Modern outdoor coverings provide essential protection and comfort, whether attached to a vehicle or a permanent structure. These systems are designed with precision, offering users the ability to enjoy outdoor spaces while being shielded from various weather conditions. To maintain and optimize these coverings, it’s important to familiarize oneself with the various elements that make up the mechanism.

Each piece of the system plays a vital role in ensuring smooth operation and long-lasting performance. From structural supports to mechanisms that control movement, these components must work in harmony to provide a seamless experience. Understanding how each element functions will not only aid in troubleshooting but also help in enhancing the overall efficiency of the system.

In the following guide, we will explore the different parts involved in these shading solutions, breaking down their roles and significance. This knowledge is invaluable for anyone looking to ensure their outdoor covering remains in peak condition for years to come.

Understanding the Components of Solera Awnings

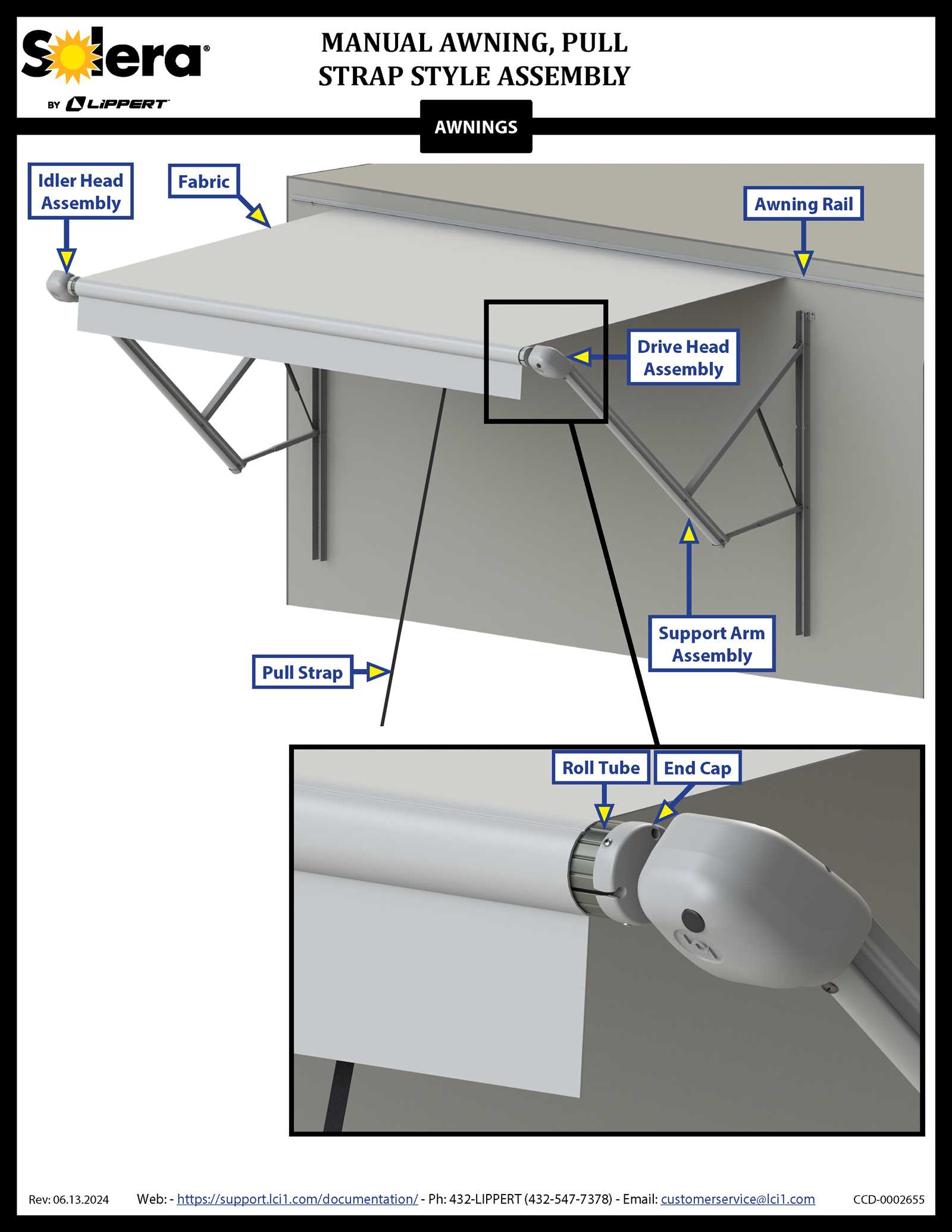

To better appreciate the structure of these outdoor coverings, it’s essential to explore the different elements that work together to provide shade and protection. Each part has a specific function, contributing to the overall durability and ease of use.

- Supportive Arms: These are designed to provide stability and ensure the fabric remains taut when extended, giving the shelter a solid foundation.

- Roller Tube: This component holds the fabric and facilitates smooth extension and retraction. Its quality directly impacts the operation and longevity of the covering.

- Fabric Material: The protective fabric is usually made from weather-resistant materials to shield against sunlight and rain, ensuring a comfortable outdoor experience.

- Mounting Brackets: These fixtures secure the entire system to the side of the vehicle or building, allowing it to remain firmly attached during use.

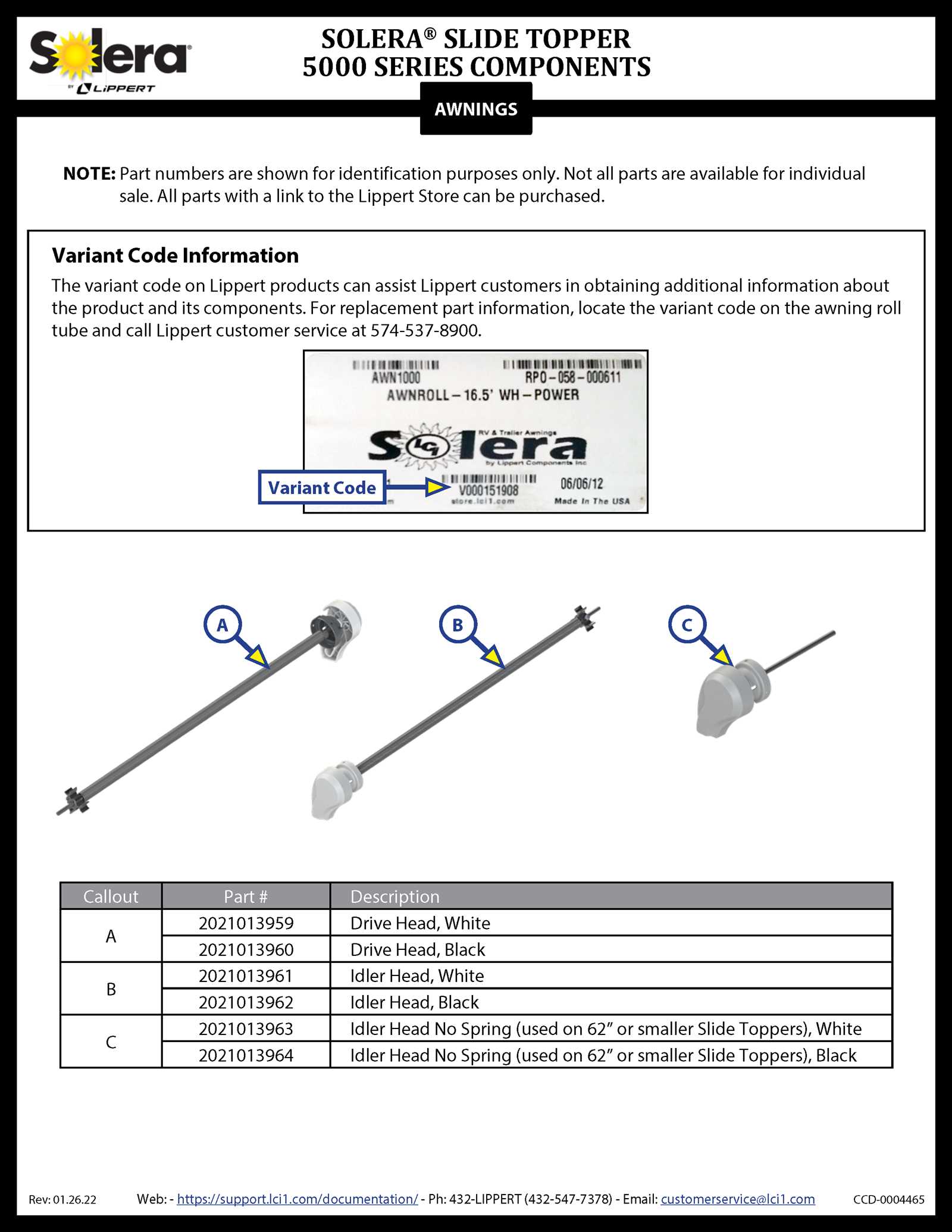

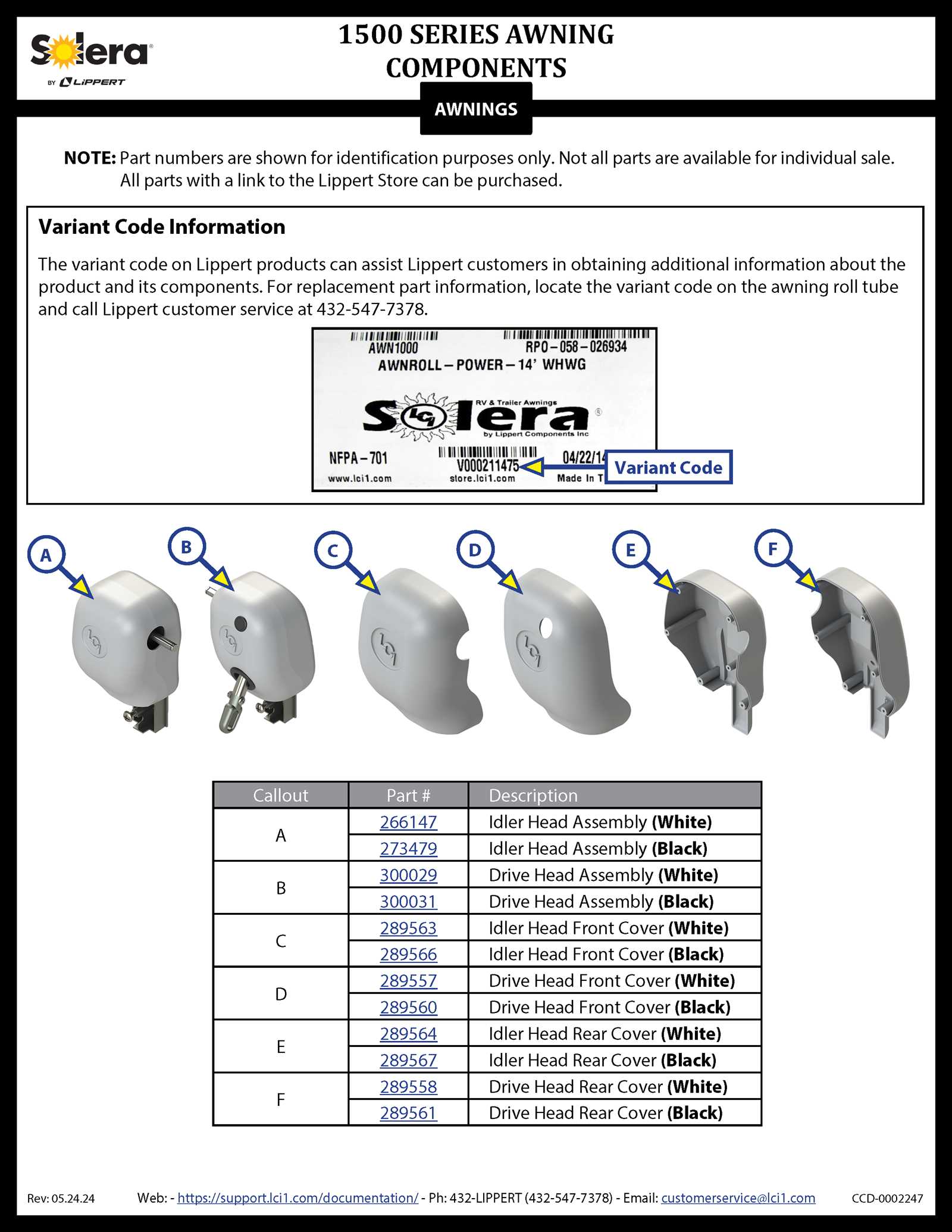

- Key Mechanisms in Lippert Solera Systems

The operation of these advanced structures relies on several core components that ensure smooth performance. Understanding the individual roles of these mechanisms can greatly enhance maintenance and troubleshooting efficiency. Each element is designed to work in harmony, creating a system that is both durable and easy to manage.

Motor and Drive System

The motor is the powerhouse, driving the extension and retraction functions. It connects to a drive shaft that transmits power to the arms, enabling precise control over movement. This setup allows the structure to function automatically or with manual intervention, depending on the model.

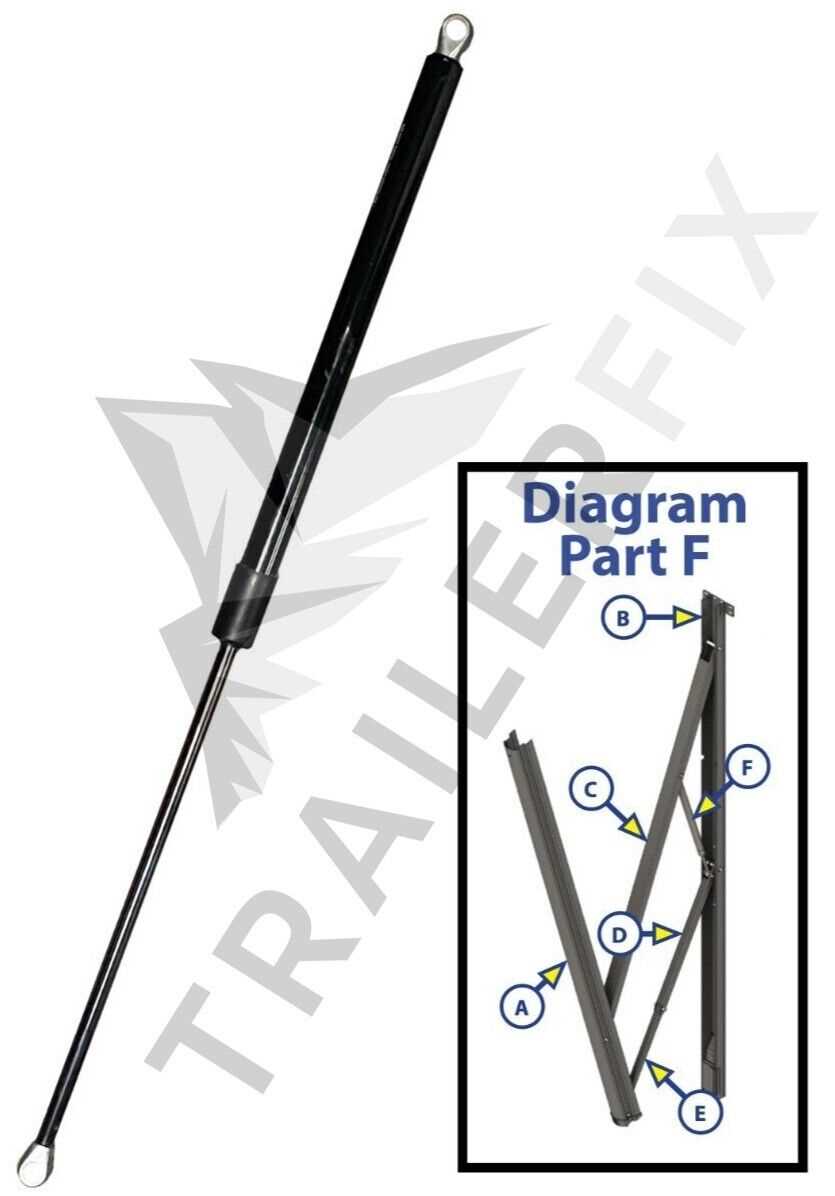

Support Arms and Frame

The support arms provide stability and control over the positioning. These arms are linked to the frame, which forms the backbone of the system. Together, they ensure that the setup remains steady under various conditions, offering long-term reliability.

Common Parts Found in Solera Awnings

Outdoor shading systems are composed of various essential elements that ensure their proper function and durability. Understanding the key components of these systems is important for maintenance, repair, or replacement when necessary. Each element contributes to the smooth operation and overall performance, ensuring reliable coverage and protection from the elements.

Main Structural Elements

Key structural components are responsible for the framework and support of the shading system. These elements provide stability and allow for smooth extension and retraction, enabling the setup to adjust to different conditions. Some of these components are made from high-quality materials to withstand outdoor exposure and provide long-term use.

Mechanical and Control Mechanisms

The mechanisms that control movement are crucial to the ease of operation. These include gears, motors, or manual cranks that enable the system to open and close efficiently. These components are designed for convenience, ensuring that adjustments can be made with minimal effort, whether automatically or manually.

Component Function How to Identify Key Components of Outdoor Shade Systems

Understanding the various elements of outdoor shade systems can help with both installation and maintenance. Each system consists of multiple parts that work together to provide shade and protection. Identifying these elements can ensure that replacements or repairs are made efficiently.

- Support Structures: These are the main beams that hold the system in place, providing stability and support.

- Fabric Rollers: The mechanism responsible for smoothly extending and retracting the covering material.

- Tension Arms: Adjustable components that maintain the appropriate tension, ensuring the covering remains taut.

- Motor or Crank Mechanism: Depending on the model, this either automates the system or allows for manual operation.

By recognizing these key elements, you can better manage the upkeep of your shading solution and ensure its long-term functionality.

Replacement Tips for Damaged Awning Components

When dealing with wear and tear on outdoor shading systems, it’s important to address damaged elements promptly to ensure smooth operation. Knowing which items may need replacement and how to approach repairs can save time and extend the life of your equipment.

- Inspect all brackets and fasteners regularly. Loose or broken pieces can cause misalignment or malfunction.

- Check the fabric for any signs of tears or fraying. Minor damage can be patched, but larger sections might need a full replacement.

- Examine the support arms. If they’re bent or show signs of stress, consider replacing them to prevent further complications.

- Ensure that the tension springs are functioning properly. If the system struggles to retract or extend, the springs may require adjustment or substitution.

- Lubricate moving parts to keep the system running smoothly, and replace any worn-out components that may affect performance

Guide to Manual and Automatic Outdoor Canopies

Outdoor shade systems offer both convenience and flexibility, allowing users to enjoy shelter from the sun or rain. These systems can be operated manually or through automated mechanisms, providing different options for ease of use and adaptability to various environments. Understanding the differences between these two types of sunshades can help you decide which system best suits your outdoor needs.

Manual Canopies: Effort and Control

With a manual system, you have complete control over the extension and retraction process. These models require physical effort to operate, but they are known for their durability and reliability. They are often preferred in environments where power is not readily available or when users seek a straightforward solution that minimizes the risk of mechanical failure.

Automatic Systems: Ease and Convenience

Automatic versions are equipped with motorized functions that allow users to extend or retract the shade with the push of a button. These systems offer superior convenience, especially for those looking to manage

Features of Awning Support Arms

The support arms are an essential component of the outdoor shading system, providing stability and smooth operation. Designed for durability and ease of use, they ensure proper tension and extension, enhancing the overall functionality of the setup. Below are some key characteristics of these support structures.

- Durability: Built from robust materials, the support arms are made to withstand various weather conditions, ensuring long-lasting performance.

- Adjustability: These arms offer customizable length and angle, allowing users to control the extension and height according to their needs.

- Ease of Installation: The design includes features that make the setup process straightforward, reducing the time required for assembly.

- Stability: Enhanced tension systems are integrated into the arms, providing greater steadiness during use, even in windy conditions.

Function of the Fabric Roller Tube

The fabric roller tube plays a crucial role in ensuring the smooth operation and durability of the entire canopy system. It is the central component responsible for supporting the fabric and providing the necessary tension for easy extension and retraction. By distributing the load evenly, the tube helps maintain the fabric’s integrity during usage and reduces the risk of sagging or damage over time.

Core Responsibilities

This tubular structure is designed to handle both the weight of the fabric and the mechanical forces applied during operation. It ensures a balanced roll-up process, making it easier to deploy and retract the covering. Additionally, it helps protect the fabric from unnecessary strain, extending the lifespan of the system.

Ensuring System Stability

Besides holding the fabric, the tube also contributes to overall stability. Its durable build prevents warping or bending, even under constant movement or exposure to

Electrical Components in Solera Awning Systems

Modern outdoor coverings incorporate a variety of electronic elements that ensure smooth operation and enhance user experience. These components play a crucial role in automating key functionalities, providing convenience and efficiency.

Key Electronic Modules

The core of the system relies on several important electronic devices. Control units manage the extension and retraction, while sensors detect weather conditions, adjusting the system automatically when necessary. These modules work in unison to maintain optimal performance and protection.

Power Supply and Wiring

Power distribution is facilitated by dedicated circuits that connect the system to a reliable energy source. Cables and connectors ensure consistent electrical flow, and fuse boxes provide essential protection against power surges.

Component Function Control Unit Manages operations and system behavior Maintenance of Solera Awning Hardware

Regular upkeep of outdoor shading system components is essential for ensuring long-term functionality and preventing unexpected issues. Proper care helps to extend the lifespan of the structure and reduces the likelihood of repairs.

Here are some important steps to keep in mind when maintaining these components:

- Inspect all connections and fasteners for signs of wear or loosening.

- Check for any corrosion or rust that may appear due to exposure to outdoor elements.

- Lubricate moving parts, such as joints and hinges, to ensure smooth operation.

- Regularly clean the system to remove dust, debris, and any other build-up that could affect performance.

By following these simple steps, you can help ensure the system operates reliably over time, minimizing

How to Upgrade Your Outdoor Cover System Components

Maintaining and improving the performance of your outdoor cover system is essential for ensuring long-term durability and convenience. By replacing outdated or worn-out elements with newer, more efficient components, you can enhance the functionality and extend the lifespan of your setup. This section will guide you through the steps of upgrading the key mechanisms, focusing on efficiency and ease of installation.

Step-by-Step Component Replacement

Begin by identifying which elements require replacement, whether it’s the support structure, mechanical arms, or motorized mechanisms. Newer models offer advanced features that improve performance and make operation smoother. Ensure you have the right tools and follow the manufacturer’s instructions to avoid any issues during the upgrade process.

Optimizing for Better

Differences Between Manual and Electric Awning Models

The choice between manually operated and electrically powered models is significant for users seeking convenience and functionality. Each type offers unique benefits and features that cater to different preferences and needs.

Manual models rely on a physical mechanism to extend and retract the cover. Users must operate a crank or similar device, which can be both a simple and cost-effective option. This type is often favored for its straightforward design and lower maintenance requirements. Additionally, they do not rely on an electrical supply, making them suitable for various environments, including areas prone to power outages.

In contrast, electric models provide enhanced convenience, allowing users to control the deployment of the cover with the push of a button. This automatic operation is ideal for those who prioritize ease of use and accessibility, especially in larger setups where manual handling may be cumbersome. Furthermore, these versions often come equipped with features like remote control and integrated sensors, which can enhance user experience by adjusting the cover based on environmental conditions.

Ultimately, the choice between these two variants hinges on individual preferences regarding control, ease of use, and specific situational requirements. Whether opting for a manual or electric version, understanding the key distinctions will aid in making an informed decision.

Installation Tips for Solera Awning Components

When setting up your outdoor shelter, proper guidance is essential for a successful installation. Understanding the individual elements and their functions will significantly enhance the overall process. Attention to detail and following a systematic approach can prevent common pitfalls and ensure a seamless experience.

Begin with Preparation: Before starting, gather all necessary tools and components. Review the manufacturer’s guidelines and familiarize yourself with each item. A well-organized workspace will help streamline the installation, making it easier to locate parts when needed.

Follow the Sequence: It is crucial to adhere to the recommended order of assembly. Start with the foundational structure before attaching additional elements. This methodical approach not only enhances stability but also simplifies the installation process.

Secure Connections: Ensure that each connection is tight and secure. Loose fittings can lead to instability and potential damage. Utilize appropriate hardware and tools to achieve a robust installation. Regularly check for any signs of wear or looseness to maintain the integrity of the structure.

Test Functionality: Once assembled, perform a thorough check of the entire setup. Ensure that all moving parts operate smoothly and that there are no obstructions. Testing the mechanism before full use will help identify any issues early, allowing for timely adjustments.

By adhering to these guidelines, you can ensure a successful assembly and long-lasting performance of your outdoor shelter components.