In the realm of mechanical engineering, the intricate interplay of various elements plays a pivotal role in the efficiency of systems. These components, often taken for granted, are essential for the seamless transfer of force and motion. By examining these intricate mechanisms, one can gain valuable insights into how they operate and contribute to overall functionality.

The examination of specific mechanisms reveals a complex arrangement of elements, each serving a distinct purpose. This understanding not only enhances our knowledge of mechanical systems but also aids in troubleshooting and improving their design. Familiarity with these components allows engineers and technicians to optimize performance and ensure reliability.

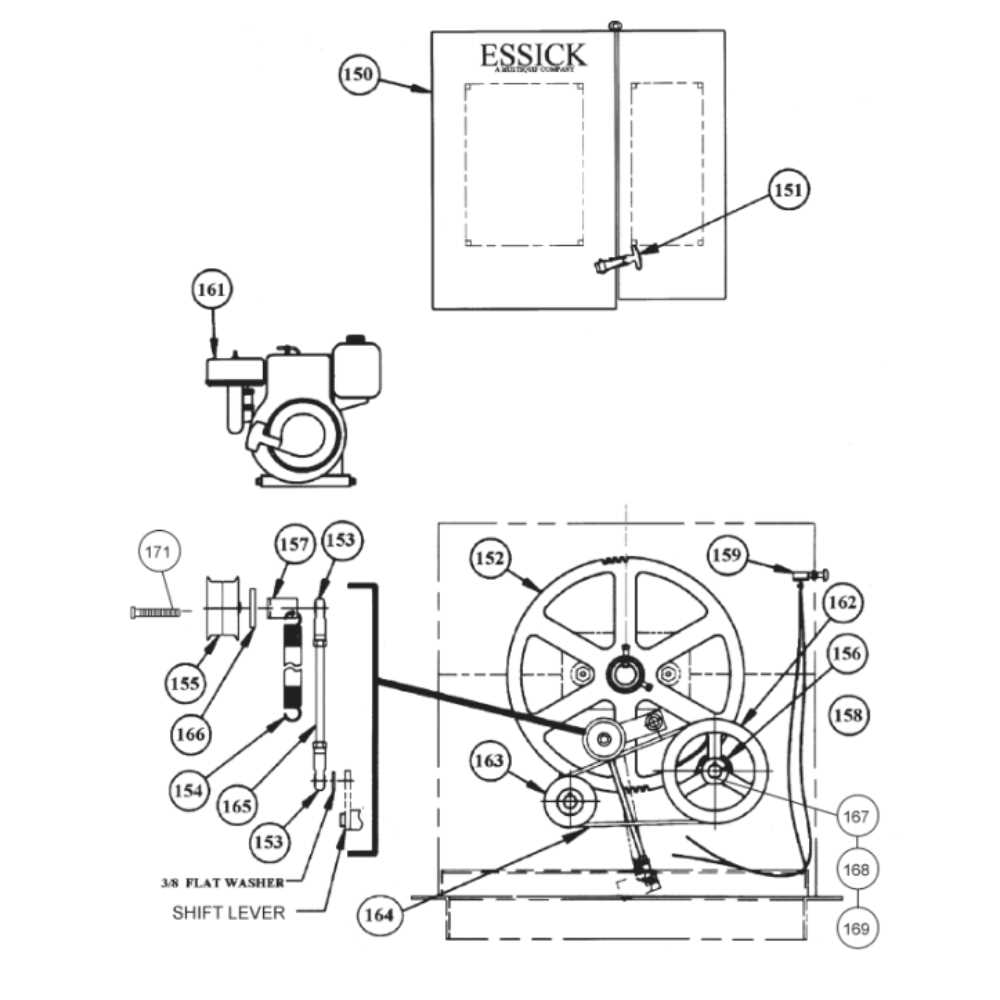

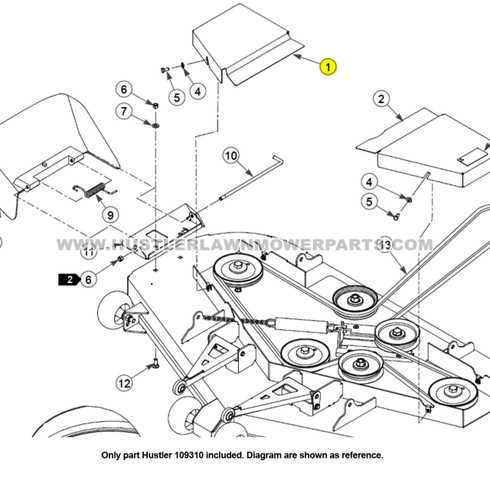

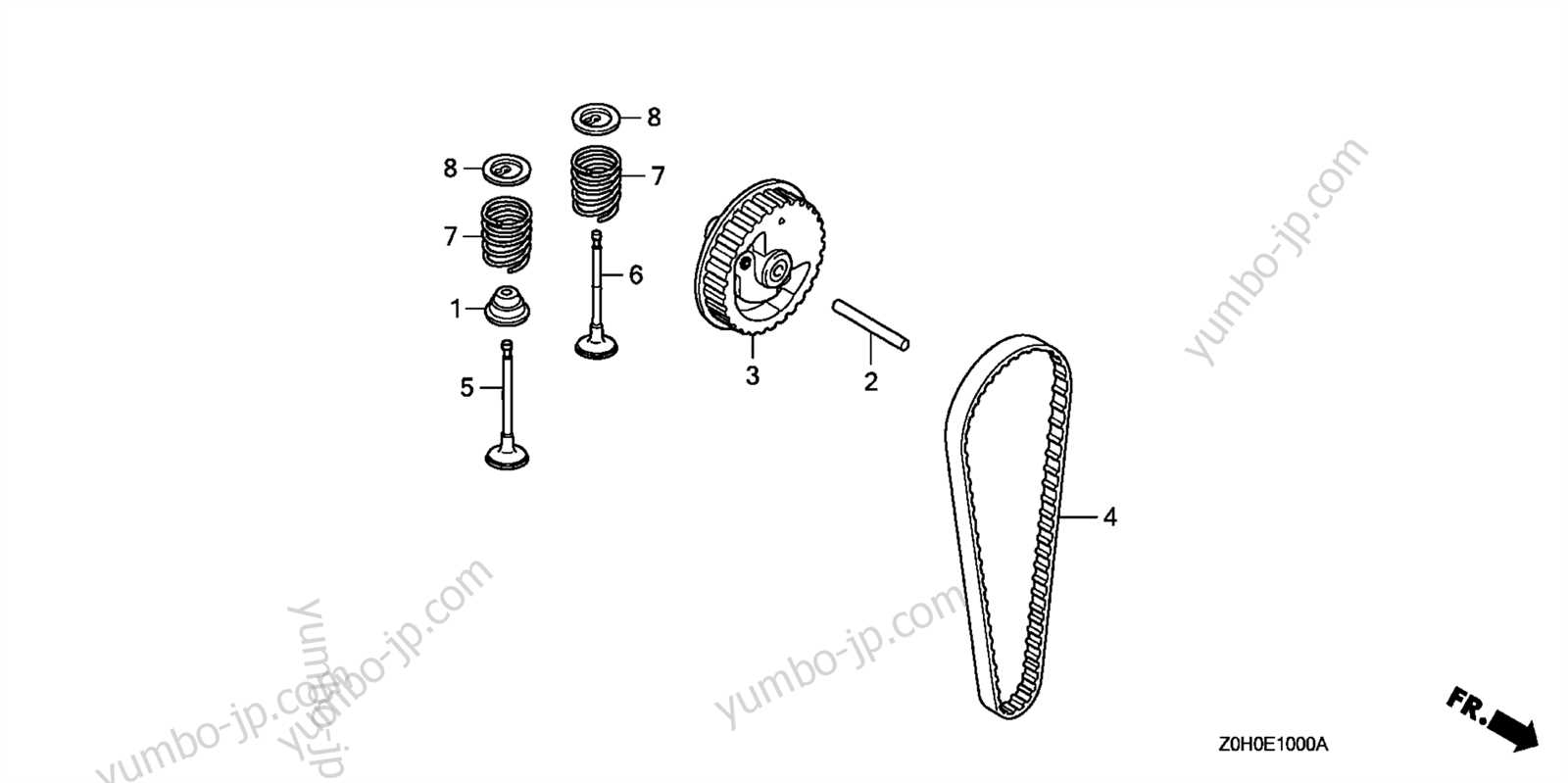

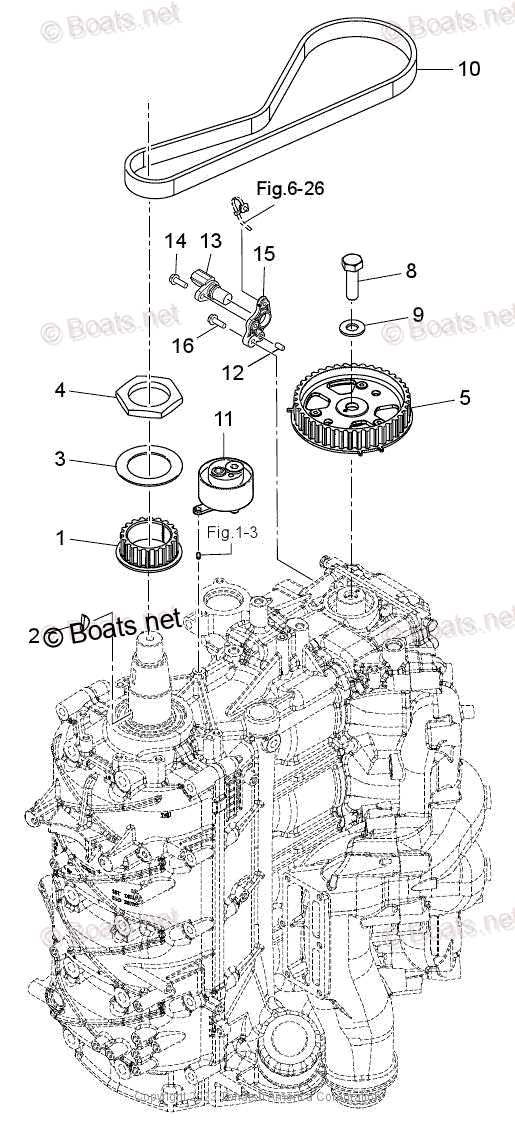

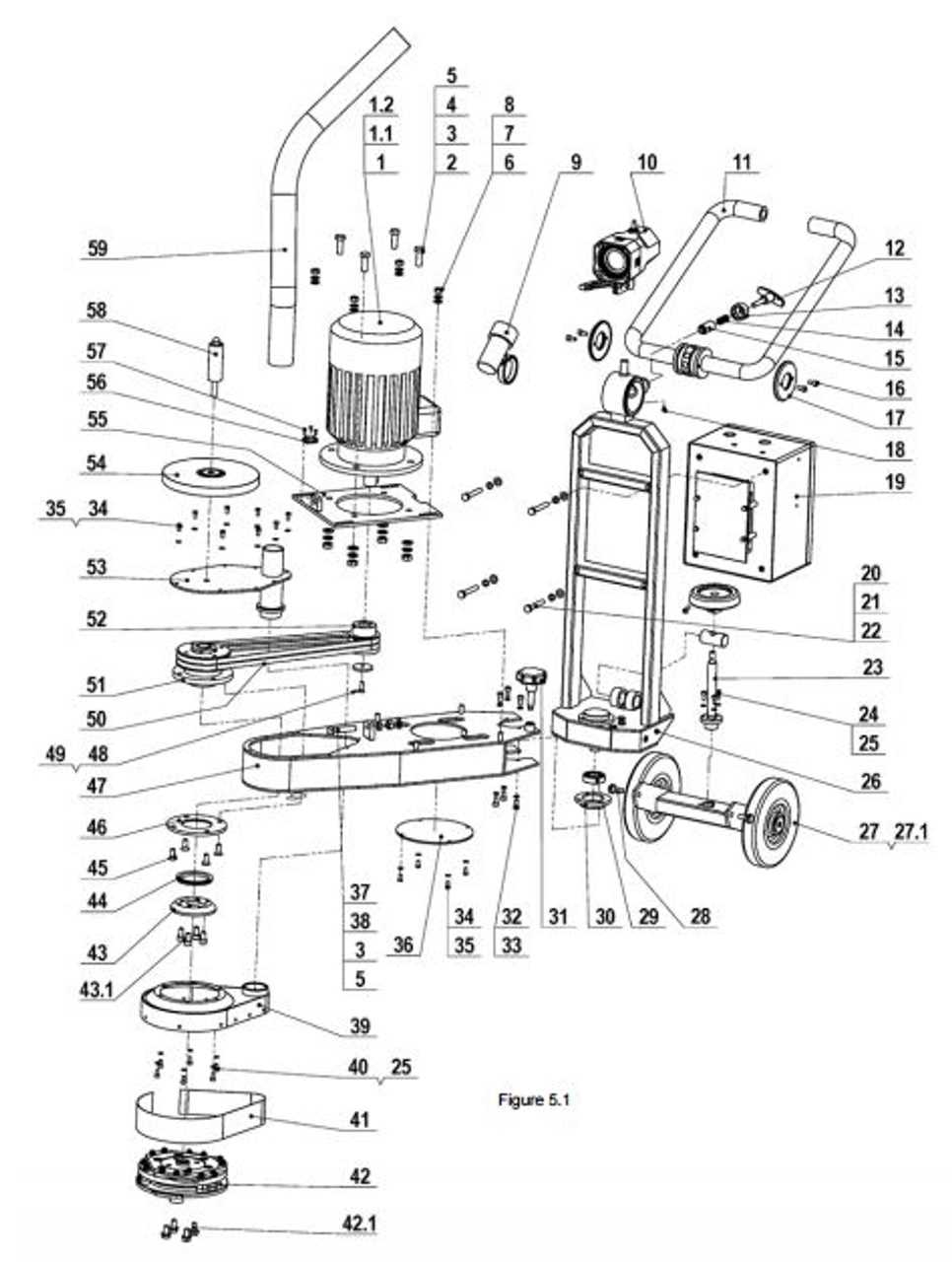

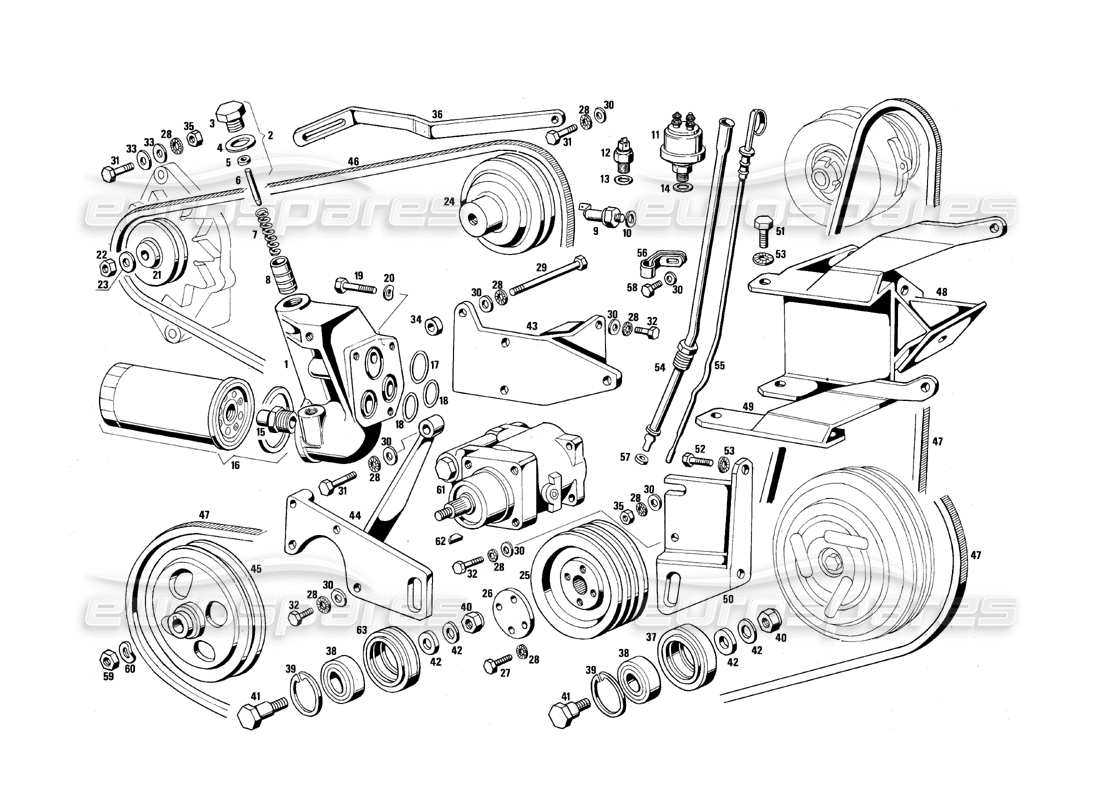

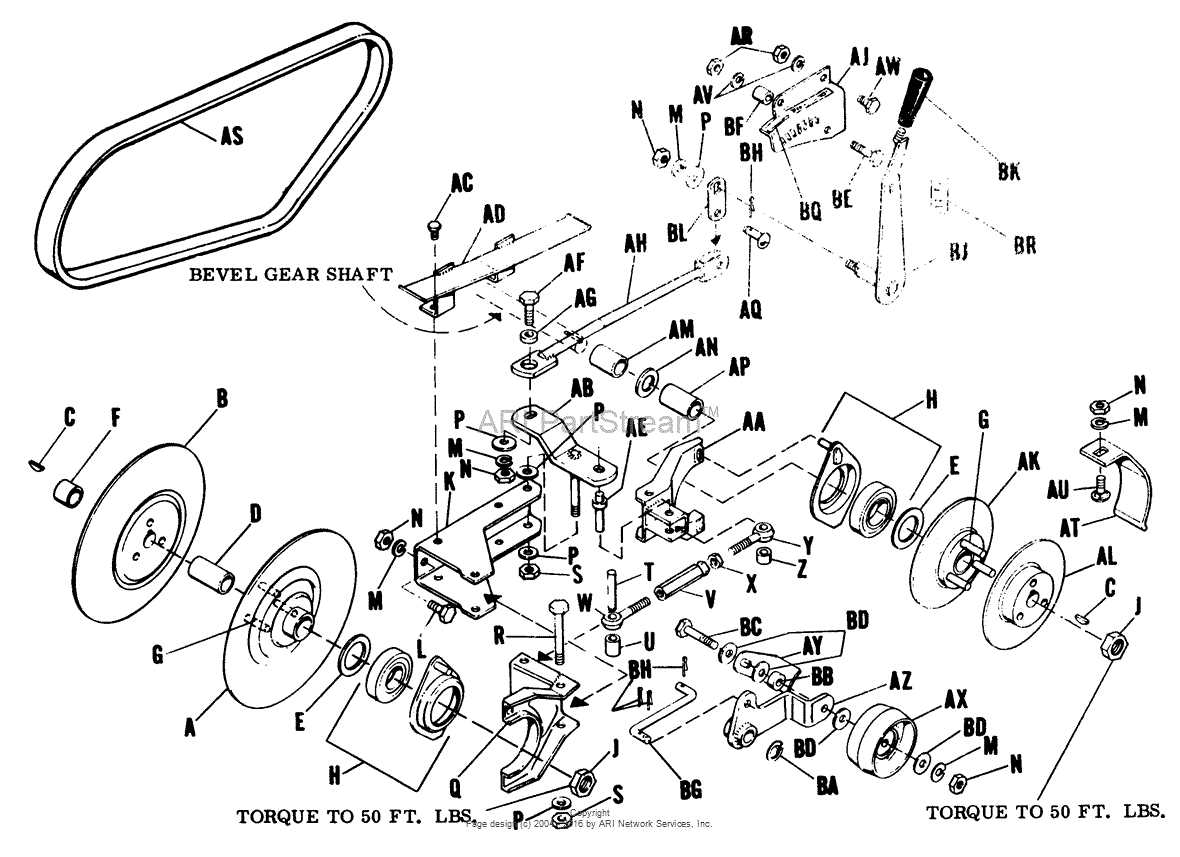

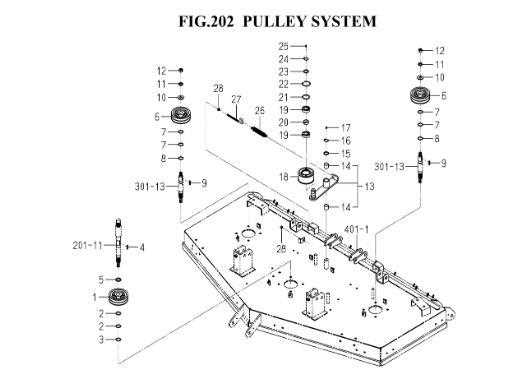

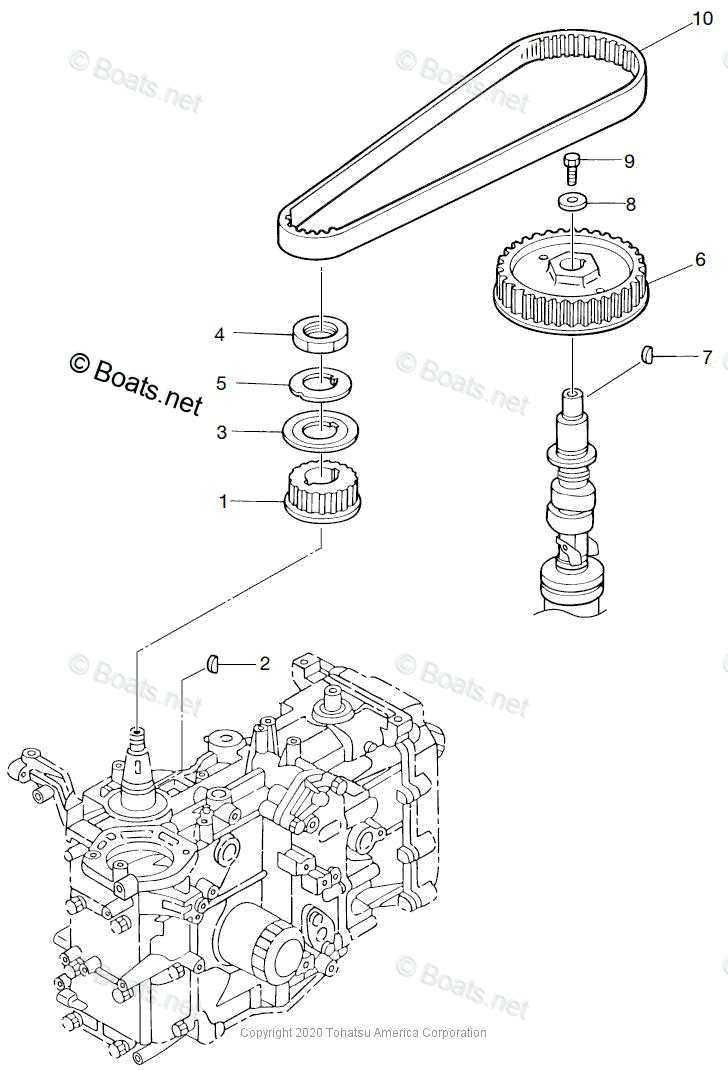

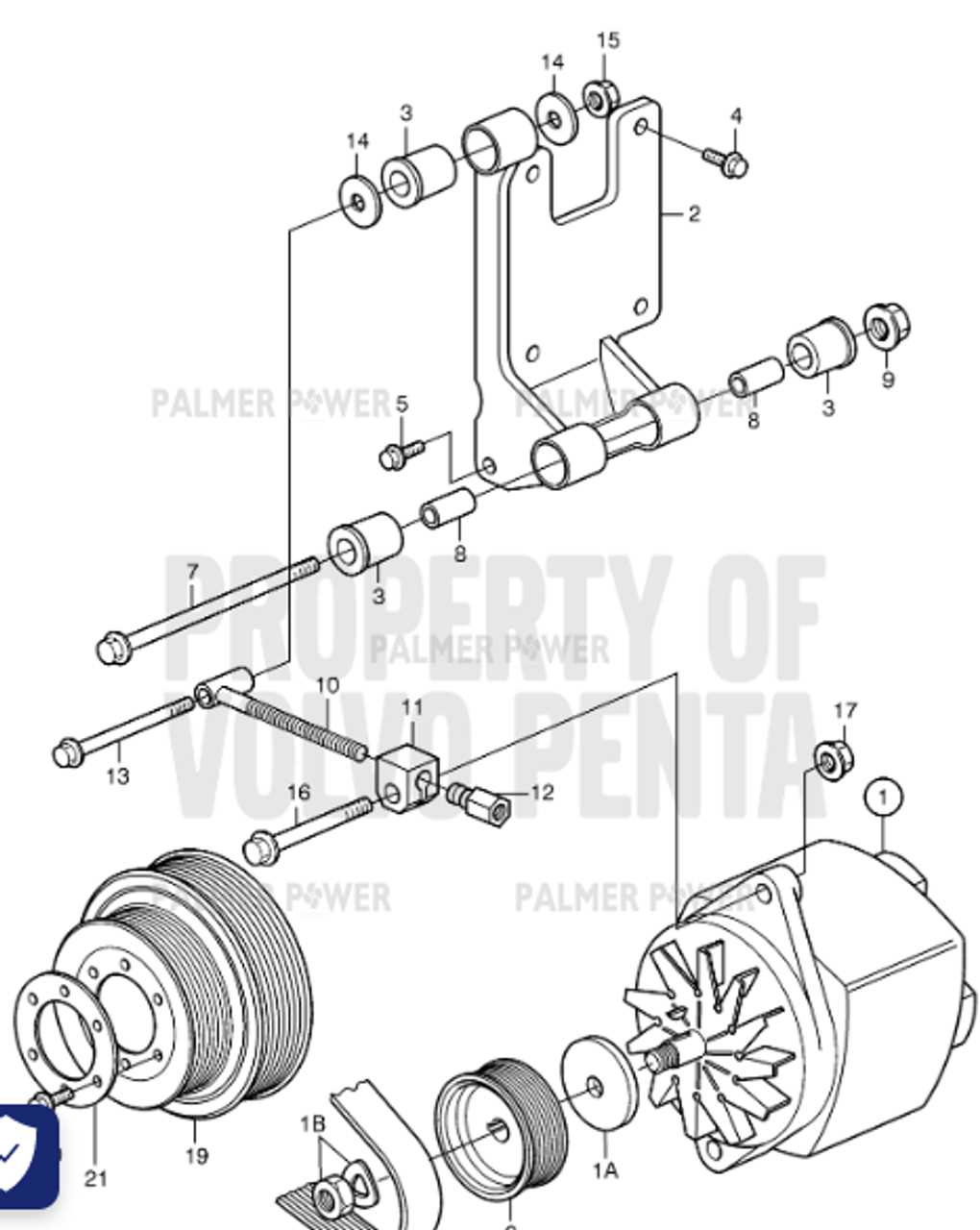

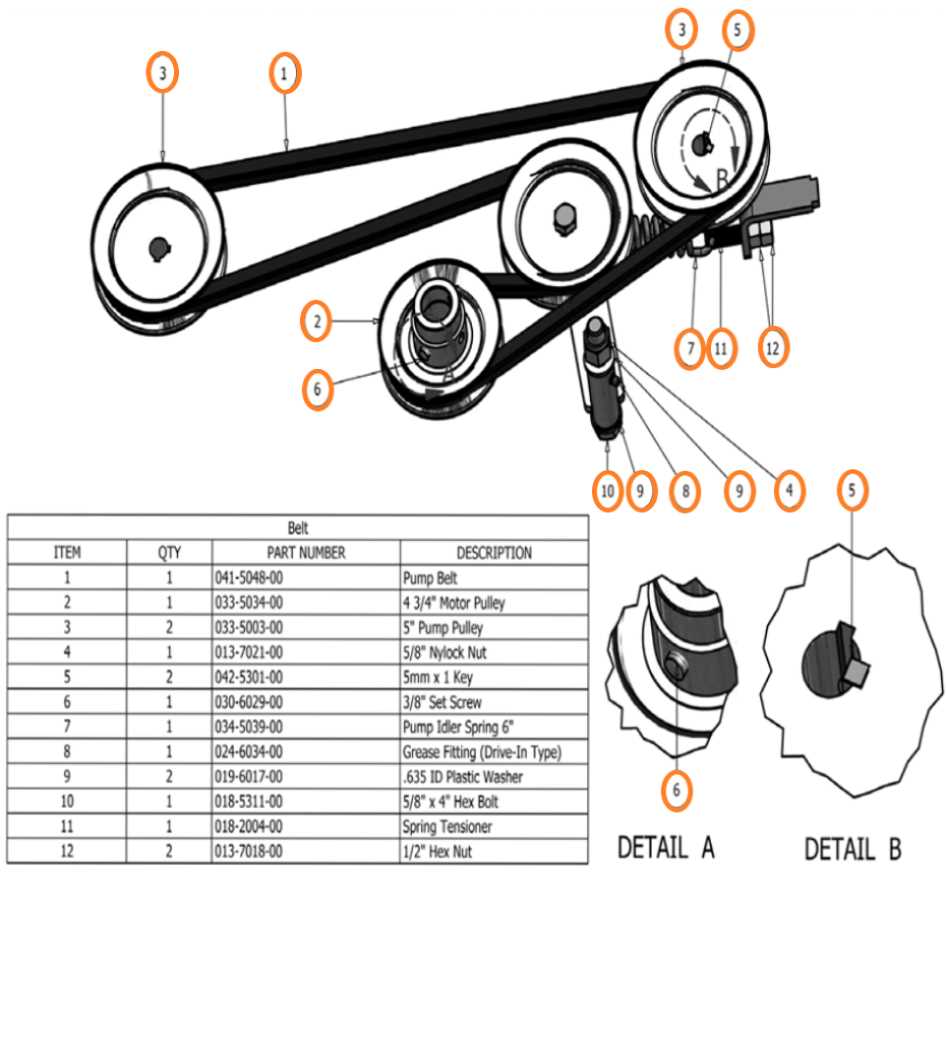

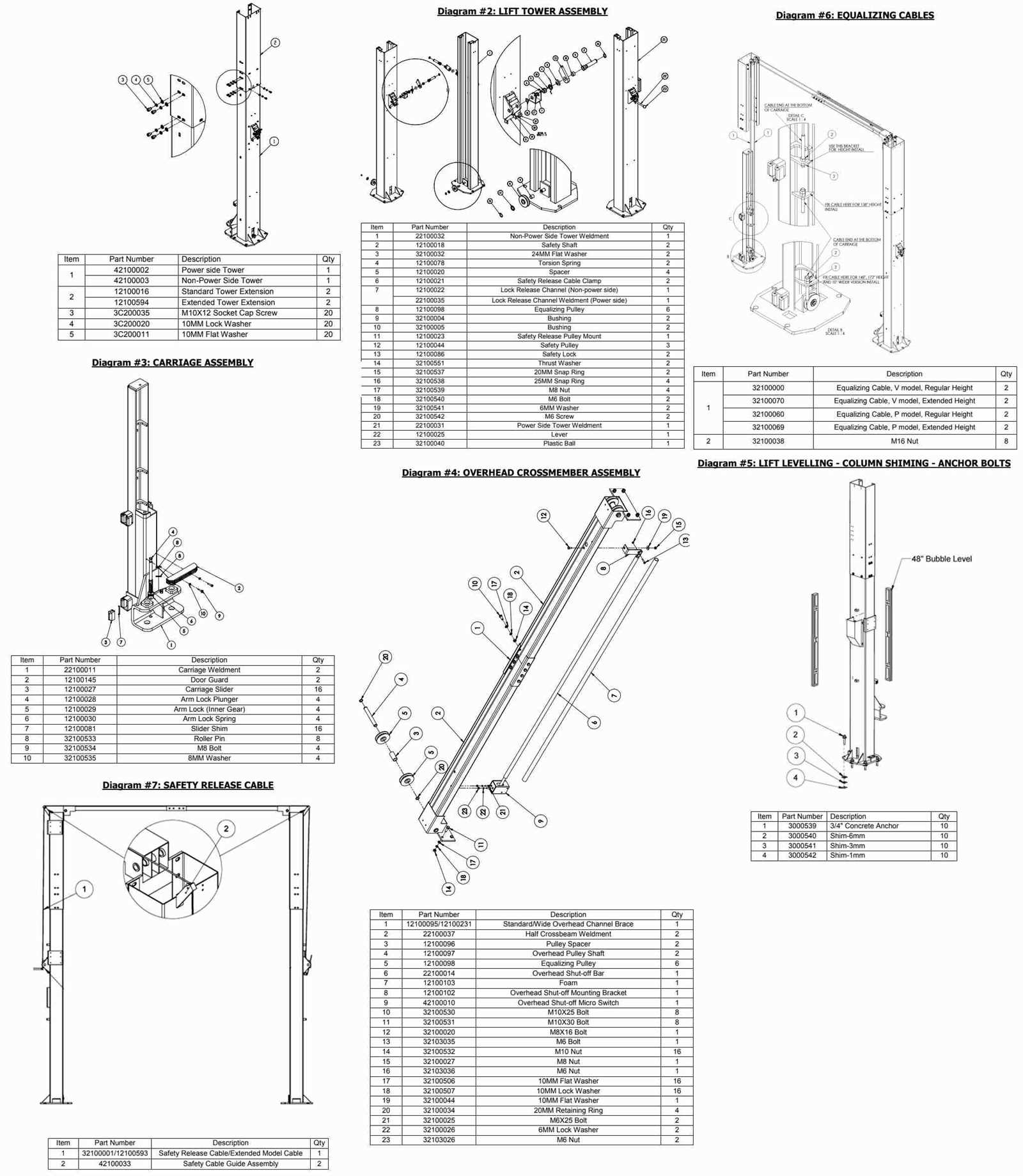

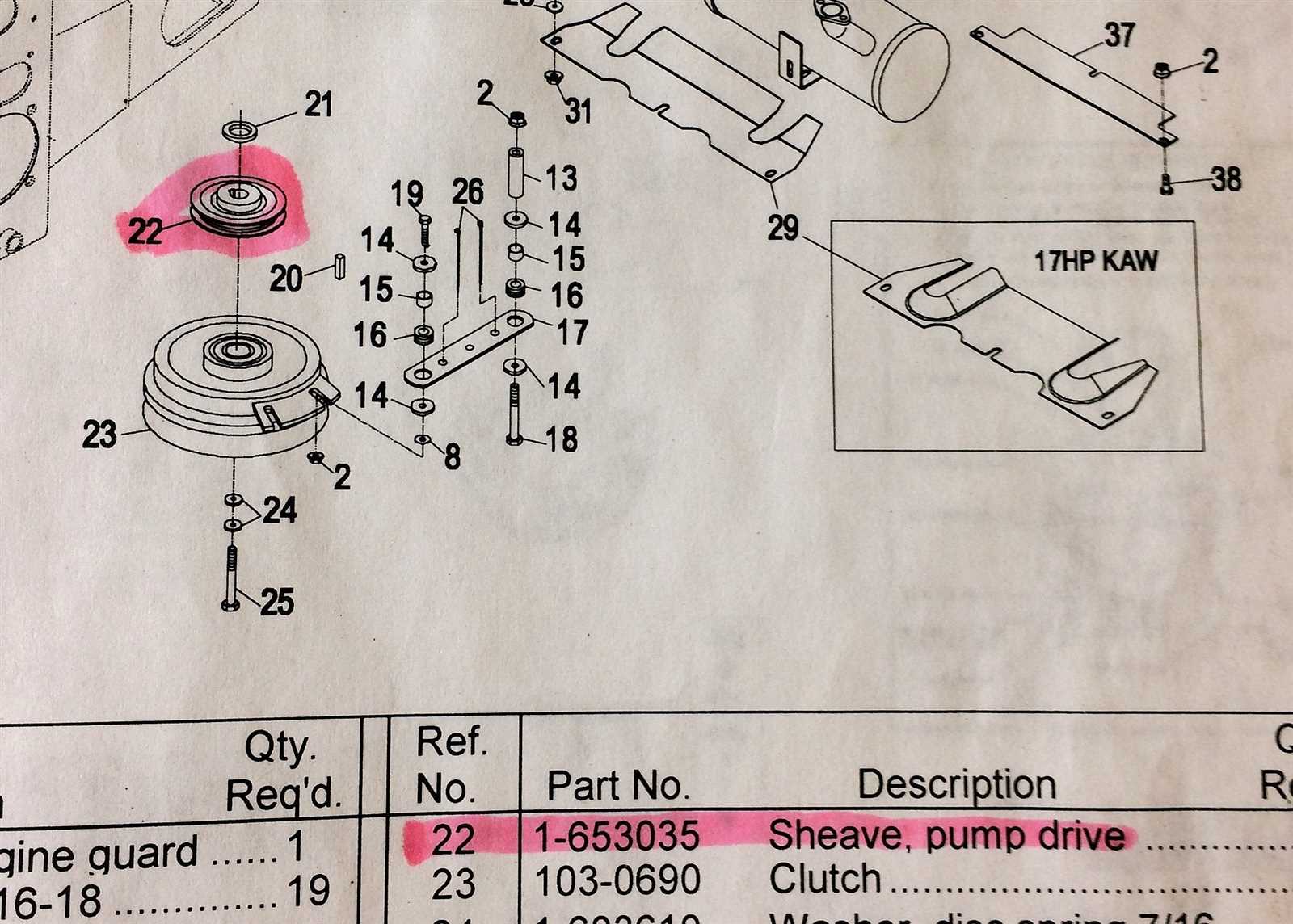

Visual representations of these configurations can greatly facilitate comprehension. By breaking down each segment and illustrating their relationships, one can appreciate the harmony within these systems. Such illustrations are invaluable tools for both education and practical application, serving as a bridge between theoretical concepts and real-world implementation.

Understanding Pulley Systems

This section explores the fundamental mechanics and applications of systems designed to lift and move heavy objects with ease. By leveraging the principles of force and movement, these setups transform challenging tasks into manageable activities, enhancing efficiency across various fields.

Basic Principles

At their core, these systems operate on the idea of distributing weight and minimizing effort. By utilizing ropes or belts, users can redirect force, making it simpler to elevate loads. The configuration of these systems can greatly influence the amount of effort required for lifting.

Applications in Daily Life

From construction sites to home garages, these setups are prevalent in many scenarios. They assist in lifting vehicles, moving equipment, and even in theatrical settings to manipulate stage elements. Understanding their function ultimately allows for improved safety and effectiveness in various tasks.

Components of a Pulley Mechanism

This section explores the essential elements that contribute to the functionality of a mechanical system designed to lift or move objects with ease. Understanding these components is crucial for mastering how this assembly operates effectively.

- Wheel: The circular element around which the rope or cable moves.

- Rope or Cable: The flexible material that transmits force and motion.

- Axle: The rod that supports the wheel and allows it to rotate.

- Frame: The structure that holds the wheel and axle in place.

- Sheave: A grooved wheel that guides the rope and reduces wear.

Each of these components plays a vital role in ensuring the system operates smoothly and efficiently, allowing for the ultimate manipulation of heavy loads with minimal effort.

Types of Pulleys Explained

Understanding the various kinds of wheel and rope systems is essential for effective lifting and movement applications. Each design serves specific functions and is optimized for different tasks, providing unique benefits based on the context in which they are used. This section will explore the most common configurations, detailing their characteristics and applications.

| Type | Description | Applications |

|---|---|---|

| Fixed | Stationary wheel that changes the direction of force applied to the rope. | Construction, flag raising, simple lifting tasks. |

| Movable | Wheel that moves with the load, effectively reducing the force needed to lift heavy objects. | Construction cranes, block and tackle systems. |

| Compound | Combination of fixed and movable wheels, allowing for a significant reduction in the effort needed to lift loads. | Heavy machinery, shipping, and lifting operations. |

| Grooved | Features a channel or groove to guide the rope, preventing slippage and ensuring smooth movement. | Elevators, conveyor belts, and complex machinery. |

| Sheave | A wheel with a groove designed to hold and guide a rope or cable, often used in rigging. | Sailing, industrial lifting systems, and mechanical applications. |

Applications of Pulley Systems

These mechanical devices play a vital role in various industries, providing efficient solutions for lifting and moving loads. Their versatility allows for numerous applications across different sectors, making tasks easier and more effective.

- Construction:

- Hoisting materials to significant heights.

- Facilitating the movement of heavy equipment on-site.

- Manufacturing:

- Assisting in the assembly line processes.

- Enhancing material handling capabilities within factories.

- Aerospace:

- Used in the maintenance of aircraft for lifting components.

- Integral in cargo handling systems in airports.

- Maritime:

- Loading and unloading cargo on ships.

- Supporting rigging systems on sailboats.

- Entertainment:

- Used in stage productions for moving scenery and equipment.

- Facilitating aerial performances and stunts.

The adaptability of these systems ensures they remain essential tools in a wide range of applications, proving their importance in both everyday tasks and specialized operations.

How to Read Pulley Diagrams

Understanding visual representations of mechanical systems is crucial for effective operation and maintenance. These illustrations provide insights into the arrangement and function of various components, enabling users to grasp the underlying mechanics quickly.

Firstly, familiarize yourself with the symbols used. Each element typically represents a specific component, such as wheels or belts, with distinct markings that indicate their roles. Recognizing these symbols is essential for accurate interpretation.

Next, pay attention to the relationships between components. Lines connecting elements often signify movement or interaction. Tracing these connections helps to understand the flow of force within the system.

Finally, practice analyzing different illustrations to build your confidence. The more you engage with these visual tools, the easier it becomes to decipher their meaning and apply that knowledge effectively.

Maintenance Tips for Pulleys

Regular upkeep of lifting mechanisms is crucial to ensure their longevity and efficiency. Implementing a maintenance routine not only enhances performance but also minimizes the risk of unexpected failures. By following a few simple guidelines, users can maintain optimal functionality and safety.

Inspection Guidelines

Routine inspections are essential for identifying wear and tear. Check for any signs of damage, corrosion, or misalignment. Regular assessments can help in detecting issues before they escalate, allowing for timely repairs.

| Inspection Type | Frequency | Key Points |

|---|---|---|

| Visual Inspection | Weekly | Look for cracks, rust, or abnormal wear. |

| Functional Test | Monthly | Ensure smooth operation and check load capacity. |

| Lubrication Check | Quarterly | Inspect and apply lubricant to reduce friction. |

Proper Usage Practices

Adhering to recommended usage guidelines is vital for maintaining the integrity of lifting systems. Avoid overloading and ensure that all components are properly aligned during operation. Educating users on correct handling techniques can greatly reduce wear and prolong service life.

Common Issues with Pulleys

In mechanical systems, several challenges can arise, impacting efficiency and functionality. Recognizing these obstacles is essential for ensuring optimal operation and longevity of equipment.

1. Wear and Tear

Over time, components can degrade, leading to performance issues. Key factors include:

- Friction between moving parts

- Environmental exposure to dust and moisture

- Inadequate lubrication

2. Misalignment

Proper alignment is crucial for smooth operation. Misalignment can cause:

- Increased strain on components

- Uneven wear

- Potential failure of connected systems

Materials Used in Pulley Construction

The selection of materials for constructing lifting mechanisms plays a crucial role in their performance and longevity. Various factors, including load capacity, environmental conditions, and cost, influence the choice of materials. Understanding the properties of these materials helps ensure optimal functionality and reliability.

Metal is one of the most common choices for these systems due to its strength and durability. Steel, in particular, is favored for its high tensile strength, making it ideal for heavy loads. Additionally, aluminum is often used when weight reduction is essential, providing a good balance between strength and weight.

Plastics also find their applications in certain scenarios, particularly in environments where corrosion resistance is necessary. Materials like polypropylene and nylon are lightweight and offer decent strength, making them suitable for lower-load applications.

Composites, which combine multiple materials, can offer unique advantages, such as enhanced resistance to environmental factors while maintaining a low weight. These materials are increasingly used in specialized applications where traditional options may fall short.

Overall, the choice of construction materials directly affects the performance and efficiency of these mechanical systems. Proper material selection ensures that they operate safely and effectively under various conditions.

Advantages of Using Pulleys

Incorporating mechanical systems can significantly enhance efficiency in various applications. These systems allow for the effective transfer of force and motion, facilitating tasks that would otherwise require considerable effort. This advantage makes them indispensable in numerous industries.

One key benefit is the ability to lift heavy objects with minimal effort. By redirecting force, they reduce the amount of energy needed to accomplish tasks, which can be crucial in construction and manufacturing settings.

Additionally, these systems contribute to improved safety. They help prevent strain injuries by minimizing manual lifting, allowing workers to handle loads more comfortably and securely.

Furthermore, they offer versatility in design and application. Whether used in simple setups or complex machinery, these mechanisms can be tailored to meet specific operational needs, making them a valuable asset in both residential and industrial environments.

Design Considerations for Pulleys

When creating a system that incorporates rotating mechanisms for lifting or redirecting force, several essential factors must be taken into account. These elements influence not only the efficiency and effectiveness of the mechanism but also its longevity and safety during operation. A thoughtful design approach can significantly enhance performance and user satisfaction.

Material Selection

The choice of materials plays a crucial role in the durability and functionality of the system. Strong yet lightweight substances are preferred to minimize load without compromising strength. Steel, aluminum, and high-strength plastics are common options. Each material presents unique advantages and trade-offs, making it vital to consider factors such as environmental conditions, expected loads, and wear resistance.

Load Capacity and Safety Factors

Understanding the maximum weight that the system will handle is imperative. Designers must incorporate appropriate safety factors to account for unexpected stresses or overloads. This involves not only calculating the theoretical limits but also testing the mechanism under real-world conditions. Regular maintenance and inspections can prevent failures, ensuring the system operates reliably over time.