When working with vintage off-road machines, it’s crucial to have a clear understanding of the essential elements that make up their structure. These vehicles, known for their durability and rugged design, have a specific internal configuration that requires careful consideration. Each component plays a vital role in ensuring smooth operation, and being familiar with their arrangement can significantly help in maintenance or repair tasks.

One of the most important aspects of maintaining such a vehicle is recognizing how various parts fit together. By visualizing the overall structure, you can better navigate the process of replacing or upgrading individual components. The internal and external assemblies are designed to work in harmony, creating a reliable and efficient machine capable of handling diverse terrains.

Whether you’re performing a full restoration or simply conducting routine maintenance, having a detailed breakdown of how the vehicle’s elements are organized will make the task much easier. Understanding these intricate details can save time

Honda ATC 70 Parts Diagram

This section provides a comprehensive overview of the mechanical layout and structure of a popular small-engine off-road vehicle. Understanding the key components and how they fit together is essential for proper maintenance and repairs, ensuring the long-term performance and safety of the machine.

Key Components Overview

The vehicle’s structure consists of various interconnected elements that work together to deliver smooth operation. Below is a breakdown of the main sections, providing a clear picture of the internal workings.

- Frame and Suspension

- Engine Block and Transmission

- Fuel System and Exhaust

- Electrical Wiring and Lighting

- Braking System

Detaile

Overview of Honda ATC 70 Components

The following section provides a detailed look into the essential elements that make up this classic three-wheeled vehicle. Each part plays a vital role in ensuring smooth performance, durability, and reliability during operation. This overview highlights the key elements without diving into technical schematics.

Core Mechanical Structures

- Frame: The sturdy framework serves as the foundation, supporting other critical parts.

- Suspension: Designed to absorb shocks and provide a comfortable ride over rough terrain.

- Braking System: Ensures control and safety, allowing smooth deceleration and stopping power.

Engine and Power Delivery

- Motor Unit: A compact yet powerful unit responsible for driving the vehicle forward.

- Transmission: Transfers energy from the engine to the wheels, offering seamless gear shifts.

- Exhaust System:

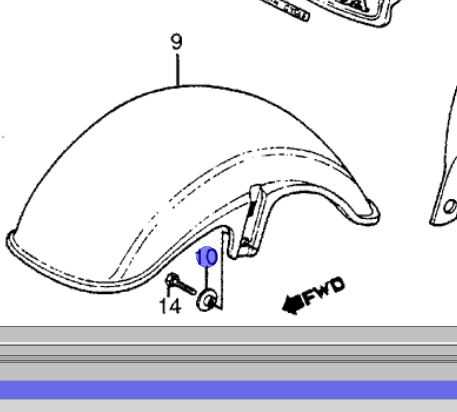

Frame and Suspension Structure Breakdown

The structure of the frame and the suspension system is crucial for ensuring stability and comfort during operation. Understanding the key elements involved in these components can help enhance performance and extend the overall durability of the vehicle. This section provides an in-depth exploration of how each part contributes to the system’s integrity and function.

Component Description Frame Serves as the foundation, supporting the entire assembly and connecting all mechanical parts. Its design plays a significant role in overall stability. Front Suspension Absorbs shocks from uneven terrain, maintaini Understanding the Engine Assembly Layout

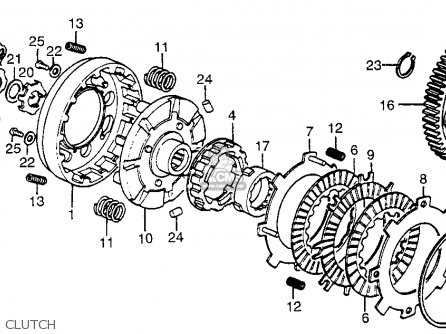

The engine assembly is a complex system that consists of various interconnected components working in unison. Each part plays a crucial role in ensuring the engine operates smoothly and efficiently. Familiarizing yourself with the overall layout of these elements can help in better understanding how the power unit functions and how its various components interact with one another.

Component Description Cylinder The main section where combustion occurs, converting fuel into mechanical energy. Piston Moves within the cylinder, compressing the air-fuel mixture and driving the crankshaft. Cr Fuel System Components and Layout

The fuel system is a vital part of ensuring efficient operation by supplying the engine with the necessary fuel. Understanding the configuration and components involved can help maintain smooth performance and proper functioning over time. This section outlines the various elements that make up this essential system, as well as their arrangement.

Key Elements of the Fuel System

Several core components work together to manage fuel delivery. These include a storage unit for the fuel, conduits that carry it to the engine, and mechanisms that regulate the flow. Proper coordination between these elements ensures a steady and safe fuel supply.

Layout of the Fuel Flow

The structure of the fuel system is designed to facilitate efficient flow from the reservoir to the engine. Strategic placement of valves and control mechanisms helps maintain optimal pressure and prevents any blockages or leaks, ensuring reliable performance.

Electrical System Parts and Connections

This section provides an overview of the components involved in the electrical framework of the vehicle, emphasizing their roles and interconnections. Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring optimal performance.

Key Components of the Electrical Framework

The electrical system includes various essential components, each serving a specific function. From the battery that stores energy to the wiring harness that facilitates connectivity, every part plays a vital role in the overall operation. Below is a table outlining the primary components and their descriptions:

Component Description Battery Stores electrical energy and provides power to the system. Wiring Harness Network of wires that connects various electrical components. Fuse Protects the system by breaking the circuit in case of overload. Starter Motor Initiates the engine’s operation by turning the crankshaft. Ignition Coil Transforms low voltage from the battery into high voltage to create a spark. Connections and Interactions

Proper connections among the components are essential for the electrical system’s functionality. Each part must be securely connected to ensure reliable operation and avoid issues such as short circuits or power losses. Regular inspection of these connections can help prevent potential failures and enhance the system’s longevity.

Steering and Handlebar Setup

Setting up the steering mechanism and handlebars is crucial for optimal handling and rider comfort. Proper alignment and adjustment ensure that the vehicle responds accurately to the rider’s inputs, enhancing safety and performance.

The following table outlines the key components involved in the steering system, along with their functions:

Component Function Handlebars Control direction and maintain balance Stem Connects handlebars to the front fork Throttle Grip Regulates engine power Brake Lever Activates the braking system Steering Stem Bearings Allow smooth rotation of handlebars Regular inspection and maintenance of these elements are essential to ensure a safe and enjoyable riding experience. Adjustments should be made based on the rider’s preferences and comfort level.

Wheel and Tire Configuration

Understanding the arrangement and specifications of wheels and tires is essential for optimal performance and handling of any all-terrain vehicle. Proper configuration can significantly influence traction, stability, and overall ride comfort.

When selecting wheels and tires, several key factors should be considered:

- Size: The dimensions of the wheels and tires affect the vehicle’s ground clearance and maneuverability.

- Tread Pattern: Different tread designs provide varying levels of grip on different surfaces, impacting traction and handling.

- Material: The composition of tires can affect durability and performance under diverse conditions.

- Inflation Pressure: Maintaining the correct tire pressure is crucial for ensuring safety and maximizing performance.

Choosing the right combination enhances not only the vehicle’s performance but also its longevity. Regular inspections and maintenance of the wheel and tire setup are vital to ensure safe and efficient operation.

Braking System Parts Overview

The braking mechanism of a vehicle plays a crucial role in ensuring safety and control during operation. Understanding its components is essential for proper maintenance and functionality.

Key elements of this system include:

- Brake Pads: These are responsible for generating friction against the wheels, enabling effective stopping power.

- Brake Discs: Also known as rotors, these components work in conjunction with brake pads to create the necessary force to halt movement.

- Calipers: These devices house the brake pads and apply pressure against the discs when the braking action is initiated.

- Brake Lines: Essential for transferring hydraulic fluid, these lines connect the brake pedal to the calipers.

- Master Cylinder: This part converts the force from the brake pedal into hydraulic pressure, which is then transmitted to the calipers.

Regular inspection and maintenance of these components are vital for optimal performance and safety.

Exhaust System Layout and Key Parts

The exhaust system plays a crucial role in ensuring optimal performance by efficiently directing gases away from the engine. Understanding its configuration and essential components is vital for maintenance and upgrades.

The layout typically consists of several interconnected elements. The exhaust manifold collects exhaust gases from the engine cylinders and channels them into the header. This part is designed to minimize back pressure and enhance engine efficiency.

Following the header, the exhaust pipe extends toward the rear, allowing gases to flow freely. It is crucial to choose a pipe with the right diameter to prevent restrictions. The muffler, located further along the system, reduces noise produced by the escaping gases, creating a smoother auditory experience.

Lastly, the tailpipe finishes the system by expelling the gases into the atmosphere. Proper maintenance and occasional inspection of these components can greatly extend the lifespan of the entire exhaust assembly.

Maintenance Tips for ATC 70 Components

Regular upkeep of your three-wheeled vehicle’s elements ensures optimal performance and longevity. By paying attention to key components and implementing effective maintenance strategies, you can enhance reliability and prevent potential issues. Below are essential recommendations for maintaining various parts of your vehicle.

Component Maintenance Tips Engine Check oil levels frequently and replace with high-quality lubricant. Clean air filters to ensure proper airflow. Tires Inspect tire pressure regularly and adjust to recommended levels. Look for signs of wear and replace as needed. Brakes Test brake responsiveness and check for wear on pads. Replace brake fluid at recommended intervals to ensure effective stopping power. Chain Keep the chain lubricated and tensioned properly. Regularly inspect for signs of wear and replace if necessary. Battery Inspect battery terminals for corrosion. Ensure connections are tight and clean, and check the charge regularly.