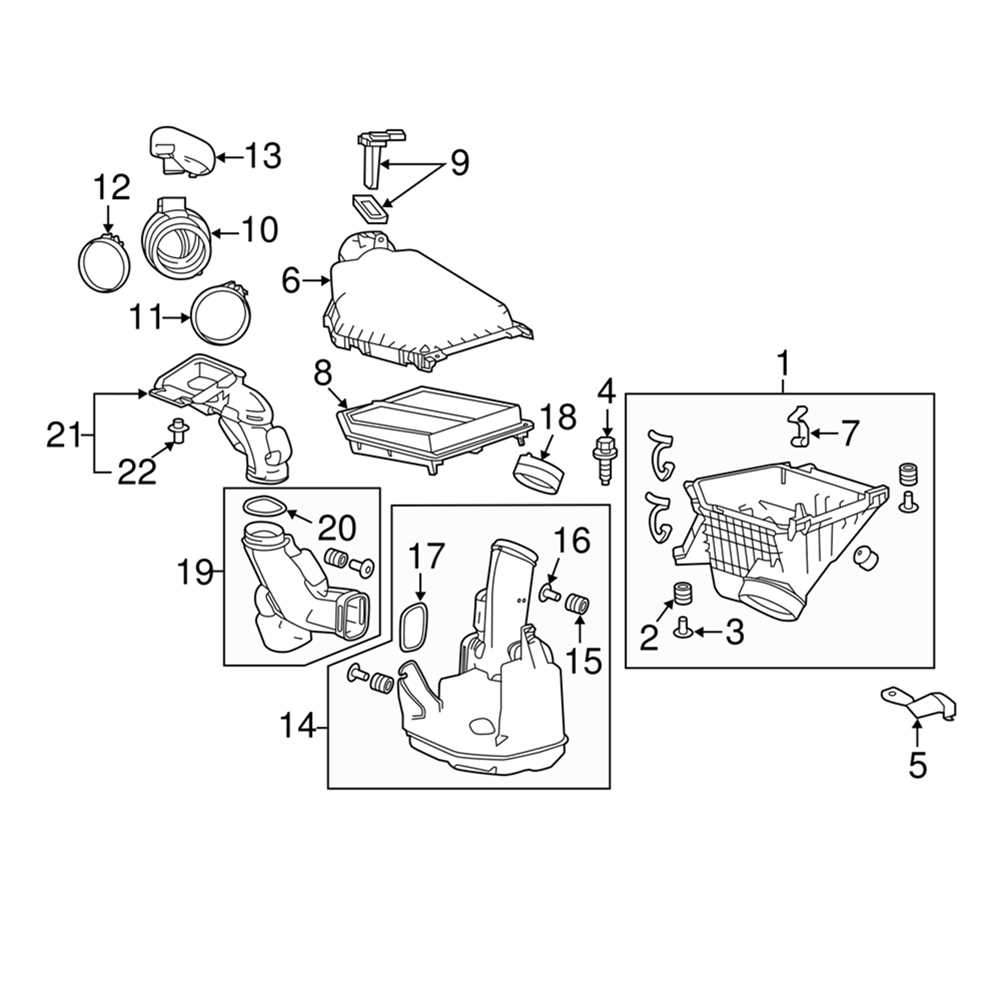

The intricate workings beneath the hood play a vital role in keeping a vehicle running smoothly. Every element in the system contributes to the overall performance, ensuring that the machine operates efficiently and reliably. It’s important to know how these various elements interact to achieve the best functionality.

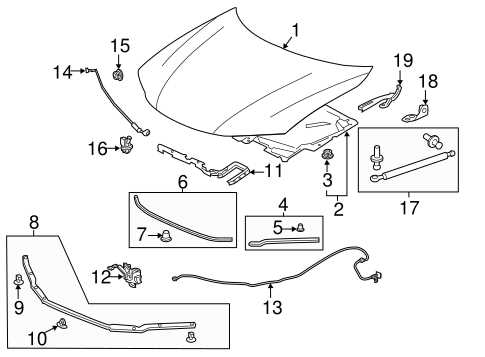

Exploring the layout of different components helps in identifying where each piece fits and how they collaborate to optimize power and efficiency. Recognizing the key elements in the system can be crucial for troubleshooting issues or performing routine maintenance

2013 Honda Accord Engine Overview

The power unit in this popular midsize vehicle offers a combination of efficiency and reliable performance, catering to diverse driving needs. Known for smooth operation and balanced capabilities, it provides a solid choice for those seeking a dependable experience on the road. Its design emphasizes longevity and consistent output, making it a favorite for daily use and long journeys alike.

Various configurations are available, each crafted to deliver a specific blend of power and fuel economy. These setups cater to both the demands of city commuting and the need for higher performance during highway driving. The mechanics are engineered to adapt seamlessly, ensuring a responsive and enjoyable ride under different conditions.

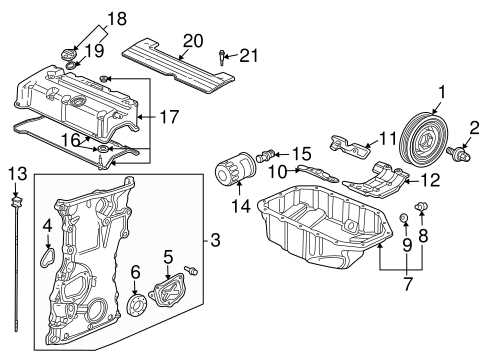

Main Components of the Engine

Understanding the various elements that contribute to the functioning of a motor can help in maintaining its performance and troubleshooting issues. This section provides an overview of the primary mechanical systems found within most combustion-powered vehicles.

One of the essential parts is the combustion chamber, where the air-fuel mixture ignites, producing energy. Nearby, the pistons move within cylinders, converting this energy into motion. The crankshaft, linked to the pistons, transforms the linear movement into rotational force, driving the vehicle forward.

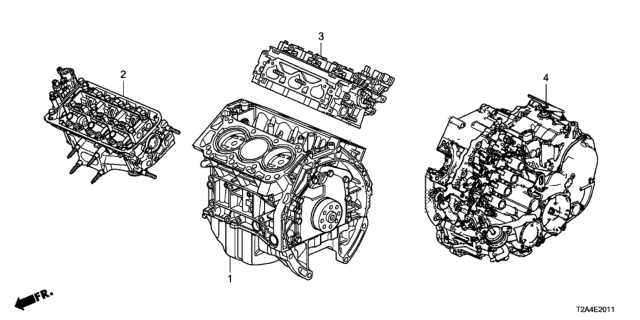

Understanding the Cylinder Head Layout

The cylinder head is a crucial component in the upper part of the power unit, playing a key role in the function of the internal combustion system. It covers the top of the cylinders and helps manage the intake of air and fuel, as well as the expulsion of exhaust gases. A well-designed layout contributes to improved performance and efficiency.

Key Features of the Cylinder Head

The structure includes multiple sections, each serving a specific purpose in the combustion process. For instance, the intake and exhaust ports allow for the movement of gases,

Engine Block and Internal Parts

The main structure of the power unit serves as the foundation for the various components within the system. It houses several essential elements that contribute to the mechanical function and efficiency of the vehicle’s propulsion mechanism. The configuration and arrangement of these components play a crucial role in maintaining the overall stability and performance.

Core Structure Components

The central framework contains chambers and passages that facilitate the operation of various mechanisms. These include spaces for rotational assemblies and fluid circulation, which help in reducing friction and temperature buildup. The

Cooling System Components Explained

The cooling system is essential for maintaining the optimal temperature of a vehicle’s power unit. It ensures that the machine operates efficiently, preventing excessive heat buildup that can lead to severe damage. This section will delve into the key elements that make up the cooling mechanism, providing an understanding of their roles and how they contribute to keeping the temperature under control.

| Component | Function | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Radiator | Acts as a heat exchanger, dissipating thermal energy from the coolant into the surrounding air, ensuring the fluid remains at a suitable temperature. | |||||||||||

| Thermostat |

| Component | Function |

|---|---|

| Serpentine Belt | Drives multiple accessories |

| Tensioner Pulley | Maintains belt tension |

| Idler Pulley | Guides the belt routing |

| Alternator Pulley | Generates electrical power |

| Power Steering Pulley | Assists with steering control |

Engine

The core component of any vehicle is the machinery responsible for converting fuel into mechanical energy. This system plays a crucial role in ensuring optimal performance and efficiency. Understanding its structure and functionality is essential for maintaining and enhancing the vehicle’s capabilities.

Components Overview

This machinery consists of various essential elements that work in harmony. Key components include the cylinder block, pistons, and crankshaft, all contributing to the conversion process. Each part has a specific role, from creating combustion to delivering power to the transmission system.

Maintenance Importance

Regular upkeep of this vital machinery ensures longevity and reliability. Routine checks of fluid levels, filters, and belts help prevent issues that may lead to decreased performance or unexpected failures. Keeping all components in optimal condition is fundamental for a smooth driving experience.