When it comes to maintaining and repairing a high-performance tool, grasping the layout and functionality of its components is essential. This knowledge not only ensures efficient operation but also extends the lifespan of the equipment. By delving into the intricate arrangement of elements within a specific model, users can become more adept at troubleshooting and performing necessary upgrades.

Visual aids play a crucial role in this understanding, as they allow for a clearer representation of how various sections interconnect. Whether you’re a seasoned professional or a passionate DIY enthusiast, familiarizing yourself with the configuration can significantly enhance your hands-on experience. This exploration not only promotes safety but also empowers users to tackle issues with confidence.

In this section, we will explore the detailed organization of components, highlighting key features and functionalities. By breaking down the various sections, we aim to provide a comprehensive guide that will aid in both routine maintenance and more extensive repairs. This foundational knowledge is vital for anyone looking to maximize the efficiency and reliability of their equipment.

Understanding Stihl 025 Diagrams

Comprehending technical illustrations is essential for efficient maintenance and repair tasks. These visuals provide crucial insights into the various components of equipment, facilitating a clearer understanding of assembly and functionality.

Here are key aspects to consider:

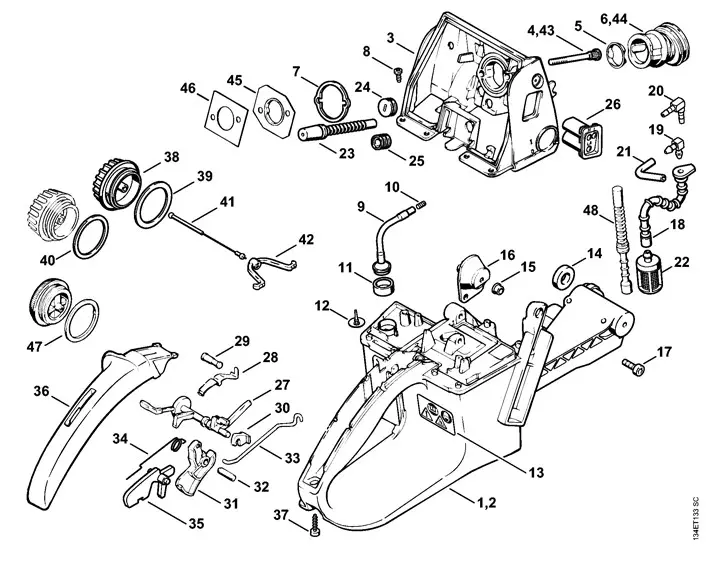

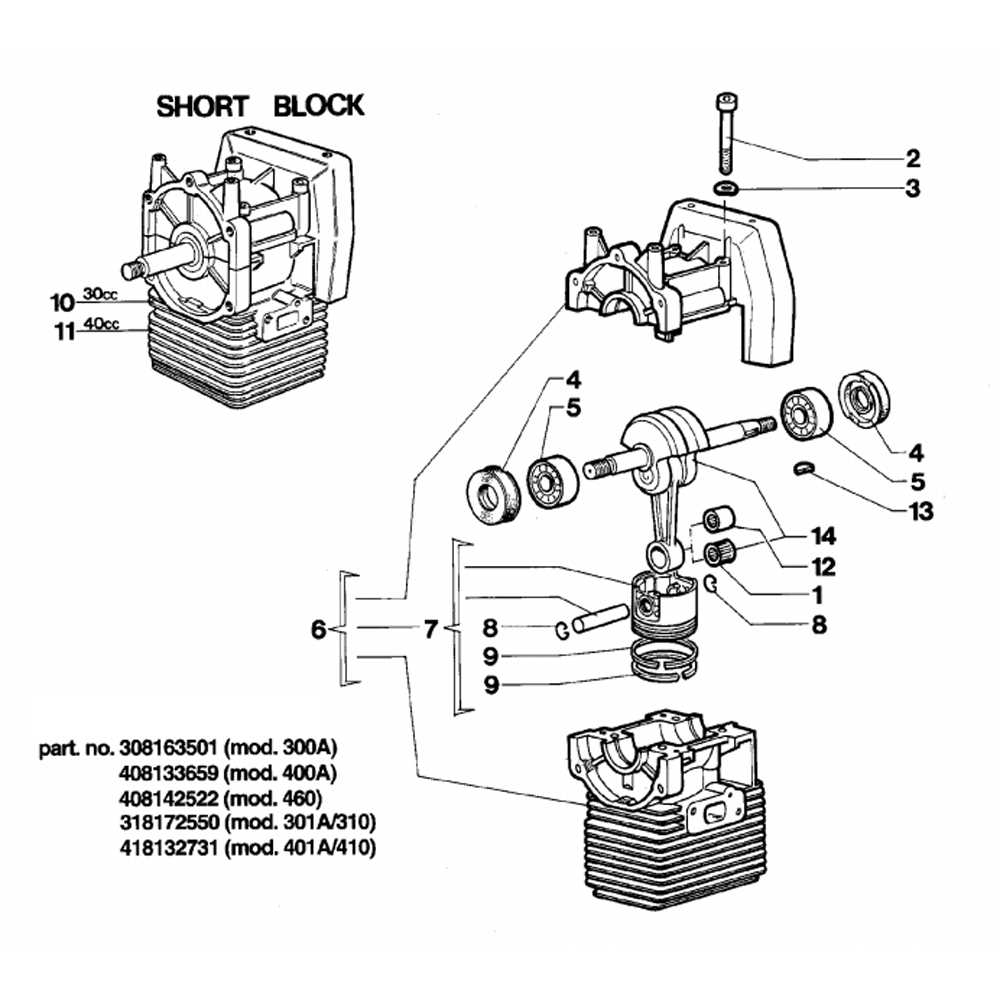

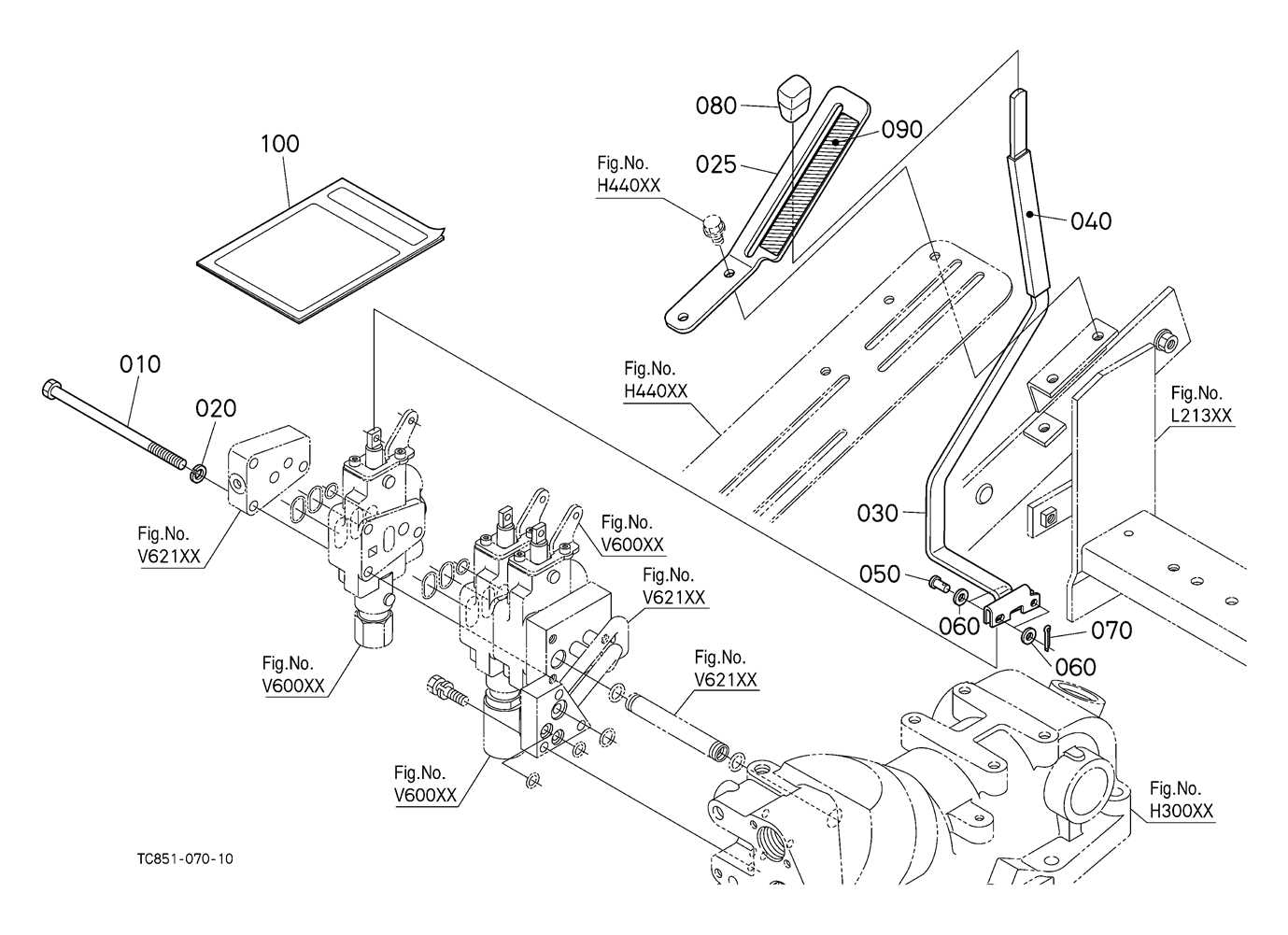

- Component Identification: Recognizing each element helps in troubleshooting and replacement.

- Assembly Guidance: Clear depictions assist in correctly assembling or disassembling machinery.

- Maintenance Insights: Understanding wear points and maintenance needs improves longevity.

By mastering these illustrations, users can enhance their repair skills and ultimately improve equipment performance.

Key Components of Stihl 025

This section explores the essential elements that contribute to the functionality and performance of a specific model of chainsaw. Understanding these components is crucial for both maintenance and operation, ensuring optimal efficiency and longevity.

Essential Parts

- Engine: The powerhouse that drives the entire unit.

- Bar and Chain: Integral for cutting, they work together to achieve precise results.

- Air Filter: Maintains engine performance by preventing dirt and debris from entering.

- Fuel System: Critical for powering the engine, comprising the tank and lines.

Operational Features

- Starter Mechanism: Facilitates the ignition of the engine.

- Clutch: Engages and disengages the chain, enhancing user control.

- Handle: Designed for comfort and maneuverability during operation.

Importance of Accurate Schematics

Precise visual representations play a crucial role in understanding complex machinery. They serve as essential guides, allowing users to navigate components effectively. By providing a clear layout, these illustrations enhance the user experience and promote efficient maintenance and repairs.

Clarity and Efficiency

Having a reliable visual reference enables individuals to identify parts swiftly, reducing time spent on troubleshooting. This clarity fosters a smoother workflow, ultimately leading to enhanced productivity.

Safety Considerations

Accurate representations also contribute to safety. Understanding how components fit together helps prevent errors during assembly or disassembly, minimizing the risk of accidents. Inadequate information can lead to missteps, while well-structured visuals ensure safer operations.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone working with machinery or tools. These visual representations provide a detailed view of various components and their interconnections, facilitating effective maintenance and repair. By familiarizing yourself with the layout and symbols used, you can enhance your ability to diagnose issues and source the right elements for your equipment.

Familiarize with Symbols and Notations

Every illustration uses specific symbols and notations to represent different components. It’s crucial to understand what each symbol signifies, as this knowledge will help you locate the parts you need. Look for a legend or key that explains the symbols, making it easier to interpret the drawing accurately.

Identify the Assembly Sequence

In addition to recognizing individual components, pay attention to the assembly sequence depicted. This will guide you in understanding how parts fit together, which is particularly useful when reassembling after repair. Analyzing the flow of the illustration will aid in visualizing how to approach disassembly and reinstallation effectively.

Common Issues with Stihl 025

When it comes to outdoor power equipment, certain challenges frequently arise, impacting performance and usability. Identifying these common problems can enhance maintenance and prolong the lifespan of the machinery. Here, we delve into prevalent difficulties that users encounter, along with practical solutions.

| Issue | Description | Solution |

|---|---|---|

| Hard to Start | Engine fails to ignite or requires multiple attempts. | Check the fuel mixture and inspect the spark plug for wear. |

| Poor Performance | Reduced power output during operation. | Clean or replace the air filter and ensure the fuel line is unobstructed. |

| Excessive Vibration | Unusual shaking during use, causing discomfort. | Inspect the anti-vibration mounts and tighten any loose screws. |

| Fuel Leaks | Visible dripping of fuel from the unit. | Examine the fuel lines and tank for cracks and replace damaged components. |

| Stalling | Engine unexpectedly stops during operation. | Check the ignition system and ensure proper carburetor adjustment. |

Addressing these common issues with prompt attention not only enhances the efficiency of the tool but also ensures a safer experience while using it. Regular maintenance checks are recommended to prevent these problems from escalating.

Replacement Parts Overview

Maintaining machinery requires a thorough understanding of essential components that ensure optimal performance. When components wear out or become damaged, timely replacement is crucial to extend the life of the equipment and maintain its efficiency.

Quality is paramount when selecting replacements; using original or high-quality substitutes can significantly impact performance. It’s important to delve into specifications and compatibility to ensure the ultimate functionality of your equipment.

Moreover, regular inspection can help identify potential issues before they escalate, allowing for proactive measures. By prioritizing the right components, users can achieve better longevity and reliability from their machinery.

Tools for Maintenance and Repair

Effective upkeep and restoration of equipment require a variety of specialized implements. These tools are essential for ensuring optimal performance, longevity, and safety. From basic hand tools to advanced diagnostic devices, having the right equipment at your disposal makes a significant difference in the maintenance process.

Hand Tools are fundamental for routine tasks. Screwdrivers, wrenches, and pliers are indispensable for tightening, loosening, and adjusting components. Investing in a high-quality set can save time and reduce frustration during repairs.

Power Tools can expedite more demanding jobs. Drills, saws, and grinders enhance efficiency and precision, allowing for more complex tasks to be completed with ease. Selecting the appropriate power tool for specific jobs is crucial for achieving desired results.

Diagnostic Equipment plays a vital role in identifying issues. Multimeters and compression testers help assess performance and pinpoint malfunctions, making troubleshooting much more straightforward. Understanding how to use these tools effectively is essential for any maintenance technician.

Finally, Safety Gear cannot be overlooked. Gloves, goggles, and ear protection are essential to safeguard against potential hazards while working. Prioritizing safety ensures that maintenance and repair tasks can be completed without unnecessary risks.

By equipping yourself with the right tools, you enhance your ability to maintain and repair machinery effectively, leading to improved functionality and durability.

Identifying Faulty Components

Recognizing malfunctioning elements in machinery is crucial for maintaining optimal performance and longevity. Various signs can indicate that a specific component may require inspection or replacement. By understanding these indicators, operators can prevent further damage and ensure the equipment operates efficiently.

Common symptoms of defective parts include unusual noises, excessive vibrations, and difficulty starting the machine. Regular monitoring of performance and conducting routine checks can help identify issues early on. Below is a table summarizing some typical indicators and their possible implications.

| Indicator | Possible Implication |

|---|---|

| Unusual Noises | Worn bearings or loose fittings |

| Excessive Vibration | Imbalance or damaged components |

| Difficulty Starting | Fuel delivery issues or ignition problems |

| Overheating | Poor lubrication or clogged air filters |

By systematically observing these symptoms and addressing them promptly, users can maintain the reliability and efficiency of their equipment, ultimately leading to better performance and reduced downtime.

Benefits of Using Original Parts

Utilizing authentic components for your equipment ensures optimal performance and longevity. These items are specifically designed to fit perfectly and work seamlessly, providing numerous advantages over generic alternatives.

Quality Assurance

- Manufactured to strict standards

- Consistent performance

- Durability and reliability

Enhanced Safety

- Reduced risk of malfunction

- Improved user safety

- Compliance with manufacturer guidelines

Step-by-Step Repair Process

This section provides a comprehensive guide to effectively addressing common issues that may arise with your equipment. By following these detailed steps, you can ensure a smooth and efficient restoration process, minimizing downtime and enhancing performance.

Preparation and Safety

Before starting any maintenance or repair work, it is crucial to gather the necessary tools and equipment. Ensure you have protective gear, such as gloves and goggles, to safeguard against potential hazards. Additionally, disconnect the power source to prevent accidental activation while working on the machinery.

Disassembly and Inspection

Begin by carefully removing the outer casing and any components that may obstruct access to the internal mechanisms. Take your time to examine each part for wear, damage, or obstructions. Documenting the arrangement of components can be helpful for reassembly. Pay special attention to any signs of corrosion or buildup that could hinder performance.

Tips for Long-Term Care

Maintaining equipment in peak condition ensures its longevity and reliability. Implementing a few simple practices can significantly enhance performance and extend its lifespan. Proper care not only helps avoid costly repairs but also ensures safety during operation.

Regular Maintenance

- Clean the exterior regularly to remove dirt and debris.

- Check and replace filters as needed to ensure optimal airflow.

- Inspect and sharpen blades to enhance cutting efficiency.

- Lubricate moving parts to minimize wear and tear.

Safe Storage Practices

- Store in a dry, cool place to prevent rust and corrosion.

- Keep equipment covered to protect against dust and moisture.

- Avoid leaving fuel in the tank for extended periods to prevent degradation.

- Regularly check for any signs of damage or wear before storage.

Where to Find Diagrams Online

Accessing visual representations of machinery components can significantly enhance repair and maintenance tasks. Numerous online resources cater to enthusiasts and professionals alike, offering detailed illustrations and breakdowns. These platforms provide essential information for troubleshooting and understanding assembly, ensuring users can efficiently tackle projects.

One of the best places to start is manufacturer websites, which often host official resources for their products. Additionally, dedicated forums and community websites frequently share valuable insights and documentation. Online marketplaces and auction sites may also feature listings that include visual aids, allowing buyers to understand the items better.

Finally, educational platforms and video-sharing sites can be invaluable for those seeking tutorials and visual guidance. By exploring these avenues, users can gain access to comprehensive materials that facilitate effective repairs and maintenance.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and their maintenance. Understanding these aspects can enhance the longevity and performance of your equipment.

- What should I do if a component is damaged?

- Assess the extent of the damage.

- Consult the manufacturer’s guidelines for replacement.

- Consider professional repair if necessary.

- How often should I replace key components?

Regular inspections are crucial; replace parts based on wear and usage.

- Where can I find genuine replacements?

Authorized dealers or official online stores typically offer authentic components.

- Can I use aftermarket components?

While they may be cost-effective, ensure they meet quality standards to avoid performance issues.