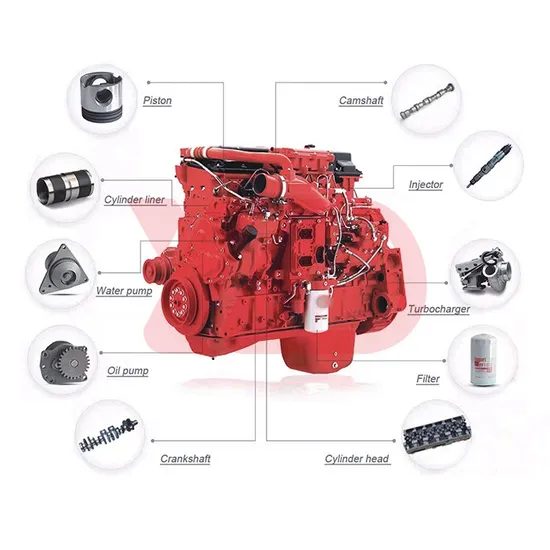

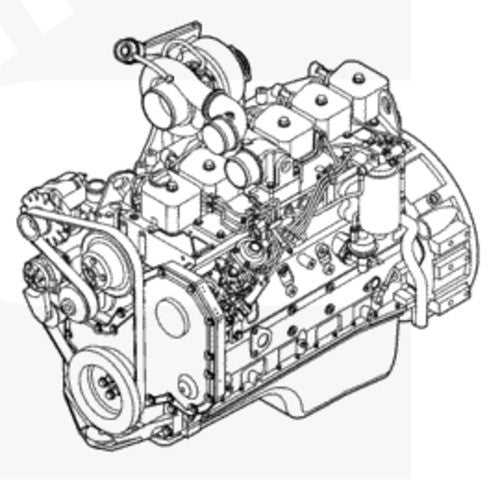

In the intricate world of engine mechanics, a comprehensive grasp of individual elements is essential for optimal performance and maintenance. Each component plays a pivotal role in the overall functionality, influencing efficiency and reliability.

To achieve a thorough understanding, it is beneficial to explore visual representations that showcase the interconnections and roles of various elements. Such resources serve as valuable guides for technicians and enthusiasts alike, facilitating a deeper appreciation of the machinery at hand.

By delving into the structure of these essential components, one can uncover the ultimate synergy that powers engines. This knowledge empowers individuals to tackle challenges with confidence and precision, ensuring longevity and peak operation.

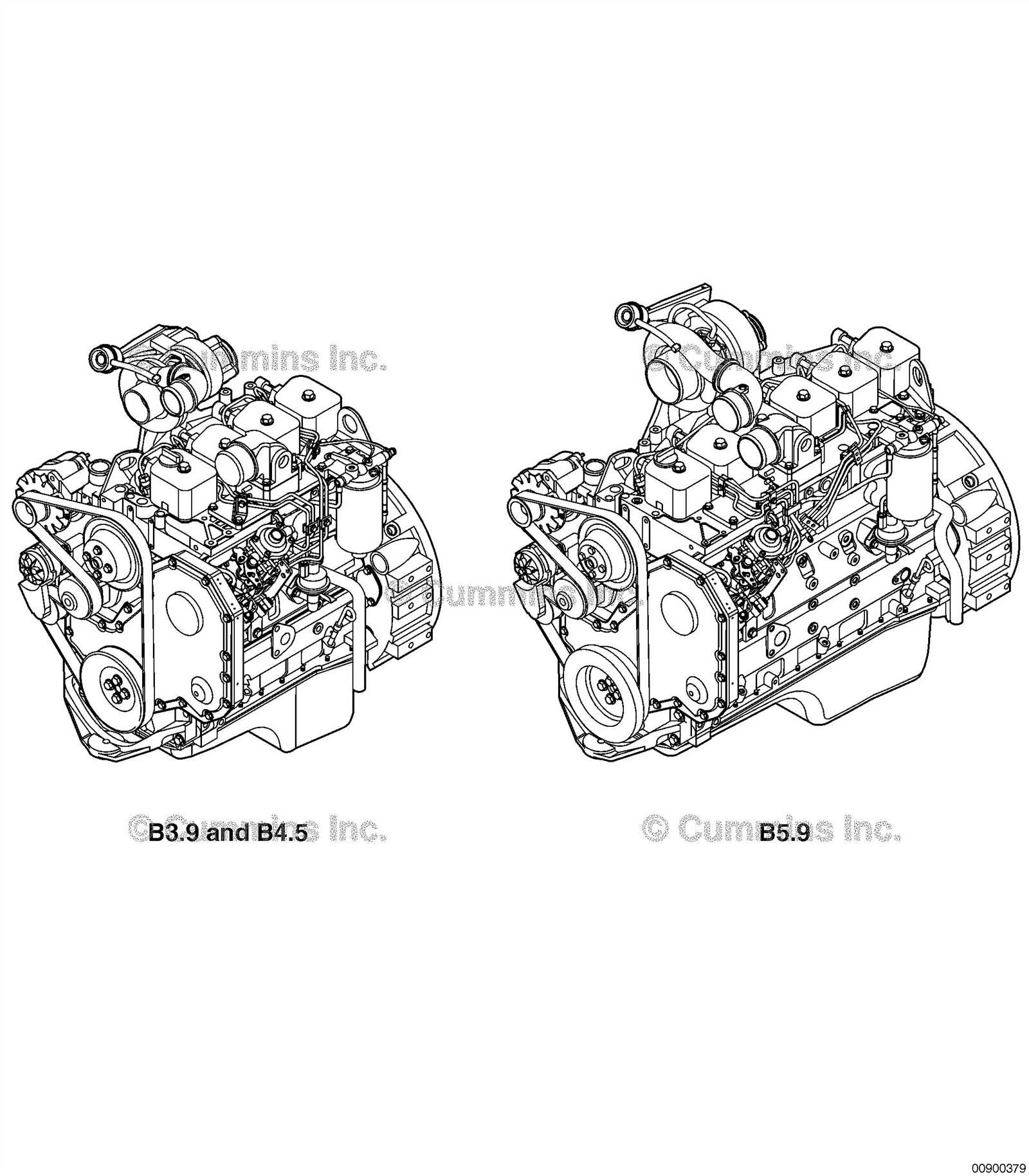

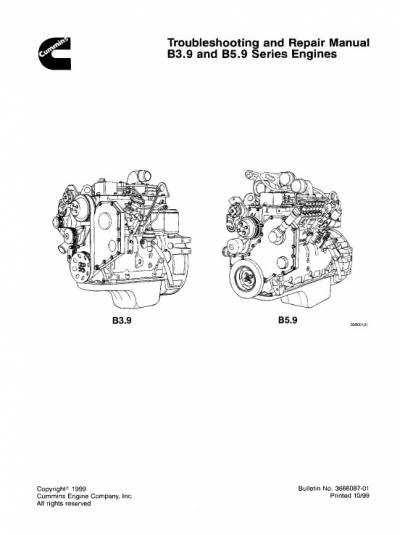

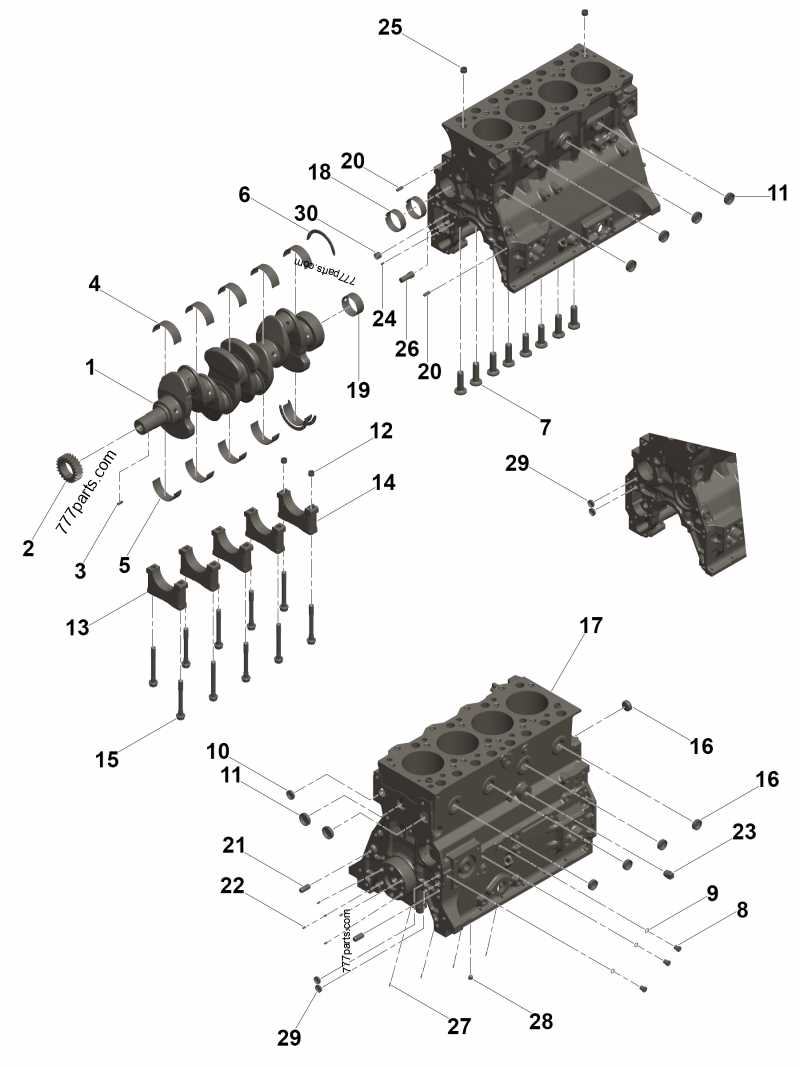

Cummins B3 3 Parts Overview

This section provides a comprehensive look at the components associated with the B3 engine model, highlighting their significance in the overall functionality and efficiency of the system. Each element plays a crucial role in ensuring optimal performance and reliability, making it essential to understand their interconnections and operational purposes.

Key Components

Among the main elements are the fuel injection system, the cooling mechanism, and the exhaust configuration. The fuel injection system is vital for delivering the right amount of fuel at precise timings, which enhances combustion efficiency. Meanwhile, the cooling mechanism ensures that the engine operates within safe temperature limits, preventing overheating and prolonging lifespan. Lastly, the exhaust configuration facilitates the safe expulsion of combustion gases, contributing to a cleaner and more efficient operation.

Functionality and Maintenance

Understanding the functionality of these components is essential for effective maintenance. Regular checks and timely replacements can significantly improve performance and minimize downtime. Identifying wear and tear early on allows for proactive measures, ensuring that the engine remains in peak condition throughout its operational life.

Understanding the Engine Components

Grasping the intricacies of an engine’s structure is vital for effective maintenance and performance optimization. Each element plays a crucial role in the overall functionality, contributing to the engine’s efficiency and longevity.

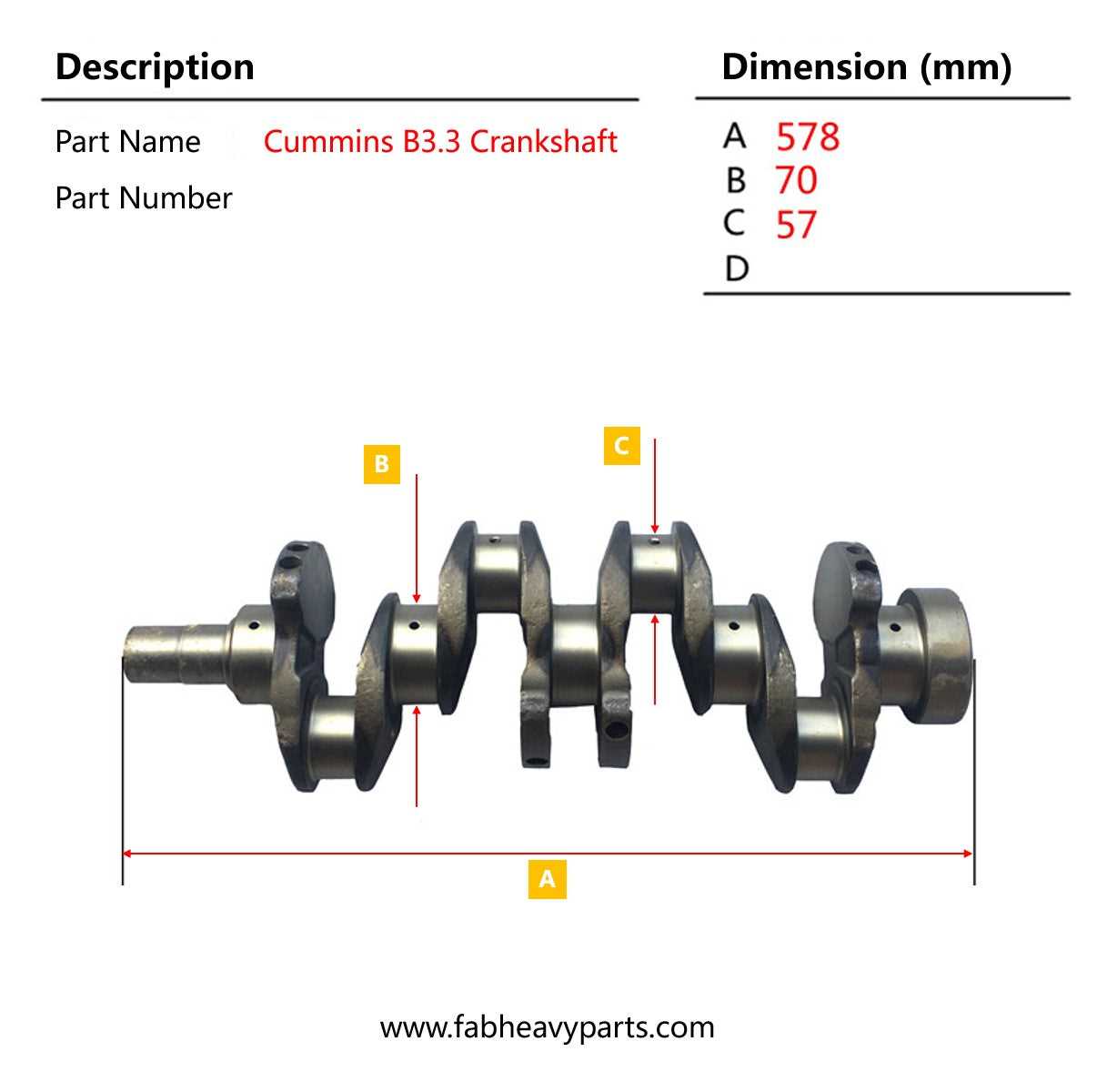

Core Elements

The essential components, such as the combustion chamber, crankshaft, and pistons, work in harmony to generate power. Understanding their interactions provides insight into the engine’s operational principles.

Supporting Systems

In addition to the main elements, auxiliary systems like lubrication and cooling are equally important. These systems ensure that the core components function smoothly, preventing overheating and wear.

Importance of Diagram Analysis

Understanding the visual representation of components and their interrelations is crucial for effective maintenance and repair. Analyzing these illustrations allows professionals to identify critical areas and improve efficiency in troubleshooting. This process enhances overall comprehension of the system’s functionality and design, leading to better decision-making.

Enhanced Problem-Solving Skills

By examining these visuals, technicians can pinpoint issues more accurately. This not only saves time but also reduces the risk of errors, ensuring that repairs are executed correctly. With a clear understanding of how elements interact, the ultimate goal of restoring optimal performance is more easily achieved.

Streamlined Training Processes

Utilizing visual aids in training programs allows new learners to grasp complex concepts quickly. These representations serve as valuable tools for both teaching and reference, enabling a smoother transition into practical applications. As a result, teams become more proficient and confident in their abilities.

Key Features of the Cummins B3

This section explores the distinctive attributes of a powerful engine model, emphasizing its design and performance characteristics that set it apart in the industry. The combination of efficiency and reliability makes it a preferred choice for various applications.

Durability: Built with robust materials, this engine offers exceptional longevity and withstands demanding conditions.

Efficiency: Optimized fuel consumption ensures a lower environmental impact while maintaining high performance.

Versatility: Suitable for diverse applications, this engine excels in both industrial and commercial settings.

Advanced Technology: Incorporating innovative engineering, it enhances operational capabilities and reduces maintenance needs.

Common Applications of the Engine

This engine type is widely utilized across various industries due to its reliability and efficiency. Its versatility allows it to power a range of equipment, making it a preferred choice in numerous applications.

- Construction Equipment:

- Excavators

- Bulldozers

- Loaders

- Agricultural Machinery:

- Tractors

- Harvesters

- Irrigation Systems

- Industrial Applications:

- Generators

- Compressors

- Hydraulic Pumps

- Transportation:

- Heavy-duty Trucks

- Buses

- Specialty Vehicles

These engines are chosen for their robustness and adaptability, making them essential for meeting the demanding needs of various sectors.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your engine operates at peak efficiency. Adopting a systematic approach to maintenance not only extends the lifespan of your equipment but also enhances its overall reliability. By following a few key practices, you can prevent unexpected breakdowns and optimize performance.

Routine Checks

Conducting frequent inspections is crucial. Check fluid levels, including oil and coolant, to ensure they are within recommended ranges. Changing filters regularly can prevent contaminants from affecting engine performance. Additionally, keeping an eye on belts and hoses for wear and tear will help avoid costly repairs.

Lubrication and Cleaning

Proper lubrication is vital for reducing friction and wear. Utilizing high-quality lubricants will contribute to smoother operation. Furthermore, maintaining cleanliness in the engine compartment will prevent dirt and debris from obstructing vital components. Regular cleaning of air intake and exhaust systems will also improve efficiency and performance.

Identifying Component Wear and Tear

Understanding the signs of degradation in machinery is crucial for maintaining optimal performance and longevity. Regular inspections can reveal critical issues that, if left unaddressed, may lead to costly failures. This section explores key indicators to monitor during evaluations.

| Indicator | Description |

|---|---|

| Visual Inspection | Look for cracks, corrosion, or discoloration on surfaces. |

| Abnormal Noises | Listen for unusual sounds, which may indicate friction or misalignment. |

| Performance Drops | A decrease in efficiency can signal underlying issues needing attention. |

| Leakage | Fluid leaks can point to worn seals or gaskets that require replacement. |

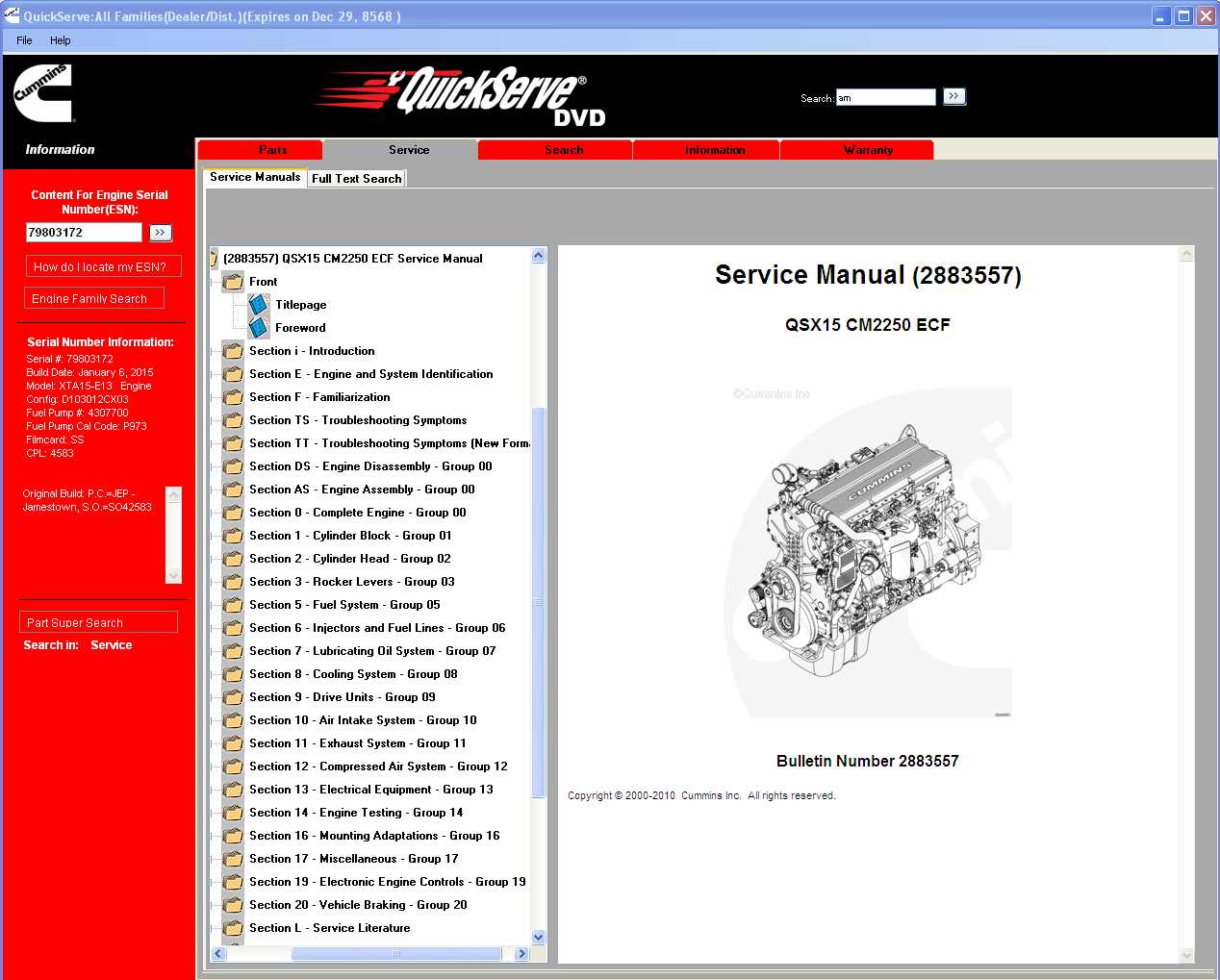

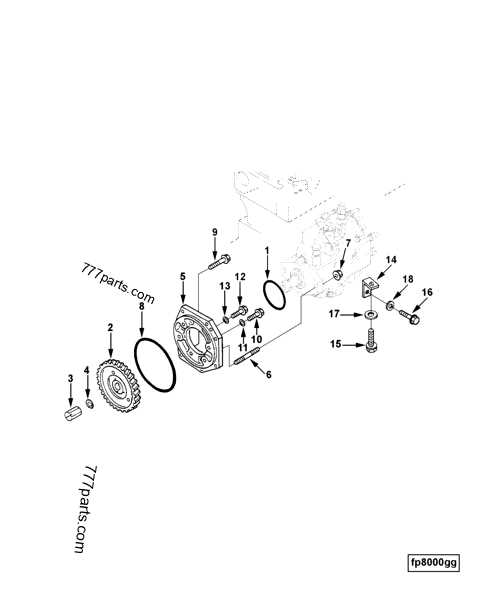

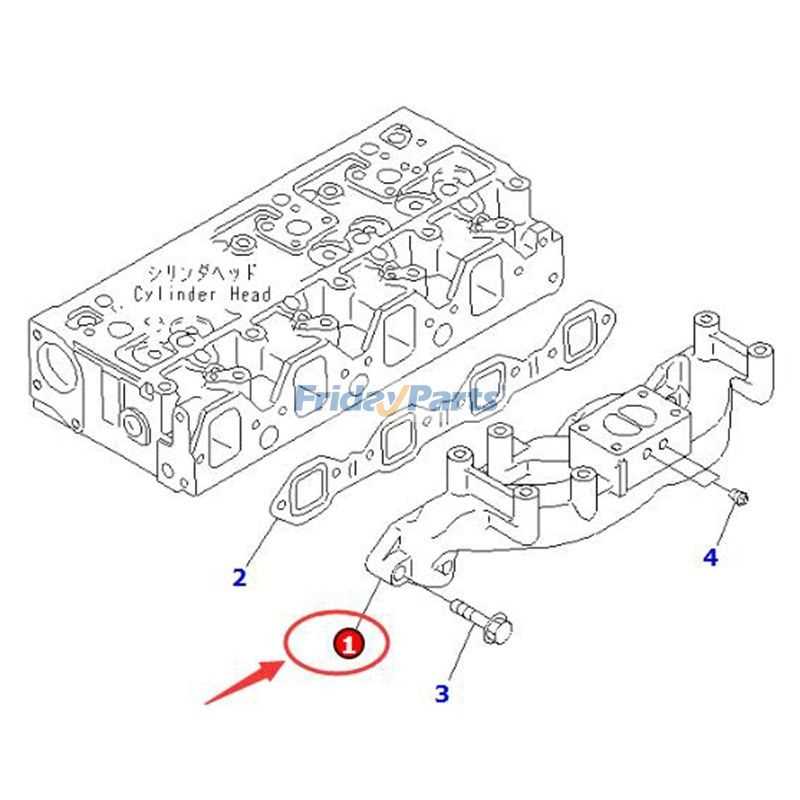

How to Read Engine Diagrams

Understanding mechanical layouts is crucial for anyone involved in engine maintenance or repair. These visual representations serve as blueprints that convey intricate details about components and their relationships. By familiarizing yourself with these illustrations, you can gain insight into the functionality and assembly of an engine.

Key Elements to Focus On

When analyzing mechanical layouts, several aspects are essential for effective comprehension. Pay attention to the following elements:

| Element | Description |

|---|---|

| Symbols | Each component is represented by a unique symbol, which may vary by manufacturer. |

| Connections | Lines indicate how components are linked, showing flow paths or electrical connections. |

| Labels | Clear identification of parts assists in understanding their function and location. |

Interpreting Layouts for Troubleshooting

These illustrations are invaluable for diagnosing issues. By referencing the symbols and connections, you can pinpoint potential failures and determine necessary repairs. A systematic approach will help in navigating through the information efficiently, making it easier to resolve problems swiftly.

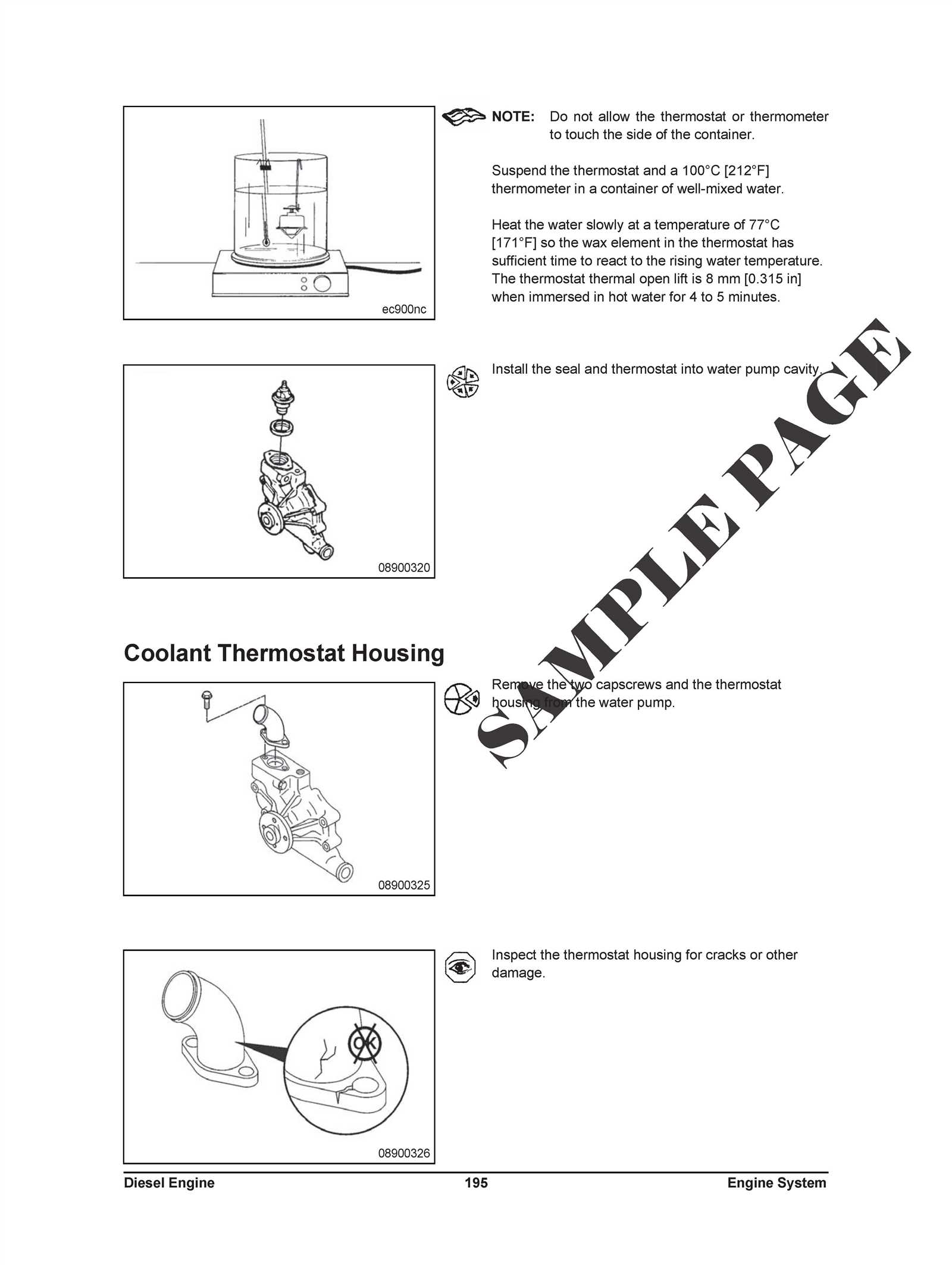

Parts Replacement Procedures Explained

Effective maintenance relies on understanding how to properly substitute components within a system. This process is essential to ensure optimal performance and longevity. By following specific protocols, one can facilitate seamless integration of new elements, minimizing downtime and enhancing efficiency.

Preparation Steps

Before initiating the replacement process, it is crucial to gather all necessary tools and materials. Inspection of the current assembly is vital to identify any additional issues that may require attention. Creating a clean workspace can significantly reduce the risk of contamination or damage during the procedure.

Replacement Procedure

Once preparations are complete, begin by carefully removing the existing component. Employ appropriate techniques to avoid damaging surrounding structures. After extraction, inspect both the new and old items for compatibility and quality. When installing the new unit, ensure that all connections are secure and adhere to manufacturer specifications. Finally, conduct a thorough testing phase to confirm that the system operates as intended, and address any anomalies promptly.

Manufacturer Specifications and Standards

Understanding the guidelines set by manufacturers is crucial for ensuring optimal performance and reliability of any mechanical system. These specifications encompass various aspects, including dimensions, materials, tolerances, and operational parameters, which are essential for maintaining the integrity of components throughout their lifecycle.

Adhering to established standards not only guarantees compatibility between different elements but also enhances safety and efficiency. Manufacturers typically follow rigorous testing protocols to validate their products against these specifications, ensuring that they meet industry benchmarks and regulatory requirements.

Incorporating these guidelines during the design and assembly processes helps prevent potential failures and extends the service life of equipment. By prioritizing adherence to these standards, users can achieve superior operational outcomes and minimize maintenance costs over time.

Frequently Asked Questions About B3

This section addresses common inquiries related to the B3 engine model. Here, we provide insights to help users better understand its features, maintenance, and operational aspects.

- What is the B3 engine?

The B3 engine is a robust power unit known for its reliability and efficiency. It is commonly utilized in various industrial applications.

- What are the main applications of the B3 engine?

This engine is widely used in construction machinery, agricultural equipment, and other heavy-duty applications due to its durability.

- How do I perform routine maintenance on the B3?

Regular maintenance includes checking fluid levels, replacing filters, and inspecting belts and hoses. It’s advisable to follow a scheduled maintenance plan.

- What are common issues faced with the B3 engine?

Some typical problems include overheating, fuel injection issues, and abnormal noises. Early detection can prevent significant damage.

- Where can I find support or spare components for the B3?

Support and components are available through authorized dealers and service centers specializing in industrial engines.

- What is the warranty coverage for the B3 engine?

Warranty coverage may vary by dealer, so it is essential to review the terms provided at the time of purchase.

Comparing B3 with Other Cummins Models

This section explores the distinctions between the B3 variant and its counterparts, highlighting unique features and performance characteristics that set them apart in the industry.

Key comparisons include:

- Power Output: The B3 often provides a specific range of horsepower suitable for various applications.

- Fuel Efficiency: Some models prioritize economy, while the B3 balances power and consumption effectively.

- Size and Weight: The B3’s compact design may offer advantages in space-constrained environments compared to larger models.

When evaluating these engines, consider:

- Intended usage and application requirements.

- Maintenance and serviceability based on design differences.

- Cost-effectiveness over the lifespan of the engine.

Ultimately, understanding these variations helps in making informed decisions tailored to specific operational needs.

Resources for Further Learning

Expanding your knowledge on machinery components can significantly enhance your understanding and expertise. Numerous materials are available that cover various aspects of mechanical systems, offering insights into their function, maintenance, and optimization.

Books: Consider exploring technical manuals and industry-standard literature that delve into engine mechanics and system design. These resources often provide detailed explanations and practical examples.

Online Courses: Platforms offering courses in mechanical engineering or automotive technology can serve as an ultimate resource. Look for classes focusing on engine functionality and repair techniques.

Forums and Communities: Engaging with online communities can be invaluable. Participate in discussions and seek advice from experienced professionals who can share practical knowledge and tips.

YouTube Channels: Many educational channels provide video tutorials that visually demonstrate repair processes and component functions, making complex topics more accessible.

Technical Websites: Websites dedicated to engineering and mechanical systems often feature articles, case studies, and white papers that can deepen your understanding and keep you updated on the latest advancements.