The structure of any mechanical system requires a thorough understanding of how its various elements are arranged and interconnected. Each piece plays a critical role in the overall function, contributing to the efficient performance and longevity of the equipment. Understanding the interrelationship between these components is essential for maintenance, troubleshooting, and repairs.

Identifying specific elements and their placement within the system allows users to locate and replace individual units when necessary. The overall blueprint offers a clear overview of where each part fits, providing a practical guide for those who manage the upkeep and restoration of complex machinery.

Having a detailed visual reference is invaluable for ensuring that everything is assembled correctly and operates smoothly. The following guide offers an organized and detailed look at the key elements and how they are positioned within the machinery.

Understanding Key Components of the Model

When exploring the internal structure of this machinery, it’s essential to grasp the functionality of its primary sections. Each element plays a crucial role in ensuring smooth operation, from the core engine systems to the smaller mechanical connections that keep everything synchronized. By understanding how these individual units interact, you can ensure proper maintenance and efficient performance.

Identifying Critical System Assemblies

Understanding the main structures within a mechanical system is essential for effective maintenance and repairs. Each major component plays a vital role in ensuring the seamless operation of the entire setup. By recognizing key assemblies, it becomes easier to troubleshoot issues, replace worn elements, and maintain optimal performance.

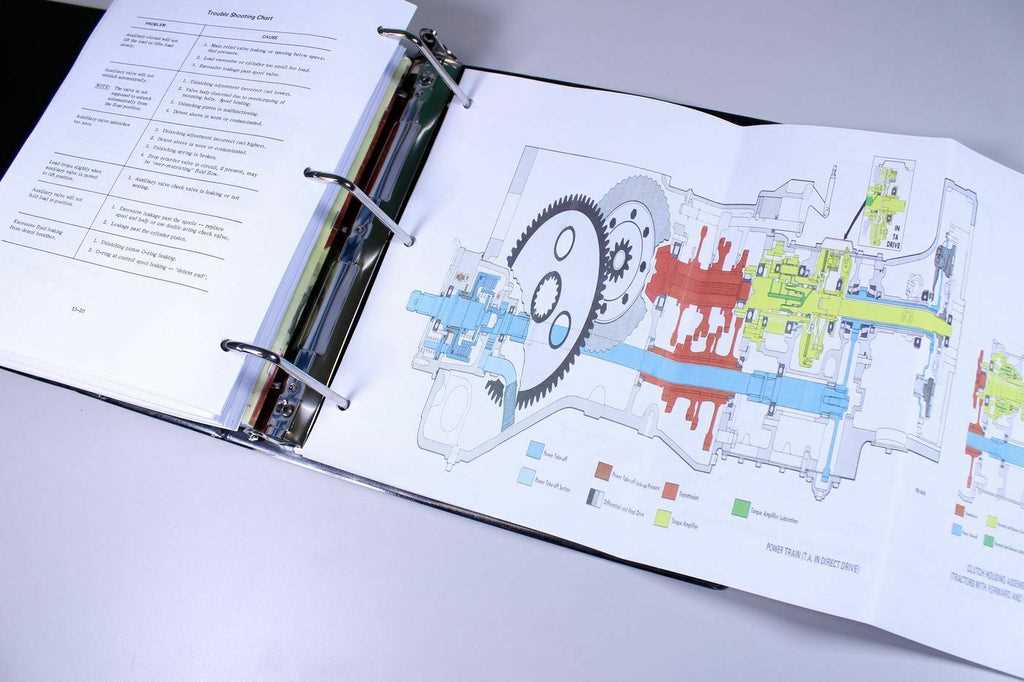

Powertrain and Transmission Structures

The heart of any mechanical setup lies in its powertrain and transmission. These areas work together to generate and distribute energy throughout the system, ensuring motion and efficiency. Identifying components in this section allows operators to manage power output, control speed, and handle torque adjustments during operation.

Hydraulic and Steering Mechanisms

Equally important are the hydraulic and steering mechanisms, responsible for controlling movement and precise adjustments. These assemblies contribute to the overall handling and maneuverability of the system, making them crucial in both routine and demanding tasks. By keeping

Overview of Mechanical Structures and Functions

The equipment consists of several key assemblies that work together to ensure optimal operation. Each of these components has a specific role, contributing to the overall performance of the machine. By understanding the interaction between these elements, users can better maintain and troubleshoot the system, ensuring its longevity and effectiveness in various tasks.

Key Assemblies and Their Roles

The structure includes various mechanical elements such as the engine, transmission, and hydraulic system, each designed to fulfill a particular function. The engine generates the necessary power, while the transmission efficiently channels this power to the appropriate systems. Hydraulics enable controlled movement, allowing for precision in operation.

Synchronization and Operation

All mechanical assemblies are carefully synchronized to deliver seamless performance. This coordination between moving parts ensures smooth transitions between different oper

Exploring Engine Component Placement

The configuration and positioning of various engine elements play a crucial role in ensuring smooth operation and easy maintenance. Understanding the layout of these components allows for more effective troubleshooting and repairs, ensuring that everything works in harmony. This section will guide you through the essential elements within the engine compartment, explaining their roles and how they fit together.

Primary Power Generating Elements

At the heart of any engine lies a complex arrangement of systems that convert fuel into mechanical energy. The main components involved in this process are positioned to ensure maximum efficiency. These include the cylinders, pistons, and crankshaft, all working in concert to drive the machine forward.

Auxiliary Systems for Optimal Performance

Supporting the primary power source, various auxiliary systems are distributed strategically around the engine. These include the cooling mechanism, lubrication channels, and exhaust system. Their placement is optimized to maintain temperature, reduce friction, and ensure efficient expulsion

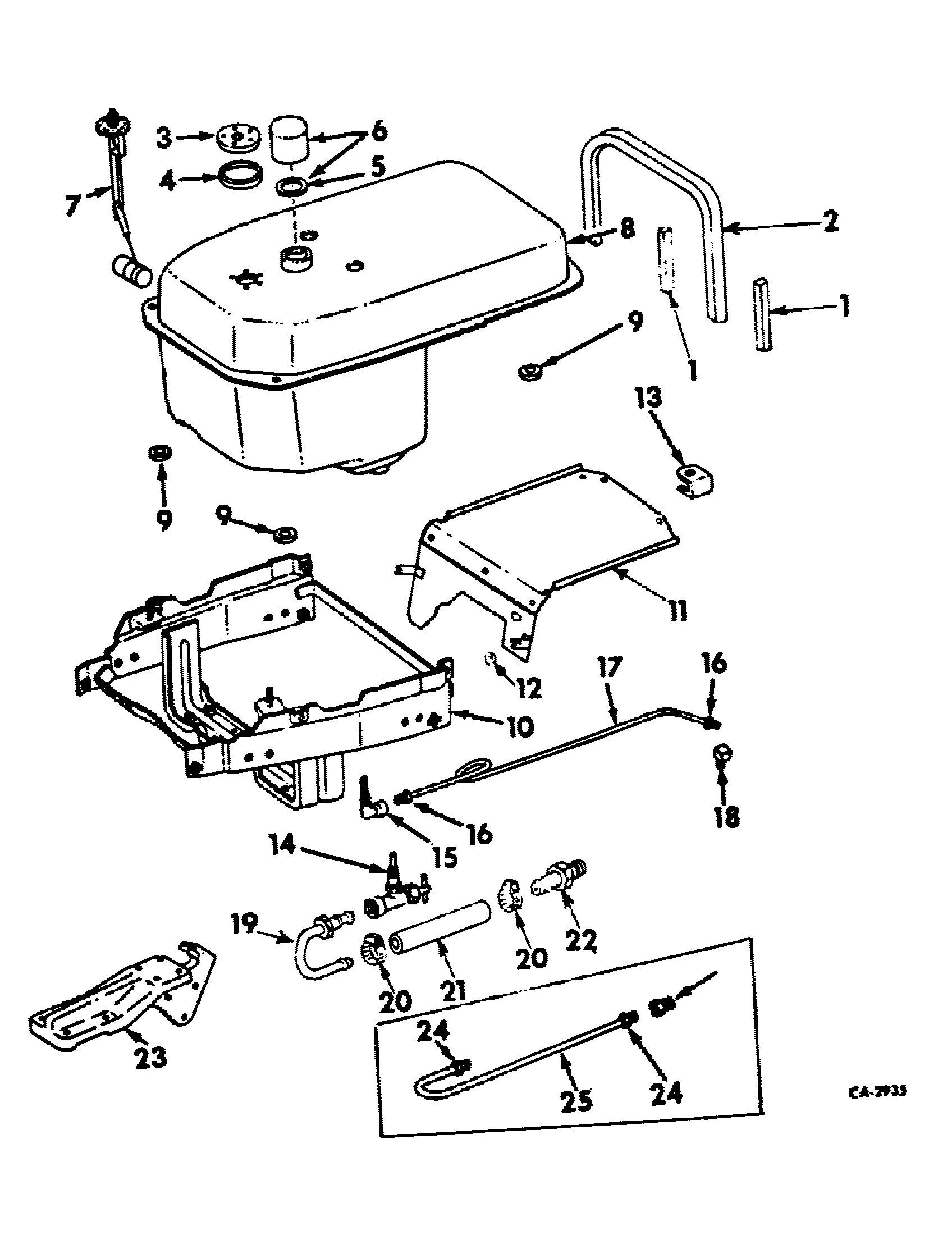

Hydraulic System Layout and Configuration

The hydraulic system plays a critical role in ensuring the smooth operation of various mechanical components. Understanding its structure and how different elements interact is essential for maintaining optimal performance. This section provides an overview of the configuration, focusing on the main components that enable fluid movement and control.

Pumps serve as the heart of the system, driving

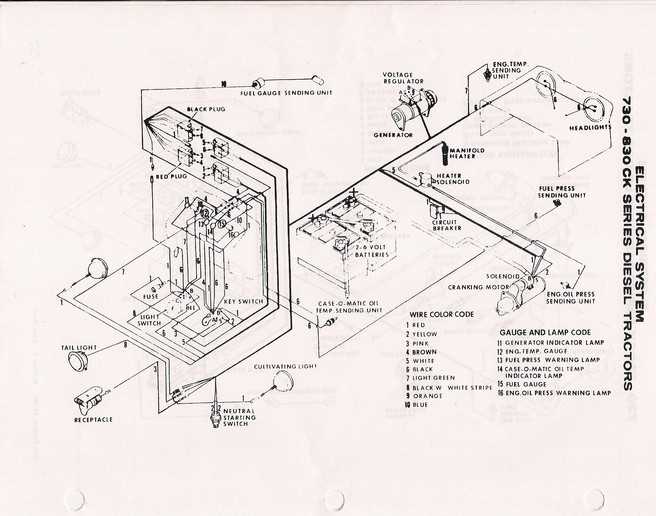

Wiring and Electrical Schematic Insights

This section delves into the intricacies of electrical connections and wiring configurations essential for the effective operation of various machinery. Understanding these components is crucial for diagnosing issues and ensuring optimal performance.

In many mechanical systems, the layout of electrical circuits is designed to provide power and facilitate communication between different parts. The following table outlines key electrical components, their functions, and typical connection points found in similar systems:

| Component | Function | Connection Points |

|---|---|---|

| Battery | Supplies electrical energy | Main power terminal |

| Starter Motor | Initiates engine operation | Battery terminal, ignition switch |

| Alternator | Recharges battery and powers electrical systems | Battery terminal, electrical system |

| Fuses | Protects circuits from overload | Wiring harness, various components |

| Relays | Controls high-current circuits with low-current signals | Control switch, power source |

By examining these electrical components, users can gain a clearer understanding of how power is distributed and managed within the machinery. This knowledge serves as a foundation for effective troubleshooting and maintenance practices.

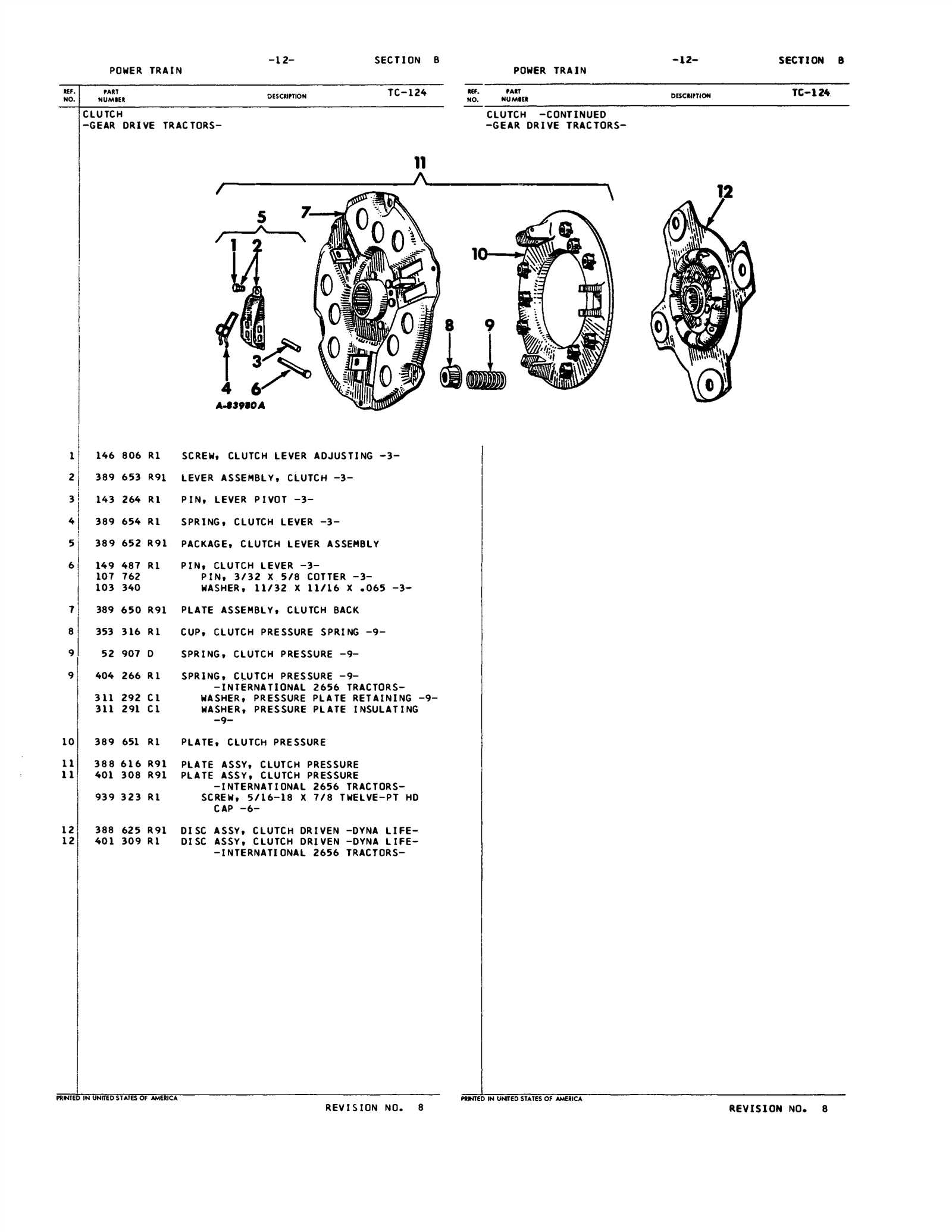

Transmission and Drive Mechanism Breakdown

The intricate workings of a vehicle’s transmission and drive system play a crucial role in its overall functionality. Understanding these components provides valuable insights into how power is transmitted from the engine to the wheels, ensuring smooth operation and optimal performance. This section delves into the various elements involved in this essential mechanism, highlighting their roles and interconnections.

Gearbox Structure: At the heart of the drive system lies the gearbox, a complex assembly designed to manage gear ratios. This component allows for efficient speed and torque adjustments, enabling the vehicle to navigate varying terrains effectively. The interaction between gears facilitates seamless shifts, ensuring that power is distributed appropriately.

Drive Shaft Dynamics: The drive shaft serves as a vital link between the engine and the wheels. Its primary function is to transmit rotational energy, converting it into motion. Understanding the mechanics of this component is essential, as it affects the overall efficiency of the vehicle. Proper alignment and maintenance are critical to prevent unnecessary wear and enhance durability.

Clutch Operation: The clutch system plays a pivotal role in engaging and disengaging the engine from the transmission. This mechanism allows for smooth transitions between gears, making it easier to control the vehicle during acceleration and deceleration. A well-functioning clutch system is essential for maintaining optimal performance and preventing strain on the drivetrain.

Final Drive Assembly: The final drive assembly further contributes to the power distribution process. This component is responsible for adjusting the rotational speed before it reaches the wheels, ensuring that the vehicle can achieve desired speeds while maintaining control. Understanding the layout and functioning of this assembly is crucial for effective troubleshooting and repairs.

Steering and Control

The steering and control systems are essential components that contribute to the overall maneuverability and responsiveness of agricultural machinery. These systems are designed to facilitate smooth handling, allowing operators to navigate various terrains with ease and precision. Proper functioning of these mechanisms ensures efficient operation, promoting productivity in the field.