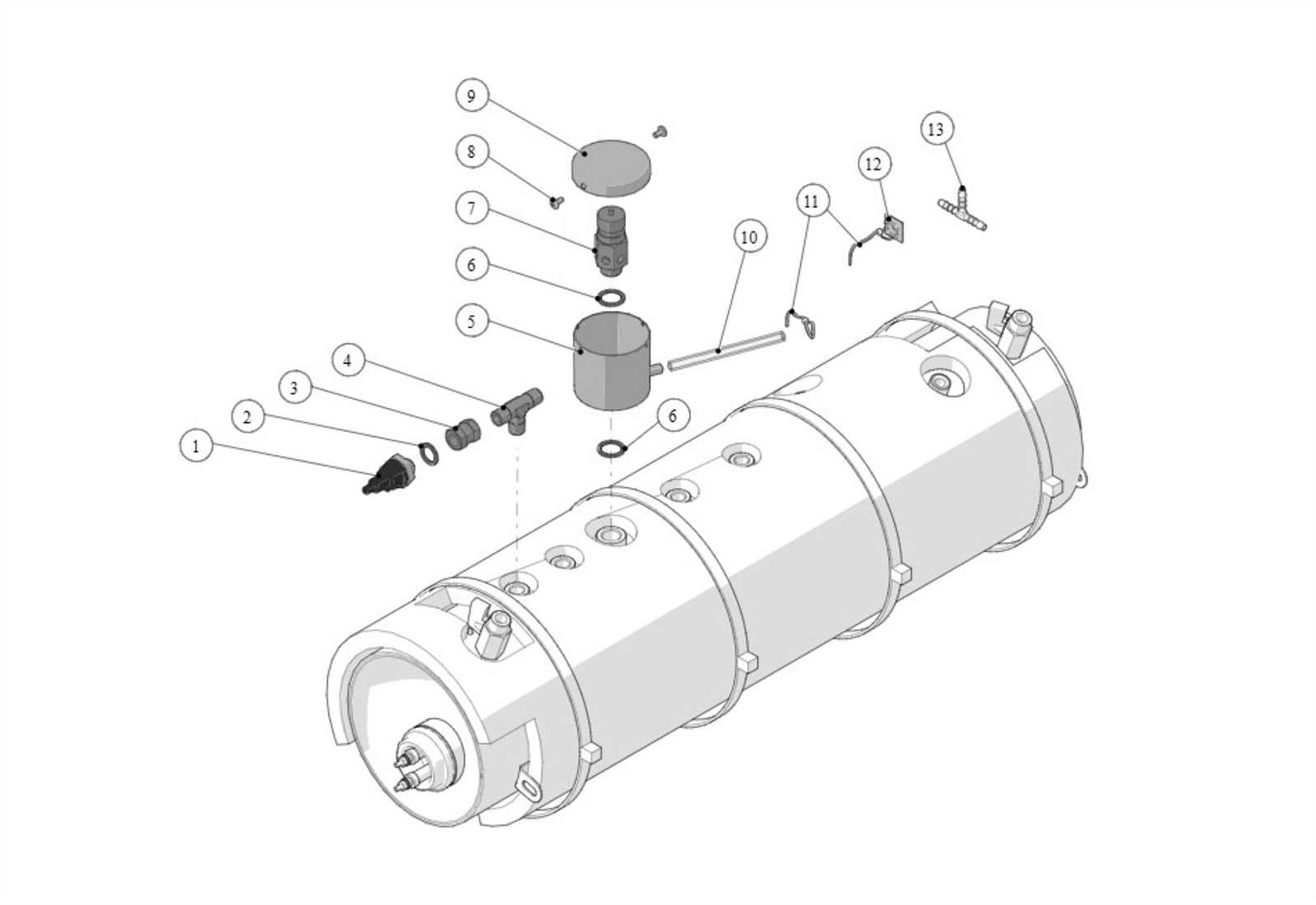

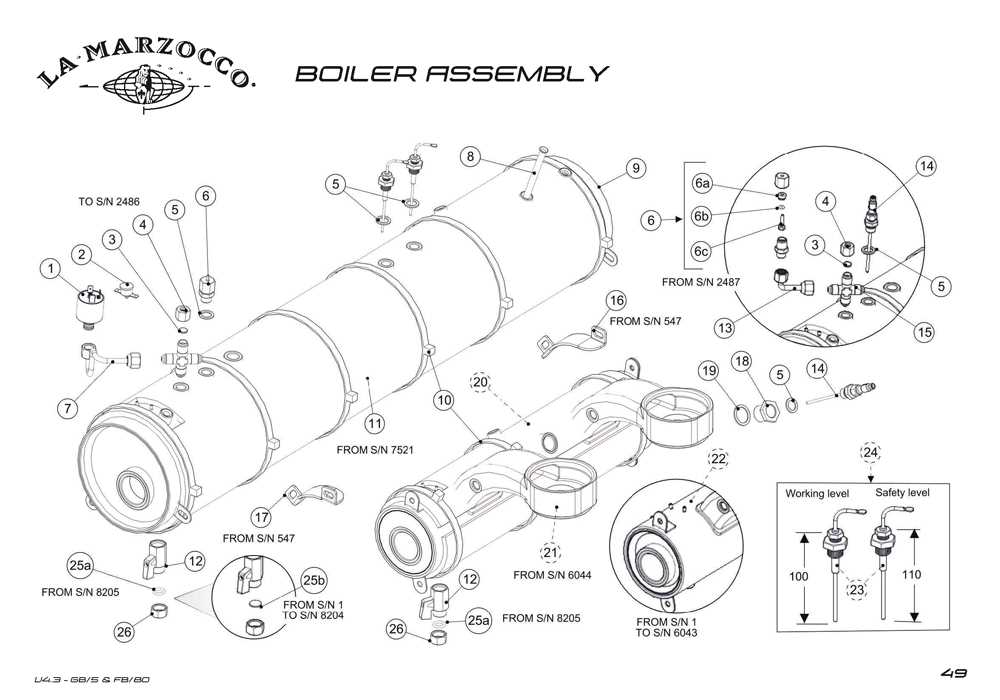

The boiler system is a crucial component in espresso machines, serving as the heart that generates and maintains the necessary temperature for brewing. This assembly consists of various elements working in harmony to ensure that water is heated efficiently and distributed appropriately throughout the machine. A well-functioning boiler system is vital for achieving consistent quality in every cup.

Components of the Boiler Assembly

Key elements of the boiler assembly include the heating element, water inlet, and pressure relief valve. The heating element is responsible for elevating the temperature of the water to the desired level, while the water inlet controls the flow of water into the system. The pressure relief valve ensures that excess pressure does not build up, safeguarding the overall operation and longevity of the unit.

Importance of Temperature Control

Temperature regulation within the boiler is essential for optimal extraction of coffee flavors. Maintaining the right temperature allows for the proper dissolution of oils and compounds in coffee grounds. A reliable temperature control system helps prevent overheating and under-extraction, which can compromise the quality of the beverage. Understanding these principles is fundamental for anyone seeking to master the art of espresso making.

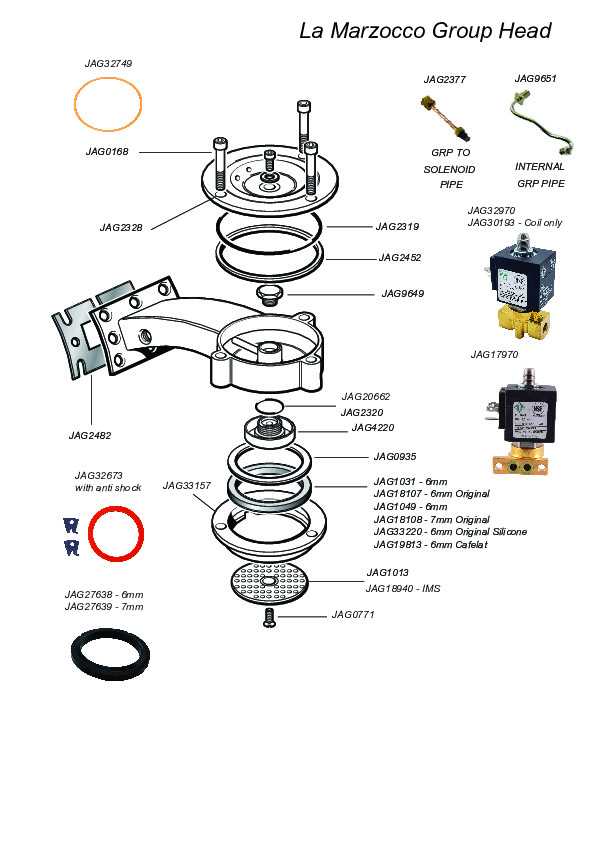

Group Head and Portafilter Details

The group head and portafilter assembly are crucial components in the brewing process, ensuring optimal extraction and flavor development in espresso. These elements work in harmony to deliver the perfect shot, highlighting the importance of their design and functionality.

The group head serves as the interface between the machine and the brewing basket, playing a pivotal role in maintaining temperature stability and even water distribution. This is essential for achieving a consistent and rich extraction, which is vital for a high-quality beverage.

On the other hand, the portafilter holds the ground coffee and is responsible for channeling water through the grounds during extraction. The ergonomic design of the portafilter enhances user experience, making it easy to attach and detach from the machine while ensuring a secure fit to prevent leaks.

Together, these components not only contribute to the efficiency of the brewing process but also influence the overall aesthetic of the espresso machine. Regular maintenance and an understanding of their functionality can greatly enhance the longevity and performance of the equipment.

Exploring the Electrical System

The intricate electrical framework within sophisticated brewing machines is essential for their efficient operation. Understanding this system involves examining the various components that work harmoniously to ensure optimal performance. From the control mechanisms to the heating elements, each part plays a crucial role in achieving the desired brewing results.

Key Components and Their Functions

Central to the electrical setup are the various sensors and switches that monitor and regulate temperatures, pressure, and water flow. These components provide critical feedback to the machine, allowing for real-time adjustments to enhance brewing quality. Additionally, wiring and connectors ensure reliable communication between all elements, maintaining the stability of the entire system.

Safety and Maintenance Considerations

Regular inspection of the electrical components is vital to prevent potential malfunctions. Users should be aware of common issues such as wear and tear on wiring or degradation of connectors. Implementing preventive maintenance strategies can prolong the lifespan of the equipment and ensure a consistently high-quality coffee brewing experience.

Water Supply and Pump Mechanisms

The efficiency and functionality of espresso machines rely heavily on their water sourcing and pumping systems. These components work together to ensure that the brewing process is consistent and effective, providing the perfect cup every time. Understanding the intricacies of these mechanisms can help operators maintain optimal performance and troubleshoot issues as they arise.

Water Intake System

The water intake system serves as the initial point of entry for the liquid that is essential for brewing. This system typically includes a reservoir or a direct line connection, allowing for a steady flow of water. Filters may also be employed to remove impurities, ensuring that the water is clean and suitable for brewing. A well-designed intake system minimizes the risk of clogs and ensures an uninterrupted supply.

Pumping Mechanisms

Central to the operation of espresso machines are the pumping mechanisms, which create the pressure needed for extraction. These pumps are engineered to provide consistent pressure and flow rates, crucial for optimal brewing. Various types of pumps, such as rotary or vibratory, can be found in different models. Each type offers unique benefits in terms of noise levels, maintenance, and performance. Regular inspections and maintenance of these components are vital to prevent malfunctions and extend the lifespan of the machine.

Steam Wand Functionality Explained

The steam wand is a vital component in many espresso machines, designed to create frothy milk and steam for various beverages. Its operation combines the mechanics of heating water and air infusion, allowing for the transformation of liquid into a creamy texture. This feature is essential for baristas aiming to craft high-quality drinks, such as lattes and cappuccinos, showcasing the artistry of espresso preparation.

Mechanics of Operation

When engaged, the steam wand releases hot vapor generated by the machine’s boiler. This steam is then directed through a small nozzle, where it encounters the milk in a pitcher. The high temperature and pressure of the steam introduce air into the milk, creating microbubbles. This process not only heats the milk but also alters its consistency, resulting in a velvety foam that enhances the overall flavor and appearance of the final drink.

Maintenance Tips

To ensure optimal performance, regular cleaning and maintenance of the steam wand are crucial. After each use, it is important to purge any residual milk or foam by briefly releasing steam. This practice prevents clogs and ensures consistent functionality. Additionally, periodic deep cleaning with appropriate solutions can help maintain hygiene and prolong the lifespan of the steam wand, contributing to the quality of the beverages produced.

Thermal Stability Features

In the realm of espresso craftsmanship, maintaining consistent temperatures is crucial for achieving optimal extraction. The innovative engineering behind modern brewing equipment focuses on minimizing temperature fluctuations throughout the brewing process, ensuring that each cup produced meets the highest standards of quality.

Advanced Heating Systems play a pivotal role in achieving temperature consistency. These systems utilize state-of-the-art technology to quickly reach and maintain the desired brewing temperature, reducing waiting times and enhancing efficiency.

Thermal Insulation is another key aspect that contributes to thermal stability. By effectively minimizing heat loss, well-designed equipment can maintain the necessary temperature for longer periods, allowing baristas to produce high-quality beverages even during peak service hours.

Furthermore, precise temperature controls enable users to adjust settings according to their specific brewing requirements. This adaptability ensures that each shot of espresso is extracted at the ideal temperature, resulting in a balanced flavor profile that showcases the nuances of the coffee beans.

Ultimately, these features collectively enhance the overall brewing experience, empowering professionals to deliver exceptional coffee consistently.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your coffee machine. Regular attention to specific components and systems can greatly enhance performance and prevent potential issues down the line. Adopting a proactive maintenance routine will not only safeguard your investment but also improve the quality of your brews.

Regular Cleaning

Routine cleaning is fundamental to the longevity of your equipment. Be diligent in removing coffee grounds, residue, and oils that accumulate over time. Utilize appropriate cleaning solutions and follow the manufacturer’s guidelines for disassembling and cleaning various components. This practice prevents clogging and ensures consistent flavor profiles in every cup.

Check for Wear and Tear

Inspecting components regularly for signs of wear and tear can prevent costly repairs. Look for any abnormalities, such as leaks or unusual noises, which may indicate underlying issues. Addressing these concerns promptly can avert more significant malfunctions, ensuring your machine operates smoothly for years to come.

Common Issues and Troubleshooting

Every machine, especially those used in busy environments, can occasionally encounter technical difficulties. Understanding the typical problems and knowing how to address them efficiently is essential for maintaining smooth operation and preventing disruptions.

- Temperature Inconsistency: A frequent issue that can lead to poor performance. Ensure all heating elements are functioning properly, and check the thermostat settings regularly.

- Pressure Fluctuations: If you notice irregularities in pressure, inspect the water lines and valves for any blockages or leaks that might cause instability.

- Water Flow Issues: Slow or inconsistent water flow may be a sign of clogged filters or a malfunctioning pump. Cleaning or replacing these components can resolve the issue.

- Steam Wand Blockage: If the steam wand is not producing enough steam or is entirely blocked, disassemble and clean the nozzle and tube to remove any build-up.

- Electrical Problems: In case of power failures or unresponsive buttons, check the wiring

Ordering Replacement Parts Online

When it’s time to find replacement components for your equipment, the process can often seem complex. Fortunately, modern online stores offer a streamlined experience, ensuring that you can quickly locate the right items for repair or maintenance needs. This section will guide you through how to efficiently source and order components from online suppliers.

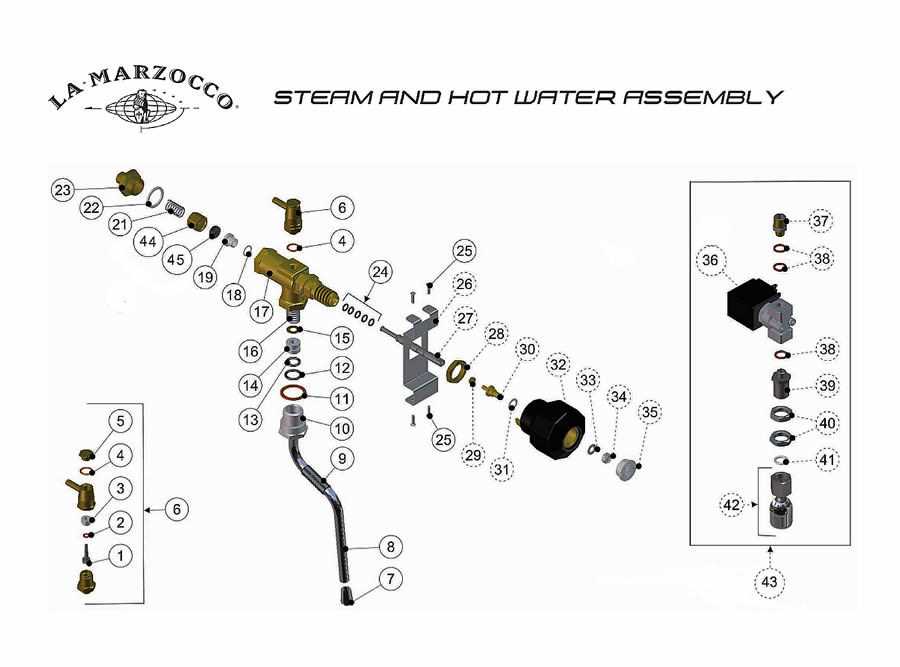

Step Description 1 Identify the exact component you need by referencing available manuals or service documentation. 2 Find reputable online retailers that specialize in providing the necessary equipment parts. 3 Compare pric Using the Parts Diagram Effectively

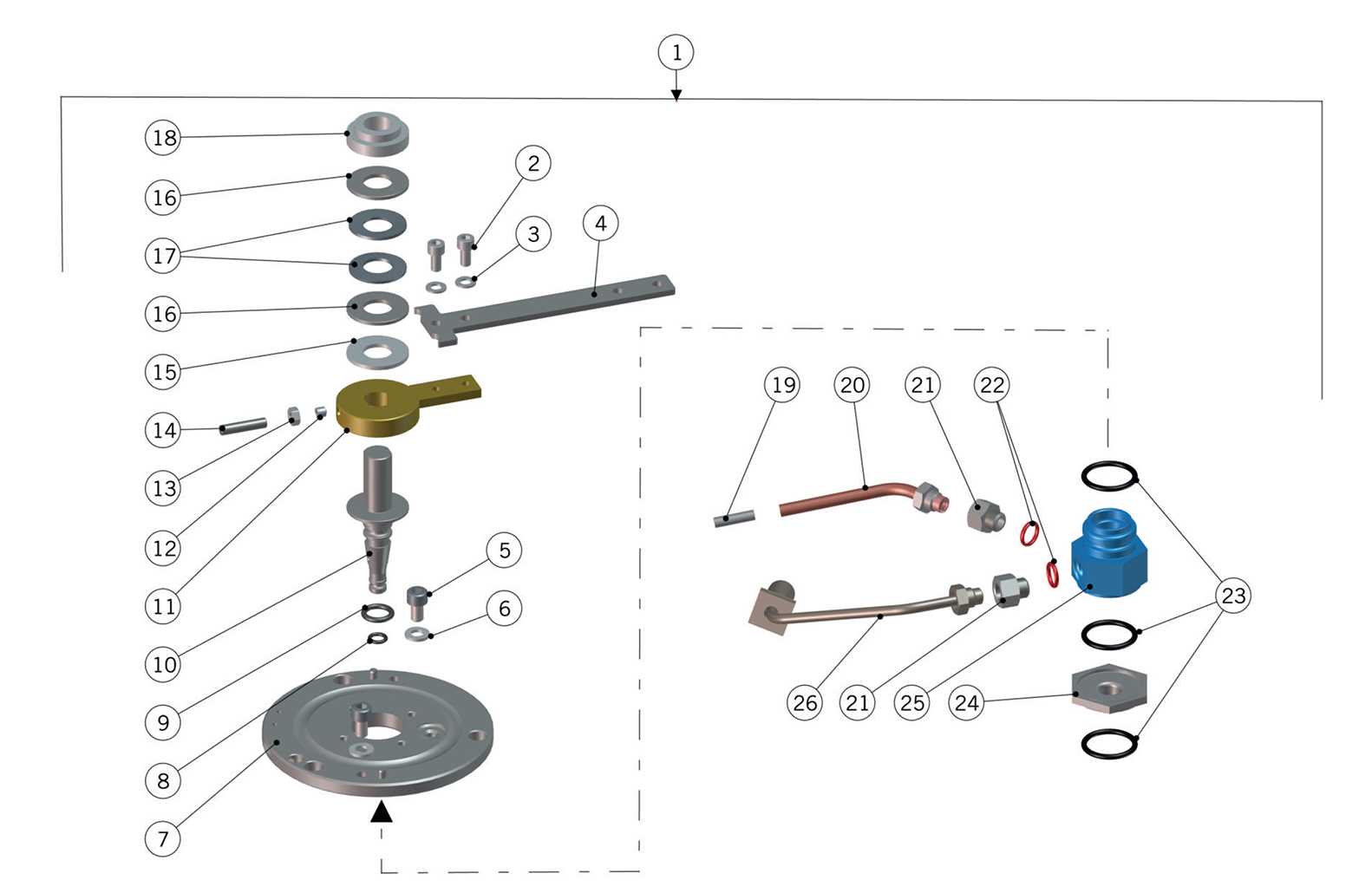

Understanding how to navigate technical illustrations is essential for maintenance and troubleshooting. These visual guides break down complex systems into their individual components, making it easier to identify specific elements and their connections. By focusing on the layout, users can quickly assess how different elements interact and pinpoint areas that may require attention or replacement.

One of the most valuable approaches is to familiarize yourself with the overall structure before diving into specific details. Knowing where each section is located within the schematic allows for more efficient problem-solving, whether you’re replacing a worn-out piece or conducting routine maintenance.