Understanding the essential elements of complex farming machinery can greatly improve its performance and longevity. Each component plays a crucial role in ensuring optimal functionality, and a comprehensive grasp of their placement and interaction can help in maintaining and troubleshooting your equipment.

This guide will take you through a structured breakdown of critical hardware, illustrating how they work together to ensure smooth operations. By identifying and familiarizing yourself with these key mechanisms, you’ll be better equipped to handle repairs, adjustments, and replacements when necessary.

Explore the intricacies of these systems, and uncover how small adjustments can make a significant impact on the efficiency and productivity of your agricultural tasks. The following information will provide a visual representation, coupled with in-depth descriptions to enhance your technical knowledge.

Understanding the Components of the White 6100 Planter

Efficient performance in planting machinery depends on the synergy of several crucial components working together seamlessly. By grasping the role of each mechanism, one can ensure better maintenance, improved functionality, and an extended lifespan for the equipment.

Row Units and Their Importance

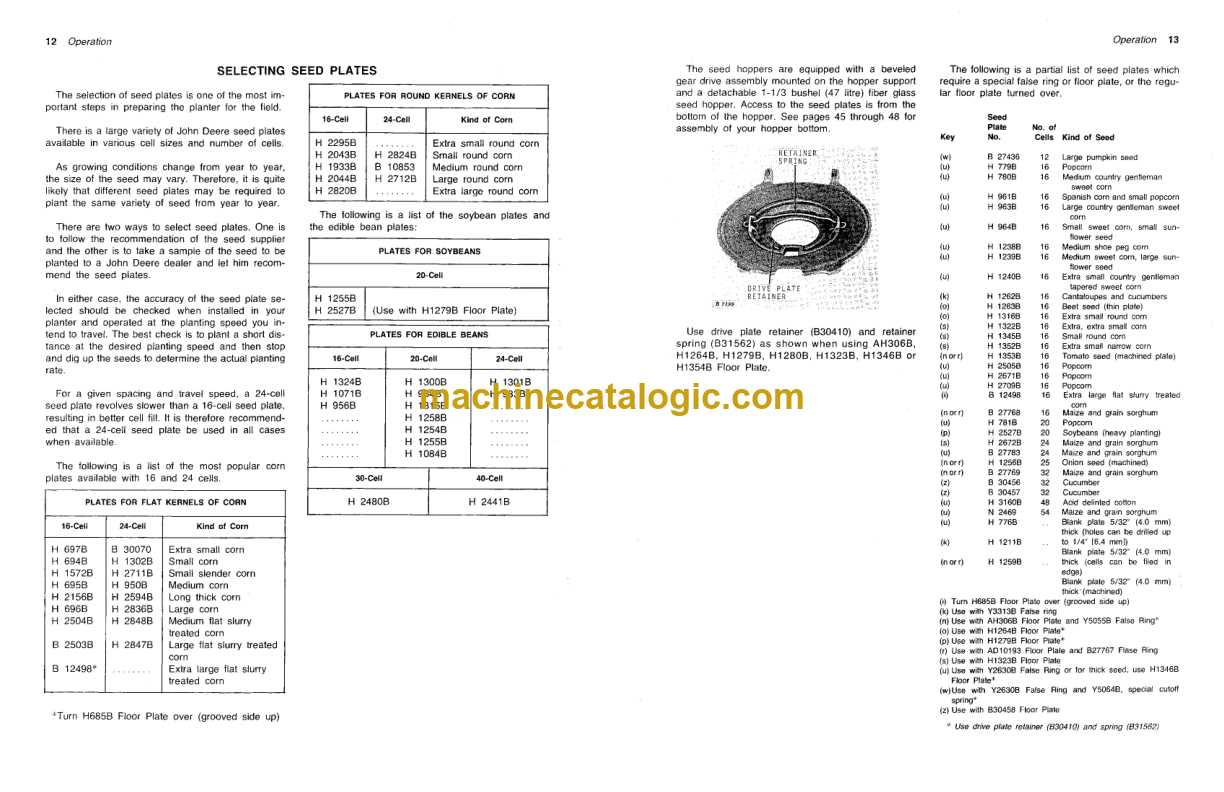

Row units play a critical role in planting accuracy, regulating seed placement and depth. These assemblies consist of various mechanisms such as seed meters, opener disks, and closing wheels, each responsible for precise seed delivery and soil coverage. Proper calibration and maintenance of these units directly impact planting success.

Seed Delivery System

The seed distribution process relies heavily on an efficient delivery system. This system ensures that seeds are consistently fed into the ground at the correct intervals. Components like seed tubes and meters work together to guarantee smooth and accurate flow, preventing jams or irregular spacing.

Key Features of the White 6100 Planter

This equipment is renowned for its reliability and precision in the field. Designed to maximize productivity, it offers a range of innovative technologies that support efficient planting, ensuring consistent results across various soil types. Its construction emphasizes durability, while advanced features contribute to user convenience and superior crop outcomes.

Efficient Seed Distribution: Equipped with an advanced metering system, the machine ensures accurate seed spacing and depth. This guarantees uniform germination and optimal growth, which ultimately leads to better yields. The mechanism is adjustable, allowing for customization based on crop type and conditions.

Adjustable Depth Control: The system includes precision depth control settings, allowing for exact seed placement. This feature helps adapt planting techniques to different field conditions, ensuring that each seed is planted at the ideal depth for successful sprouting.

Durability and Build Quality: Built with rugged materials, the equipment withstands tough field conditions and long hours of operation. The robust

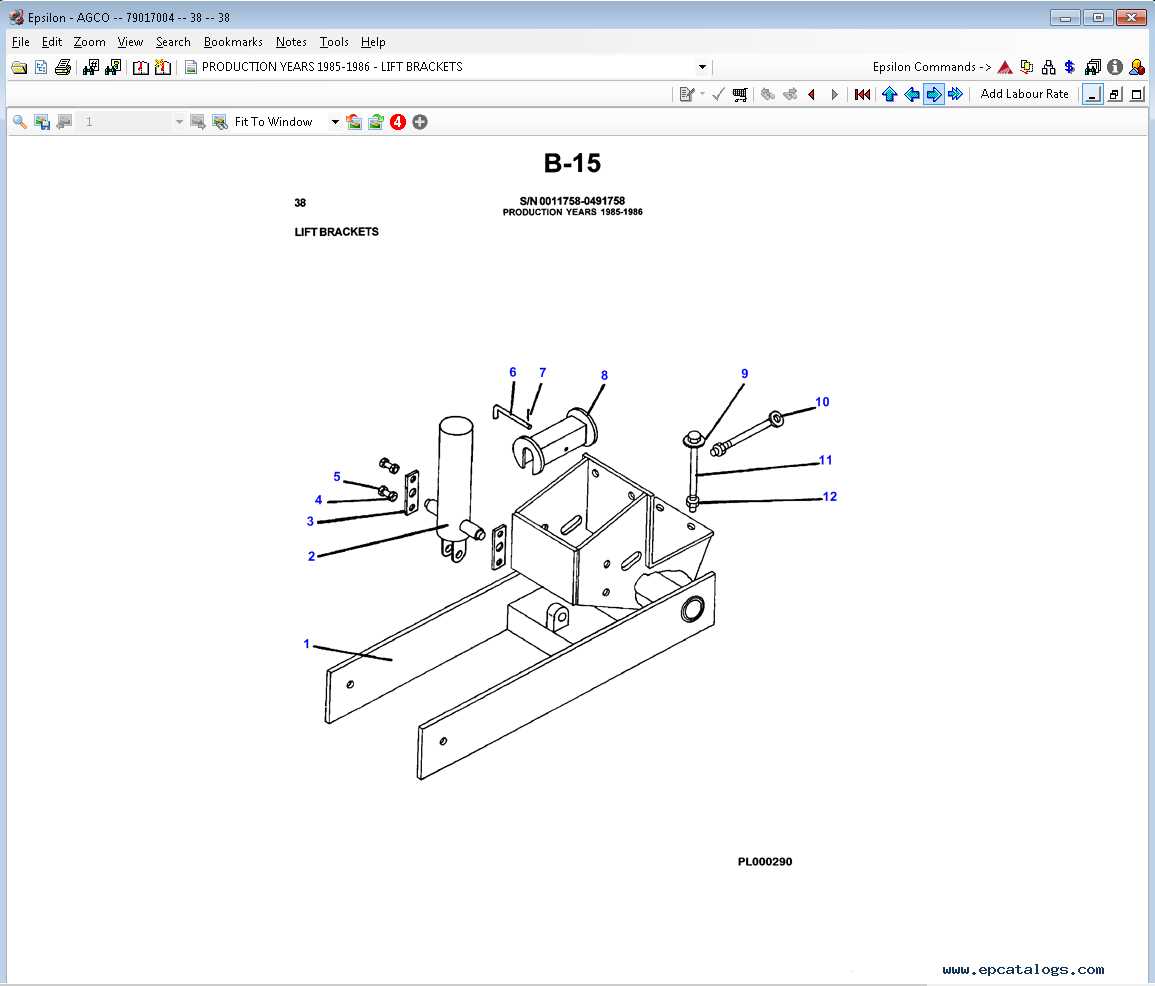

How to Identify Parts on a White 6100 Planter

Understanding the various elements that make up your agricultural equipment is key to maintaining optimal performance. Recognizing individual components is crucial for efficient troubleshooting, replacement, and routine upkeep. In this section, we will explore practical methods for locating and distinguishing the essential features of your machinery, helping you ensure smooth operation and reduce downtime.

| Component | Location | Function | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Seed Meter | Located near the row unit | Controls the release and spacing of seeds | |||||||||||||||||

| Disc Opener | Attached to the row unit arms | Opens furrows for precise seed placement | |||||||||||||||||

| Maintenance Task | Frequency |

|---|

| Aspect | Original Equipment Manufacturer (OEM) | Aftermarket Options |

|---|---|---|

| Cost | Generally higher | More affordable |

| Availability | Limited | Widely available |

| Quality | Consistent | Varies by supplier |

| Customization | Standardized | Often customizable |

| Warranty | Typically included | Varies |

When considering alternative solutions, it’s essential to research reputable suppliers and read reviews from other users. Engaging with farming communities can also provide insights into effective aftermarket options. Ultimately, exploring these choices can lead to enhanced performance and reduced operational costs, making it a worthwhile endeavor for anyone in the agricultural sector.

Where to Find a Reliable Diagram of the White 6100 Planter

Locating a dependable schematic for agricultural equipment can significantly enhance maintenance and repair efforts. Understanding the intricate components of machinery is essential for ensuring optimal functionality and longevity. Various resources exist that can provide detailed visual aids to assist in identifying and replacing crucial elements of your equipment.

Online Platforms: The internet hosts a plethora of websites dedicated to agricultural machinery resources. Websites specializing in farming equipment often feature comprehensive guides and illustrations. These platforms may also offer downloadable manuals that include thorough breakdowns of various models, making them an excellent starting point for your search.

Manufacturer Resources: Visiting the official website of the manufacturer can yield a wealth of information. Many manufacturers provide downloadable resources, including user manuals and maintenance guides, which typically contain detailed schematics. These documents ensure that you are referencing accurate and model-specific information.

Local Dealers: Engaging with local dealerships or repair shops that specialize in agricultural equipment can also be beneficial. These professionals often have access to proprietary resources and may offer printed materials or advice on where to find specific illustrations that pertain to your machinery.

Online Forums and Communities: Participating in online forums or social media groups focused on agricultural machinery can connect you with other enthusiasts and professionals. Members often share valuable insights and resources, including links to diagrams or personal compilations that can aid in your quest for reliable information.

Library and Archive Resources: Public or specialized libraries may hold archives of agricultural manuals and schematics. These resources are often underutilized but can provide unique insights and detailed illustrations for various equipment types, including the one you are researching.

By exploring these diverse avenues, you can effectively locate a reliable schematic that meets your specific needs, thereby enhancing your understanding and care of your agricultural machinery.