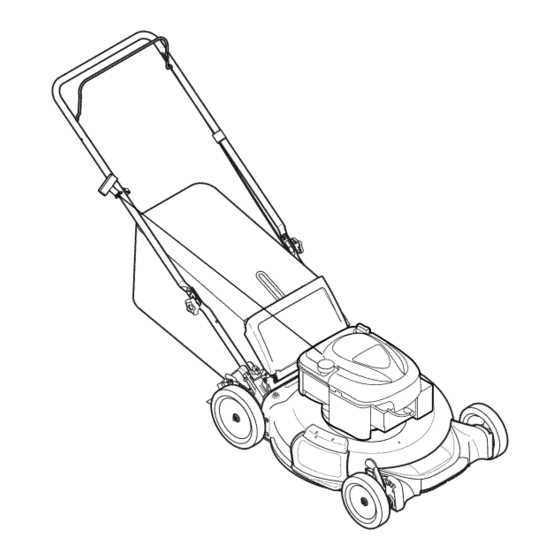

Understanding the inner workings of a lawn mower is essential for anyone looking to maintain or repair their equipment effectively. Each element plays a crucial role in ensuring smooth operation, and knowing how to identify them can make all the difference when troubleshooting or performing regular upkeep. This section will provide a comprehensive overview of the key elements, offering insights into their functionality and importance.

Whether you are dealing with the drive system, cutting blade, or engine assembly, every piece contributes to the overall performance. A clear understanding of these systems enables users to make informed decisions when it comes to maintenance or replacement. By familiarizing yourself with these components, you can extend the life of your equipment and keep it running

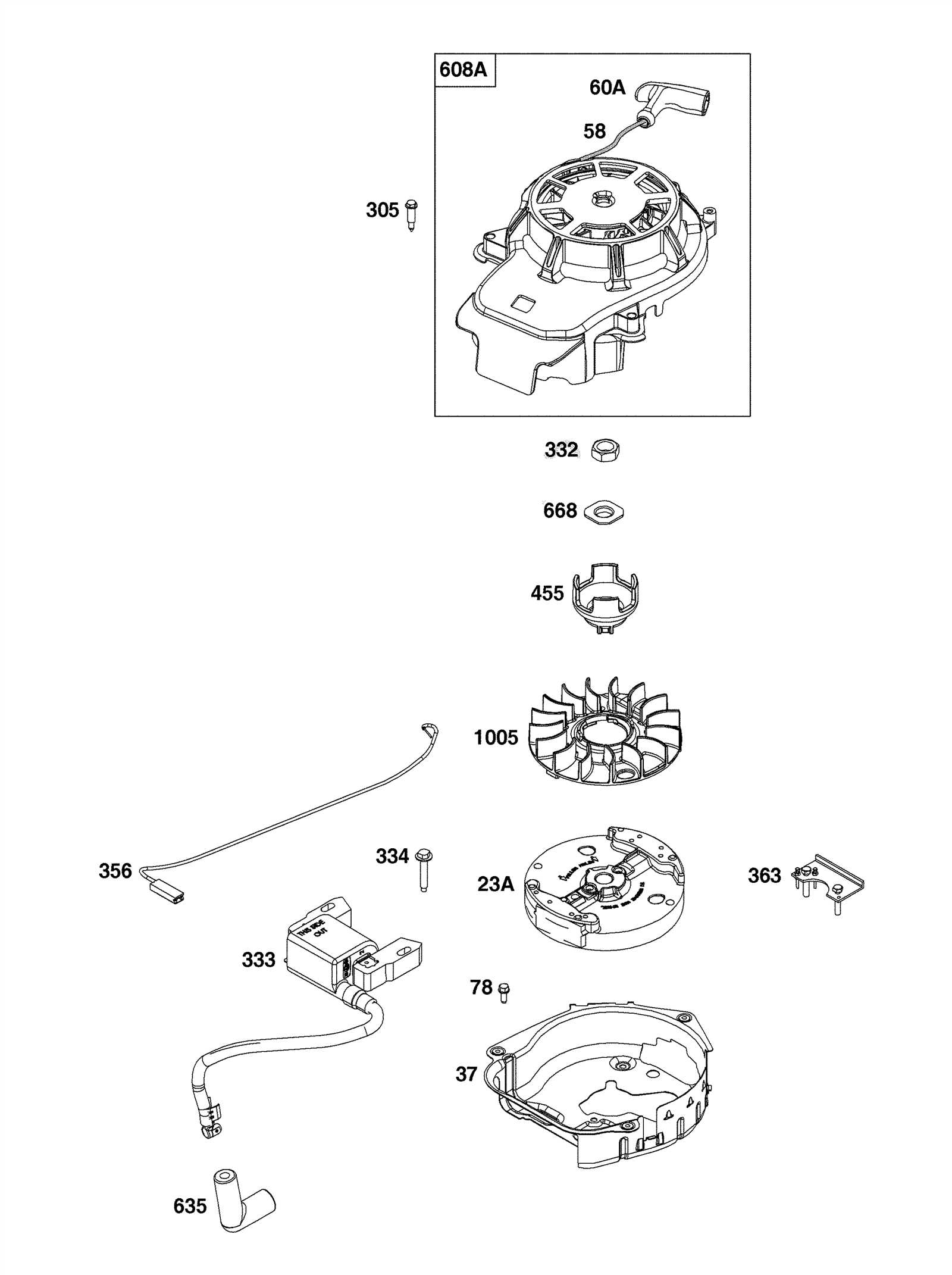

Understanding the Parts Diagram

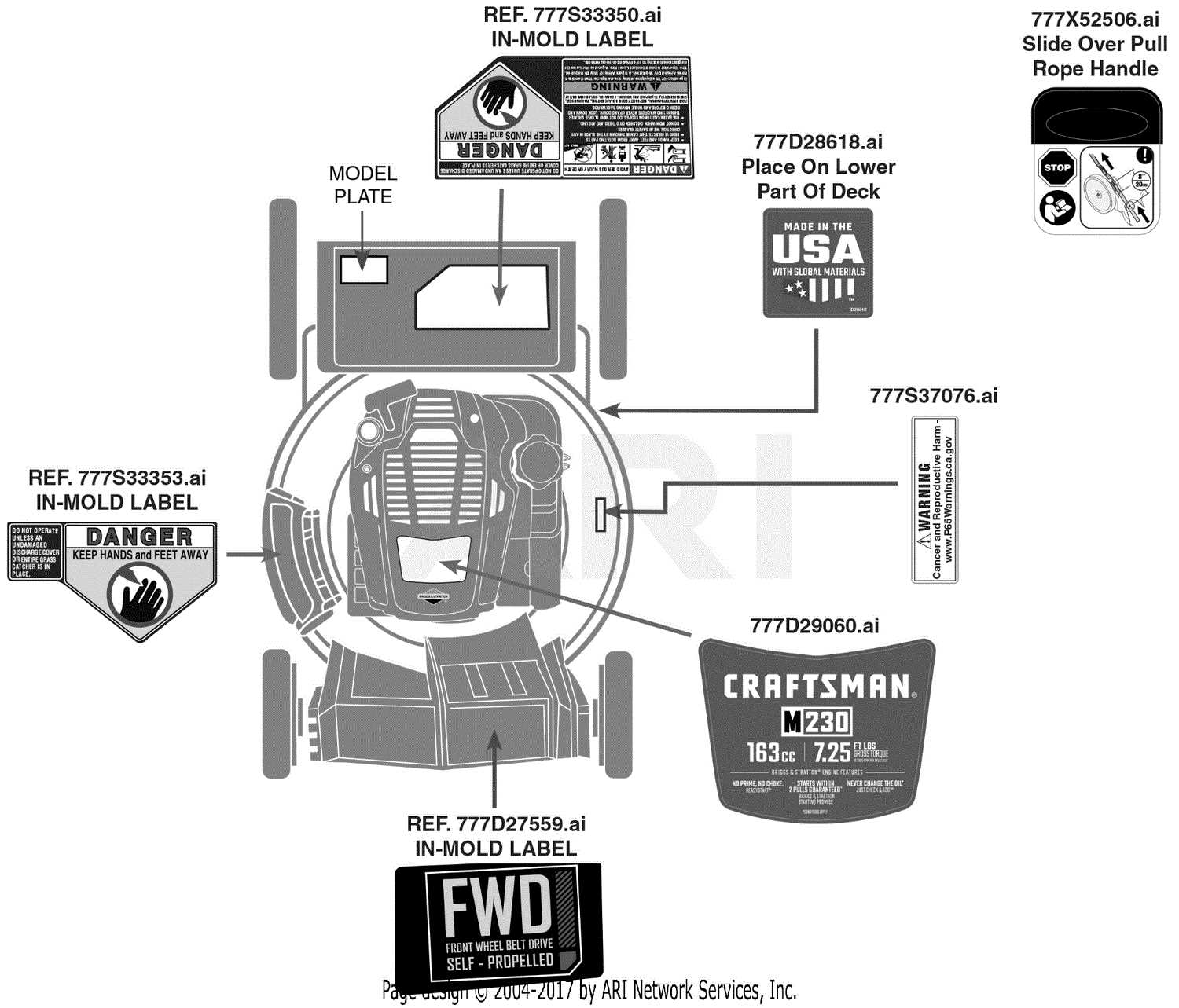

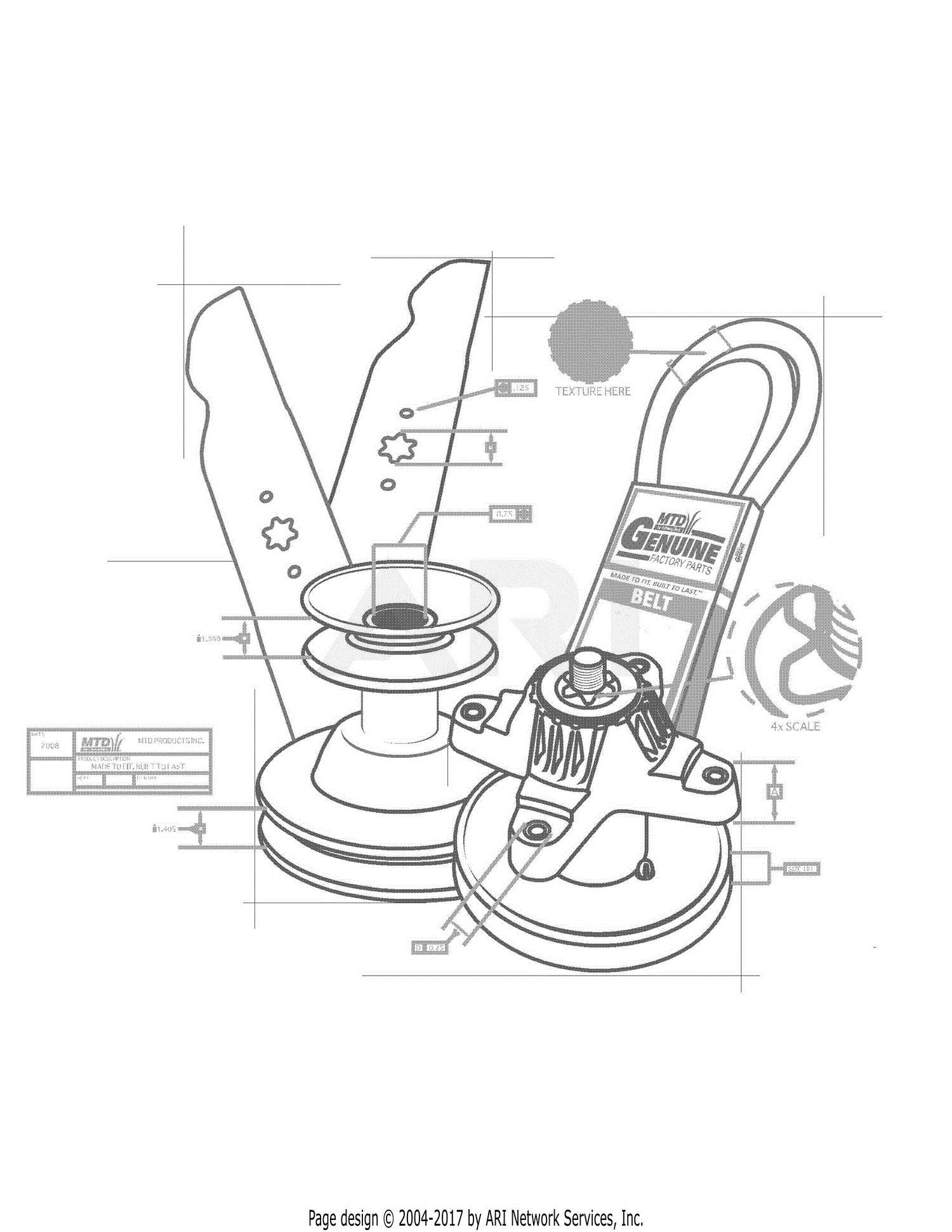

A detailed illustration of components offers a clear visual representation of how each element is organized and how they function together. This breakdown helps users identify and understand the relationship between various sections, ensuring better comprehension of the machine’s overall structure.

Key Components Overview

The diagram typically highlights essential mechanisms, including drive systems, cutting units, and control elements. By reviewing these illustrations, users can gain a clear understanding of where each part is located and how it contributes to the unit’s performance. Identifying these critical sections can make troubleshooting and maintenance much simpler.

Benefits of Visual Reference

A visual reference makes it easier to identify the correct elements for replacement or adjustment. It also simplifies the learning process by providing a concrete guide to follow, ensuring all components are installed correctly. This type

Common Issues with Craftsman M230

Many users encounter similar problems when dealing with this type of lawn equipment, especially after prolonged use. This section highlights the most frequent issues, offering possible solutions to ensure proper operation and avoid unnecessary repairs.

Engine Starting Problems

- Dirty air filters often prevent the engine from starting. Cleaning or replacing them may resolve the issue.

- Stale fuel can lead to ignition issues. Draining the old fuel and refilling with fresh gasoline can be an effective fix.

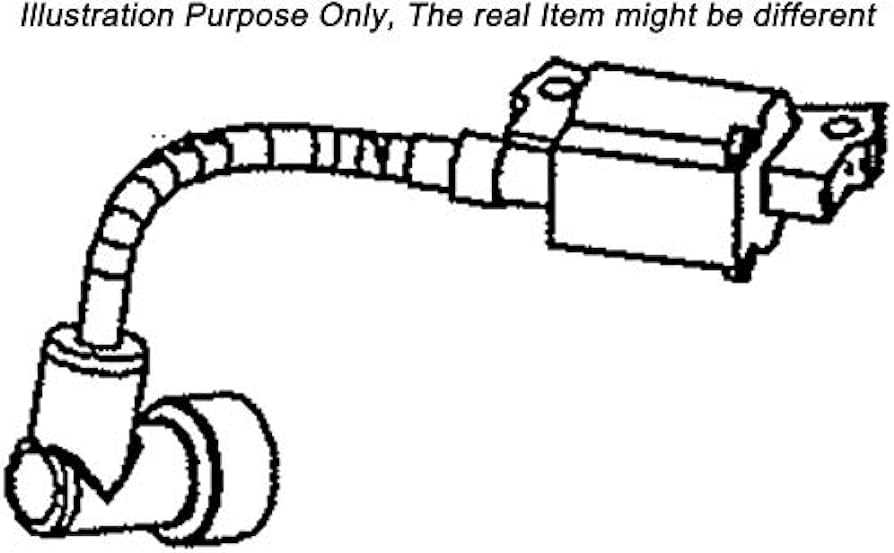

- Check the spark plug for dirt or wear; a malfunctioning spark plug may hinder the ignition process.

Uneven Cutting

- Blades may become dull or damaged, leading to an uneven cut. Sharpen or replace the blades as necessary

Replacement Parts and Availability

When maintaining or repairing your equipment, it is essential to understand the availability of necessary components. Reliable and easily accessible replacements ensure that your machine continues to operate efficiently, minimizing downtime and extending its lifespan.

Finding Compatible Components

Locating compatible replacement pieces can be straightforward if you know where to look. Online retailers, specialized stores, and even local suppliers may offer a range of options suited to your needs. It is important to verify the compatibility of each piece to avoid further complications during installation.

Ensuring Long-Term Availability

Over time, manufacturers may discontinue certain models or parts, making it difficult to find specific components. To avoid potential shortages, it’s wise to purchase critical items early or stock up on frequently needed replacements. Regular maintenance checks can also help anticipate needs before a problem arises, ensuring uninterrupted functionality.

Tools Required for Assembly

When preparing for the setup process, it’s essential to have the correct instruments on hand. Proper equipment ensures efficient assembly, reducing the risk of errors or delays. Having everything ready beforehand also contributes to a smoother and safer installation process.

Basic Hand Tools

To begin, you will need standard tools like a wrench set, screwdrivers, and pliers.

Step-by-Step Assembly Guide

This guide will walk you through the entire process of assembling your equipment, ensuring every component is fitted properly for optimal functionality. By following these instructions, you will be able to put together each part of your machine efficiently and safely.

Step 1: Begin by organizing all necessary components. Lay them out in a clean and accessible workspace, ensuring nothing is missing before starting the assembly.

Step 2: Attach the base to the main frame. Ensure the connections are

Maintenance Tips for Longevity

Regular upkeep is essential to ensure your equipment performs efficiently over time. By incorporating a few simple maintenance routines, you can extend the lifespan of your machine and keep it running smoothly, regardless of its purpose or configuration.

Clean and Inspect Regularly

One of the most effective ways to preserve your machine is by cleaning it after each use. Dirt and debris can accumulate, causing wear on critical components. Make sure to inspect moving parts for any signs of damage or excessive wear. Frequent inspections help you catch potential issues before they lead to costly repairs.

Lubrication and Adjustments

To ensure smooth operation, all moving elements should be properly lubricated. Check the lubrication points and apply the recommended oil or grease at regular intervals. Additionally,

Identifying Parts by Model Number

Knowing how to locate specific components using a model number can greatly simplify maintenance and repair tasks. Each item within a tool or device is usually assigned a unique identification code, helping users to find exactly what they need.

Steps for Finding Components

- Locate the model number on the equipment. This is usually found on a label or metal plate.

- Use the model number to access detailed breakdowns of individual components online or in the manual.

- Identify the needed component by comparing its position or function within the equipment.

Benefits of Using Model Numbers

- Reduces confusion by ensuring accurate matches between components and equipment.

- Speeds up the ordering process for replacements or repairs.

- Hel

Upgrades for Improved Performance

Enhancing the efficiency of your lawn equipment can significantly extend its lifespan and improve its overall capabilities. By focusing on key components, you can ensure smoother operation, increased durability, and more consistent results. Various modifications are available that allow for improved functionality and optimized performance.

Upgrade Benefit Considerations High-Performance Blades Sharper cuts, less effort Requires regular sharpening Enhanced Air Filters Better engine efficiency Needs frequent replacement Where to Find OEM Parts

When you’re in need of genuine replacement components for your equipment, it’s crucial to know the right places to look. Original equipment manufacturer (OEM) parts ensure proper fit and functionality, helping to maintain the longevity and performance of your machine. Below are some reliable sources to locate these authentic components.

Authorized Dealers

One of the most reliable ways to find OEM components is through authorized dealers. These businesses have direct access to genuine items from the manufacturers, guaranteeing their authenticity. Additionally, dealers often provide customer support, helping you choose the right product for your machine.

Online Retailers

Many trusted online platforms offer OEM components. These websites frequently have extensive catalogs and search tools to help you quickly locate the correct items. Make sure to verify the seller’s credentials to ensure you’re getting the real deal.

DIY Repair Solutions

When faced with a malfunctioning device, exploring self-repair options can save time and money. Understanding the components and their functions is essential for efficient troubleshooting. This section will guide you through practical solutions to common issues.

Common Issues and Fixes

- Power Problems: Check the power source, and ensure connections are secure. Consider replacing faulty cables.

- Performance Issues: Clean and lubricate moving parts to enhance efficiency.

- Noisy Operation: Inspect for loose parts or debris that may be causing friction.

Tools Needed for Repairs

- Basic Toolkit: A set of screwdrivers, pliers, and wrenches will suffice for most tasks.

- Cleaning Supplies: Use brushes and compressed air to remove dirt from sensitive areas.

- Lubricants: Apply suitable oils to moving components to ensure smooth operation.

Consulting the User Manual

Referring to the user manual is essential for understanding the features and functionalities of your device. This resource provides comprehensive guidance, ensuring you can operate and maintain your equipment effectively.

Within the manual, you will find detailed instructions on various aspects, including:

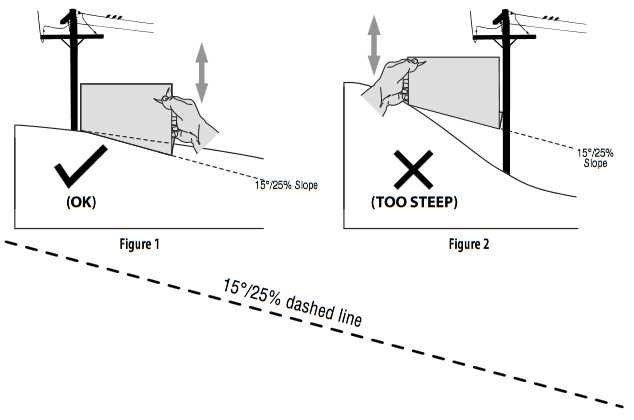

- Safety precautions to follow during use

- Step-by-step assembly instructions

- Maintenance tips for optimal performance

- Troubleshooting common issues

Utilizing this resource can help extend the lifespan of your device and enhance your overall experience. It is advisable to keep the manual accessible for quick reference whenever needed.