Understanding the various elements that make up cooling systems is essential for maintaining their performance and extending their lifespan. These systems are designed with a combination of interconnected units, each playing a specific role in ensuring efficient temperature control. By gaining insight into these elements, users can better handle maintenance and troubleshooting tasks.

Each component within the system has a distinct function, contributing to the overall operation. Recognizing how these parts interact can simplify the process of identifying issues and performing regular upkeep. From mechanical sections to control mechanisms, a detailed understanding can lead to more effective management.

In addition to basic maintenance, a thorough grasp of the assembly allows users to replace specific elements when needed. This knowledge helps in selecting suitable replacements and guarantees that the system continues to operate smoothly, even when adjustments are required.

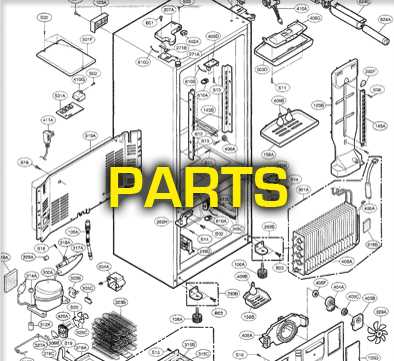

True Refrigeration Parts Diagram

Understanding the layout of various components is crucial for maintaining cooling equipment. This section explores how different elements interact and support efficient cooling performance, offering a visual guide to the intricate connections within the machinery. Identifying these elements helps in diagnosing issues and optimizing the setup.

Key Functional Components

The system includes numerous interconnected pieces, each playing a specific role in maintaining optimal temperature. The cooling mechanism relies on airflow regulation and heat exchange, with key pieces working in harmony to achieve precise conditions. Regular maintenance ensures that each segment functions as intended.

Arrangement and Connectivity

The placement and connection of each element directly influence the overall performance. Recognizing how these elements align with each other is essential for effective operation and troubleshooting. A clear understanding of the setup helps in pinpointing potential issues and carrying out adjustments when needed.

Overview of Cooling Components

Cooling systems rely on a combination of elements working in harmony to maintain low temperatures. These elements ensure efficient heat transfer and proper airflow, creating an environment suitable for preserving freshness. Understanding these components allows for better management of the cooling process.

Main Elements and Their Functions

One of the key parts of the system includes the compressor, which acts as the driving force, ensuring the flow of cooling substances. Another essential element is the evaporator, responsible for drawing in warmth and converting it into a cooler state. Together, they create a balanced cooling cycle that prevents temperature fluctuations.

Supportive Components

In addition to the main parts, there are other

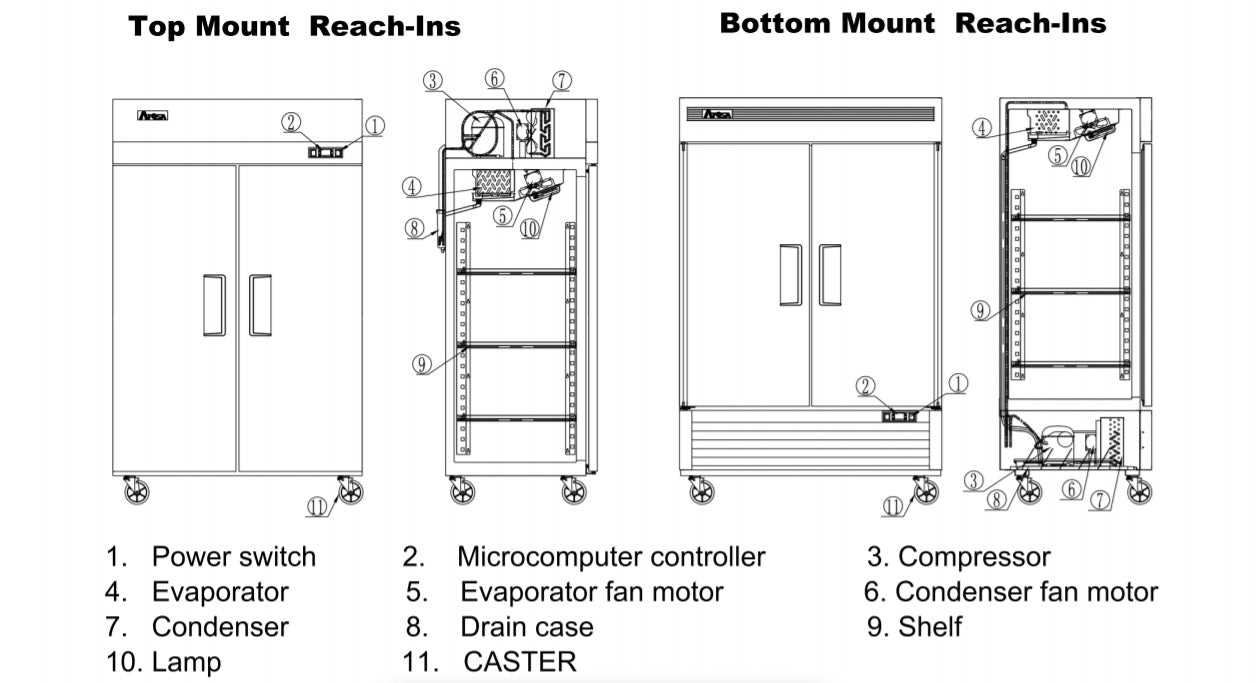

Key Parts in Commercial Refrigerators

Understanding the essential elements within large cooling units is crucial for maintaining efficient operation in commercial settings. Each component plays a role in ensuring the system functions smoothly, providing the necessary cooling for various products.

Main Cooling Elements

Several core components contribute to the cooling process, each working together to maintain optimal temperature levels. Here are some of the most important elements:

- Compressor: Acts as the heart of the cooling system, circulating the coolant and regulating pressure within the unit.

- Evaporator: Absorbs warmth from inside the unit, helping to keep the interior space at the desired coolness.

- Condenser: Responsible for releasing the collected warmth outside the unit, aiding in maintaining a steady climate inside.

Support

Understanding Refrigeration System Layout

The design of a cooling system involves a network of components working together to maintain optimal temperature levels. Each element has a specific role in controlling, moving, and removing heat from the environment. The overall arrangement ensures efficiency and smooth operation, making sure that the temperature remains stable under various conditions.

Key Components in the setup include mechanisms for compression, circulation, and heat exchange. These parts collaborate to transport and release thermal energy, ensuring the system functions seamlessly. Flow management plays a crucial role in directing the coolant through each stage, contributing to the consistency of the process.

Proper placement of each element is essential for

Main Elements of True Units

Understanding the primary components of cooling systems is crucial for maintaining their efficient operation. Each component plays a role in ensuring a stable environment within the equipment, contributing to optimal performance and durability over time. Below, we highlight some of the key parts that make these systems function seamlessly.

Cooling Mechanism

The cooling process relies heavily on a few vital mechanisms. The compressor serves as the engine, circulating

Guide to Internal Refrigerator Mechanisms

This section explores the essential components and their functions within the cooling appliance. Understanding these elements is crucial for anyone interested in maintaining or troubleshooting these units, as they work together to ensure optimal performance and longevity.

Understanding the Cooling Cycle

The cooling cycle is the heart of any unit, involving a series of processes that facilitate temperature regulation. It begins with the compression of refrigerant, which transitions into a gaseous state, absorbing heat from the interior space. This heat is then expelled outside as the refrigerant condenses back into a liquid, allowing the cycle to repeat. This continual process maintains a stable environment for food storage.

Key Components and Their Functions

Several vital elements contribute to the effectiveness of the cooling system. The compressor serves as the engine, pressurizing the refrigerant. The condenser dissipates heat, while the evaporator absorbs heat within the interior. Each of these mechanisms plays a critical role in achieving efficient temperature control, ensuring that the appliance operates smoothly.

Identifying Essential Cooling Parts

Understanding the fundamental components of a cooling system is crucial for maintaining optimal performance and efficiency. Each element plays a unique role in the overall functionality, ensuring that the desired temperature is achieved and sustained. By recognizing these critical elements, users can troubleshoot issues more effectively and enhance the longevity of their equipment.

Compressor: This vital unit serves as the heart of the system, responsible for circulating refrigerant throughout the cooling cycle. It compresses the refrigerant gas, increasing its pressure and temperature before it enters the condenser.

Condenser: Situated outside or at the back, this component dissipates heat from the refrigerant. As the high-pressure gas flows through, it cools down and transforms into a liquid state, allowing for efficient heat exchange.

Expansion Device: Often a capillary tube or expansion valve, this mechanism regulates the flow of refrigerant into the evaporator. By lowering the pressure of the refrigerant, it enables the cooling process to commence effectively.

Evaporator: Located inside the unit, this component absorbs heat from the surrounding air. The refrigerant, now in a low-pressure liquid state, evaporates within the coils, drawing heat and cooling the air that circulates through the system.

Recognizing these essential elements empowers users to ensure their cooling system operates smoothly and effectively. Regular maintenance and inspections can prevent malfunctions, prolonging the life of the entire apparatus.

Diagram Explanation for Cooling Systems

The functionality of cooling mechanisms relies on a series of interconnected components that work harmoniously to maintain desired temperatures. Understanding the layout and relationships between these elements is essential for effective operation and maintenance.

Essential Elements

Each cooling arrangement comprises various crucial units, including compressors, condensers, evaporators, and expansion valves. These components serve specific roles in the thermal management process, ensuring the efficient transfer of heat from one area to another.

Operational Workflow

In a typical cooling setup, the compressor pressurizes refrigerant, enabling it to absorb heat effectively. As the refrigerant circulates through the system, it transitions between liquid and gas states, facilitating heat exchange. Recognizing how these elements interact can significantly enhance troubleshooting and optimization efforts.

Ultimately, familiarity with the configuration of these crucial units leads to a better grasp of how cooling solutions operate and aids in identifying potential areas for improvement.

Exploring Compressor and Condenser Parts

The heart of any cooling system lies in its essential components, which play a crucial role in the overall functionality. Among these, the mechanisms responsible for compressing and condensing gases are vital for maintaining optimal temperatures. Understanding these elements provides insight into how they work together to achieve efficient thermal management.

Compressor serves as a vital engine, pressurizing the refrigerant and enabling it to flow through the system. This process is essential for transforming low-pressure gas into a high-pressure vapor, facilitating its movement toward the next stage.

Condenser follows closely in this sequence, responsible for converting vapor back into a liquid state. By dissipating heat, it plays a significant role in releasing energy and ensuring the cycle continues effectively. The design and function of these components significantly influence the performance and efficiency of the entire setup.

By examining the interaction between these two key elements, one gains a better understanding of their importance in achieving reliable cooling solutions.

Detailed Look at Evaporator Components

The evaporator is a crucial element in cooling systems, facilitating the heat exchange process that enables the cooling cycle to function efficiently. Understanding its various components helps in comprehending how this system operates and maintains optimal temperatures.

At the heart of the evaporator lies a series of essential elements that work together to ensure effective cooling. These include the evaporator coil, expansion valve, and other associated fittings that contribute to the overall performance. Each component has a specific role, and their interplay is vital for achieving desired outcomes.

| Component | Description |

|---|---|

| Evaporator Coil | A series of tubes where the refrigerant absorbs heat from the surrounding air, facilitating the cooling process. |

| Expansion Valve | Regulates the flow of refrigerant into the evaporator, maintaining optimal pressure and temperature for efficient heat absorption. |

| Insulation | Prevents heat exchange between the evaporator and the external environment, enhancing efficiency. |

| Drain Pan | Catches condensation that forms during the cooling process, preventing water damage and promoting proper drainage. |

Each of these components contributes significantly to the effectiveness and efficiency of the cooling system, ensuring a comfortable environment in various applications.

Visual Breakdown of Cooling Parts

This section aims to provide a comprehensive overview of essential components involved in the cooling mechanism of appliances. Understanding these elements is crucial for anyone looking to maintain, troubleshoot, or enhance the performance of cooling systems.

Essential Components Overview

The cooling system is composed of various integral elements, each playing a vital role in the efficient operation of temperature control. Key components include the compressor, which circulates refrigerant, and the condenser, where heat exchange occurs. Additionally, the evaporator serves as the cooling chamber, while expansion devices regulate refrigerant flow.

Functionality of Key Elements

Each component works in harmony to ensure optimal cooling performance. For instance, the compressor compresses refrigerant gas, raising its pressure and temperature, before sending it to the condenser. Here, the gas releases heat, transitioning into a liquid state. This cycle continues as the refrigerant travels through the evaporator, absorbing heat from the surroundings, thus maintaining the desired coolness.

True Units Parts Replacement Guide

This section provides a comprehensive overview of the components associated with cooling units, emphasizing the importance of timely replacements to ensure optimal functionality. By understanding the various elements involved, users can make informed decisions regarding maintenance and upgrades, ultimately enhancing performance and longevity.

To assist in identifying and replacing components, refer to the table below which outlines common issues, recommended replacements, and their corresponding specifications:

| Issue | Recommended Replacement | Specifications |

|---|---|---|

| Temperature inconsistencies | Thermostat | Digital, adjustable range 32°F to 40°F |

| Noisy operation | Compressor | Voltage 115V, horsepower 1/3 HP |

| Leaking fluids | Seal kit | Compatible with standard units, includes gaskets |

| Inadequate airflow | Fan motor | Voltage 115V, RPM 1500 |

Maintenance Tips for True Systems

Regular upkeep of cooling units is essential for optimal performance and longevity. Proper attention ensures that these appliances function efficiently, reducing energy consumption and minimizing unexpected breakdowns. Following some straightforward maintenance guidelines can help enhance their reliability.

1. Clean the Condenser Coils: Keeping the coils clean is vital for efficient heat exchange. Dust and debris can accumulate, hindering performance. Periodically inspect and clean the coils using a soft brush or vacuum to ensure they remain free from obstructions.

2. Check the Door Seals: Worn or damaged door seals can lead to temperature fluctuations. Regularly inspect seals for wear and replace them if necessary. This simple step can improve energy efficiency by preventing cold air from escaping.

3. Monitor Temperature Settings: Ensuring the correct temperature is crucial for food preservation. Regularly verify the temperature settings with a calibrated thermometer and adjust as needed to maintain optimal conditions.

4. Schedule Professional Inspections: It is advisable to have a qualified technician inspect the system annually. Professionals can identify potential issues before they escalate, ensuring that all components function properly.

5. Maintain Proper Airflow: Ensure that airflow around the unit is not obstructed by objects or other equipment. Proper ventilation is crucial for efficient operation, so keep the area clear and well-ventilated.

By adhering to these maintenance practices, users can significantly enhance the lifespan and efficiency of their cooling systems, ensuring they operate smoothly throughout their service life.