The efficient functioning of any power tool relies on the intricate relationship between its various components. A comprehensive understanding of these elements can enhance the user’s ability to maintain and troubleshoot their equipment effectively. In this section, we will explore the essential building blocks that contribute to the overall performance and reliability of a specific model, allowing for a deeper appreciation of its design and functionality.

By examining the individual elements and their respective roles within the assembly, users can gain valuable insights into how to optimize their tool’s performance. Whether it is for repair, replacement, or simply enhancing operational efficiency, knowing the intricacies of each component is crucial. This knowledge empowers users to make informed decisions regarding maintenance and upgrades, ultimately prolonging the lifespan of their equipment.

Additionally, recognizing the interconnectivity of these parts is vital. Each element plays a specific role that affects the others, and a disruption in one can lead to a chain reaction impacting overall functionality. By understanding this complex network, users can troubleshoot issues more effectively and implement solutions that restore their tool to optimal working condition.

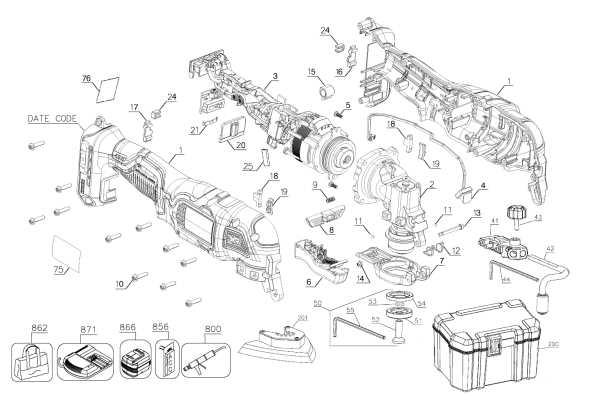

Dewalt DCD996 Parts Overview

This section provides a comprehensive look at the various components and assemblies of a renowned power tool. Understanding the different elements is essential for effective maintenance, repair, and enhancement of performance. Here, we will delve into the key features and functionalities of each component, ensuring users have a well-rounded knowledge of their equipment.

- Motor Assembly: The heart of the tool, responsible for driving the action and delivering power to the attachments.

- Gearbox: This component plays a crucial role in transferring power from the motor to the output shaft, affecting speed and torque.

- Chuck: The mechanism that holds the drill bits securely in place, enabling users to switch between different bit sizes quickly.

- Battery Pack: A vital element that powers the tool, available in various capacities to suit different needs and preferences.

- Handle and Housing: Designed for ergonomics and comfort, these parts ensure a firm grip while operating the equipment.

Familiarity with these components allows users to make informed decisions regarding repairs, upgrades, and optimal usage. Below, we will outline additional elements and their significance.

- Trigger Switch: Controls the tool’s activation, allowing for precise control over power delivery.

- Cooling Fan: Helps to dissipate heat during prolonged use, ensuring the longevity of the internal components.

- LED Light: Provides illumination in dark or confined spaces, enhancing visibility while working.

Understanding the intricacies of these components is crucial for maximizing the tool’s efficiency and durability.

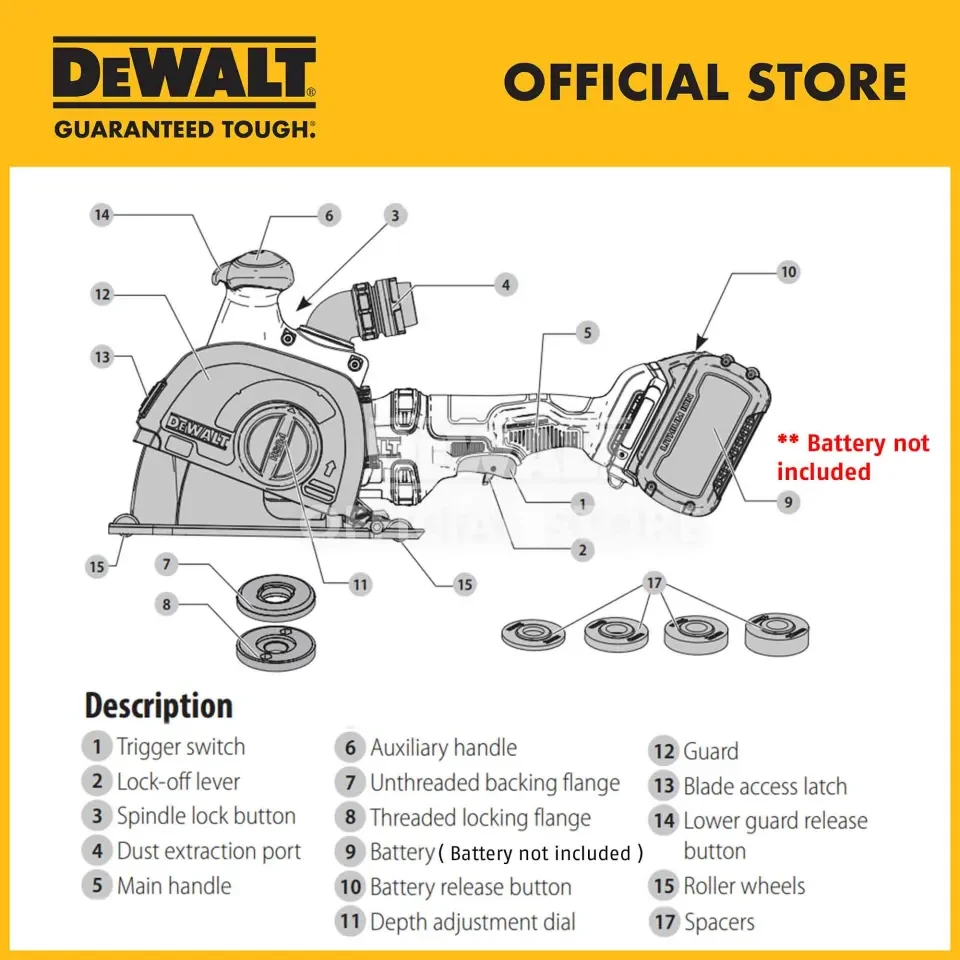

Key Components of the Tool

This section focuses on the essential elements that contribute to the functionality and performance of the tool. Understanding these components is crucial for effective usage and maintenance.

- Motor: The heart of the device, providing the necessary power for various applications.

- Gearbox: This mechanism transfers power from the motor to the output, allowing for different speed and torque settings.

- Chuck: The clamping device that securely holds the drill bits or attachments in place.

- Battery: A rechargeable power source that ensures portability and convenience during operation.

- Trigger: A control element that allows the user to regulate the tool’s activation and speed.

- Handle: Designed for comfortable grip and control, enhancing user experience during operation.

- Clutch: An adjustable feature that prevents over-tightening by disengaging the motor when the desired torque is reached.

Familiarity with these components not only aids in effective use but also assists in troubleshooting and performing maintenance tasks.

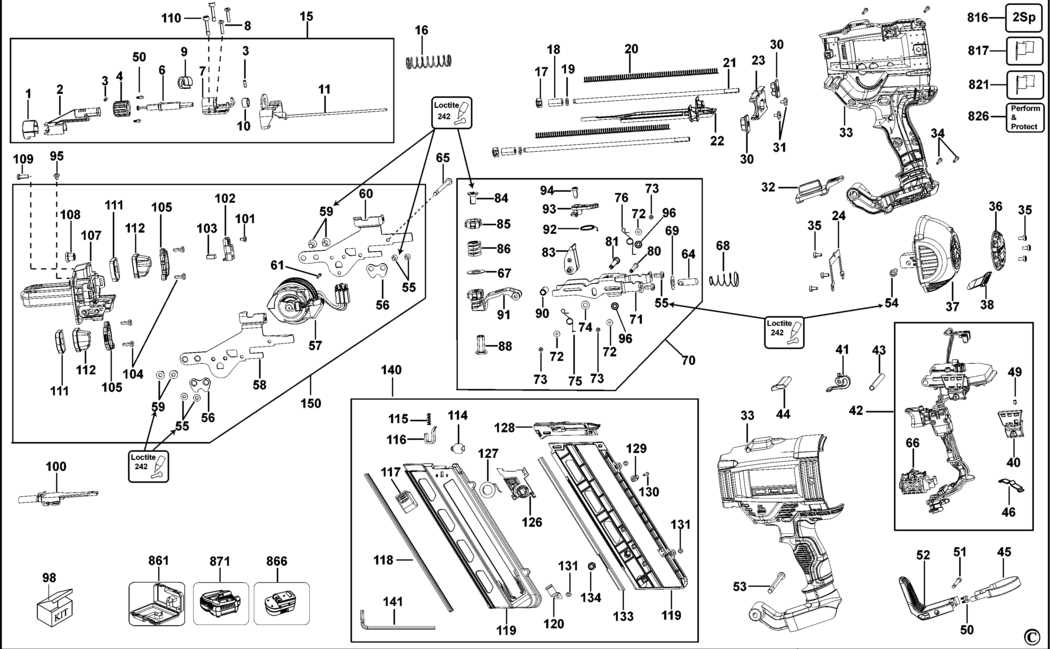

Understanding the Assembly Layout

Examining the configuration of components within a power tool is crucial for comprehending its functionality and maintenance. This section will delve into the structural arrangement, highlighting key elements that contribute to the tool’s performance and reliability.

Key Components

Familiarity with the main constituents of the device can enhance operational efficiency. Here are the primary elements:

- Motor Unit

- Gearbox Assembly

- Battery Housing

- Trigger Mechanism

- Chassis

Assembly Insights

Understanding how these components interact can help in troubleshooting and repairs. Consider the following:

- The motor unit is the powerhouse, converting electrical energy into mechanical energy.

- The gearbox regulates speed and torque, crucial for different applications.

- The battery housing ensures a secure fit for energy storage, affecting runtime.

- The trigger mechanism allows for precise control, enabling users to manage power output.

- The chassis provides structural integrity, protecting internal components from damage.

Gaining insight into this assembly layout not only aids in better usage but also extends the lifespan of the tool through informed maintenance practices.

Common Issues with Parts

When working with power tools, users often encounter various challenges related to their components. Understanding these common problems can help in effective troubleshooting and maintenance. Below are some frequent issues that may arise and how they can impact tool performance.

- Wear and Tear: Over time, certain components may degrade due to regular use, affecting efficiency and functionality.

- Improper Alignment: Misalignment of elements can lead to decreased performance, resulting in excessive strain and potential failure.

- Debris Accumulation: Dust and debris can accumulate in crucial areas, causing blockages and overheating.

- Compatibility Issues: Using incorrect or incompatible components can hinder the overall performance and durability of the tool.

To mitigate these issues, regular inspections and maintenance are essential. Identifying and addressing problems early can prolong the lifespan of your equipment and ensure optimal functionality.

- Conduct routine checks for wear on moving parts.

- Ensure proper alignment during assembly.

- Regularly clean and clear any debris.

- Use manufacturer-recommended components for replacements.

By staying proactive and informed about these common issues, users can maintain their tools more effectively and avoid unnecessary downtime.

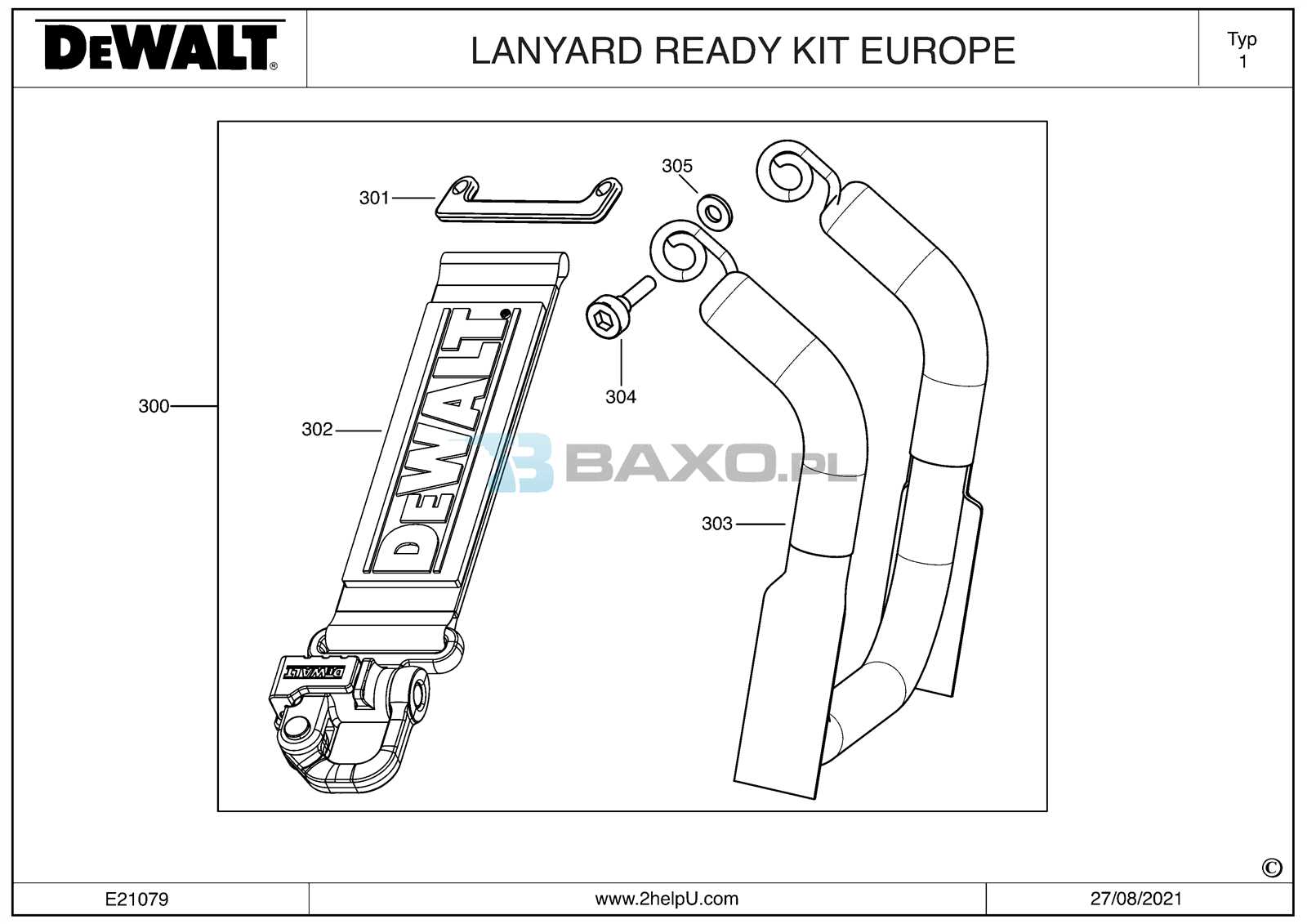

Identifying Replacement Parts Easily

When it comes to maintaining power tools, knowing how to quickly locate and identify necessary components is crucial. Whether you’re performing repairs or upgrading your equipment, having a clear understanding of the elements involved can save time and effort. This guide provides useful tips for simplifying the identification process of components in your tools.

Utilizing Resourceful Guides

Consulting comprehensive manuals or reference materials can significantly enhance your ability to recognize specific components. Many manufacturers offer detailed guides that illustrate various elements and their functionalities. These resources often include clear visuals and descriptions, making it easier to understand how each piece fits into the overall assembly.

Leveraging Online Communities

Engaging with online forums and communities can also be beneficial for identifying replacement components. Fellow enthusiasts and experts frequently share insights, experiences, and recommendations that can lead to quicker identification. Participating in these discussions not only provides valuable knowledge but also fosters a sense of camaraderie among users with similar interests.

By employing these strategies, you can navigate the identification process with confidence, ensuring that your tools remain in optimal condition and function efficiently.

Benefits of Genuine Parts

Using authentic components in your equipment is essential for maintaining optimal performance and longevity. Genuine items are specifically designed to fit perfectly and work seamlessly with your tools, ensuring that they operate efficiently and safely. This approach minimizes the risk of malfunction and enhances the overall user experience.

Quality Assurance

One of the primary advantages of authentic components is their superior quality. These items undergo rigorous testing and meet stringent industry standards. Here are some key points highlighting this benefit:

- Manufactured from high-quality materials for durability.

- Consistent performance across different applications.

- Reduced likelihood of breakdowns and maintenance issues.

Enhanced Compatibility

Another significant benefit is the assurance of compatibility. Authentic components are designed specifically for your equipment, providing a perfect fit. Consider the following advantages:

- Ensures seamless integration with existing systems.

- Reduces the chances of installation errors.

- Helps preserve warranty coverage by adhering to manufacturer recommendations.

Comparison of Different Models

The evaluation of various tools within a specific category reveals significant differences in features, performance, and usability. Understanding these distinctions can help users make informed decisions based on their needs and preferences. This section explores several options available in the market, highlighting their unique characteristics and advantages.

Power and Performance: One of the critical aspects to consider is the power output of each model. Higher torque and voltage typically translate to better performance in demanding tasks. However, some users may prioritize battery life and weight for ease of handling, especially during prolonged use.

Features: Different variants often come equipped with distinct functionalities. For instance, some may include advanced settings for speed and torque adjustment, while others might offer built-in LED lighting for better visibility in dark workspaces. Evaluating these features helps in choosing a model that best fits specific applications.

Durability and Build Quality: The construction quality of tools can greatly impact their longevity. Some models are designed with robust materials that withstand heavy usage, while others may prioritize lightweight designs for portability. Comparing the durability of various options can aid in selecting a reliable tool for both professional and home use.

Price and Value: Cost is often a determining factor when selecting a tool. Models vary widely in price, and it is essential to assess whether the features justify the investment. Understanding the overall value offered by each option can lead to a more satisfying purchase.

By examining these aspects, users can better appreciate the differences among various models, ultimately leading to a more effective and enjoyable working experience.

Maintenance Tips for Longevity

To ensure the durability and optimal performance of your power tool, regular maintenance is essential. Implementing effective care practices can significantly extend its lifespan and maintain efficiency, allowing you to tackle various tasks with confidence. This section outlines key maintenance strategies that will help you keep your equipment in excellent working condition.

Regular Cleaning

Maintaining cleanliness is crucial for the functionality of your tool. Dust, debris, and residue can accumulate over time, affecting performance. Regularly clean the exterior and interior components to prevent build-up and ensure smooth operation.

Lubrication and Inspection

Proper lubrication of moving parts minimizes friction and wear. Additionally, routine inspections help identify potential issues before they escalate. Check for signs of damage or excessive wear, and address any concerns promptly to avoid costly repairs.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean exterior and interior | After each use | Prevents build-up, enhances performance |

| Lubricate moving parts | Every month | Reduces friction, extends lifespan |

| Inspect for wear and damage | Every three months | Identifies issues early, prevents breakdowns |

| Replace worn components | As needed | Ensures optimal performance, maintains safety |

Parts Compatibility with Other Tools

Understanding the interchangeability of components across various power tools can enhance both functionality and maintenance efficiency. When users seek to replace specific elements or upgrade their equipment, knowing which components are compatible with other brands or models is essential. This knowledge can lead to improved performance and cost savings by allowing users to utilize existing assets instead of purchasing new tools.

Commonly Compatible Components

Many brands share similar designs and engineering standards, which means that certain accessories, batteries, and chargers may work interchangeably. For example, drills and drivers often use standardized battery sizes, enabling users to power multiple devices without the need for additional charging units. Additionally, attachments like drill bits and socket sets can often be utilized across different makes and models, enhancing versatility in various tasks.

Benefits of Compatibility Awareness

Familiarity with which components can be used interchangeably not only saves time and money but also maximizes the potential of the tools in a user’s collection. By integrating compatible accessories, users can tailor their equipment to meet specific project requirements without investing heavily in brand-specific solutions. This flexibility can be particularly advantageous for professionals who rely on multiple tools to complete a wide range of tasks.

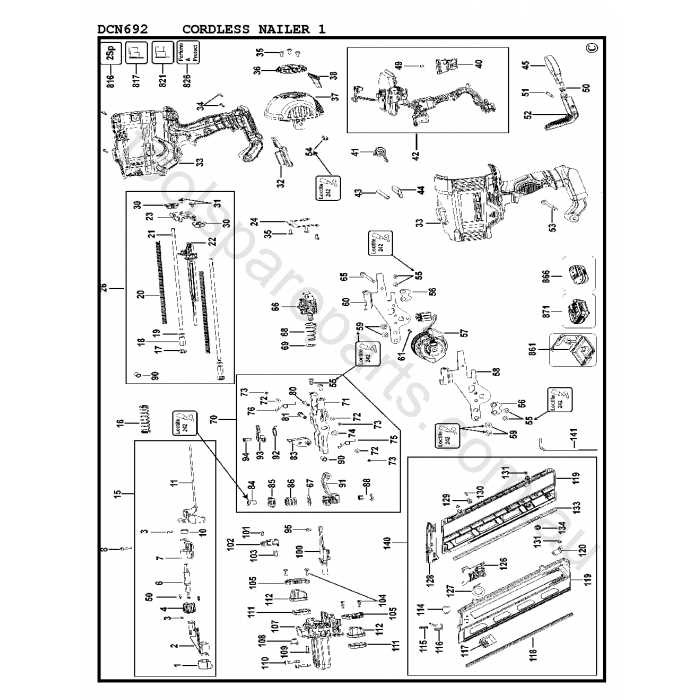

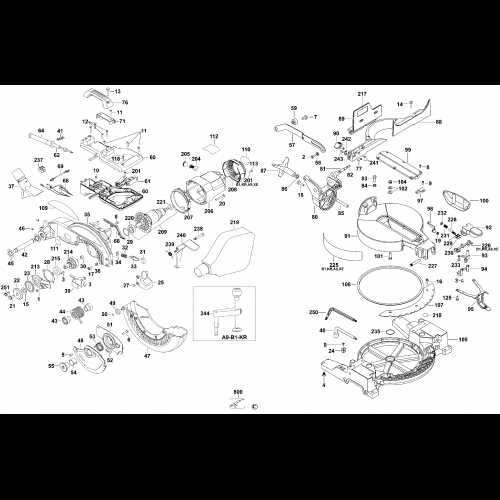

How to Access the Diagram

Accessing the visual representation of components and their arrangements is crucial for effective maintenance and repair. This process can greatly simplify understanding the assembly and identifying specific elements within the tool.

To obtain the schematic view, follow these steps:

- Visit the official website of the manufacturer.

- Navigate to the section dedicated to service or support.

- Use the search function to locate the relevant model.

- Look for resources such as manuals, guides, or schematics.

- Download the file or view it online as needed.

Additionally, consider these alternative methods:

- Check local hardware stores that may provide printed materials.

- Join online forums or communities focused on tool repair for shared resources.

- Contact customer service for assistance in obtaining the necessary documents.

Utilizing these methods will ensure you have the required visual aid for efficient troubleshooting and repairs.

Frequently Asked Questions

This section addresses common inquiries regarding the components and assembly of a popular power tool model. Here, you will find helpful information that can assist users in understanding its structure and functionality.

- What should I do if a part is missing?

If you notice that a component is missing, check the packaging thoroughly. If it’s not there, contact the retailer or manufacturer for assistance.

- How can I identify a specific component?

Refer to the user manual for identification guidance. Diagrams often included in the manual can help locate the necessary parts.

- Are there compatible replacements available?

Yes, numerous third-party manufacturers produce compatible alternatives. However, ensure they meet quality standards before purchasing.

- How do I maintain the tool’s components?

Regular cleaning and inspection are essential. Lubricate moving parts as recommended in the user manual to ensure smooth operation.

- Where can I find detailed assembly instructions?

Detailed assembly instructions can usually be found in the user manual or on the manufacturer’s website. Video tutorials may also be available for visual guidance.

- What warranty options are available for the tool?

Warranty details vary by manufacturer. Review the warranty information provided at the time of purchase or check online for specific terms.

Where to Purchase Replacement Parts

When it comes to maintaining your tools, sourcing components for repairs is essential. Whether you’re looking to replace a worn-out element or upgrade your device, understanding where to find quality replacements can save you time and money.

Authorized Dealers

One of the best places to find high-quality replacements is through authorized distributors. These outlets offer genuine components that ensure compatibility and reliability.

Online Retailers

Another convenient option is to explore online marketplaces. Numerous platforms specialize in tool accessories and can provide a wide range of options at competitive prices.

| Vendor Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine components, expert advice | May have higher prices |

| Online Retailers | Convenient shopping, wide selection | Verify seller ratings and product reviews |

Utilizing Diagrams for Repairs

Visual aids are essential tools for effectively addressing maintenance and repair tasks. These graphical representations provide a clear and concise view of component relationships and assembly processes, making it easier to understand complex machinery. By leveraging these illustrations, users can streamline their repair efforts, minimize errors, and enhance overall efficiency.

Benefits of Visual Aids

Employing graphical representations in repair work offers numerous advantages. Firstly, they simplify the identification of individual components and their functions, allowing for more efficient troubleshooting. Secondly, these aids can guide users through the disassembly and reassembly processes, ensuring that every piece is correctly placed and connected. Overall, the use of illustrations significantly contributes to the success of repair endeavors.

Key Considerations for Effective Use

When utilizing visual guides, it’s crucial to pay attention to detail. Carefully analyze each illustration to understand the context and arrangement of components. Furthermore, ensure that the guide corresponds to the specific model in question to avoid confusion. Taking notes or highlighting key areas can also enhance comprehension and facilitate smoother repairs.

| Component | Description | Common Issues |

|---|---|---|

| Battery | Power source for the device. | Short life, failure to charge. |

| Motor | Drives the tool’s functionality. | Overheating, noise, lack of power. |

| Chuck | Holds the bit securely. | Difficulty in tightening, bit slippage. |