When it comes to maintaining your outdoor equipment, a thorough understanding of its individual elements is essential. Each component plays a crucial role in the overall performance and longevity of the machine, ensuring that it operates smoothly and efficiently. By familiarizing yourself with these parts, you can better appreciate the intricacies of your gardening device and enhance your maintenance skills.

In this guide, we will explore the various sections of your tool, providing insights into how each piece contributes to its functionality. From the primary operational elements to the intricate smaller components, gaining clarity on their arrangement can empower you to make informed decisions during repairs and upgrades. This knowledge not only saves time but also minimizes the risk of errors during assembly or disassembly.

Furthermore, understanding the layout and relationship between different parts allows you to troubleshoot issues more effectively. Whether you are an avid gardener or a casual user, grasping the essentials of your equipment’s configuration will undoubtedly enhance your gardening experience and ensure optimal results in your outdoor endeavors.

Understanding Stihl HS56C Parts

Grasping the components of a hedge trimmer is essential for effective maintenance and operation. Each element plays a vital role in ensuring optimal performance and longevity of the tool.

Key aspects to consider include:

- Cutting mechanism: Understanding how blades interact can enhance cutting efficiency.

- Power system: Familiarity with the engine or motor type aids in troubleshooting and repairs.

- Handle and grip: Ergonomics are crucial for comfort during extended use.

- Safety features: Awareness of protective elements ensures user safety while operating the equipment.

By delving into these categories, one can better appreciate the ultimate functionality and maintenance requirements of the trimmer.

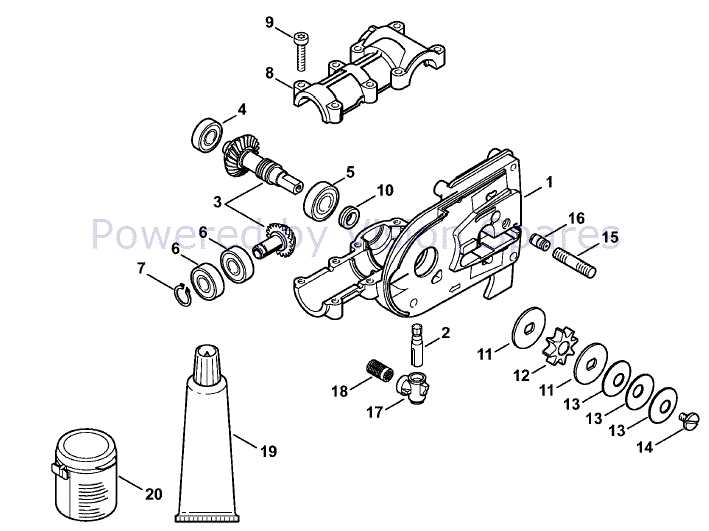

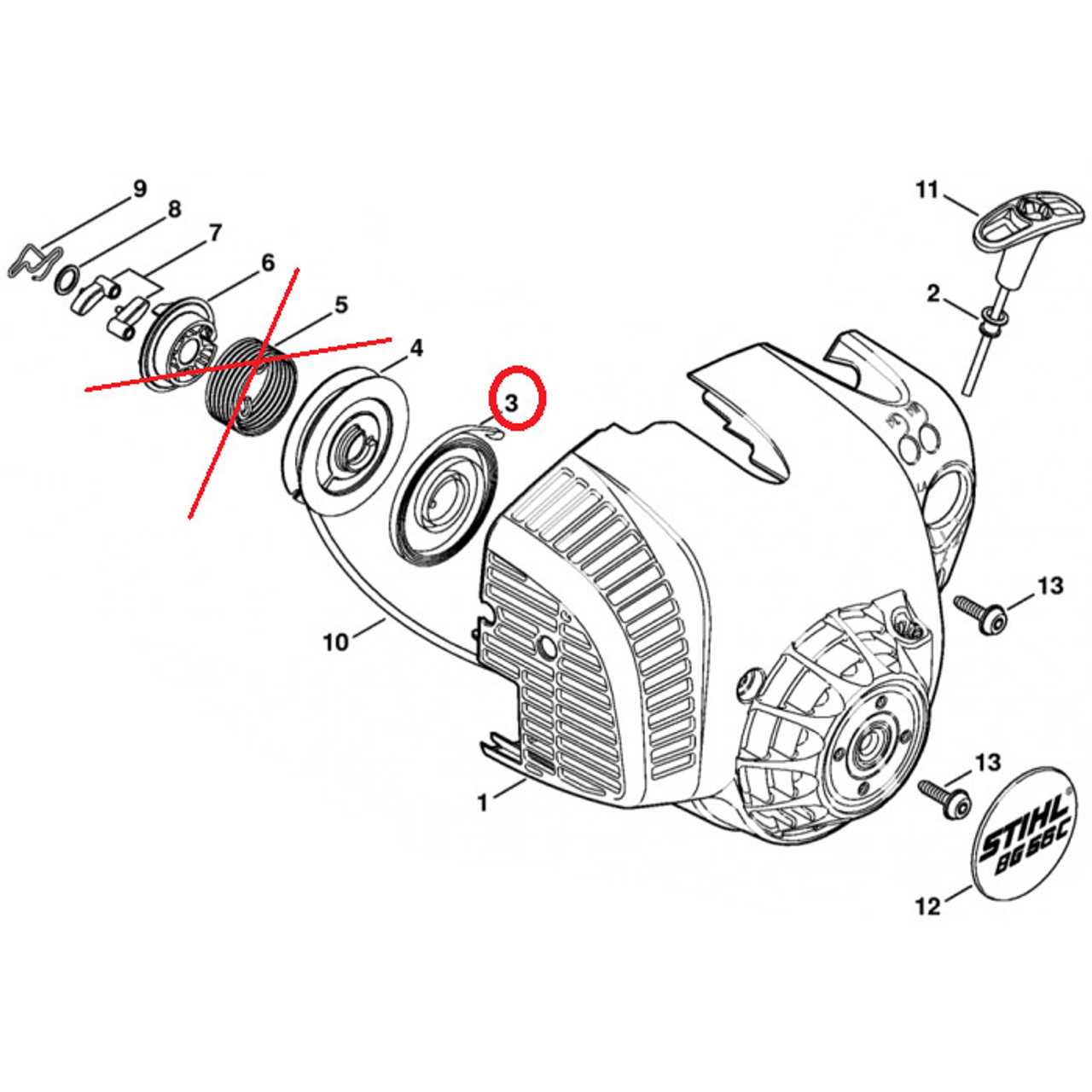

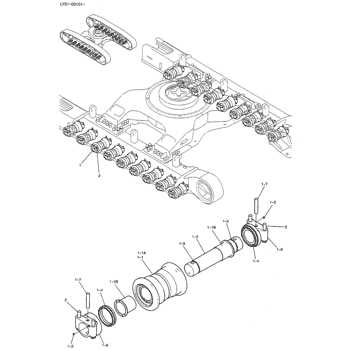

Importance of Parts Diagrams

Understanding the various components of a machine is essential for effective maintenance and repair. Visual representations of these elements facilitate the identification and organization of each section, ensuring optimal performance and longevity of the equipment.

Enhanced Understanding

Having a clear visual reference aids in comprehending how different elements interact. This knowledge is vital for both beginners and experienced users.

- Facilitates troubleshooting

- Reduces assembly errors

- Improves repair efficiency

Streamlined Maintenance

Regular upkeep is crucial for maintaining functionality. Visual aids simplify the process, allowing users to quickly locate and assess parts needing attention.

- Identify worn or damaged components

- Plan for replacements or repairs

- Ensure all necessary tools are prepared

Identifying Key Components

Understanding the essential elements of your equipment is crucial for optimal performance and maintenance. Each component plays a specific role in ensuring that the machine operates smoothly and efficiently. By familiarizing yourself with these parts, you can enhance both functionality and longevity.

Essential Elements

Among the primary elements are the motor, cutting blades, and housing. The motor is the powerhouse, driving the entire mechanism. The cutting blades are vital for achieving precise trimming, while the housing protects internal components and contributes to overall stability.

Maintenance and Replacement

Regular inspection of these parts is recommended to identify wear and tear. If you notice any degradation, prompt replacement is essential to maintain efficiency. Keeping a checklist of these components can aid in timely maintenance and prevent unexpected breakdowns.

Common Issues with Stihl HS56C

When operating hedge trimmers, users may encounter several typical problems that can hinder performance. Understanding these challenges can aid in effective maintenance and prolong the tool’s lifespan.

| Issue | Description |

|---|---|

| Engine Trouble | Difficulty starting or stalling during operation is common, often due to fuel issues or ignition problems. |

| Blade Dullness | Over time, blades may lose their sharpness, leading to inefficient cutting and increased effort. |

| Vibration | Excessive vibrations can indicate loose components or imbalance, affecting user comfort and control. |

| Fuel Leaks | Leaking fuel can arise from damaged lines or seals, posing safety hazards and reducing efficiency. |

Where to Find Parts Diagrams

Locating visual representations of components for various equipment can be essential for effective maintenance and repairs. These illustrations help users understand the arrangement and functionality of each piece, facilitating easier identification when sourcing replacements or upgrades. With the right resources, one can quickly access detailed layouts that enhance the repair process.

One of the best places to search for these resources is the official manufacturer’s website, where you can often find comprehensive manuals and technical information. Additionally, authorized retailers may provide access to similar resources, ensuring authenticity and accuracy. Online forums and communities dedicated to equipment enthusiasts are also valuable, as members often share links and insights into where to locate these essential visuals.

For a more extensive search, consider utilizing specialized online databases or parts suppliers that focus on specific equipment types. These platforms typically offer user-friendly interfaces to easily navigate through the various illustrations and find exactly what you need. Lastly, don’t overlook local repair shops, as they may have printed materials or recommendations for reliable online sources.

Interpreting Diagrams Effectively

Understanding visual representations can greatly enhance your ability to assemble, repair, or analyze equipment. By honing your skills in reading these visuals, you can streamline processes and avoid common pitfalls.

Here are some key strategies to interpret these visuals effectively:

- Familiarize Yourself with Symbols: Different visuals use specific icons and notations. Knowing what each symbol represents is crucial.

- Follow the Flow: Identify the sequence of components and how they interact with each other to understand the overall structure.

- Refer to Annotations: Often, these representations include notes that provide additional insights; don’t overlook them.

- Practice Makes Perfect: The more you engage with these visuals, the better you will become at quickly interpreting them.

By mastering these techniques, you will ultimately enhance your proficiency in working with complex machinery. Dive into the details, and you’ll find clarity and confidence in your tasks.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your gardening equipment. By implementing a few simple practices, you can significantly extend the lifespan of your tools while optimizing their performance.

| Tip | Description |

|---|---|

| Clean After Use | Remove debris and dirt to prevent corrosion and damage. |

| Sharpen Blades | Keep cutting edges sharp for efficient operation and to reduce wear. |

| Check Fuel | Use fresh fuel and store it properly to avoid engine issues. |

| Inspect Components | Regularly check all parts for wear and replace as needed. |

| Store Properly | Keep equipment in a dry, sheltered location to prevent rust and damage. |

Ordering Genuine Replacement Parts

Ensuring optimal performance and longevity of your equipment relies heavily on sourcing authentic components. Choosing original replacements guarantees compatibility, quality, and reliability, ultimately enhancing the overall efficiency of your tools.

When looking to acquire these essential items, consider the following steps:

- Identify the specific component needed for your equipment.

- Visit authorized retailers or online platforms that specialize in original components.

- Verify the part number to ensure you are ordering the correct item.

- Check for customer reviews and ratings to assess the reliability of the seller.

- Compare prices across different sources to find the best deal without compromising quality.

By following these guidelines, you can confidently obtain the necessary replacements to keep your tools in peak condition.

Tools Needed for Repair

When embarking on a repair project, having the right equipment at your disposal is essential for ensuring a smooth and efficient process. The appropriate tools not only facilitate the task at hand but also enhance the overall quality of the repairs. Understanding which implements to gather beforehand can significantly reduce downtime and prevent unnecessary frustration.

Basic Hand Tools are fundamental for most maintenance tasks. A set of screwdrivers, wrenches, and pliers will be indispensable. Pay attention to the sizes and types needed for the specific components you will be working on.

Specialized Instruments may also be required depending on the complexity of the repair. Items such as torque wrenches or precision measuring tools can make a notable difference in achieving the desired results.

Safety Gear should never be overlooked. Gloves, goggles, and ear protection are critical to safeguard yourself from potential hazards during the repair process.

Lastly, consider having Organizational Tools such as trays or bins to keep small parts sorted. This will not only streamline your workflow but also minimize the risk of losing essential components.

DIY Repairs vs. Professional Help

When it comes to fixing tools and equipment, the decision between tackling repairs yourself or seeking expert assistance can be pivotal. Each approach has its own merits and drawbacks, influencing both time and cost considerations.

| DIY Repairs | Professional Help |

|---|---|

| Cost-effective; minimal expenses | Higher costs; expert fees apply |

| Learning experience; enhances skills | Quick solutions; saves time |

| Flexible schedule; work at your own pace | Guaranteed quality; professional standards |

| Potential for mistakes; risk of further damage | Experienced troubleshooting; reliable outcomes |

Ultimately, the choice between do-it-yourself fixes and hiring a specialist hinges on your confidence, the complexity of the issue, and the value you place on your time.

Comparing Stihl HS56C to Other Models

When evaluating different models of hedge trimmers, it’s essential to consider various factors such as performance, weight, and ergonomics. Each model brings its unique features and capabilities to the table, making the comparison an important aspect for potential users looking to find the best fit for their needs. Understanding these differences can aid in making a well-informed decision.

Performance and Efficiency

In terms of cutting power, some models may offer higher blade speeds or more robust engines, which can lead to quicker trimming times and cleaner cuts. Others might prioritize energy efficiency, allowing for longer operational times on a single charge or tank of fuel. Evaluating the efficiency metrics of different hedge trimmers can significantly influence user satisfaction.

Weight and Maneuverability

Weight is another crucial consideration, especially for extended use. Lighter models tend to be easier to handle, reducing fatigue during longer sessions. However, heavier machines may provide more stability and durability. The balance between weight and ease of maneuverability is a key factor that differentiates one model from another, impacting the overall user experience.

Online Resources for Stihl Users

Accessing reliable information is essential for enthusiasts and professionals alike. Numerous online platforms offer valuable insights, tutorials, and community support for those who operate various equipment. These resources enhance user experience and provide guidance for maintenance and troubleshooting.

Helpful Websites

- Manufacturer’s Official Site: A go-to source for manuals and specifications.

- Forums: Community-driven discussions where users share experiences and solutions.

- YouTube Channels: Visual tutorials for repairs and operational tips.

Mobile Apps

- Service Tracking: Apps to monitor maintenance schedules and service history.

- Parts Locators: Tools to find local suppliers or order components online.

- Repair Guides: Step-by-step instructions for common issues and fixes.