In the world of high-performance application tools, comprehending the intricate assembly of various components is essential for effective operation. This section delves into the essential elements that contribute to the functionality of these instruments, shedding light on how each piece interacts within the overall system. By examining the arrangement of these items, users can gain valuable insights into maintenance and troubleshooting processes.

Furthermore, recognizing the specific roles of each component can enhance the user’s ability to operate the tool efficiently. Knowledge of the structure not only aids in proper usage but also empowers individuals to make informed decisions when it comes to repairs or upgrades. As we explore this topic, the focus will remain on clarity and practical application, ensuring that the information presented is both accessible and actionable.

Whether you are a seasoned professional or a novice, understanding the configuration and function of these elements is crucial for achieving optimal results. This exploration will serve as a guide to navigate the complexities involved, ultimately leading to improved performance and longevity of your equipment.

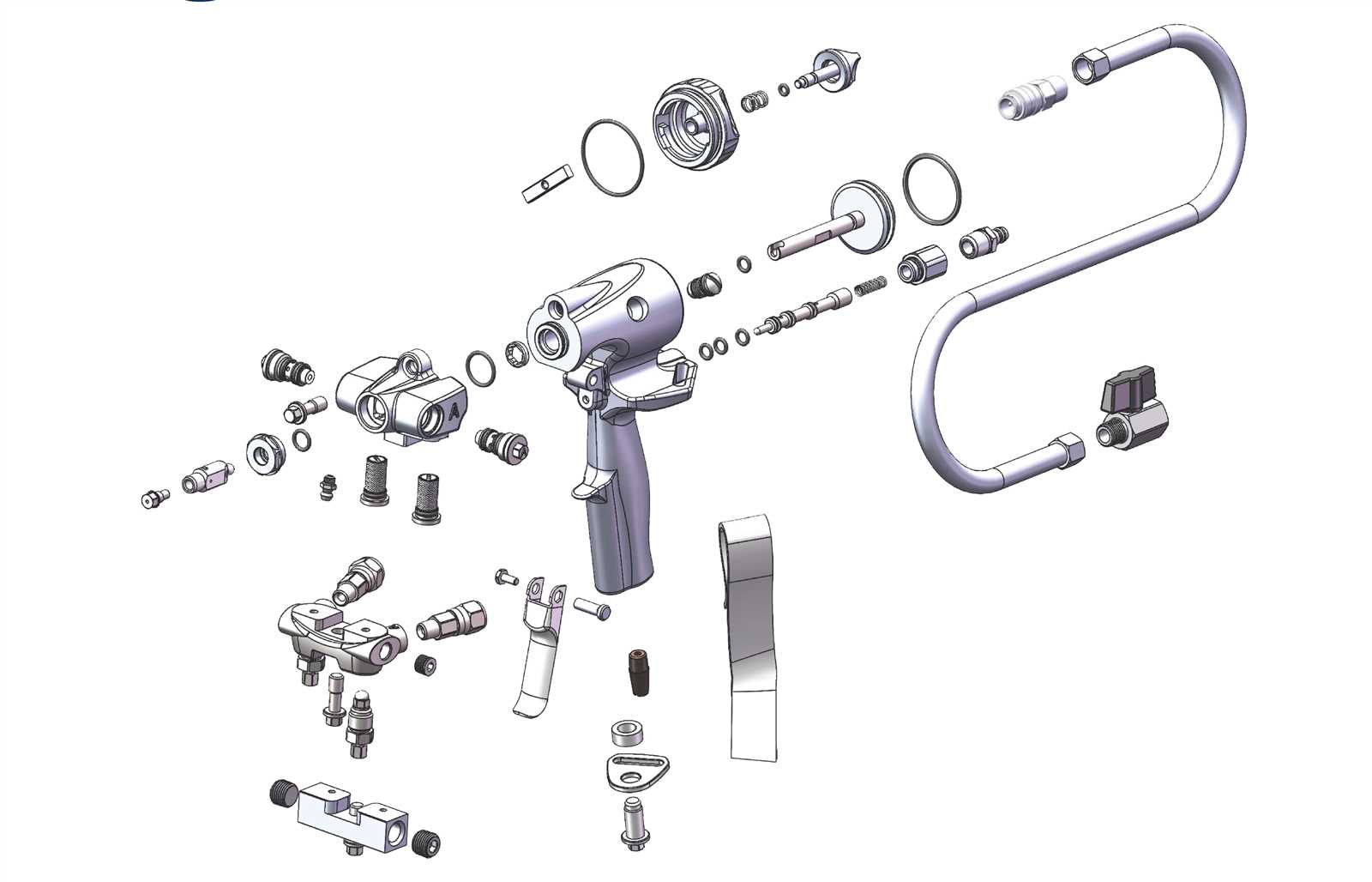

Key Components of the Gun

This section provides an overview of essential elements that contribute to the functionality and efficiency of the spraying apparatus. Understanding these components is crucial for effective maintenance and operation.

| Component | Function |

|---|---|

| Trigger | Initiates the flow of material when pressed, allowing for precise control during application. |

| Fluid Needle | Regulates the material flow, ensuring an even and consistent spray pattern. |

| Air Cap | Creates the spray pattern by atomizing the fluid as it exits the nozzle. |

| Handle | Provides a comfortable grip for maneuverability and ease of use during spraying tasks. |

| Material Hose | Transports the fluid from the container to the nozzle, allowing for uninterrupted application. |

Functionality of Each Part

The various components of a spraying apparatus each serve a unique role in ensuring efficient operation. Understanding how these elements interact can enhance overall performance and maintenance.

1. Trigger Mechanism: This element initiates the flow of the substance, providing control over the application process. A responsive trigger ensures precise distribution, allowing for consistent coverage.

2. Fluid Intake Valve: This part regulates the entry of the material into the system. Its design influences the speed and volume of the flow, impacting the efficiency of the spraying task.

3. Nozzle: Serving as the exit point, the nozzle determines the pattern and size of the spray. Its design affects how finely or broadly the substance is dispersed, playing a crucial role in achieving desired results.

4. Pressure Regulator: This component maintains optimal pressure within the apparatus, preventing fluctuations that could disrupt application. Proper regulation is essential for achieving uniform coverage and avoiding waste.

5. Cleaning Mechanism: An efficient cleaning system ensures that the components remain free from residue. This is vital for maintaining performance and extending the lifespan of the equipment.

Common Issues with Parts

When dealing with equipment components, several challenges may arise that affect performance and efficiency. Understanding these common difficulties can help in diagnosing problems and maintaining optimal functionality.

Frequent Malfunctions

Malfunctions often occur due to wear and tear or improper handling. Symptoms may include inconsistent output or difficulty in operation. Regular inspections can aid in identifying these issues early on.

Compatibility Challenges

Compatibility between different components is crucial. Using incompatible elements can lead to poor performance or damage. It’s important to ensure that all pieces are designed to work together harmoniously for best results.

Maintenance Tips for Longevity

To ensure optimal performance and extend the lifespan of your equipment, implementing regular care practices is essential. By following a structured maintenance routine, you can prevent potential issues and keep your tools functioning smoothly.

Regular Cleaning: After each use, thoroughly clean all components to remove any residue. This prevents buildup that can lead to clogs and operational failures.

Lubrication: Periodically apply appropriate lubricants to moving parts. This minimizes friction and wear, promoting smoother operation.

Inspection: Regularly inspect your equipment for signs of wear or damage. Early detection of issues can save time and resources in the long run.

Storage: When not in use, store your tools in a dry, cool environment. Proper storage helps prevent rust and degradation of materials.

Replacement of Worn Parts: Keep an eye on components that may need replacement due to wear. Timely replacement can prevent further damage and ensure continued efficiency.

Replacement Part Options Available

When maintaining a high-performance spraying device, it’s crucial to explore various alternatives for essential components. Ensuring that each element is compatible and reliable can significantly enhance the efficiency and longevity of the equipment.

Aftermarket Alternatives

Aftermarket options provide a cost-effective solution without compromising quality. These components are designed to meet or exceed the original specifications, allowing users to maintain performance while reducing expenses.

Original Equipment Manufacturer Options

Choosing original manufacturer alternatives guarantees compatibility and quality assurance. These components are specifically designed for the equipment, ensuring optimal performance and reliability over time.

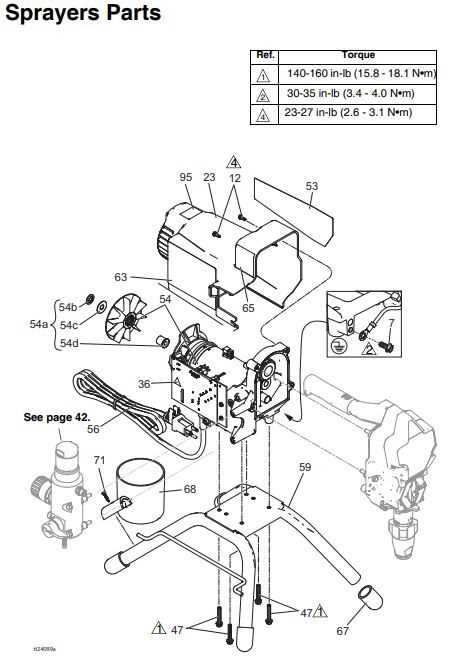

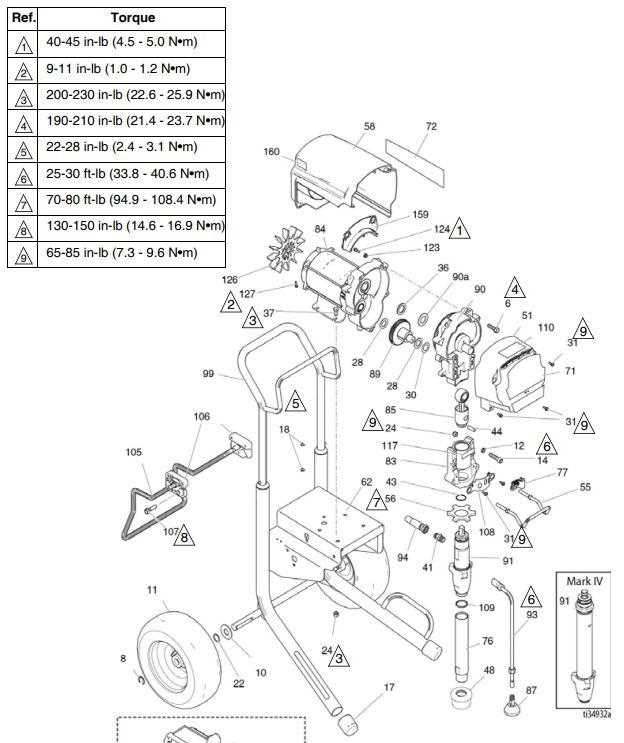

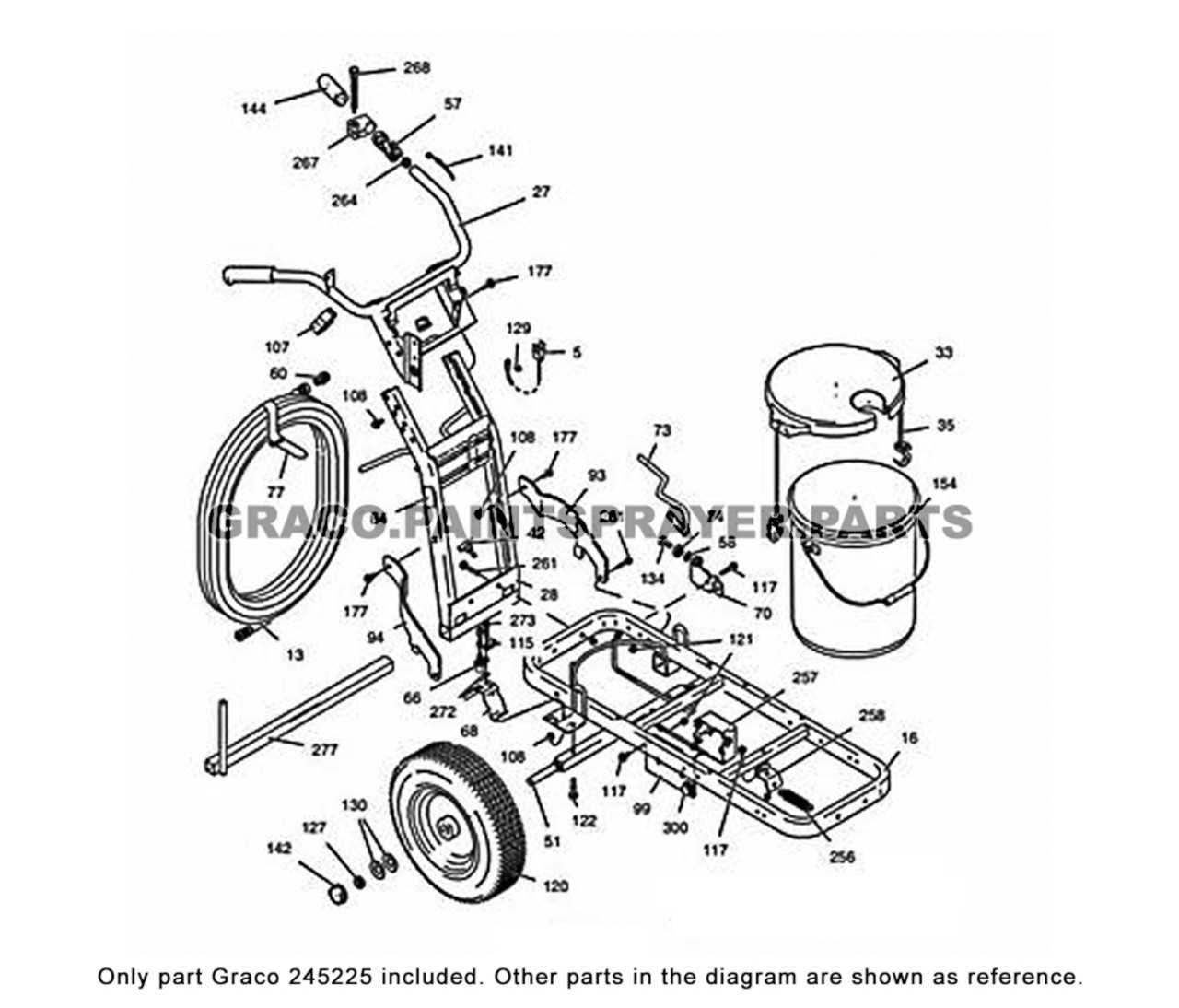

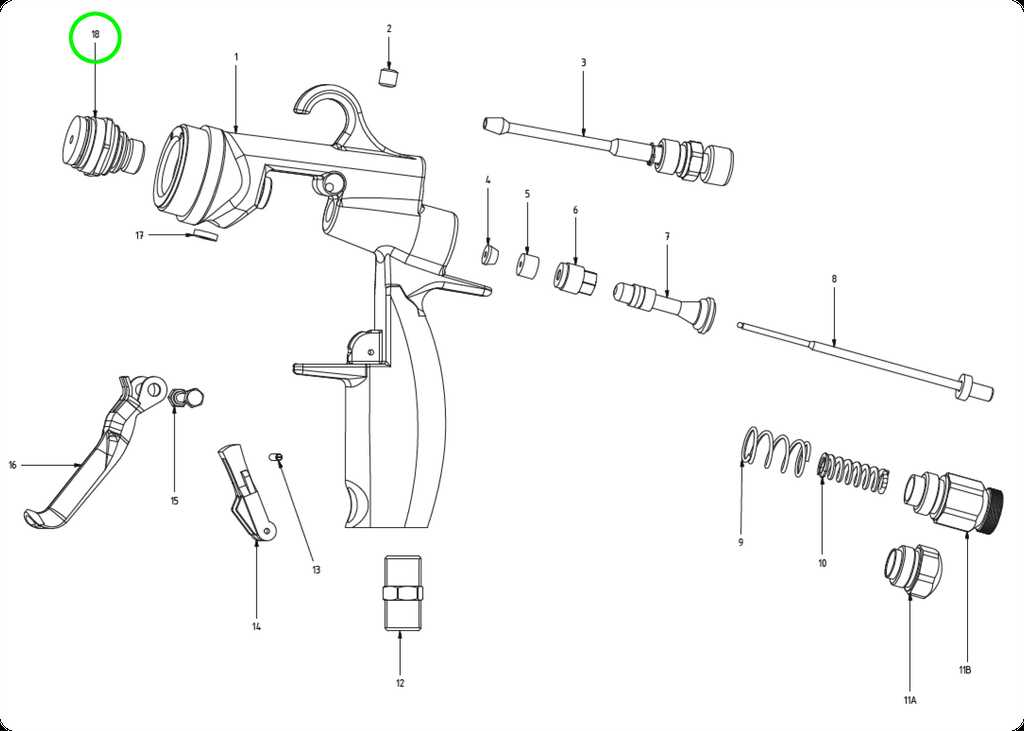

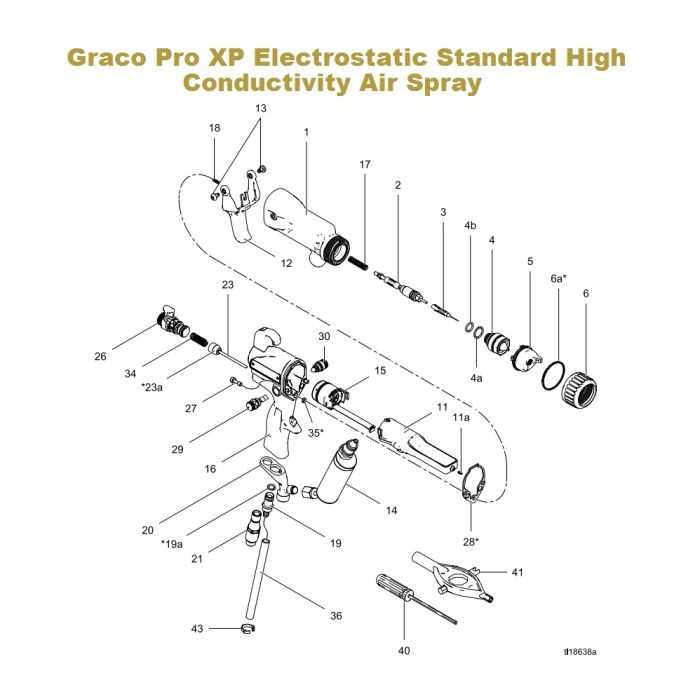

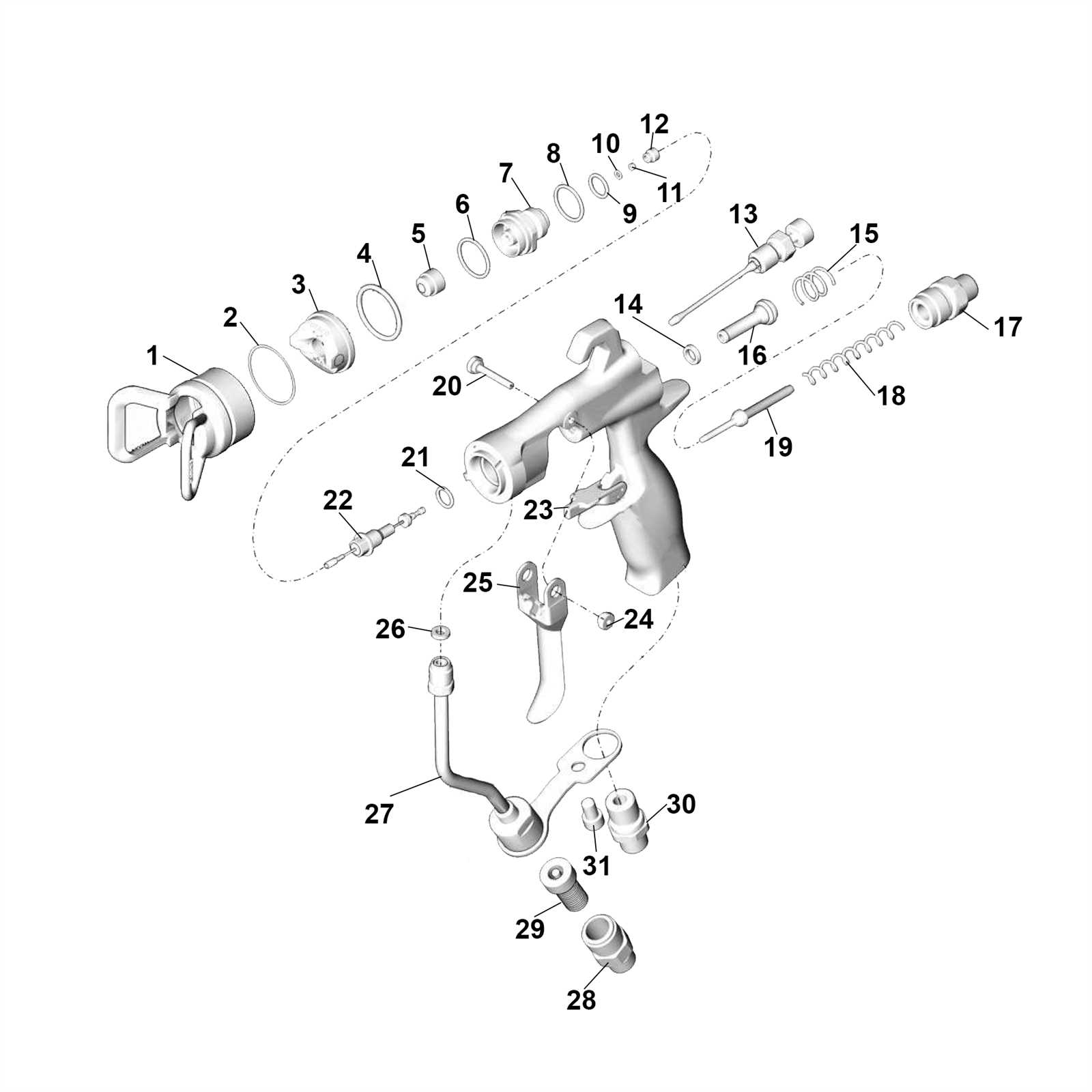

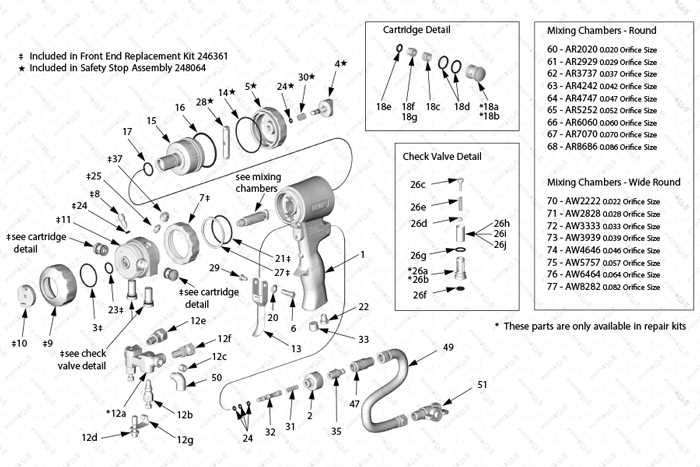

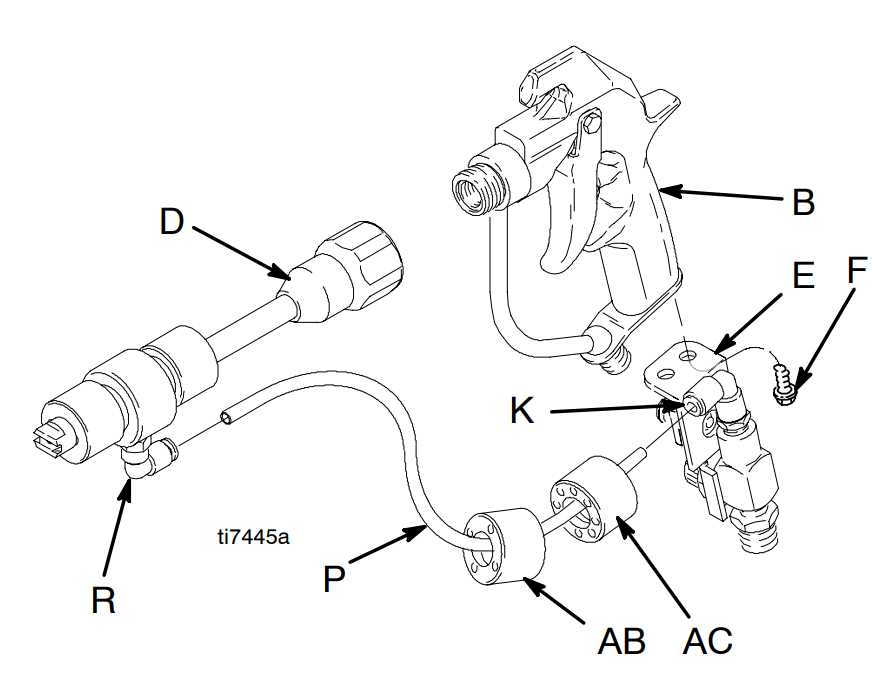

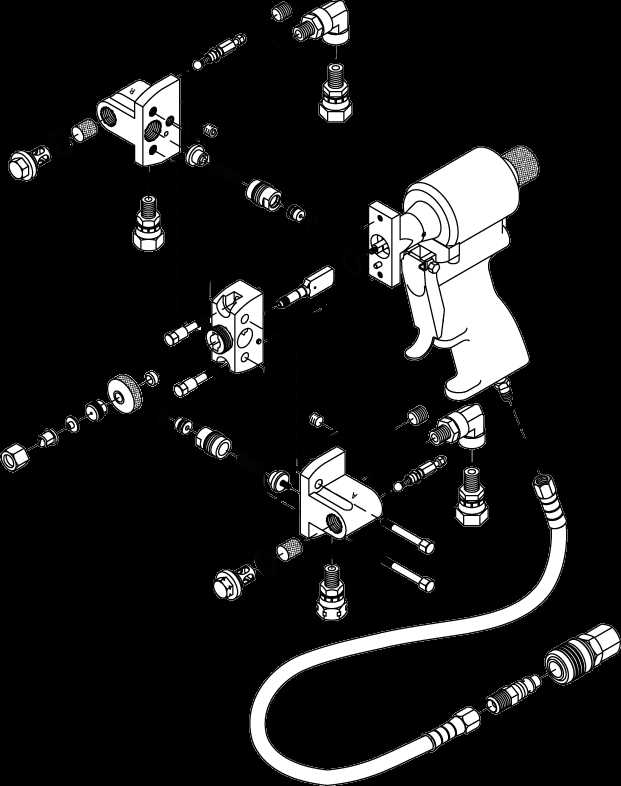

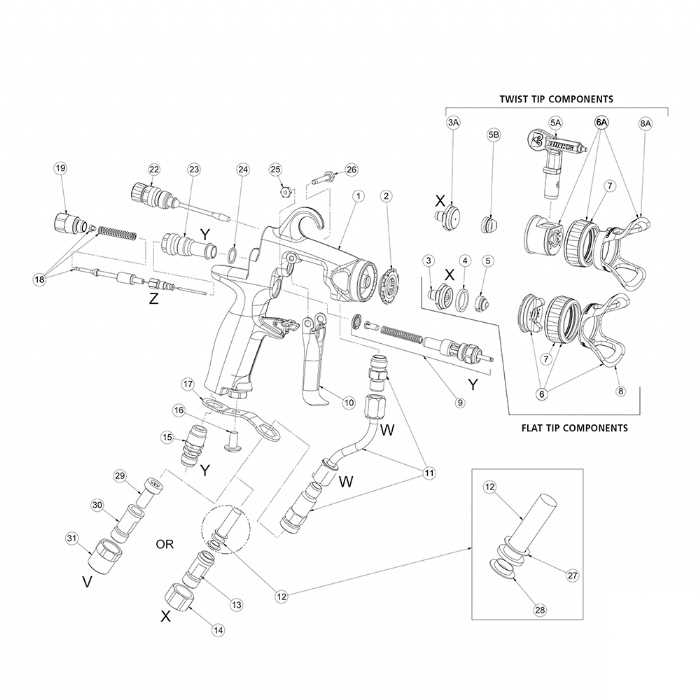

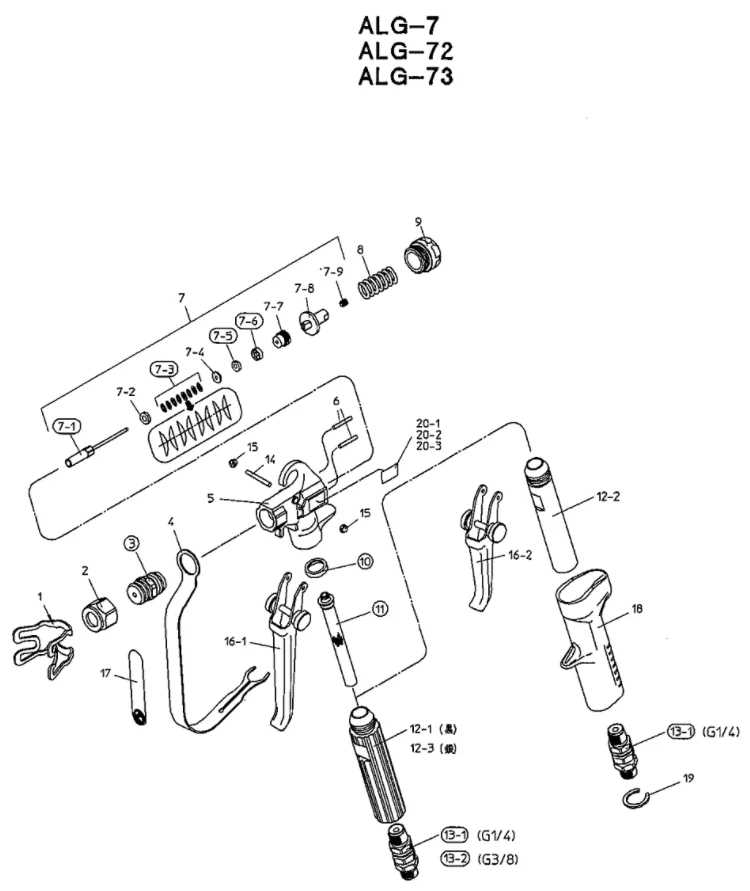

Identifying Parts in Diagrams

Understanding the components illustrated in technical drawings is essential for effective assembly and maintenance. Clear recognition of each element enables users to operate equipment efficiently and troubleshoot issues with greater ease.

Common Features to Look For

When examining illustrations, focus on key features that denote specific elements. Look for unique shapes, sizes, and markings that can help differentiate between various components. Familiarizing yourself with these characteristics can significantly enhance comprehension.

Using Reference Guides

Supplementing your knowledge with reference materials can greatly aid in identifying elements. Manuals or online resources often provide additional context, including descriptions and functions, which can clarify the role of each illustrated item. This approach ensures a thorough understanding of the entire assembly.

Assembly Instructions for Users

Proper assembly is essential for optimal performance and longevity of your equipment. This section provides a comprehensive guide for users to efficiently assemble their device, ensuring that each component fits together seamlessly.

Step-by-Step Assembly Guide

Begin by gathering all necessary components and tools. Ensure that the workspace is clean and organized to facilitate the assembly process. Follow these steps:

- Identify all components: Familiarize yourself with each item included in the package.

- Assemble the base: Secure the base unit to provide stability.

- Attach the main body: Align the main section with the base and ensure it locks into place.

- Integrate additional elements: Follow the order specified in the instruction manual for attaching supplementary features.

Final Checks and Maintenance

Once assembly is complete, perform a thorough inspection to ensure all connections are tight and secure. Conduct a test to confirm proper functionality. Regular maintenance is crucial; refer to the maintenance guidelines for optimal care and upkeep.

Safety Precautions While Using

Ensuring safety during the operation of equipment is paramount to avoid accidents and injuries. Adhering to recommended safety measures can significantly reduce risks associated with using high-pressure devices.

Here are essential precautions to consider:

- Always wear appropriate personal protective equipment, including gloves, goggles, and masks.

- Ensure that the work area is well-ventilated to prevent the buildup of hazardous fumes.

- Inspect the equipment thoroughly before each use to identify any signs of damage or wear.

- Keep bystanders and untrained individuals at a safe distance from the work area.

- Be aware of the pressure settings and avoid exceeding the manufacturer’s recommendations.

By following these guidelines, users can maintain a safer working environment and enhance the overall effectiveness of their tasks.

Benefits of Using Graco Products

Utilizing high-quality equipment designed for precision and durability can significantly enhance performance in various tasks. These advanced tools are engineered to provide exceptional reliability and efficiency, making them a valuable choice for professionals and DIY enthusiasts alike.

Enhanced Efficiency: When using these superior devices, users can complete projects more quickly and with greater accuracy. This efficiency reduces overall time spent on tasks, allowing for increased productivity.

Durability and Longevity: The robust construction of these tools ensures they withstand the rigors of regular use, minimizing the need for frequent replacements. Investing in reliable equipment translates to long-term savings and reduced downtime.

Versatility: Many of these products are designed to handle a variety of applications, making them adaptable to different project requirements. This flexibility allows users to tackle diverse tasks without needing multiple tools.

Improved Results: Utilizing top-tier tools often leads to better quality outcomes. The precision offered by these devices ensures that tasks are executed flawlessly, resulting in professional-grade finishes.

Resources for Further Assistance

When seeking support for your equipment, various sources can provide valuable insights and troubleshooting tips. These resources can enhance your understanding and ensure effective use of your tools.

- Manufacturer’s Website: Visit the official site for manuals, FAQs, and product specifications.

- Online Forums: Engage with communities where users share experiences, advice, and solutions to common issues.

- Social Media Groups: Join groups dedicated to equipment enthusiasts for tips and shared knowledge.

- Instructional Videos: Look for video tutorials that demonstrate assembly, maintenance, and troubleshooting procedures.

- Customer Support: Reach out to the customer service team for direct assistance with specific queries or problems.