In the realm of precision equipment, having a thorough grasp of the internal structures and configurations is crucial. This knowledge allows users to maintain, repair, and enhance their devices effectively. Clear illustrations and outlines serve as valuable tools for anyone looking to delve deeper into the mechanics of their gear.

Exploring the intricate layouts of individual elements can illuminate the assembly process and highlight potential areas for improvement. Such resources not only assist in troubleshooting but also empower users to make informed decisions regarding modifications and upgrades. By familiarizing oneself with the configurations, one can maximize the performance and longevity of their equipment.

Whether for maintenance or enhancement, understanding these schematics fosters a greater appreciation for the craftsmanship behind the machinery. Armed with this insight, users can ensure that their devices operate at optimal levels, leading to a more satisfying experience overall.

Understanding Umarex XBG Components

This section provides an overview of the various elements that make up a specific type of airgun. Knowing the individual components is essential for effective maintenance, repair, and enhancement of performance. Understanding how these parts work together can enhance the user experience and ensure longevity.

Key components include:

- Frame: The primary structure that houses other elements, providing stability and grip.

- Barrel: The tube through which the projectile travels, influencing accuracy and range.

- Trigger Mechanism: Responsible for initiating the firing process, affecting responsiveness and sensitivity.

- Magazine: Holds the projectiles and feeds them into the firing chamber, playing a crucial role in reloading.

- Sights: Aids in aiming and target acquisition, available in various types for improved accuracy.

- Safety Mechanism: Prevents accidental discharge, ensuring user safety during handling.

Each of these components serves a specific function, contributing to the overall performance and efficiency of the airgun. Proper understanding and familiarity with these elements will aid users in making informed decisions regarding upgrades and repairs.

Overview of Umarex XBG Design

The design of this particular air pistol showcases a blend of functionality and aesthetics. Its construction emphasizes user-friendliness and efficiency, catering to both novice and experienced shooters. The thoughtful engineering behind its layout ensures optimal performance and reliability.

Key Features

- Compact and lightweight design for easy handling.

- Ergonomic grip providing comfort during extended use.

- Durable materials ensuring longevity and resilience.

- Integrated safety mechanisms for secure operation.

Design Elements

- Streamlined silhouette promoting agility and speed.

- Precision-engineered components for enhanced accuracy.

- Accessible controls designed for quick adjustments.

- Modern aesthetics appealing to a wide range of users.

Identifying Key Parts and Features

Understanding the essential components and characteristics of a device is crucial for effective maintenance and functionality. Each element plays a specific role that contributes to the overall performance and user experience. By recognizing these key elements, users can enhance their familiarity and improve handling skills.

Below is a table outlining some of the main features and components, including their descriptions and functions:

| Component | Description | Function |

|---|---|---|

| Trigger | The mechanism that initiates firing. | Allows the user to activate the shooting function. |

| Barrel | The elongated tube through which projectiles exit. | Guides the projectile for improved accuracy. |

| Grip | The handle designed for comfortable holding. | Ensures stable handling during use. |

| Sights | Alignment aids for accurate targeting. | Helps the user aim effectively. |

| Magazine | The storage for projectiles. | Holds and feeds ammunition for firing. |

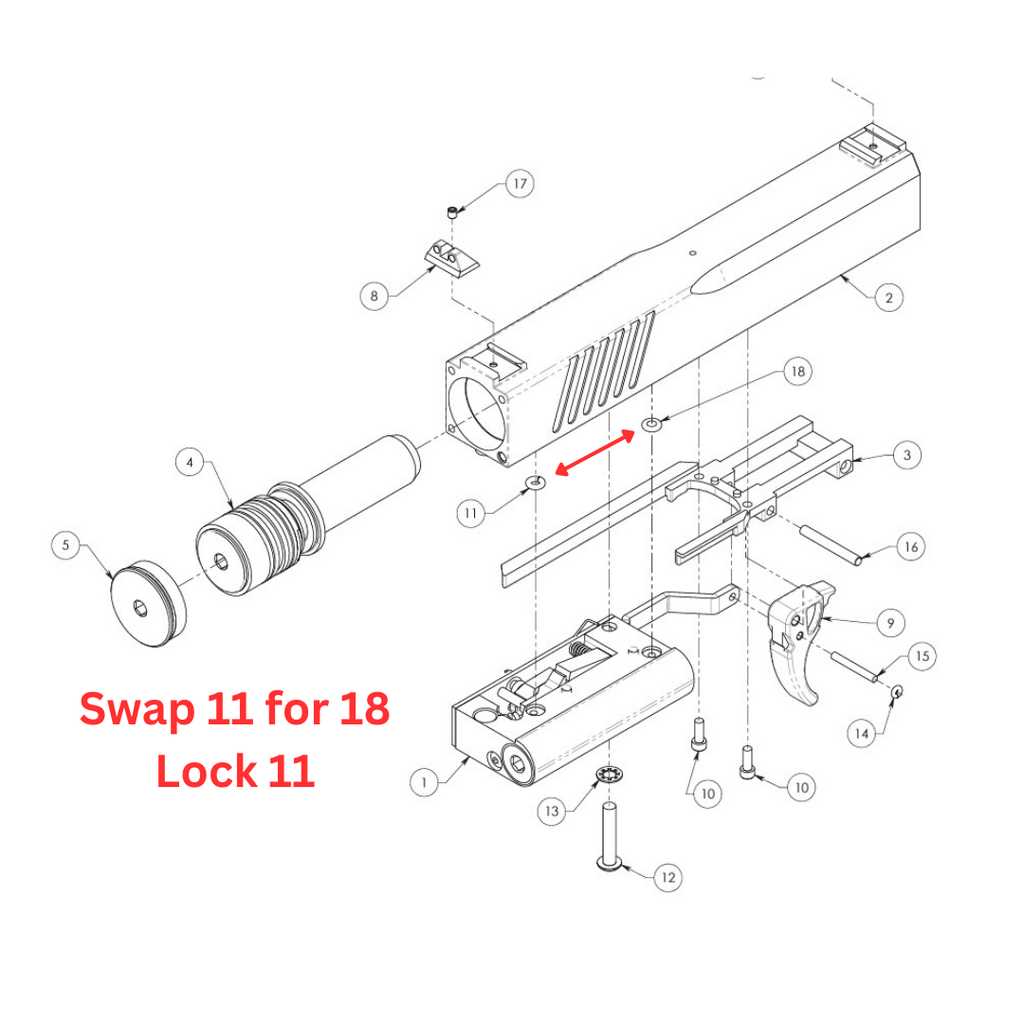

Assembly Instructions for XBG Model

This section provides comprehensive guidance on assembling the specific model in question. Following these instructions will ensure a smooth and efficient assembly process, leading to optimal performance and reliability.

Tools Required

Before starting the assembly, gather the necessary tools. You will need a standard screwdriver, pliers, and possibly a small wrench. Having all tools at hand will facilitate a quicker assembly process.

Step-by-Step Assembly Process

Begin by organizing all components on a clean, flat surface. Carefully follow the sequence of steps outlined below:

- Attach the main body to the handle, ensuring a snug fit.

- Secure any internal mechanisms using the provided screws, making sure they are tightened appropriately.

- Install the trigger assembly, checking for smooth movement.

- Finish by attaching any external components, such as the grip and safety features.

After completing the assembly, perform a thorough inspection to confirm that all parts are securely in place. This will help ensure that the model operates correctly and safely.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your device operates at its best. By following a structured maintenance routine, you can enhance its reliability, longevity, and overall functionality. This section outlines key practices that can help you achieve optimal performance.

One of the most crucial aspects of maintenance is keeping the internal components clean and free from debris. Dust and dirt can accumulate, leading to malfunctions. It is advisable to perform routine checks and clean sensitive areas carefully.

Additionally, lubrication plays a vital role in maintaining smooth operation. Applying appropriate lubricants to moving parts can reduce friction and prevent wear and tear. Ensure to use only recommended products to avoid damaging the device.

Finally, regular inspection for signs of wear or damage is imperative. Identifying issues early on can save time and money by preventing more significant problems from developing. Here is a summary table of maintenance practices:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Cleaning Internal Components | Monthly | Use a soft brush or cloth |

| Lubrication of Moving Parts | Every 3 months | Apply recommended lubricant |

| Inspection for Wear | Bi-monthly | Check for signs of damage |

Common Issues and Troubleshooting Guide

This section aims to provide insight into frequent challenges encountered with a specific type of airgun, along with practical solutions to address them. Understanding these issues and their resolutions can significantly enhance the shooting experience and ensure optimal performance.

Below are some common problems and their potential fixes:

- Inconsistent Firing:

- Check the power source to ensure it is fully charged or replaced if necessary.

- Inspect the firing mechanism for any obstructions or wear.

- Jamming:

- Clear any debris from the loading chamber and ensure the ammunition is suitable for the device.

- Lubricate moving parts lightly to improve functionality.

- Low Accuracy:

- Verify the alignment of the sights; adjustments may be necessary.

- Use high-quality ammunition for better precision.

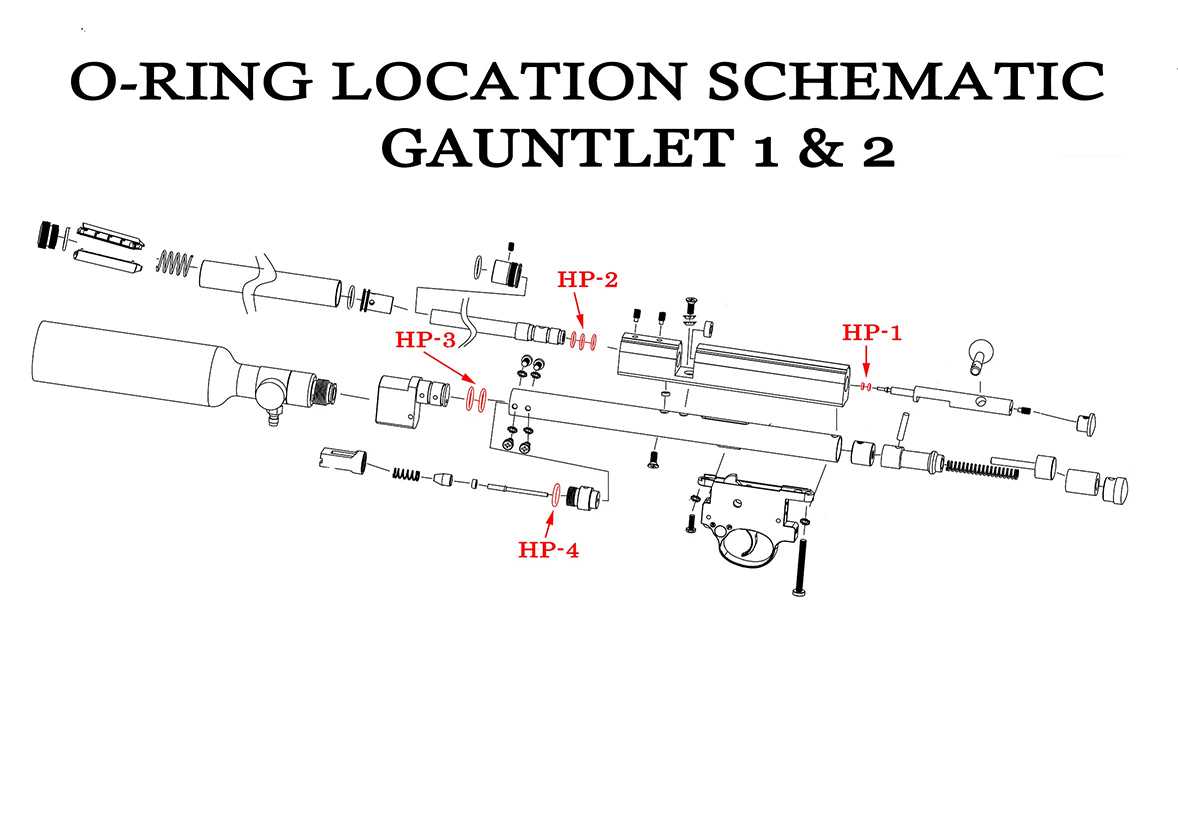

- Leaks:

- Inspect seals and O-rings for damage; replace if worn out.

- Check all connections for tightness and proper assembly.

By systematically addressing these common concerns, users can maintain the reliability and effectiveness of their airgun, leading to a more enjoyable shooting experience.

Replacement Parts Availability and Options

Access to replacement components is crucial for maintaining the functionality and longevity of any device. Knowing where to find these items and understanding the available choices can greatly enhance the overall user experience. Whether for repair, customization, or enhancement, having a reliable source for essential elements is a priority for enthusiasts and users alike.

Sources for Components

Numerous outlets provide an array of replacement elements, including online retailers, local gun shops, and specialized service centers. Online platforms often feature comprehensive catalogs, allowing users to search for specific items by model or function. Local shops may offer hands-on assistance, helping customers identify the right pieces for their needs. Additionally, forums and communities focused on enthusiasts can be valuable resources for recommendations on where to purchase these components.

Customization Options

For those looking to modify or upgrade their devices, various customization options are available. This includes everything from cosmetic enhancements to performance upgrades. Users can explore aftermarket components that offer improved durability, aesthetics, or functionality. Engaging with fellow users in community forums can provide insights into the best choices for personalization, ensuring that modifications align with individual preferences and operational requirements.

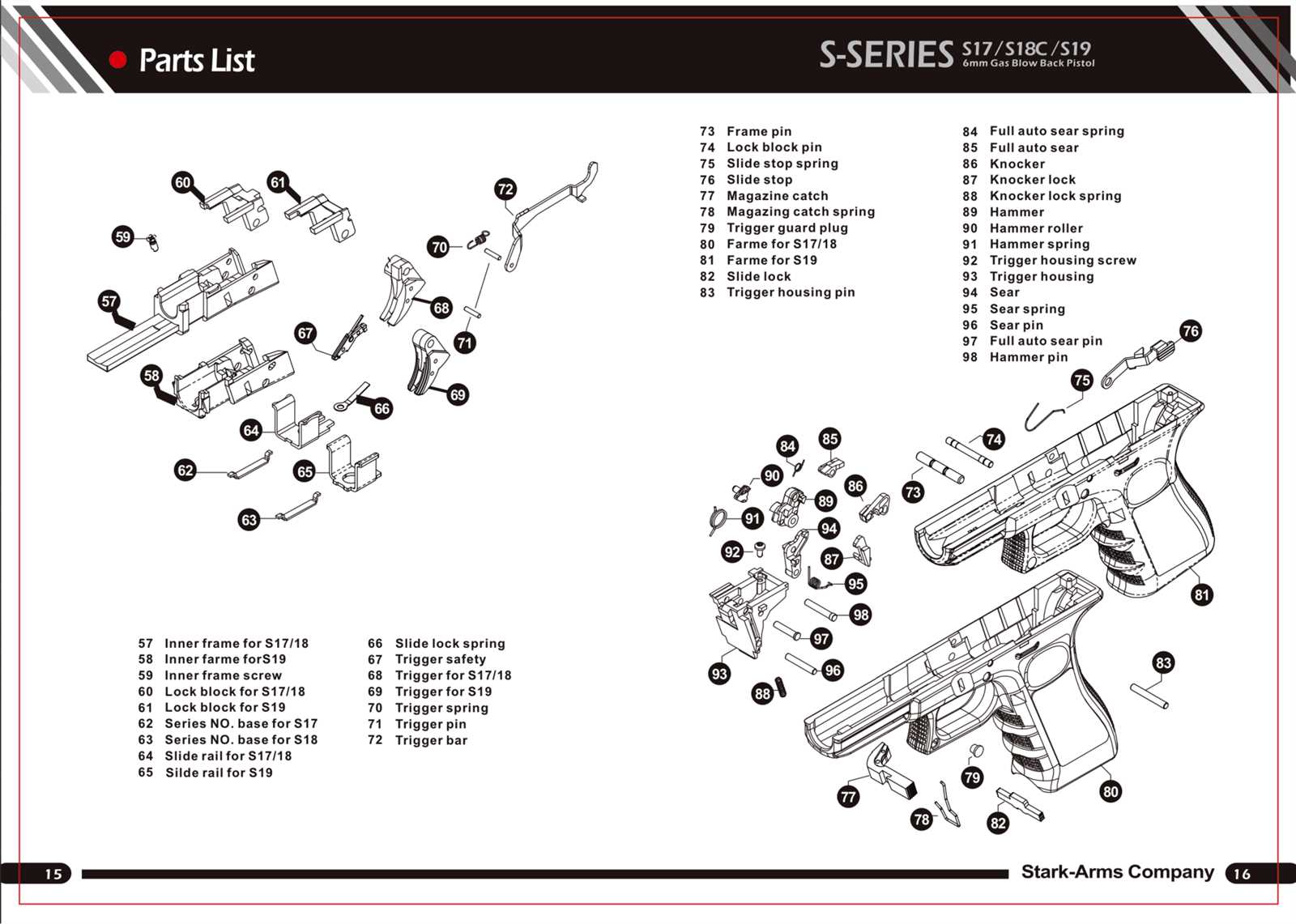

Diagrams for Easy Reference

Visual aids play a crucial role in simplifying complex information and enhancing understanding. Providing detailed illustrations can help users quickly identify components and their arrangement, making it easier to grasp functionality and maintenance requirements. This section focuses on essential visuals designed for straightforward comprehension.

Understanding the Layout

The layout of various assemblies is fundamental for effective troubleshooting and repair. Clear visuals can guide users through each element, ensuring they can follow along easily. By organizing the information logically, users can navigate through the components without confusion.

Key Components Overview

The following table summarizes the key elements for reference:

| Component Name | Description | Function |

|---|---|---|

| Element A | Main housing that encases the internal mechanisms. | Provides structure and protects the inner parts. |

| Element B | Trigger assembly for activation. | Facilitates the operation mechanism. |

| Element C | Power source compartment. | Powers the entire assembly. |

How to Interpret Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and assembly of any mechanical device. These illustrations provide a clear view of individual elements and their relationships, allowing users to identify necessary replacements and repairs. Familiarity with the structure of these visuals can significantly enhance one’s ability to manage and troubleshoot equipment.

Key Elements to Consider

- Labeling: Look for labels that indicate the names or numbers of each component. This information is essential for accurate identification.

- Numbering System: Many visuals employ a numerical system to correlate parts with a corresponding list. Understanding this system is vital for quick referencing.

- Assembly Order: Observe the order in which elements are arranged. This can help in comprehending how components fit together and the sequence of installation.

Tips for Effective Interpretation

- Familiarize yourself with common symbols used in visual guides, as they often indicate functions or features.

- Cross-reference the visual with the user manual for additional context and explanations.

- Take notes on specific components that may require attention or replacement during maintenance.

Upgrades and Customization Options

Enhancing performance and personalizing your equipment can significantly improve your overall experience. Numerous modifications are available, allowing enthusiasts to tailor their devices to meet specific preferences or enhance functionality. By exploring various components and accessories, users can transform standard models into unique setups that suit their individual styles and needs.

Performance Enhancements

One of the most sought-after improvements is enhancing the performance of your device. Consider the following options:

- Upgraded trigger mechanisms for improved responsiveness.

- Enhanced sights for better aiming accuracy.

- Performance barrels that increase range and precision.

Aesthetic Customization

Customizing the look of your equipment allows you to express your personality. Popular choices include:

- Changing grips to different textures and colors.

- Adding custom paint jobs or decals.

- Upgrading to unique stocks or forends for a distinct appearance.

Safety Precautions When Handling Parts

Ensuring safety is crucial when dealing with components related to firearms or similar devices. Proper precautions help prevent accidents and injuries, safeguarding both the user and those nearby. This section outlines essential measures to follow while working with these items, promoting a secure environment for maintenance or assembly.

Before engaging in any handling procedures, it is vital to familiarize yourself with the equipment and understand its functionality. Always wear appropriate protective gear, such as safety glasses and gloves, to minimize risks during the process.

| Precaution | Description |

|---|---|

| Read the Manual | Thoroughly review the manufacturer’s instructions to understand specific handling requirements. |

| Work in a Safe Area | Ensure the workspace is clean, well-lit, and free from distractions to maintain focus. |

| Check for Damage | Inspect all items for any signs of wear or damage before use, discarding any that may pose a risk. |

| Keep Away from Children | Store components securely and out of reach of children to prevent unauthorized access. |

| Use Tools Properly | Utilize the correct tools for assembly and disassembly to avoid unnecessary force or damage. |

By adhering to these guidelines, individuals can significantly reduce the likelihood of mishaps, ensuring a safe experience when handling components associated with firearms or similar devices.

Frequently Asked Questions About XBG

This section addresses common inquiries regarding the popular air gun model, focusing on its features, maintenance, and usage tips. Understanding these aspects can enhance the experience for both new and seasoned users.

Common Inquiries

Here are some frequently posed questions that can help clarify various aspects of this air-powered device:

| Question | Answer |

|---|---|

| What is the ideal maintenance routine? | Regular cleaning of the barrel and lubrication of moving parts will ensure optimal performance. |

| What types of ammunition can be used? | This model is compatible with specific pellet sizes that provide the best accuracy. |

| How do I troubleshoot common issues? | If performance issues arise, checking for blockages or low air pressure can often resolve them. |

| Where can I find replacement components? | Replacement parts can be sourced from authorized retailers or online specialty shops. |

Additional Tips

For those looking to improve their handling skills, practicing in a safe and controlled environment is highly recommended. Additionally, joining online forums can provide valuable insights and tips from experienced users.