The efficiency and functionality of climate control units rely heavily on the intricate network of their individual elements. A comprehensive overview of these components can aid in troubleshooting and optimizing performance. By examining the various parts involved, users can gain insights into how each element contributes to the overall operation of these systems.

In this section, we will explore the key elements that make up these air conditioning solutions, highlighting their roles and interconnections. Understanding these components is essential for anyone looking to maintain or repair their cooling systems effectively. With a clear representation of these elements, users can navigate their units with greater confidence and ensure optimal functionality.

This section aims to provide a comprehensive understanding of a renowned brand’s air conditioning systems, focusing on their essential components and how they function together. Knowledge of these elements is crucial for both maintenance and troubleshooting, ensuring optimal performance and longevity of the unit.

Key Components of the System

- Compressor: The heart of the system, responsible for circulating refrigerant and maintaining pressure.

- Evaporator: Absorbs heat from the indoor environment, providing a cooling effect.

- Condenser: Releases heat absorbed from indoors to the outside atmosphere.

- Expansion Valve: Controls the flow of refrigerant into the evaporator, regulating cooling efficiency.

- Air Filters: Ensures clean airflow by trapping dust and debris, enhancing indoor air quality.

Understanding Functionality

- The compressor compresses refrigerant gas, raising its pressure and temperature.

- The hot, high-pressure gas travels to the condenser, where it cools and condenses into a liquid.

- The liquid refrigerant passes through the expansion valve, dropping in pressure and temperature.

- As the low-pressure refrigerant enters the evaporator, it absorbs heat from the indoor air, creating a cooling effect.

- The cycle repeats as the refrigerant returns to the compressor to continue the process.

Key Components of the System

Understanding the essential elements of an air conditioning unit is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficient operation and effective climate control within a space. This section highlights the primary elements that contribute to the system’s functionality.

Major Elements

- Compressor: This device compresses refrigerant, raising its pressure and temperature, facilitating the heat exchange process.

- Evaporator Coil: Located inside the building, it absorbs heat from the indoor air, allowing the refrigerant to evaporate and cool the space.

- Condenser Coil: Positioned outside, this coil releases the absorbed heat from the refrigerant into the environment, enabling it to condense back into a liquid.

- Expansion Valve: This component regulates the flow of refrigerant into the evaporator coil, lowering its pressure and temperature before it enters the coil.

- Fan: Essential for circulating air across the coils, ensuring efficient heat exchange and consistent indoor temperatures.

Additional Components

- Thermostat: The control device that monitors and adjusts the temperature to maintain comfort levels within the space.

- Ductwork: The network of pipes that distributes conditioned air throughout the building.

- Drainage System: Responsible for removing condensation that forms during the cooling process, preventing water damage.

Understanding the Parts Layout

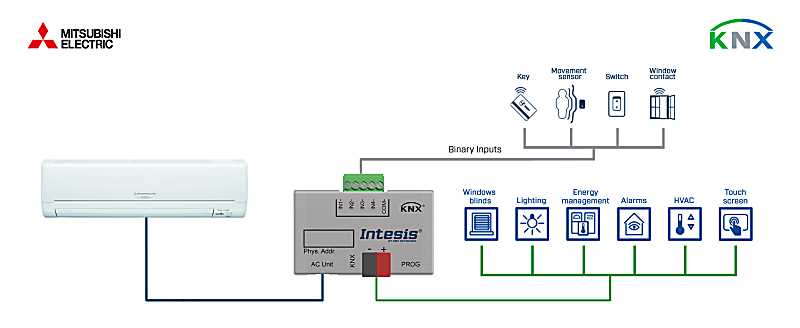

This section aims to provide a comprehensive overview of the configuration and arrangement of various components within a specific cooling system. Grasping how these elements interact and their locations is essential for effective troubleshooting and maintenance.

Key Elements of the Configuration

The assembly consists of multiple integral units that work together to achieve optimal functionality. Each segment plays a vital role in ensuring efficiency and performance. Familiarity with these units enables users to pinpoint issues and facilitate repairs.

Visual Representation and Significance

Having a visual representation of the assembly can significantly aid in understanding the relationship between components. Recognizing where each unit is positioned helps in anticipating potential challenges and enhances overall system management. A well-organized layout not only simplifies maintenance tasks but also contributes to the longevity of the equipment.

Importance of Accurate Diagrams

Precise representations are essential in any technical field, serving as vital tools for understanding and troubleshooting complex systems. These visual aids allow technicians and engineers to navigate intricate layouts effectively, ensuring that every component is correctly identified and connected.

Having reliable visuals enhances several aspects of the work process:

- Clarity: Clear illustrations help avoid confusion by providing a straightforward view of how elements interact within the system.

- Efficiency: Accurate visuals streamline repairs and installations, allowing professionals to work faster and minimize downtime.

- Safety: Correct representations reduce the risk of errors that could lead to hazardous situations, ensuring a safer working environment.

- Training: Effective diagrams serve as educational tools, facilitating the training of new technicians and helping them grasp complex concepts quickly.

In conclusion, the reliability of visual representations directly impacts the effectiveness and safety of maintenance and repair operations. Ensuring accuracy in these resources is crucial for optimal performance and longevity of the systems involved.

Common Issues with Mr. Slim Parts

When dealing with various components of a cooling system, several recurring problems can affect performance and efficiency. Understanding these common challenges can aid in effective troubleshooting and maintenance, ensuring optimal functionality.

One prevalent issue is the accumulation of dirt and debris in filters and coils, which can hinder airflow and reduce cooling efficiency. Additionally, improper installation can lead to refrigerant leaks, causing reduced cooling capacity and increased energy consumption. Furthermore, electrical malfunctions, such as faulty wiring or damaged connections, can disrupt the operation of the unit.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Clogged Filters | Poor airflow, reduced cooling | Regular cleaning or replacement |

| Refrigerant Leaks | Increased energy bills, inadequate cooling | Professional inspection and repair |

| Electrical Problems | Unit not turning on, unusual noises | Check wiring, consult an electrician |

| Faulty Thermostat | Inconsistent temperatures | Calibration or replacement |

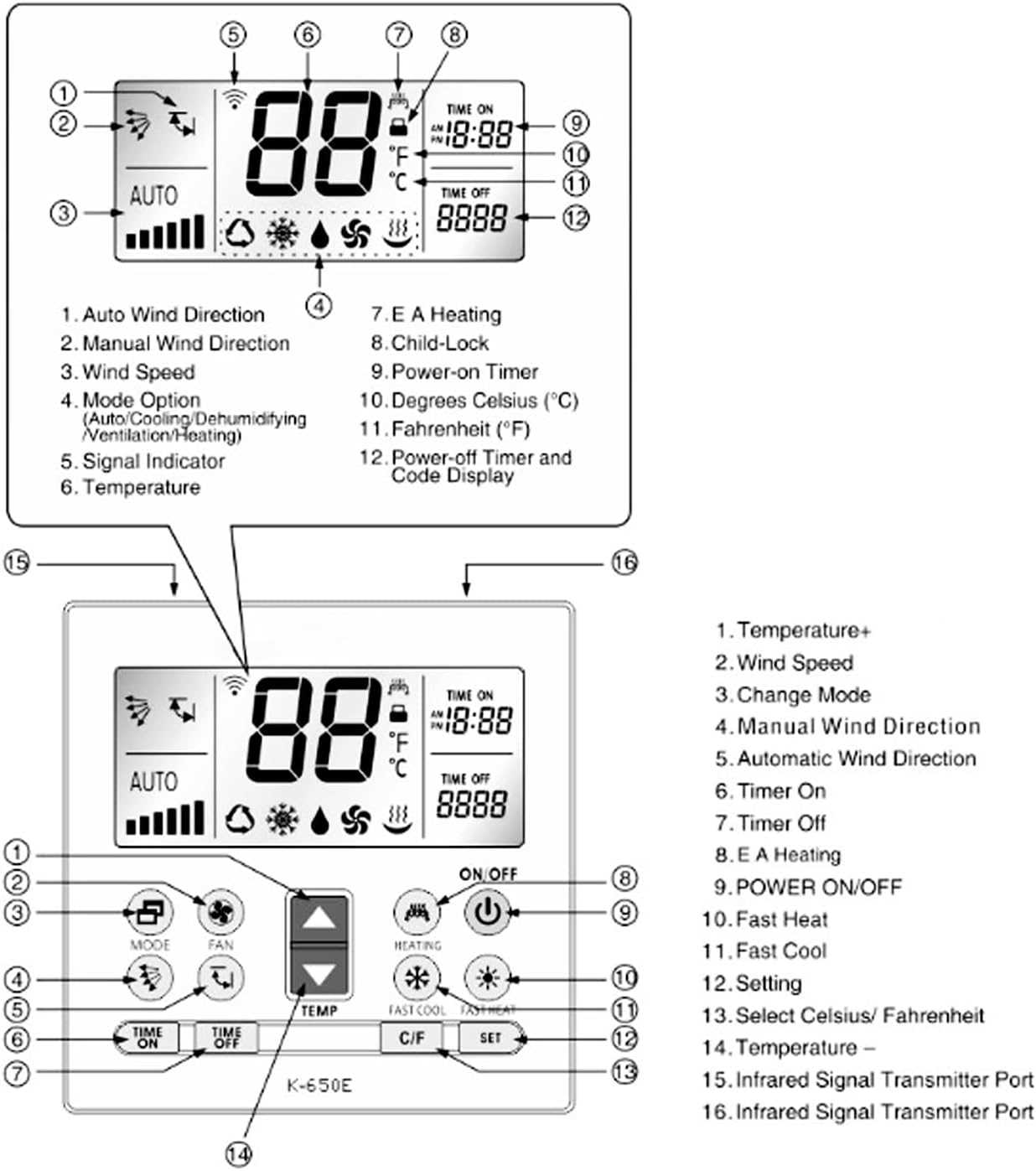

How to Read the Diagram Effectively

Understanding technical illustrations is essential for troubleshooting and maintenance. These visuals provide a wealth of information about the components and their interconnections. Mastering the art of interpreting these schematics can significantly enhance your efficiency in working with systems.

Here are some key strategies to improve your comprehension:

- Familiarize Yourself with Symbols: Each component has a specific representation. Knowing these symbols will help you identify parts quickly.

- Follow the Flow: Pay attention to how energy or signals move through the system. This can clarify how different elements interact.

- Check the Legend: Most illustrations include a legend or key. This section explains the meaning of various symbols and notations.

- Break it Down: Instead of trying to understand everything at once, focus on one section at a time. This method can make complex information more manageable.

- Refer to Documentation: Consult any accompanying manuals or guides that provide additional context for the illustrations.

By employing these techniques, you will enhance your ability to read and understand these critical resources, leading to more effective problem-solving and repair processes.

Maintenance Tips for Longevity

To ensure the extended lifespan of your cooling or heating system, regular upkeep is essential. Proper care not only enhances efficiency but also minimizes the risk of costly repairs. By following a few straightforward practices, you can maintain optimal performance and longevity of your equipment.

Regular Cleaning

Keeping your unit clean is vital for preventing dust buildup, which can impede airflow and reduce efficiency. Schedule periodic cleaning of the filters and coils to ensure optimal operation. This simple task can significantly improve performance and extend the life of the system.

Professional Inspections

Engaging a qualified technician for annual inspections is crucial. These professionals can identify potential issues before they escalate and provide necessary adjustments. Regular check-ups help maintain the unit’s efficiency and prevent unexpected breakdowns.

Identifying Replacement Parts Easily

Finding suitable components for repair or maintenance can be a straightforward process when approached methodically. By understanding key identifiers and utilizing available resources, one can simplify the task of sourcing the right items.

Key Identifiers to Look For

- Model Number: Always check the model number, as it directly relates to the specific design and requirements of your unit.

- Serial Number: This unique identifier provides additional information about the manufacturing date and batch.

- Specifications: Familiarize yourself with the technical specifications, such as size, capacity, and compatibility, to ensure a proper fit.

Where to Find Information

- Manufacturer’s Website: Most manufacturers provide detailed information and resources for their products.

- Online Retailers: E-commerce platforms often list various components along with customer reviews and specifications.

- Repair Manuals: Consult manuals or guides that come with your equipment for comprehensive details on components.

Benefits of Using Original Components

Utilizing genuine elements in any mechanical system can significantly enhance performance and longevity. These authentic components are designed to meet specific operational standards, ensuring optimal functionality and reliability over time.

Quality Assurance

One of the primary advantages of opting for original elements is the assurance of quality. Each component undergoes rigorous testing and is manufactured with high-grade materials, resulting in superior durability and efficiency. This contrasts sharply with generic substitutes, which may lack the same level of reliability.

Compatibility and Performance

Original components are engineered to work seamlessly within their intended systems, minimizing the risk of malfunctions or incompatibilities. This perfect fit enhances overall performance and reduces the likelihood of future repairs, leading to cost savings in the long run.

| Advantage | Description |

|---|---|

| Durability | High-quality materials ensure long-lasting use. |

| Reliability | Minimized risk of failure due to superior design. |

| Efficiency | Optimized for peak performance and reduced energy consumption. |

| Warranty Support | Often come with manufacturer warranties, providing peace of mind. |

Installation Guidelines for New Parts

When it comes to integrating new components into your system, following proper procedures is essential for ensuring optimal performance and longevity. This section outlines key considerations and steps to effectively incorporate these elements into your setup.

1. Prepare the Workspace: Ensure that your working area is clean and organized. Gather all necessary tools and components before starting the installation process to minimize interruptions.

2. Review Manufacturer Instructions: Always consult the provided guidelines from the manufacturer. These documents contain vital information regarding compatibility, installation techniques, and safety precautions that should not be overlooked.

3. Disconnect Power Sources: Prior to any installation, make sure to disconnect power supplies to avoid electrical hazards. This step is crucial for ensuring your safety throughout the procedure.

4. Inspect Components: Before proceeding, examine the new elements for any visible damage or defects. Reporting and replacing faulty items at this stage can save time and effort later on.

5. Follow Installation Steps: Adhere to the sequential installation process outlined in the instructions. Each step is designed to facilitate the correct placement and connection of the components.

6. Test the System: After installation, re-establish power and perform thorough testing to confirm that the newly added components function as intended. Look for any irregularities and address them immediately.

By adhering to these guidelines, you can ensure a smooth installation process that enhances the efficiency and reliability of your system.

Frequently Asked Questions

This section addresses common inquiries related to the components and functionality of a specific air conditioning system. Here, users can find concise answers to typical concerns, enhancing their understanding of the unit’s operation and maintenance.

What types of components are available?

Various elements are designed to work seamlessly within the cooling system. These include filters, fans, and control panels, each playing a vital role in ensuring efficient performance. Users can often find these items at local suppliers or through authorized distributors.

How can I troubleshoot common issues?

Many users encounter similar challenges, such as inadequate cooling or unusual noises. To resolve these problems, it is recommended to check for obstructions, inspect electrical connections, and ensure the filter is clean. If issues persist, consulting a professional technician is advisable.

Resources for Further Information

Accessing detailed resources can significantly enhance understanding and facilitate efficient maintenance of various systems. Comprehensive guides, technical specifications, and expert advice are crucial for individuals seeking to troubleshoot or improve their equipment. This section aims to highlight valuable materials that provide insights and detailed information.

Online Forums and Communities: Engaging with fellow enthusiasts and professionals through dedicated online platforms can be beneficial. These forums often contain a wealth of shared experiences, troubleshooting tips, and advice from knowledgeable members, making them an excellent starting point for inquiries.

Manufacturer’s Website: The official website of the manufacturer typically features a section for support and resources. Here, one can find product manuals, FAQs, and instructional videos that offer step-by-step guidance on various topics related to their devices.

Technical Manuals: Investing in technical manuals specific to the equipment in question can provide in-depth knowledge about its operation and maintenance. These documents often contain valuable diagrams, specifications, and troubleshooting procedures that are not readily available elsewhere.

YouTube Tutorials: Video tutorials can serve as a practical resource for visual learners. Many channels offer detailed walkthroughs and demonstrations, making complex tasks more approachable and understandable.

Local Distributors and Service Centers: Consulting local distributors or service centers can provide personalized assistance. These professionals often have extensive knowledge of the equipment and can offer tailored advice and support based on regional factors and specific needs.