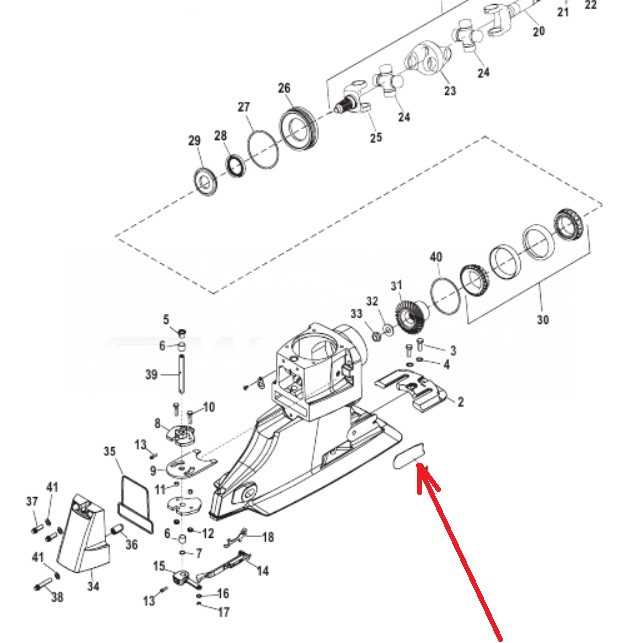

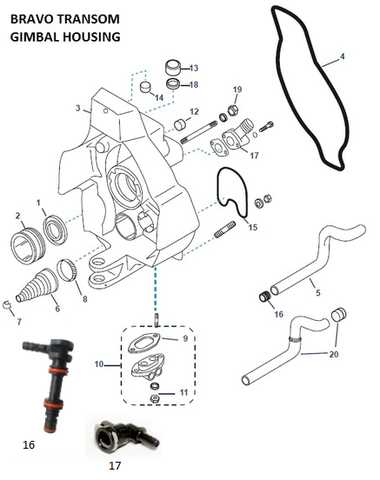

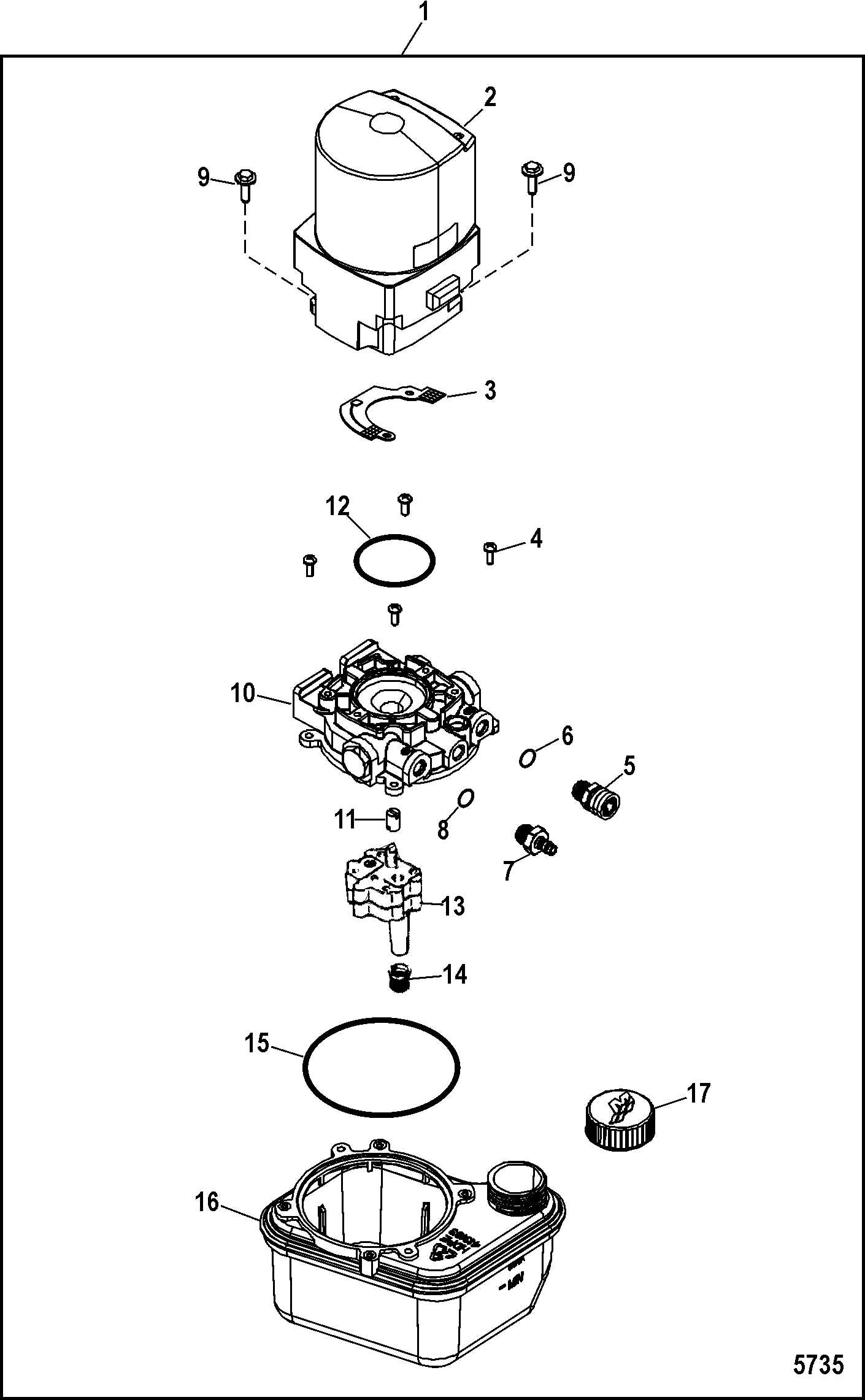

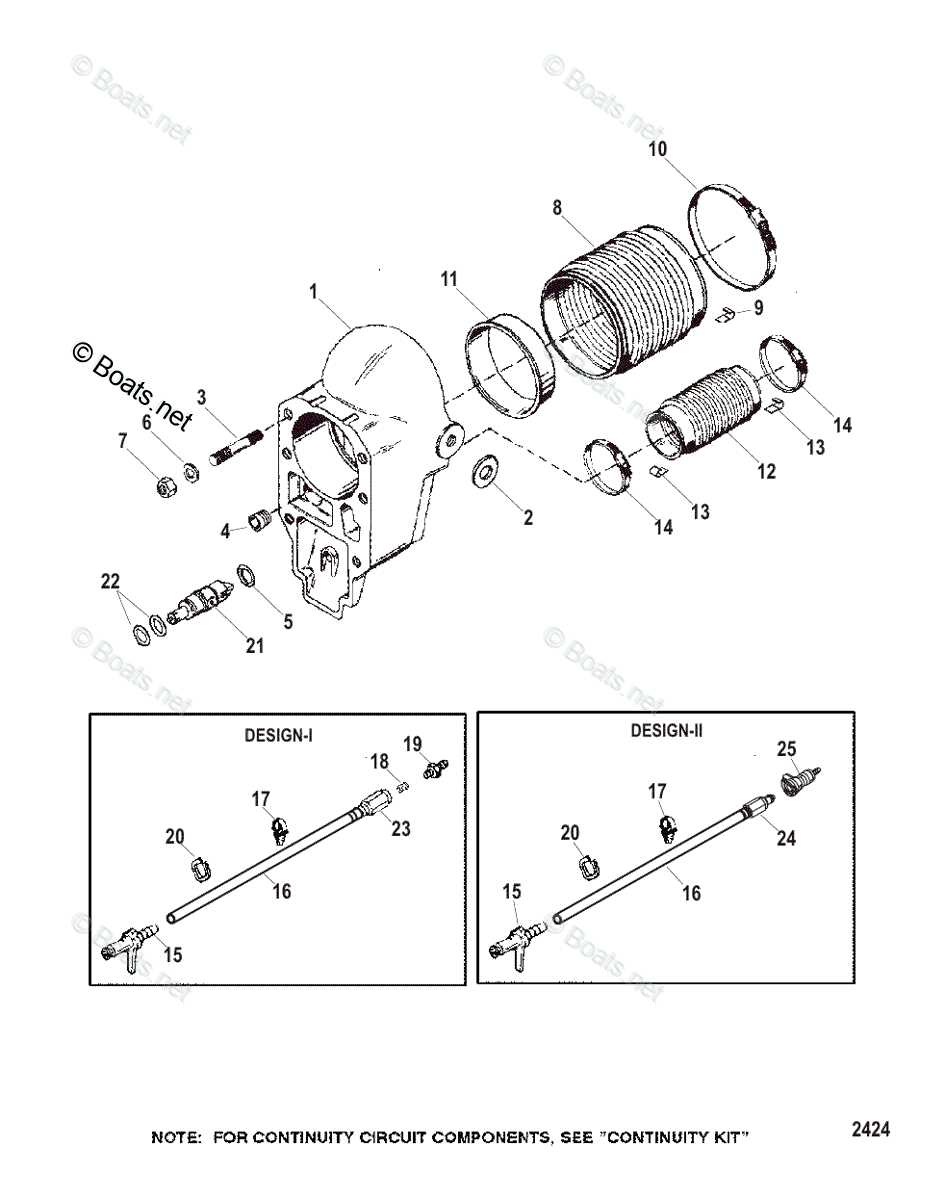

The intricacies of mechanical assemblies are essential for ensuring optimal performance and functionality. A comprehensive breakdown of these elements can provide valuable insights into their roles and interactions within the system. This section aims to shed light on the various components involved, facilitating a deeper understanding of their significance.

Visualizing the arrangement of each segment aids in grasping how they work in harmony. By examining the layout and connection points, users can appreciate the engineering behind these structures. This exploration will enhance your familiarity with the equipment, paving the way for more informed usage and maintenance practices.

Furthermore, a clear representation of the assembly not only simplifies troubleshooting but also empowers users to identify potential improvements. As we delve into this overview, expect to gain a clearer perspective on the essential elements that contribute to the overall effectiveness of the system.

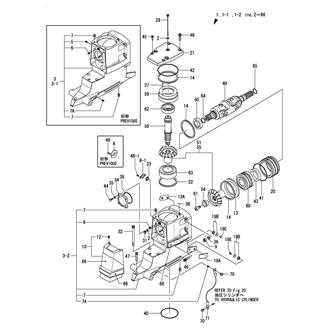

Proper installation of various elements is essential for optimal performance and longevity. This section outlines the necessary steps to ensure all components are fitted correctly and securely, providing a reliable setup.

- Preparation:

- Gather all required tools and materials.

- Review the installation guide for specific details related to each component.

- Step 1: Positioning:

- Carefully align each component with the designated mounting points.

- Ensure that the surfaces are clean and free from debris to facilitate proper attachment.

- Step 2: Securing:

- Use the provided fasteners to secure each element in place.

- Tighten all connections to the manufacturer’s specifications to prevent loosening during operation.

- Step 3: Final Checks:

- Inspect all connections to confirm they are tight and secure.

- Perform a test run to ensure proper functionality and identify any issues that may need addressing.

Following these instructions will help maintain the integrity and efficiency of the system, ensuring each component operates as intended.

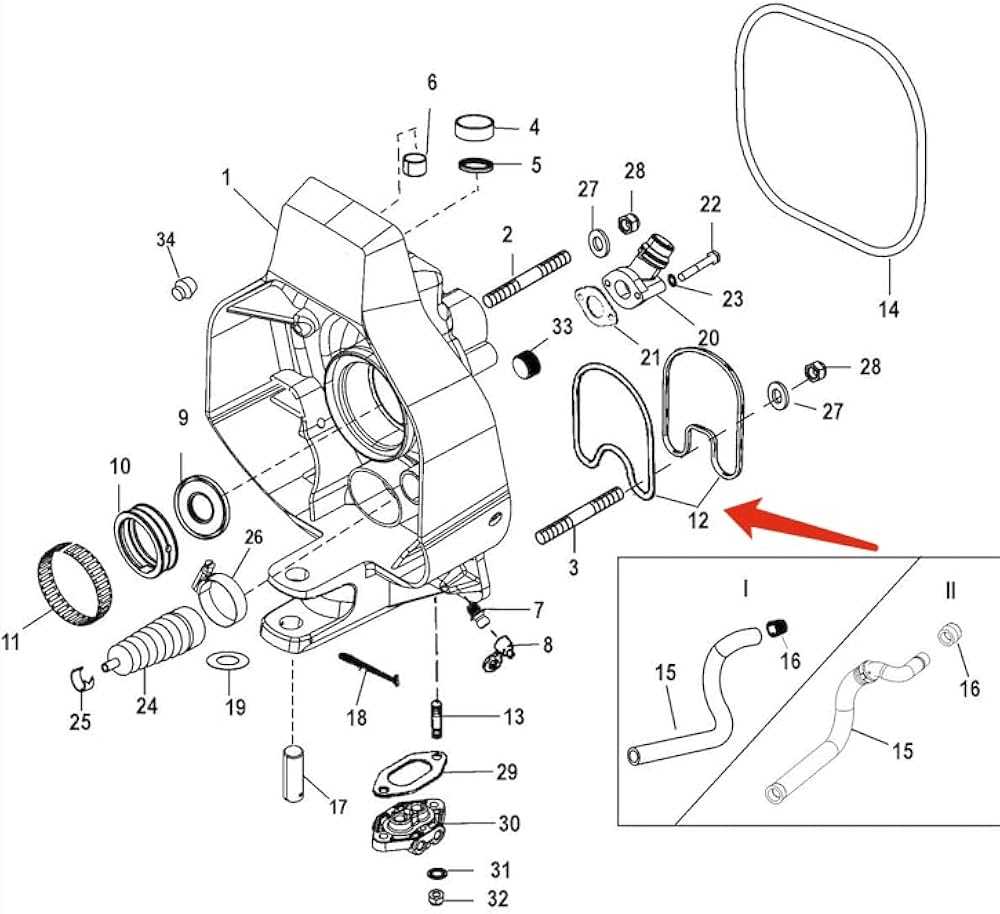

Maintenance Tips for Bravo 3

Proper upkeep of your equipment is essential to ensure optimal performance and longevity. Regular attention to key components can prevent unexpected issues and enhance overall efficiency. Implementing a few straightforward practices can make a significant difference in maintaining functionality.

1. Routine Inspections: Conduct frequent checks to identify any signs of wear or damage. Look for unusual noises, leaks, or irregular performance that may indicate underlying problems.

2. Cleaning: Keep surfaces free from debris and build-up. Regular cleaning helps to prevent corrosion and ensures that all parts function smoothly.

3. Lubrication: Apply appropriate lubricants to moving parts to reduce friction. This practice minimizes wear and helps maintain seamless operation.

4. Seasonal Maintenance: Adapt maintenance routines based on seasonal changes. For instance, prepare equipment for storage during off-seasons by following specific guidelines to protect against environmental factors.

5. Professional Check-ups: Schedule periodic evaluations by qualified professionals to address any potential issues before they escalate. Expert insight can significantly enhance reliability and safety.

By adhering to these maintenance suggestions, you can extend the lifespan of your equipment and ensure it remains in peak condition for all your activities.

Common Issues and Solutions

This section addresses frequent challenges encountered with specific mechanical systems and provides practical resolutions to enhance functionality and reliability. Understanding these common concerns is essential for maintaining optimal performance and extending the lifespan of the equipment.

Frequent Problems

- Performance Degradation: A noticeable decline in efficiency may arise due to wear and tear or improper maintenance.

- Noisy Operation: Unusual sounds during operation often indicate misalignment or insufficient lubrication.

- Fluid Leaks: Leakage of operational fluids can signify damaged seals or fittings.

Proposed Solutions

- Regular Maintenance: Implementing a routine inspection and servicing schedule can prevent performance issues.

- Proper Lubrication: Ensure all moving parts are adequately lubricated to minimize friction and noise.

- Seal Replacement: Promptly replace worn seals to prevent fluid leakage and maintain operational integrity.

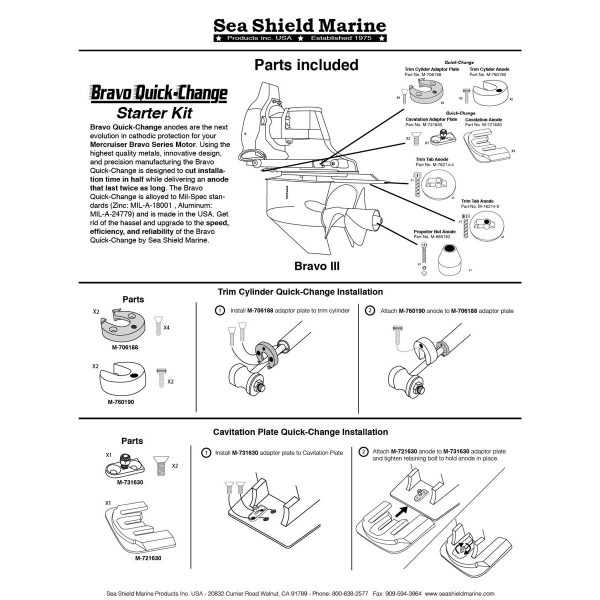

Upgrades for Enhanced Performance

Improving the overall functionality of your equipment can significantly enhance its efficiency and longevity. By incorporating various enhancements, users can achieve a smoother operation and better results. These upgrades often focus on optimizing existing components, adding new features, and ensuring compatibility with advanced technologies.

Key Enhancements

Several key modifications can be implemented to boost performance. Upgrading the core components can lead to increased reliability and effectiveness. Additionally, integrating advanced technology can provide improved user experience and adaptability to changing demands.

Maintenance Considerations

Regular maintenance of upgraded systems is crucial for sustaining peak performance. Ensuring that all components function harmoniously will prevent potential issues and extend the life of the equipment. Prioritizing maintenance routines and being proactive can yield significant benefits in the long run.

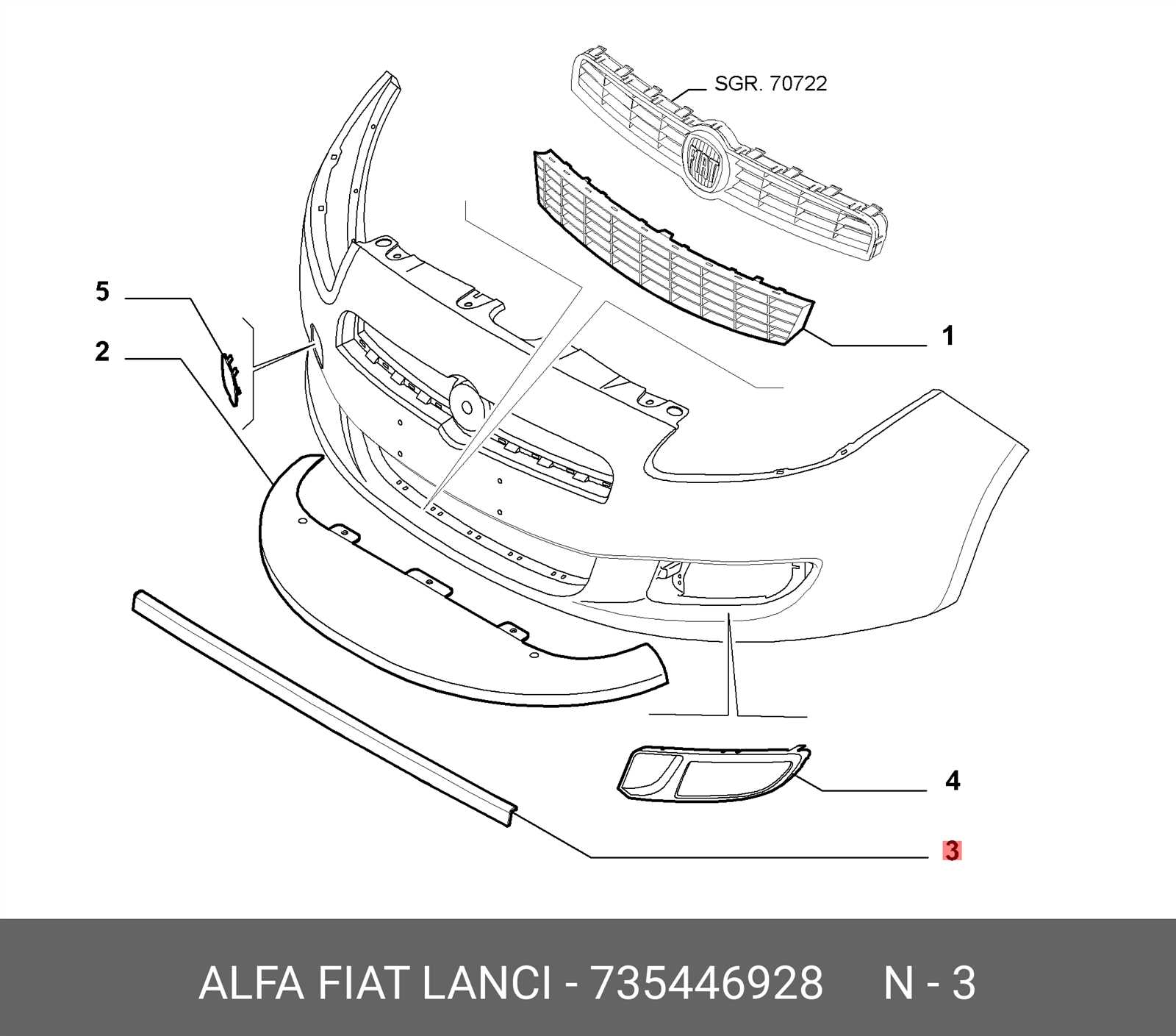

Compatibility with Other Models

Understanding the relationship between different models is essential for seamless integration and functionality. Compatibility can influence performance, ease of maintenance, and the availability of components. This section delves into how various models relate to one another and the implications for users.

Several key factors determine compatibility:

- Design similarities: Models sharing similar designs often have interchangeable components.

- Technical specifications: Matching specifications ensure optimal performance across different units.

- Manufacturer guidelines: Recommendations from the manufacturer can provide insights into compatibility.

When considering compatibility, users should take note of:

- Version differences that may affect interchangeability.

- Component functionality that can vary between models.

- Potential updates or modifications that enhance compatibility over time.

In summary, exploring the compatibility of various models allows users to make informed decisions, ensuring that they select the most suitable options for their needs.

Tools Required for Assembly

When assembling a complex mechanism, having the right tools is essential to ensure a smooth and efficient process. Various instruments and equipment are necessary to facilitate the assembly, enabling the user to perform tasks accurately and effectively.

Essential Instruments

Basic hand tools such as screwdrivers, wrenches, and pliers are fundamental for any assembly task. These instruments allow for the tightening and loosening of components, ensuring a secure fit. Additionally, a torque wrench may be required to apply specific force, preventing damage to parts.

Specialized Equipment

In some cases, specialized tools might be needed to complete the assembly effectively. Items such as alignment jigs or specific fasteners can greatly enhance precision. Furthermore, a workspace equipped with adequate lighting and organization will support a more efficient assembly experience.

Safety Precautions During Installation

Ensuring a secure and effective setup is crucial for optimal operation. Following essential guidelines helps prevent accidents and equipment damage during the installation process.

Preparation Steps

- Review the installation manual thoroughly.

- Gather all necessary tools and components beforehand.

- Verify that the workspace is clean and well-lit.

- Ensure proper ventilation if working in an enclosed area.

Personal Safety Measures

- Wear appropriate safety gear, including gloves and goggles.

- Keep hair and loose clothing secured to avoid entanglement.

- Do not work alone; have someone nearby in case of emergencies.

By adhering to these precautions, the installation process can be performed safely, minimizing risks and enhancing efficiency.

Expert Recommendations on Usage

When it comes to operating complex mechanical systems, adhering to professional advice can significantly enhance performance and longevity. Understanding key practices can facilitate optimal functionality and prevent potential issues during usage.

Essential Guidelines

- Regular Inspections: Conduct frequent checks to identify any signs of wear or damage early.

- Appropriate Lubrication: Ensure that all moving components are adequately lubricated to reduce friction and enhance efficiency.

- Correct Operational Techniques: Familiarize yourself with recommended operational methods to maximize effectiveness and safety.

- Adherence to Load Limits: Be mindful of the specified load capacities to prevent overstraining the system.

Maintenance Practices

- Follow the manufacturer’s guidelines for scheduled maintenance to keep the system running smoothly.

- Use quality replacement components to ensure compatibility and reliability.

- Document any maintenance work performed to track the system’s history and aid in future troubleshooting.

Resources for Further Learning

Expanding knowledge on related subjects can significantly enhance understanding and skills. Various materials, including books, online courses, and instructional videos, offer valuable insights into the topic. Engaging with diverse resources not only deepens comprehension but also provides practical applications.

Many online platforms feature a wealth of tutorials and guides that cover foundational principles and advanced techniques. Utilizing these resources allows learners to explore different perspectives and approaches. Additionally, joining forums and discussion groups can foster connections with others interested in similar topics, promoting collaboration and shared learning experiences.

To further support educational growth, consider accessing libraries and academic institutions, which often provide specialized texts and research articles. This comprehensive approach will ensure a well-rounded grasp of the subject and equip individuals with the necessary tools to excel in their endeavors.