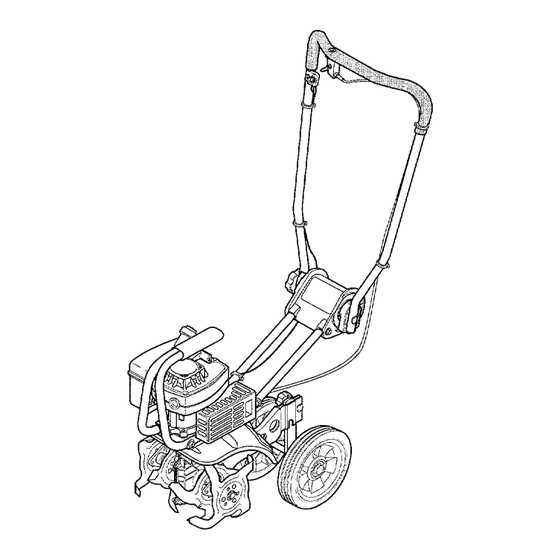

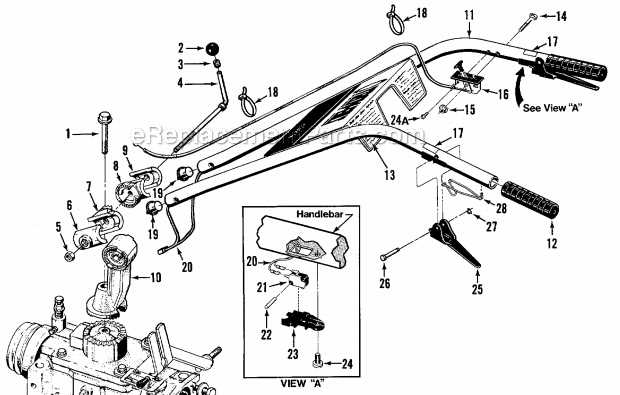

Understanding the intricate layout of various machinery can be crucial for efficient maintenance and repair. A clear representation of the different segments and how they interconnect offers both beginners and seasoned operators a valuable reference for keeping equipment in top shape. This helps in identifying any potential issues swiftly, ensuring smooth operation and longevity of the device.

For those seeking to optimize their machinery’s functionality, it is essential to have a deep knowledge of each element’s role and placement. Such insights allow users to pinpoint where adjustments or replacements are needed, providing a streamlined approach to upkeep. Detailed layouts and technical sketches can be a key resource in this process, acting as a guide during disassembly or reassembly tasks.

Beyond aiding in repairs, these graphical representations also assist

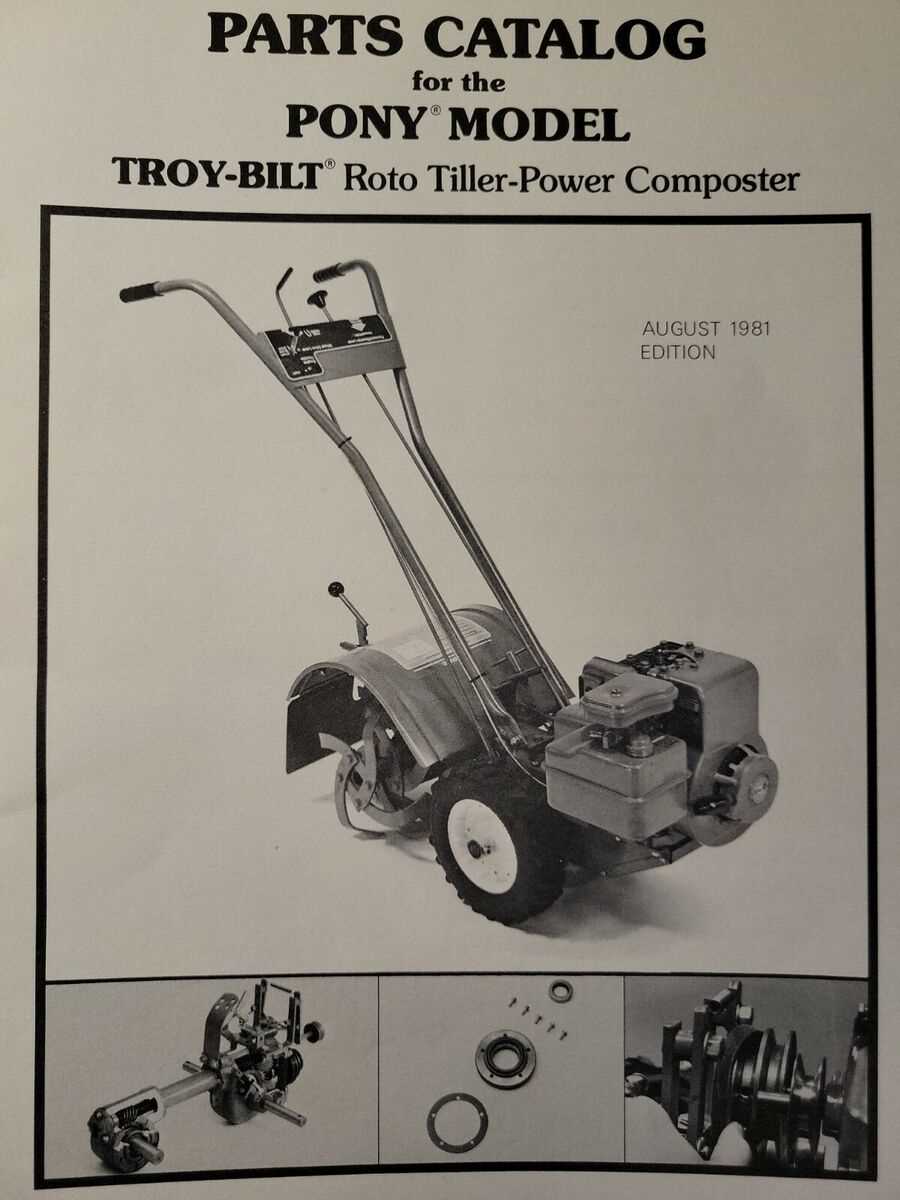

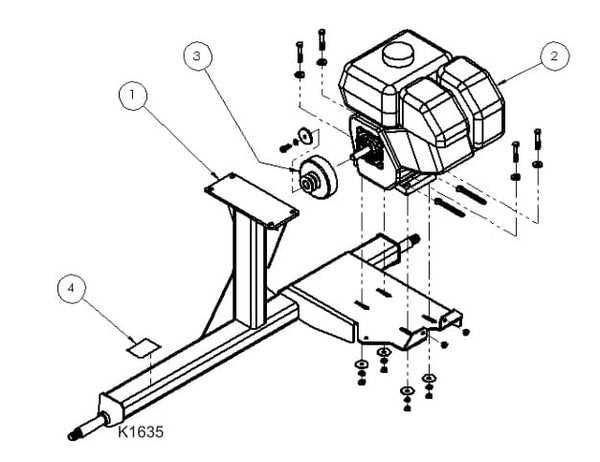

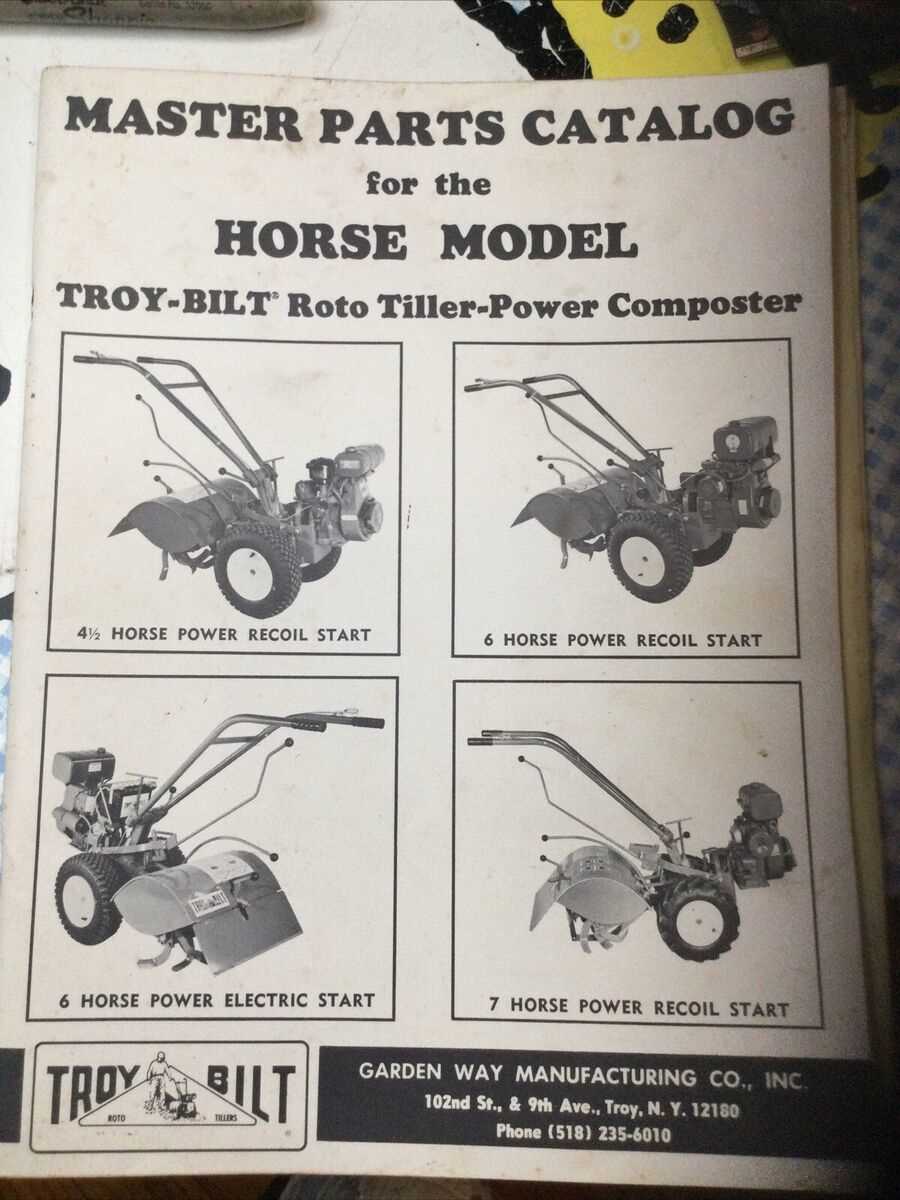

Overview of Troy-Bilt Tiller Components

This section provides a comprehensive look into the essential mechanisms and structural elements that ensure efficient soil cultivation. Understanding each component’s role helps in maintaining the equipment, ensuring its longevity and reliable performance.

Main Mechanical Elements

- Engine Assembly: The driving force behind the entire operation, converting fuel into mechanical energy, powering the blades to work through different soil conditions.

- Transmission

Key Functions of Various Tiller Parts

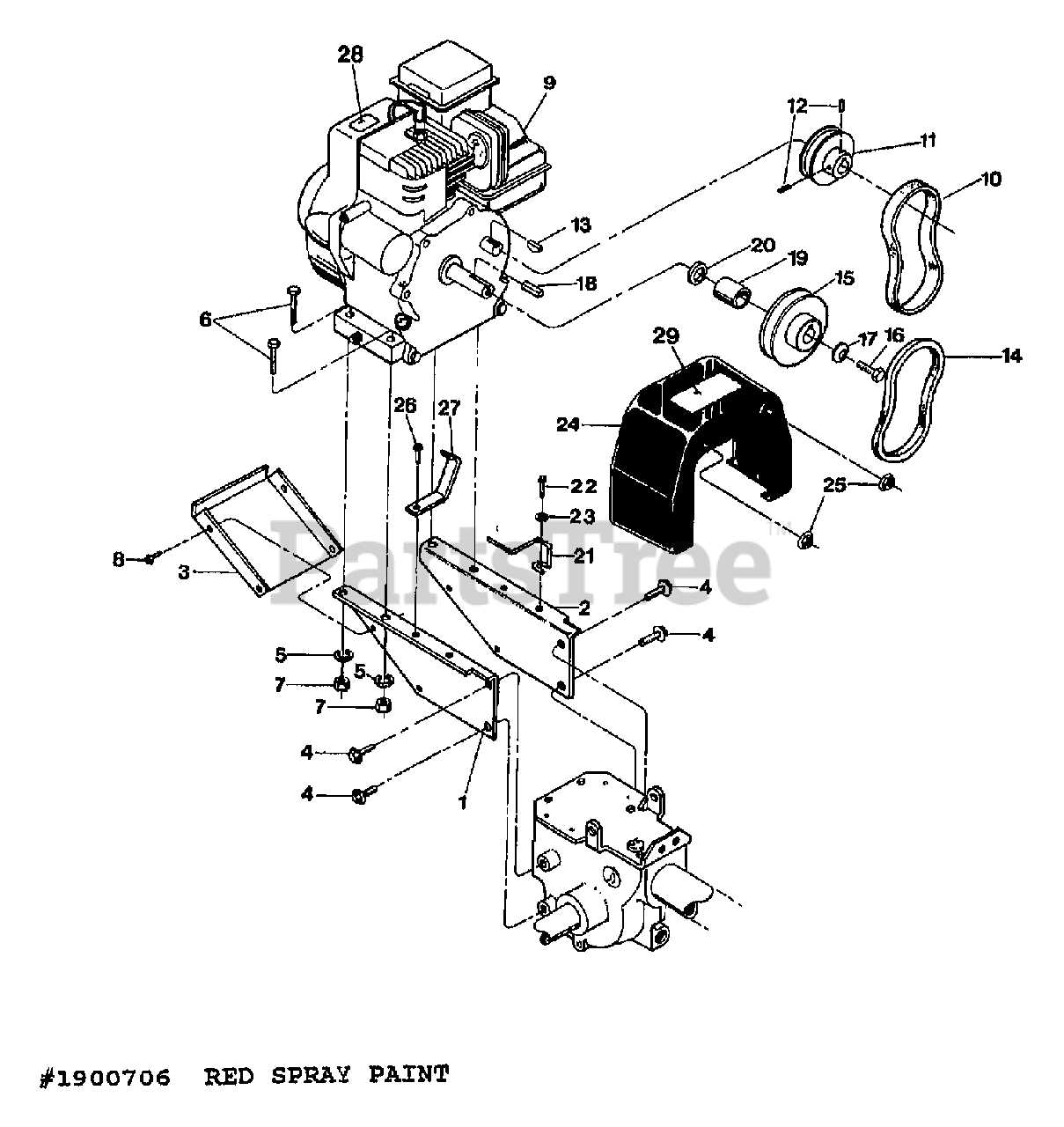

Understanding the roles of different components in a soil cultivation machine helps ensure efficient operation and maintenance. Each element is designed to perform a specific task, contributing to smooth movement, effective soil mixing, and overall durability of the equipment.

- Blades: These cutting elements rotate through the ground, breaking up soil clumps and preparing the earth for planting. Their sharp edges and angled design help to slice through tough terrain with ease.

- Transmission System:

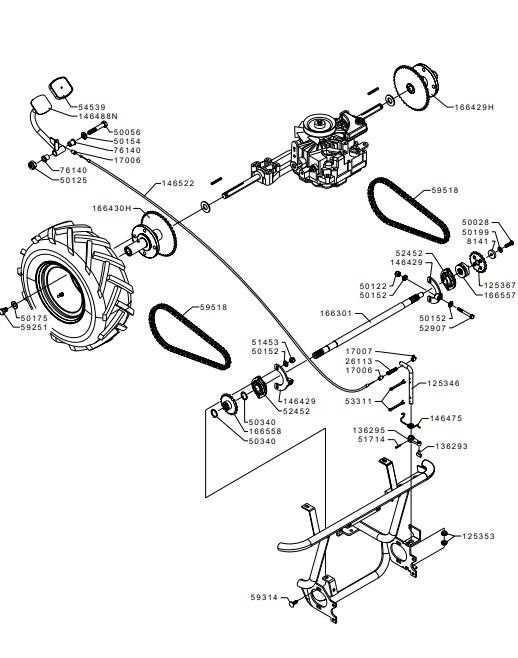

Understanding the Gearbox Assembly

The gearbox assembly plays a crucial role in transferring power efficiently from the engine to the working components. Its function is to manage speed and torque, ensuring smooth operation and providing control over different ground conditions. Understanding its structure helps in maintaining its performance and extending the lifespan of the equipment.

The core structure of the assembly involves a series of interconnected parts that work together to facilitate proper movement and force distribution. These include the primary gears, drive shaft, and various support components. Each element is designed to

How the Transmission Mechanism Works

The operation of the power transfer system is crucial for efficient ground engagement. It controls how energy is delivered from the engine to the rotating blades, ensuring smooth movement through various soil conditions. This system adjusts the speed and torque, making it adaptable to different terrains and user needs.

Energy Transfer Process

The mechanism begins by transmitting power through a series of gears and shafts. As these components interact, they convert the rotational force into a controlled movement, allowing for precise control over speed. This conversion process ensures that the right amount of force reaches the blades, optimizing their efficiency while minimizing engine strain.

Adjusting to Different

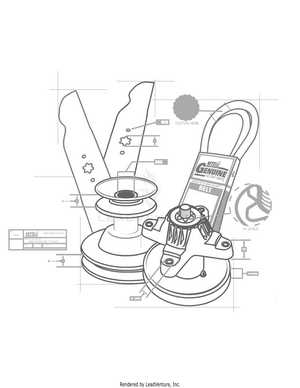

Engine Parts for Optimal Performance

Achieving peak functionality from a soil-cultivating machine depends greatly on maintaining the core components of its power source. Proper care and understanding of these elements ensure smooth operations and longevity of the device, providing consistent and reliable power for all gardening needs.

Cylinder and Piston: The heart of any power unit, the cylinder and piston must work in unison to generate the necessary force. A well-maintained cylinder allows for efficient fuel combustion, while a precisely fitted piston minimizes energy loss, ensuring powerful rotations.

Carburetor Efficiency: The role of the carburetor is crucial in blending air and fuel to deliver the right mixture into the engine chamber. A clean and

Carburetor Maintenance and Adjustment Tips

Proper upkeep and tuning of the fuel mixing component are essential for optimal engine performance. Regular checks and fine-tuning can enhance efficiency, reduce emissions, and prolong the lifespan of the machinery. Here are key practices to ensure your system operates smoothly.

- Inspect Gaskets and Seals: Regularly check for wear and tear. Replace damaged gaskets to prevent air leaks, which can affect fuel delivery.

- Clean the Fuel Bowl: Remove any debris or residue buildup in the bowl. This can help prevent blockages that hinder fuel flow.

- Adjust Idle Speed: Use the adjustment screw to set the idle speed correctly. A well-tuned idle ensures a smooth start and consistent running.

- Check Fuel Mixture: Ensure the mixture of fuel and air is appropriate. Adjust the mixture screw based on manufacturer specifications for optimal performance.

- Regular Cleaning: Periodically clean the entire assembly, including jets and passages, to avoid clogging and maintain efficiency.

Following these guidelines will help maintain a well-functioning fuel delivery system, ensuring reliable operation and effective performance.