Restoring vintage vehicles often requires a deep understanding of the different elements that come together to form the overall structure. For enthusiasts and restorers alike, having a clear overview of these elements is essential when planning or executing a restoration project.

In this section, we will dive into the various structural and external features of one iconic model from the late 60s. From the framework that supports the vehicle to the panels that define its appearance, every detail plays a critical role in bringing a classic car back to life.

By gaining insights into the individual components, you can better appreciate how each element contributes to the overall design and function of this timeless automobile. Whether you’re restoring or simply exploring, this guide will

1967 Mustang Body Parts Overview

When exploring the structure of this classic vehicle, it’s important to consider the various components that make up its external framework. Each element plays a significant role in the overall functionality and appearance. From the front section to the rear, every panel and component has its place in ensuring the car maintains its iconic look and performance.

Front Section Components: The front end includes elements like the grille, headlights, and fenders, all of which contribute to the unique and recognizable design. These elements not only define the car’s visual appeal but also provide protection and support for other critical systems.

Side Panels and Doors: The side sections consist of panels and doors, which serve both an aesthetic and functional

Front End Components Breakdown

The front structure of a vehicle consists of multiple interconnected elements that ensure both functionality and safety. These components work together to provide support, impact resistance, and alignment for the overall system. Understanding the breakdown of these elements is crucial for proper maintenance and repair.

Main Structural Elements

The primary parts of the front include reinforced sections that absorb impact, ensure the proper fitment of the hood, and allow for smooth operation of the steering mechanisms. Key elements are often designed to provide both strength and flexibility, ensuring the durability of the vehicle in different conditions.

Supportive Systems

Beyond the structural elements, several auxiliary systems are vital for performance. These include components responsible for cooling, lighting, and securing the front panels. Each of these systems plays a significant role in maintaining the vehicle’s efficiency and safety, working together with the main framework.

Rear Section Structural Elements

The rear section of a vehicle’s frame is essential for maintaining the overall stability and durability of the car. It provides support for various components and ensures that the rear portion is protected and properly reinforced. Understanding the key structural elements in this area is crucial for maintaining and restoring the vehicle’s integrity.

- Frame Rails: These long, horizontal beams run along the underside, providing foundational support and rigidity to the entire rear assembly.

- Trunk Floor: Positioned above the frame rails, the trunk floor serves as a base for the storage area while adding additional strength to the rear.

- Rear Crossmember: This horizontal bar connects the two frame rails, reinforcing the structure and helping to distribute forces during movement.

Chassis and Frame Key Details

The structure of a vehicle is essential for maintaining integrity and ensuring safe operation. The framework serves as the backbone, providing stability and support for various components, from the engine to the suspension. Understanding the key elements of the chassis and frame is crucial for maintaining a well-functioning automobile, as they directly impact durability, performance, and handling.

Frame Structure

The frame is the primary structural element that bears the weight of the vehicle and distributes it evenly. It offers support for the drivetrain and suspension system while protecting vital mechanical components. Over time, it is important to inspect the frame for any signs of wear or damage that could compromise its ability to withstand stress.

Chassis Components

The chassis includes several interconnected parts that ensure the

Interior Panel and Trim Layout

The layout of interior panels and trim plays a crucial role in defining the comfort and aesthetic of any vehicle’s cabin. These elements contribute to both the visual appeal and functionality, ensuring that the interior is well-organized and user-friendly. Proper placement and fitment of the panels and trim can significantly impact the driving experience by improving accessibility and enhancing the overall ambiance of the space.

- Door Panels: The side sections typically covering the inner structure of the doors, offering storage compartments and accommodating controls for windows and locks.

- Dash Trim: A set of decorative components that highlight the dashboard area, often framing the instrument cluster and air vents, contributing to a clean, polished appearance.

- Center Console:

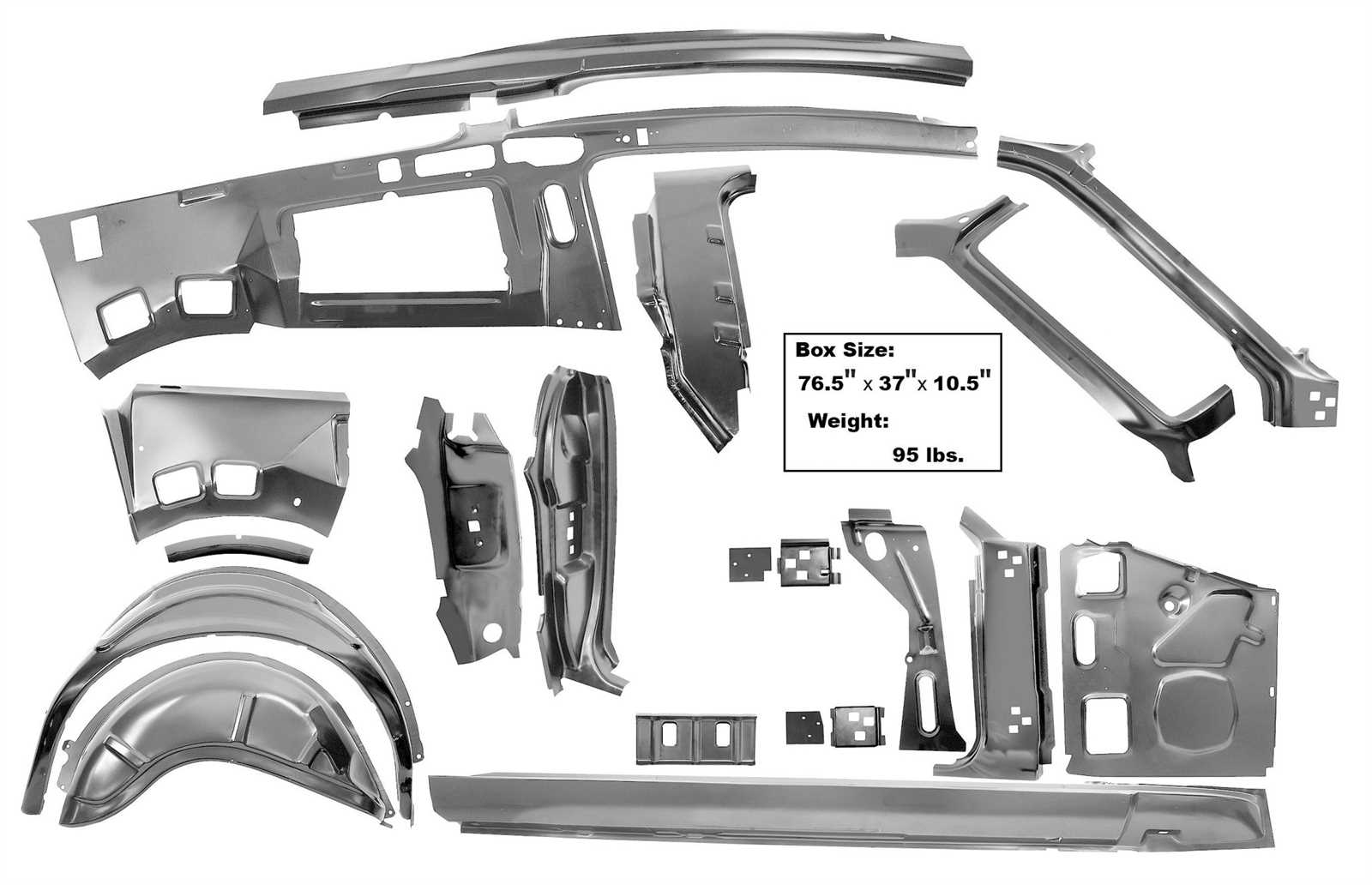

Exterior Sheet Metal Specifications

The integrity and design of a vehicle’s outer shell are crucial for both aesthetics and performance. Understanding the specifications related to the sheet metal utilized in the construction of the exterior is essential for restoration or modification projects. The materials and measurements involved play a significant role in ensuring compatibility, durability, and overall visual appeal.

The exterior metal components are typically crafted from high-quality materials that can withstand environmental challenges while providing a robust structure. Commonly used metals include steel and aluminum, each offering unique benefits regarding weight, strength, and resistance to corrosion. Dimensions for various sections, such as fenders, hoods, and door skins, are standardized to facilitate easy replacement and ensure a perfect fit during assembly.

Moreover, the thickness of the metal influences the rigidity and long-term performance of the structure. Standard gauges are often specified to maintain consistency across different models, ensuring that repair and replacement options are readily available. Understanding these specifications allows enthusiasts and professionals alike to make informed decisions when sourcing materials for restoration or enhancement tasks.

Suspension System Parts Overview

The suspension framework of a vehicle plays a crucial role in ensuring a smooth ride and stability. It consists of various components that work together to absorb shocks, maintain tire contact with the road, and enhance overall handling. Understanding these elements is essential for effective maintenance and upgrades.

Main Components of the Suspension Framework

- Shock Absorbers: These devices minimize the impact of bumps and road irregularities, providing comfort and control.

- Springs: They support the vehicle’s weight and absorb energy from road conditions, allowing for flexibility in motion.

- Control Arms: These link the chassis to the wheels, enabling precise movement and alignment during driving.

- Ball Joints: These spherical bearings facilitate smooth movement between suspension components while allowing for articulation.

Additional Components

- Stabilizer Bars: Also known as sway bars, these reduce body roll during cornering, improving stability.

- Mounts: These components connect suspension parts to the vehicle frame, ensuring proper alignment and support.

- Struts: Serving as both a shock absorber and a structural component, struts provide additional support and handling capabilities.

Maintaining these elements in good condition is vital for optimal performance and safety. Regular inspections and replacements as necessary can lead to a more enjoyable driving experience.

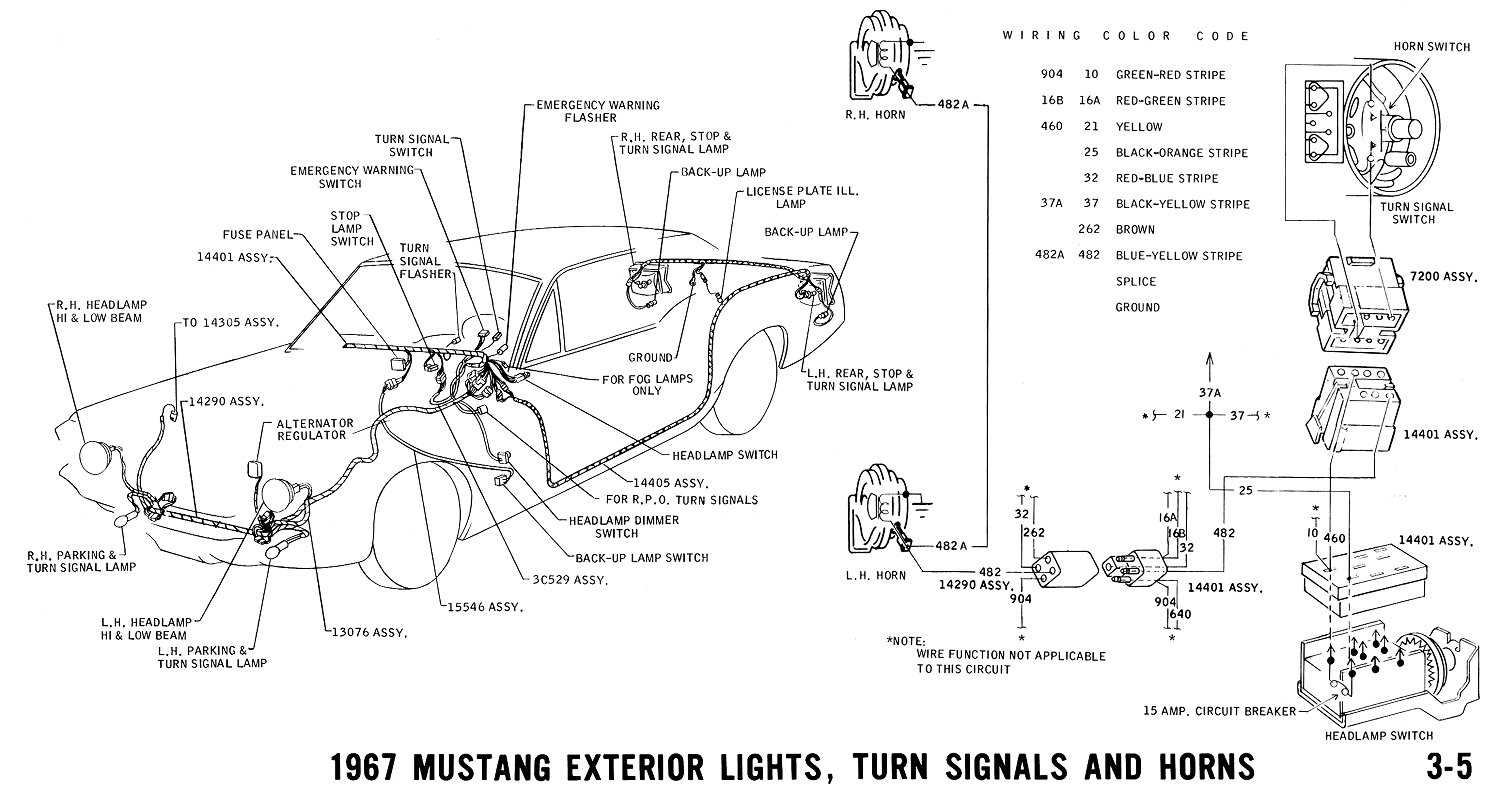

Electrical System Component Placement

Understanding the arrangement of electrical components is crucial for the efficient functioning of any vehicle’s electrical system. Proper positioning ensures that all elements can operate harmoniously, minimizing the risk of malfunctions and enhancing overall reliability.

Key Components and Their Locations

In the electrical framework, various elements play specific roles. The battery, typically located in the engine bay, serves as the primary power source, supplying energy to the entire system. Nearby, the alternator is strategically placed to recharge the battery while the engine runs. Wiring harnesses connect these components, facilitating the flow of electricity throughout the vehicle.

Importance of Accessibility

Accessibility is vital when arranging electrical elements. Components such as the fuse box and relays should be easy to reach for maintenance and troubleshooting. This consideration not only simplifies repairs but also promotes safe operation. Ensuring that these parts are organized effectively enhances the overall performance and longevity of the vehicle’s electrical network.

Windshield and Glass Frame Details

The windshield and its surrounding framework play a crucial role in both aesthetics and functionality. They not only enhance the visual appeal of the vehicle but also provide essential protection and structural integrity. Understanding the components involved in this area is vital for effective maintenance and restoration.

Components of the Windshield Assembly

The assembly consists of several key elements, including the glass itself, the frame, and the sealants used to ensure a watertight fit. The glass is usually tempered for safety, while the frame is often made from durable materials to withstand various environmental conditions.

Installation and Maintenance Considerations

Proper installation is critical to avoid leaks and ensure safety. It is important to use high-quality sealants and to follow specific guidelines during the installation process. Regular inspections can help identify any wear or damage, which should be addressed promptly to maintain the integrity of the structure.

Doors and Hinges Configuration

The arrangement and mechanics of door structures are vital for functionality and aesthetics in classic vehicles. Proper alignment and durable components ensure ease of use and longevity, enhancing the overall driving experience. Understanding the specific configuration of these elements is crucial for restoration or customization projects.

Types of Door Mechanisms

- Hinged doors: The traditional design that swings outward.

- Suicide doors: Doors that open opposite to the standard direction, often seen in vintage models.

- Scissor doors: Unique design that lifts vertically, providing an eye-catching appearance.

Components of the Door Assembly

- Hinges: Essential for allowing smooth door movement and secure attachment.

- Strikers: Ensure the door closes properly and maintains alignment.

- Weatherstripping: Prevents water and air leaks, enhancing comfort inside the vehicle.

- Latch mechanisms: Responsible for keeping the door securely closed while in motion.

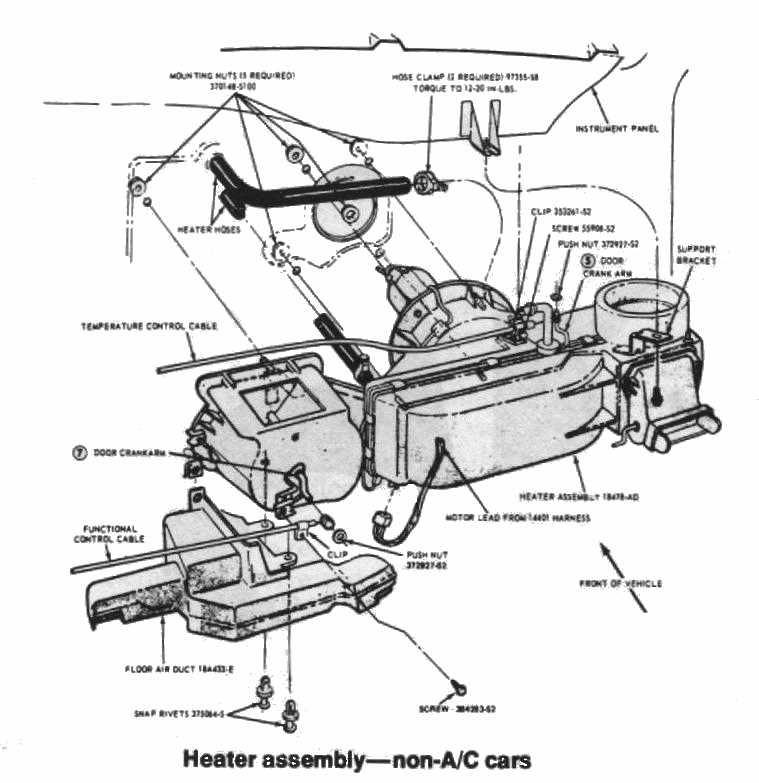

Engine Bay and Firewall Structure

The engine compartment is a crucial area of any vehicle, serving as the home for various components that contribute to its performance. Understanding the layout and design of this space can provide insights into maintenance and modifications. The firewall, positioned between the engine bay and the cabin, plays a significant role in protecting occupants from heat and noise while ensuring the integrity of the vehicle’s structure.

Component Description Firewall This barrier separates the engine bay from the interior, providing sound insulation and heat resistance. Mounting Points Secure locations for attaching various engine components, crucial for stability during operation. Hoses and Wiring Essential for connecting electrical systems and fluid circulation, ensuring the engine operates smoothly. Brackets Support structures for holding components like the battery and air filter in place.