When it comes to keeping your living space fresh and well-maintained, having a reliable tool for deep cleaning is essential. Different models of such equipment are designed to tackle various challenges, ensuring effective results for multiple surfaces. In this guide, we explore the crucial elements that make these devices function smoothly, focusing on their individual roles in delivering top performance.

Each element within the cleaning device serves a specific function, contributing to the overall efficiency of the machine. By gaining an understanding of how these components work together, users can better maintain their equipment and ensure longevity. Whether it’s the internal mechanisms or external attachments, knowing the details can make a significant difference in usage.

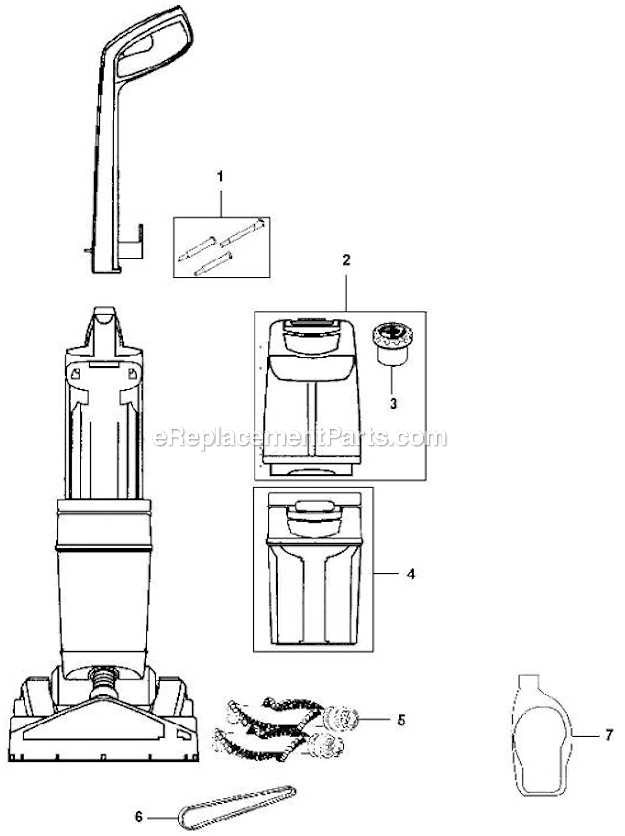

Overview of Hoover PowerDash Pet Cleaner

This compact and efficient cleaning device is designed to tackle the challenges of maintaining various floor coverings in high-traffic areas. Equipped with advanced features, it offers an effective solution for deep cleaning, ensuring that floors stay fresh and free of debris. Its lightweight structure allows for easy maneuverability, making it a practical choice for both quick touch-ups and more thorough cleaning sessions. The device’s innovative technology enhances cleaning performance, delivering impressive results without requiring significant effort from the user.

With a streamlined design, this tool combines functionality and convenience, making it an essential companion for maintaining clean and healthy living spaces. Its user-friendly interface allows for easy operation, while the powerful cleaning mechanisms ensure that surfaces are left looking renewed and refreshed after each use.

Key Components of the Cleaning System

The core of any effective floor cleaning system is a well-integrated combination of parts that work together to provide thorough and efficient results. Understanding the main elements that contribute to the overall performance helps to ensure optimal maintenance and functionality. Below is a breakdown of the most essential features that drive the system’s effectiveness.

Main Operational Mechanisms

One of the primary components includes the rotating brushes, which are designed to agitate and lift dirt from surfaces. These are paired with a water distribution system that evenly applies liquid to ensure deep cleansing. The suction unit plays a crucial role by extracting both moisture and debris, leaving the surface cleaner and drier.

Supportive Elements

Another critical feature is the tank system, consisting of separate reservoirs for clean and used water. This allows for continuous operation without cross-contamination. Additionally

Brush Roll Assembly and Functionality

The rotating brush mechanism plays a crucial role in maintaining the efficiency of floor care devices. Its primary purpose is to loosen and lift debris from various surfaces, ensuring that dirt is effectively removed. This component is designed to handle different types of fibers and textures, making it an essential part of the overall cleaning process.

Key Components of the Brush Roll

Several elements work together within the rotating brush system to optimize its performance. These include bristles, a rotating cylinder, and bearings that allow smooth and consistent movement. Each part is engineered to contribute to the thorough agitation of fibers, improving the device’s overall cleaning power.

How the Brush Roll Works

The brush roll rotates at high speed, working in tandem with the suction mechanism. As it spins, it agitates the surface, breaking up dirt and allowing it to

Water and Solution Tank Layout

The system responsible for managing liquids is designed for efficient performance. With separate compartments for holding fresh water and cleaning solutions, this layout ensures a smooth and uninterrupted flow during use. The placement of these reservoirs allows for easy access and refilling, contributing to the overall functionality and convenience of the device.

Reservoir Structure

The containers are strategically positioned to maintain balance and simplify the refill process. The water tank is typically larger to accommodate extended use, while the solution tank is sized for optimal mixing proportions. This separation also ensures that the appropriate amount of liquid is used at all times, enhancing efficiency.

Maintenance and Handling

Both tanks are easily detachable, allowing for straightforward cleaning and upkeep. Regular maintenance of these reservoirs helps prevent blockages and ensures the system operates smoothly. Proper care will extend the longevity of the equipment and improve overall results.

Hose Connections and Attachments

Ensuring the proper connection and use of the hose and its accessories is crucial for optimal performance. By following a few simple steps, users can efficiently attach the components to achieve thorough results. This section provides an overview of how to connect the hose and handle various attachments to maximize functionality.

Connecting the Hose

Start by aligning the hose with the designated port. Once positioned, press firmly to secure the connection. A properly fitted hose will prevent any leaks and allow for uninterrupted flow. Regularly check for any signs of wear or misalignment, ensuring everything stays in place during operation.

Using Attachments

Various accessories can be connected to the hose for different purposes. Whether it’s for cleaning edges or reaching narrow spaces, select the appropriate attachment, and securely fasten it to the end of the hose

Motor Unit and Power Mechanism

This section delves into the essential components responsible for the operation of the cleaning device, focusing on the engine assembly and its power delivery system. Understanding these elements is crucial for optimal performance and maintenance of the equipment.

Engine Assembly

The engine assembly is the heart of the appliance, generating the necessary force to drive the cleaning process. Key elements include:

- Motor: This component converts electrical energy into mechanical power, enabling various functions of the device.

- Fan: The fan aids in airflow management, ensuring that debris and moisture are efficiently directed during operation.

- Gears: These components facilitate the transfer of power from the motor to the working parts, influencing the speed and efficiency of the appliance.

Power Delivery System

The power delivery system plays a pivotal role in ensuring consistent performance. Its components include:

- Wiring: Quality wiring ensures reliable power flow from the source to the motor, affecting overall functionality.

- Switches: These components allow users to control the appliance’s operation, impacting convenience and safety.

- Power Source: The type of power source used (e.g., corded or battery-operated) directly influences the device’s mobility and efficiency.

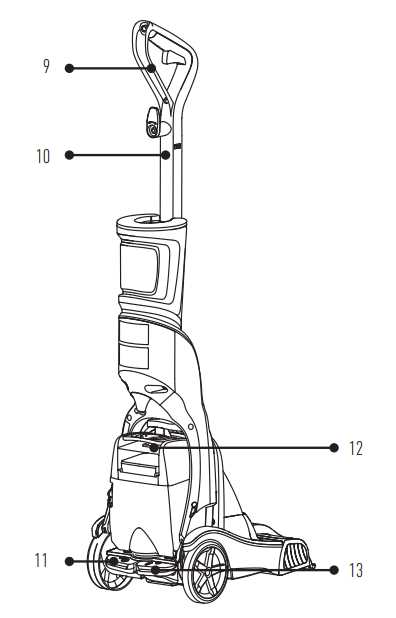

Handle and User Interface Design

The design of the handle and user interface plays a crucial role in enhancing the overall experience of using a cleaning device. An ergonomic handle allows users to maintain a comfortable grip, reducing fatigue during operation. A thoughtfully laid-out control panel ensures that essential functions are easily accessible, allowing for seamless operation without unnecessary distractions.

Ergonomics and Comfort

An ergonomic approach to the handle design significantly influences usability. A well-shaped handle accommodates various hand sizes, promoting ease of use. Additionally, soft-touch materials can provide a more comfortable grip, especially during extended periods of cleaning tasks.

Intuitive Control Layout

An intuitive interface is vital for enhancing user interaction. Controls should be clearly labeled and logically arranged to facilitate quick adjustments. Color-coded buttons or tactile indicators can further assist users in identifying functions at a glance, ensuring a smooth and efficient cleaning process.

Nozzle Structure and Cleaning Path

The design of the cleaning nozzle plays a crucial role in ensuring effective dirt removal from various surfaces. This component is meticulously engineered to facilitate optimal fluid distribution and airflow, maximizing the efficiency of the cleaning process. Understanding its configuration can enhance the user’s ability to maintain their environment with ease.

Design Features

The nozzle typically incorporates a variety of features aimed at improving functionality. A wide suction opening allows for the collection of larger debris, while strategically placed bristles enhance agitation, loosening stubborn particles embedded in fibers. Additionally, the shape of the nozzle is often contoured to navigate around furniture and into tight corners, ensuring comprehensive coverage.

Cleaning Path Efficiency

Efficiency in the cleaning path is achieved through a combination of the nozzle’s structure and the designed flow of cleaning solutions. The angle of the nozzle, along with its width, contributes to a streamlined approach, enabling users to cover more ground in fewer passes. By optimizing these elements, the apparatus not only saves time but also delivers superior results, leaving surfaces refreshed and revitalized.

Filtration System and Maintenance Tips

The filtration system plays a crucial role in ensuring optimal performance of your appliance. It effectively captures dirt and debris, maintaining cleanliness and efficiency. Regular upkeep of this system is essential for prolonging the lifespan of the device and enhancing its cleaning capabilities.

Understanding the Filtration Mechanism

Each unit typically incorporates several components that work together to trap contaminants. Here are the primary elements:

- Filters: These elements are responsible for capturing fine particles and allergens.

- Collection Chamber: This area holds the dirt and debris collected during operation.

- Seals: Ensuring a tight fit, these components prevent leaks and maintain suction power.

Maintenance Guidelines

Proper care of the filtration system is vital for ensuring that the device functions effectively. Follow these maintenance tips:

- Regularly inspect and replace filters as needed to avoid blockages.

- Clean the collection chamber frequently to prevent buildup and odors.

- Check seals for wear and replace them if any damage is observed.

- Ensure the appliance is completely dry before reassembling to avoid mold growth.

Electrical Wiring and Safety Features

Understanding the wiring and safety aspects of your cleaning device is crucial for optimal performance and user safety. Proper electrical connections ensure efficient operation, while safety features help prevent accidents and extend the lifespan of the equipment. This section will explore the fundamental elements related to electrical systems and protective mechanisms that enhance the overall functionality of the appliance.

Key Components of Electrical Wiring

- Power Cord: The power cord is essential for connecting the device to an electrical outlet. Ensure it is intact and free of damage.

- Switch Mechanism: The switch allows users to control the operation of the appliance. It should function smoothly without any sticking.

- Internal Wiring: Inside the device, wiring connects various components, such as motors and sensors. Proper insulation is vital to prevent shorts and ensure safety.

Safety Features to Consider

- Overload Protection: Many devices include a mechanism that shuts off power when overheating occurs, protecting both the user and the equipment.

- Grounding: Grounding helps to divert excess electricity away from the user, reducing the risk of electric shock.

- Fuse or Circuit Breaker: These components help to interrupt the electrical flow in case of a fault, preventing potential hazards.

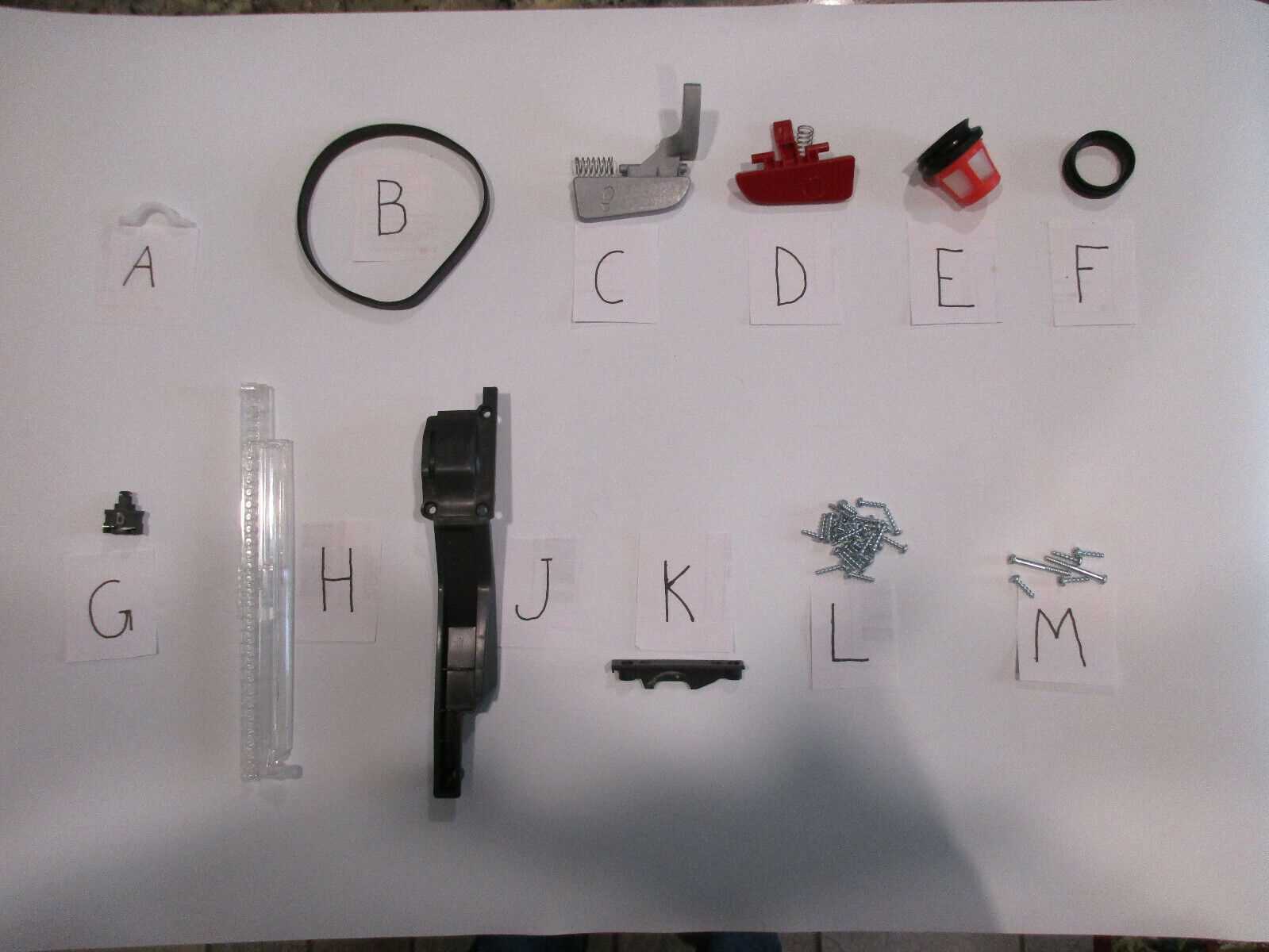

Replacing Worn or Broken Parts

Over time, various components of your cleaning appliance may experience wear and tear, leading to decreased efficiency and performance. Addressing these issues promptly is essential to maintain optimal functionality and extend the lifespan of the device. By identifying and replacing faulty elements, users can ensure their equipment continues to operate at peak performance.

Start by examining the appliance to pinpoint any damaged or ineffective components. Common signs of wear include unusual noises, leaks, or diminished cleaning effectiveness. Once you have identified the problematic areas, consult the manufacturer’s guidelines or reference materials to find suitable replacements. It is crucial to select high-quality substitutes that match the specifications of your equipment.

After acquiring the necessary replacements, proceed with the disassembly of the appliance as instructed in the user manual. Carefully remove the affected parts and replace them with the new ones, ensuring a secure fit. Following the reassembly process, conduct a thorough test to verify that the appliance is functioning correctly. Regular maintenance and timely replacements will keep your device running smoothly and effectively.