The efficient functioning of a well-known chainsaw relies on its intricate assembly of various elements. A comprehensive exploration of these components can provide valuable insights for users and technicians alike. By examining the layout and organization of these pieces, individuals can enhance their knowledge and improve maintenance practices.

Understanding the arrangement of individual elements within this chainsaw model is essential for effective troubleshooting and repair. Knowledge of how each part interacts contributes to overall performance and longevity. Through careful analysis, users can identify specific components that may require attention, ensuring optimal operation of the equipment.

Furthermore, familiarizing oneself with the configuration of these elements aids in the accurate assembly and disassembly of the chainsaw. This knowledge empowers users to undertake their own repairs with confidence, reducing reliance on professional services. Ultimately, a deeper understanding of the components not only enhances functionality but also promotes safety during usage.

Stihl 038 Parts Diagram Overview

This section provides an insightful look into the components and their arrangement within a specific model of outdoor power equipment. Understanding the configuration of various elements is essential for maintenance and repair, enabling users to keep their tools functioning efficiently.

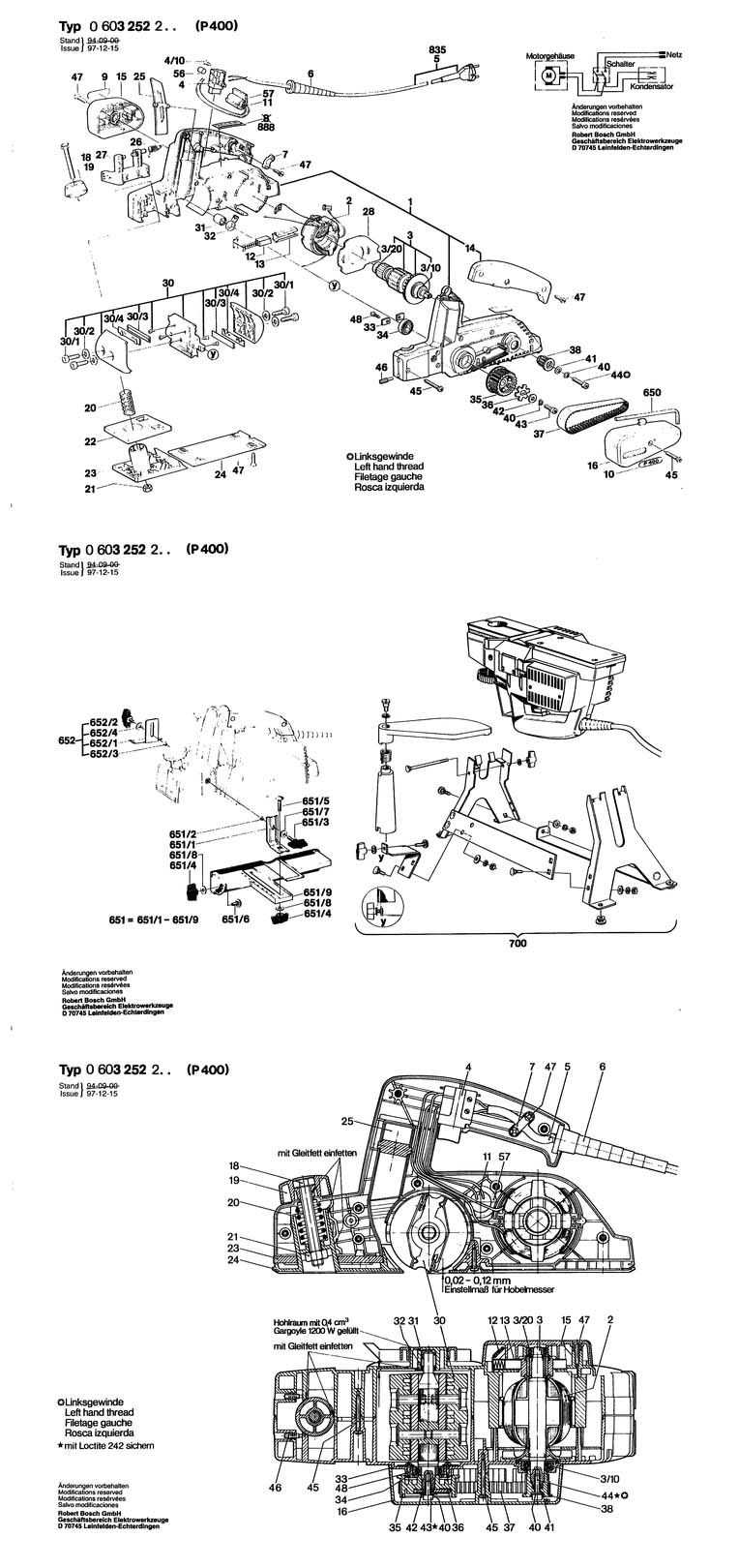

The visual representation of the assembly highlights the relationships between individual pieces, making it easier to identify and source replacements when necessary. A thorough grasp of the layout not only aids in troubleshooting but also enhances overall operational knowledge.

For enthusiasts and professionals alike, familiarity with the intricate assembly is a valuable asset. By examining the detailed breakdown, users can gain confidence in performing repairs or modifications, ensuring optimal performance from their equipment.

Understanding Stihl 038 Components

Familiarizing oneself with the various elements of a power tool is essential for effective maintenance and optimal performance. Each component plays a significant role in the overall functionality of the equipment, influencing its efficiency and reliability. This section explores the key elements that contribute to the seamless operation of a specific model, providing insights into their interrelations and importance.

Key Components and Their Functions

Among the most critical components are the engine, fuel system, and cutting mechanism. The engine serves as the heart of the machine, generating the necessary power to perform tasks. The fuel system is crucial for delivering the energy required for operation, ensuring that the engine receives a consistent supply of fuel. Lastly, the cutting mechanism, often regarded as the primary tool for executing tasks, is designed for precision and effectiveness, enhancing the overall user experience.

Maintenance Tips for Longevity

Regular upkeep of these components is vital for extending the lifespan of the tool. Routine inspections can help identify wear and tear, allowing for timely replacements and repairs. Utilizing quality replacement parts and following the manufacturer’s recommendations can further ensure that the tool remains in peak condition. By understanding the role of each element, users can better appreciate the intricacies of their equipment and make informed decisions regarding maintenance and repairs.

Importance of Parts Identification

Understanding the components of a machine is crucial for ensuring its optimal performance and longevity. Recognizing each element and its function allows users to maintain and troubleshoot effectively. This knowledge is vital not only for repairs but also for enhancing the overall efficiency of the equipment.

Accurate identification of individual elements can significantly reduce downtime and operational costs. Knowing which components need replacement or maintenance helps in making informed decisions. Additionally, it promotes safety, as proper functioning parts are essential to avoid accidents and malfunctions.

| Component Type | Function | Importance |

|---|---|---|

| Engine | Powers the machine | Critical for overall functionality |

| Fuel System | Delivers fuel to the engine | Ensures efficiency and performance |

| Electrical System | Manages ignition and power supply | Essential for starting and operation |

| Cutting Mechanism | Performs the primary function of cutting | Key for effectiveness in tasks |

| Frame | Provides structure and support | Vital for durability and stability |

Exploring Stihl 038 Assembly Parts

The assembly of outdoor power tools involves a variety of components that work together to ensure optimal performance and efficiency. Understanding these elements is crucial for maintenance and repairs, as each part plays a vital role in the functionality of the machine. This section delves into the various components found in a specific model, providing insights into their arrangement and importance.

Key Components Overview

Each assembly includes essential elements such as the engine casing, air filtration system, and ignition components. These parts are designed to withstand demanding conditions while delivering reliable operation. Familiarizing oneself with these components aids in troubleshooting and enhances the overall lifespan of the equipment.

Maintenance Considerations

Regular upkeep of individual elements not only promotes efficiency but also prevents potential issues that could lead to costly repairs. Knowing how to inspect, replace, or clean these components is fundamental for any user aiming to keep their equipment in top-notch condition. Proper care ensures longevity and optimal performance in various outdoor tasks.

Key Parts of Stihl 038 Engine

The engine of this popular tool consists of several crucial components that work together to ensure optimal performance. Understanding these elements is essential for anyone looking to maintain or repair the machine effectively. Each part plays a specific role in the overall functionality, contributing to the efficiency and reliability of the equipment.

Crankshaft serves as the heart of the engine, converting linear motion into rotational energy. This transformation is vital for powering the tool effectively. Additionally, the cylinder is where the combustion process occurs, housing the mixture of fuel and air necessary for ignition.

Another significant element is the piston, which moves within the cylinder, creating the necessary pressure for combustion. Complementing this is the carburetor, responsible for mixing fuel with air to create a combustible mixture. This component is essential for starting and running the engine smoothly.

The ignition system ensures the timely spark that ignites the fuel-air mixture, making it a critical part of the engine’s operation. Lastly, the exhaust system efficiently removes combustion gases, helping to maintain optimal engine performance and reduce emissions.

Maintenance Tips for Stihl 038

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By following a few simple practices, you can maintain its efficiency and reliability, preventing common issues and costly repairs.

Here are some crucial maintenance recommendations:

- Clean the Air Filter: A clean air filter ensures proper airflow and engine performance. Inspect it regularly and clean or replace as needed.

- Check the Fuel System: Ensure that the fuel is fresh and the fuel lines are free of cracks. Regularly inspect the fuel filter to prevent clogs.

- Inspect the Spark Plug: A well-functioning spark plug is vital for engine ignition. Clean or replace it periodically to ensure optimal performance.

- Sharpen the Cutting Tools: Dull blades can hinder performance. Regularly sharpen the cutting tools for efficient operation.

- Lubricate Moving Parts: Regular lubrication reduces friction and wear, enhancing the lifespan of moving components.

By following these maintenance tips, you can extend the life of your equipment and ensure it operates at peak efficiency.

Common Issues with Stihl 038 Parts

When working with outdoor power equipment, certain complications may arise due to the components involved. Understanding these common challenges can aid in maintenance and repair, ensuring optimal performance over time. Identifying issues early can prevent more significant problems down the line, enhancing the longevity of the machinery.

Frequent Mechanical Failures

Mechanical failures are a prevalent concern. Over time, certain elements can wear down due to extensive use or inadequate maintenance. For instance, the chain brake may become less effective, impacting safety and functionality. Regular inspections and timely replacements can significantly mitigate these risks.

Fuel and Ignition Problems

Fuel and ignition difficulties often lead to poor performance. Issues such as clogging in the fuel filter or a malfunctioning spark plug can result in starting problems or inefficient operation. Maintaining clean filters and ensuring proper fuel quality are essential steps in preventing these complications.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining its performance and longevity. Whether you’re looking to replace worn-out items or upgrade your machine, knowing where to search can significantly simplify the process. Various options are available for sourcing the necessary elements, each with its own advantages and considerations.

Online Retailers

One of the most convenient ways to acquire components is through online stores. Numerous websites specialize in machinery supplies, offering a wide selection of items. When shopping online, ensure that you check customer reviews and ratings to confirm the reliability of the seller. Additionally, look for platforms that provide detailed descriptions and images, which can help you make informed decisions.

Local Dealers and Repair Shops

Visiting local distributors and service centers can also be beneficial. These establishments often carry a range of components for various models and can offer expert advice on compatibility and installation. Building a relationship with local professionals can lead to personalized support and assistance with your specific needs.

Tools Needed for Stihl 038 Repair

When undertaking maintenance or repair of a chainsaw, having the right tools is essential for ensuring a smooth and efficient process. Proper equipment not only aids in achieving accurate results but also enhances safety during operation.

The following is a list of necessary instruments for effective repair work:

- Wrench Set: Useful for loosening and tightening various bolts and nuts.

- Screwdriver Set: Essential for removing and securing screws in different sizes.

- Chain Brake Tool: Important for safely engaging and disengaging the chain brake system.

- Fuel and Oil Mix Container: Necessary for preparing the correct fuel mixture.

- Feeler Gauges: Helpful for measuring and adjusting gaps in the ignition system.

- Cleaning Brush: Useful for removing debris and buildup from components.

- Protective Gear: Includes gloves, goggles, and hearing protection for safety during repairs.

Using the right tools not only streamlines the repair process but also prolongs the life of the equipment. Ensuring that all tools are in good condition prior to starting the job is equally important.

Comparing Stihl 038 with Other Models

This section delves into the nuances of a specific chainsaw model in relation to its competitors. Understanding the differences and similarities can aid users in making informed decisions based on their unique needs and preferences.

When evaluating this particular model against others in the market, several key aspects should be considered:

- Power Output: Analyze the engine capacity and horsepower to assess cutting efficiency.

- Weight: Compare the overall weight, which affects maneuverability and ease of use during extended tasks.

- Durability: Evaluate the build quality and materials used, as these influence longevity and performance under demanding conditions.

- Maintenance: Look into the ease of maintenance, including parts accessibility and service requirements.

- Price Point: Consider the cost in relation to features and performance, ensuring value for money.

By examining these factors, users can determine how this model stacks up against other options available in the market, leading to a more satisfactory purchase decision.

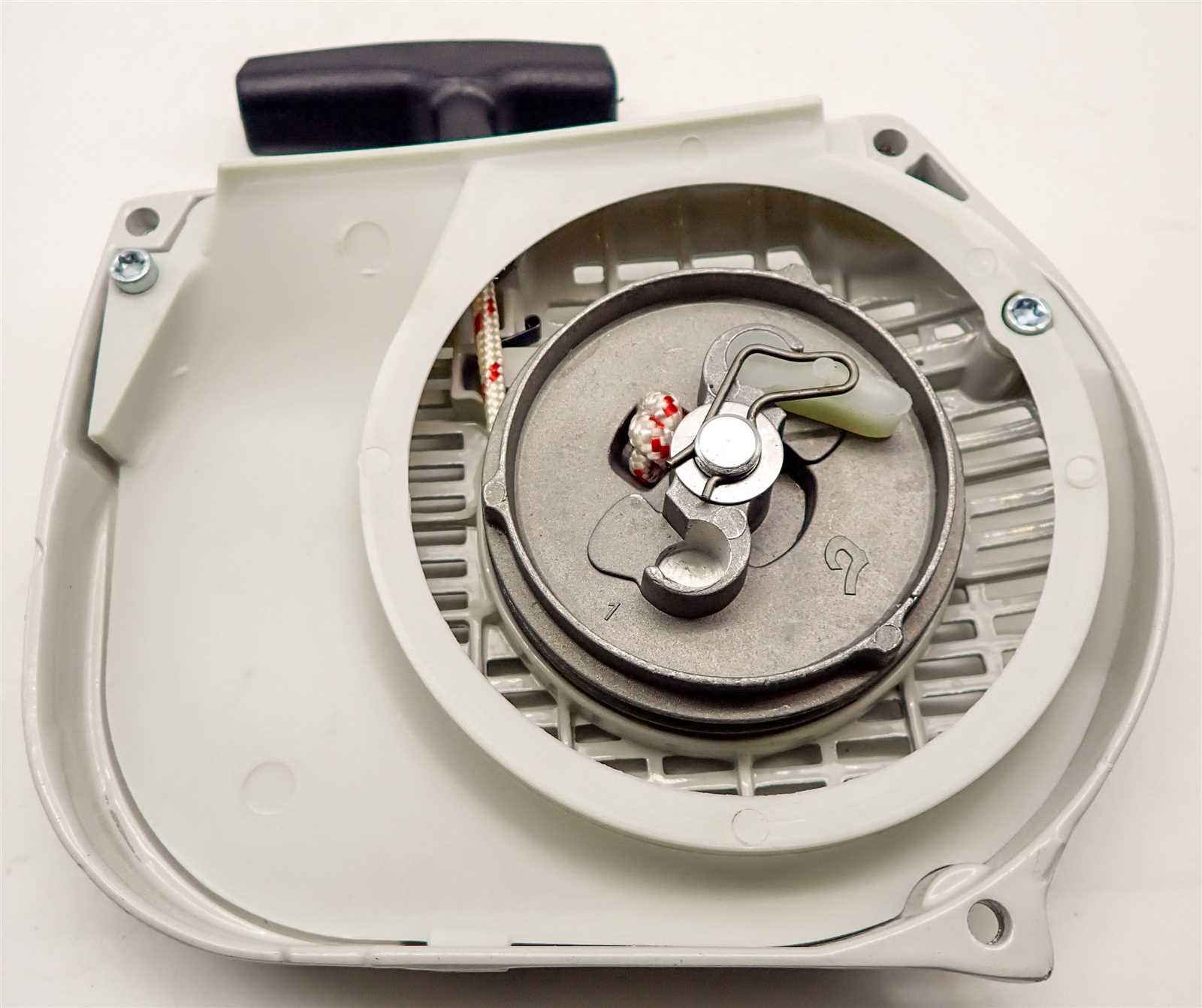

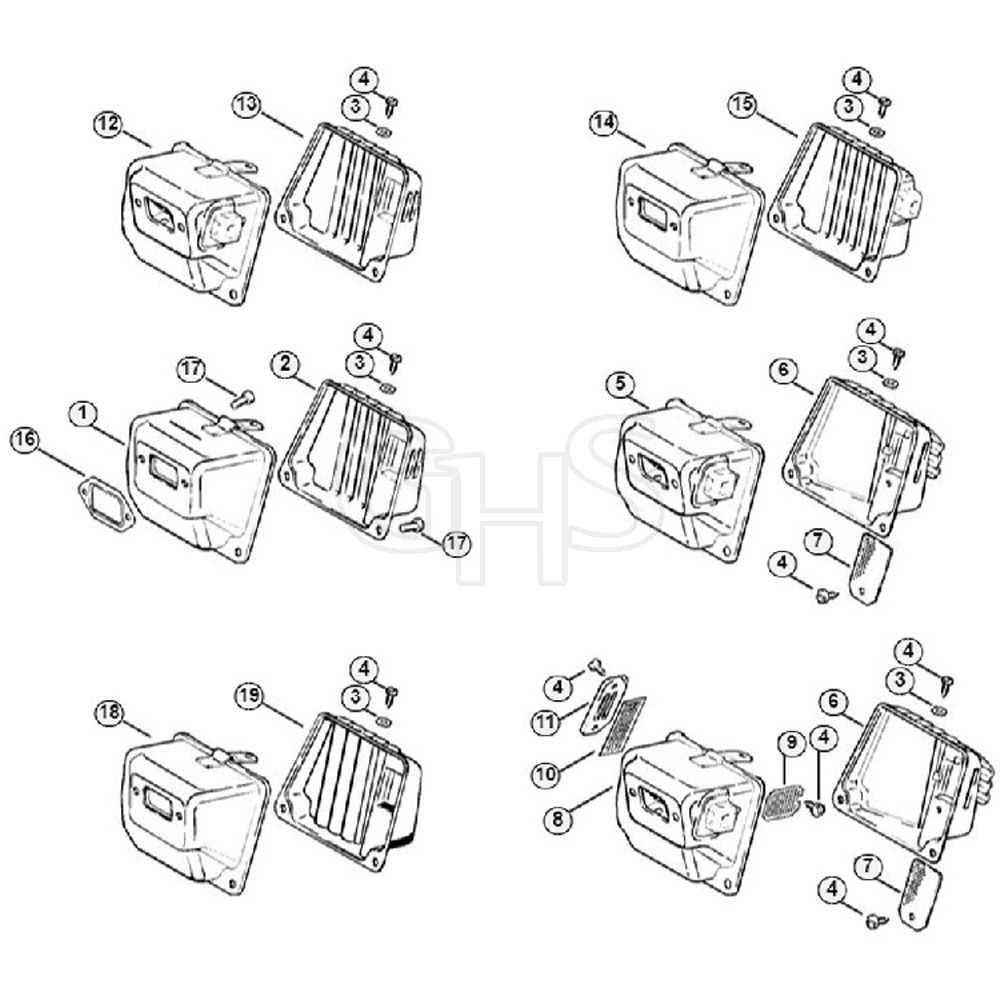

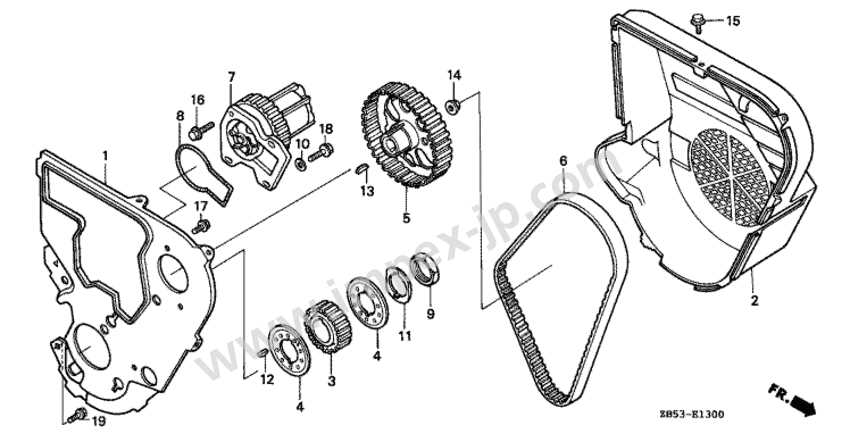

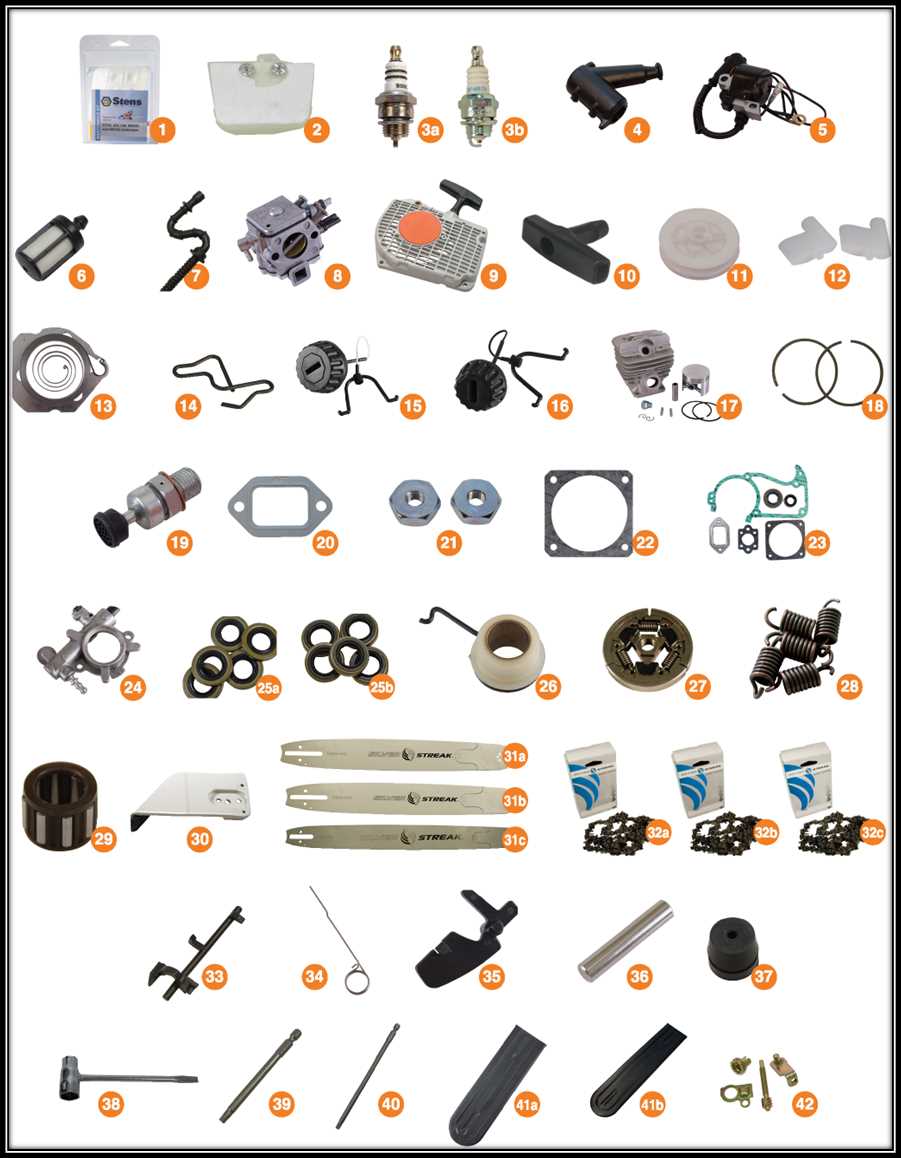

Stihl 038 Parts Diagrams Explained

Understanding the components of a specific tool can significantly enhance maintenance and repair processes. Visual representations of various elements play a crucial role in illustrating how each piece interacts within the overall structure. By examining these detailed illustrations, users can gain valuable insights into assembly, disassembly, and potential troubleshooting methods.

These graphical guides provide a comprehensive view of the internal mechanisms, ensuring that individuals can identify each segment effectively. Each labeled section highlights the function and placement of individual components, enabling a clearer understanding of the operational dynamics. Whether for routine upkeep or specific repairs, referring to these visuals ensures that users can maintain their equipment efficiently and effectively.

In addition to facilitating repairs, these representations also serve as an educational resource for new users. By studying the arrangement and relationships between various parts, individuals can develop a deeper appreciation for how the entire system operates. This knowledge empowers users to perform more advanced tasks with confidence, ultimately leading to improved performance and longevity of the equipment.

Resources for Stihl 038 Owners

For enthusiasts and users of specific outdoor equipment, having access to reliable information and resources is essential for maintenance and optimal performance. Whether you are seeking guidance on troubleshooting, repairs, or upgrades, various platforms and materials can aid in your journey.

Online Forums and Communities

Engaging with fellow users through online communities can provide valuable insights. Here are some popular platforms:

- Discussion Boards: Participate in conversations where users share experiences and solutions.

- Social Media Groups: Join dedicated groups on platforms like Facebook or Reddit to connect with others.

- Video Tutorials: Check YouTube for instructional content that covers repairs and tips.

Manuals and Guides

Having access to comprehensive guides can significantly enhance your understanding of the equipment. Consider these resources:

- User Manuals: Look for downloadable manuals that outline specifications and maintenance schedules.

- Repair Guides: Search for detailed repair instructions that can assist with specific issues.

- Maintenance Checklists: Utilize checklists to ensure regular upkeep and performance efficiency.