The intricate design of a torch system is essential for its efficient operation. Familiarity with its various components enhances usability and maintenance, ensuring a seamless experience for the user. Each element plays a pivotal role in the overall functionality, contributing to effective performance.

By exploring the individual segments of this apparatus, one can appreciate how they interact and support one another. Recognizing the specific functions and connections among these parts fosters a deeper understanding of how the device operates. Whether for professional or personal use, knowledge of these elements is invaluable for troubleshooting and optimizing performance.

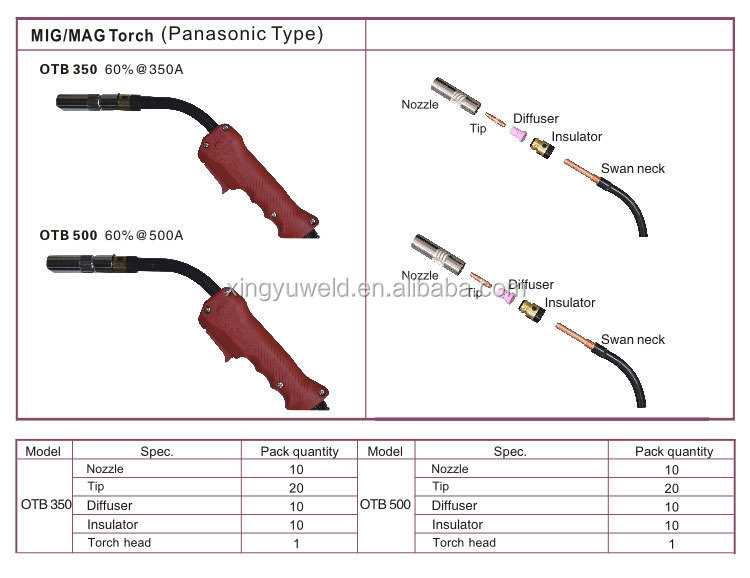

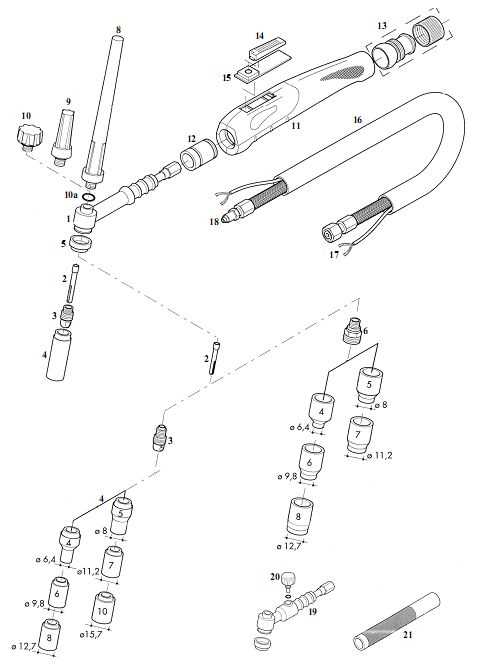

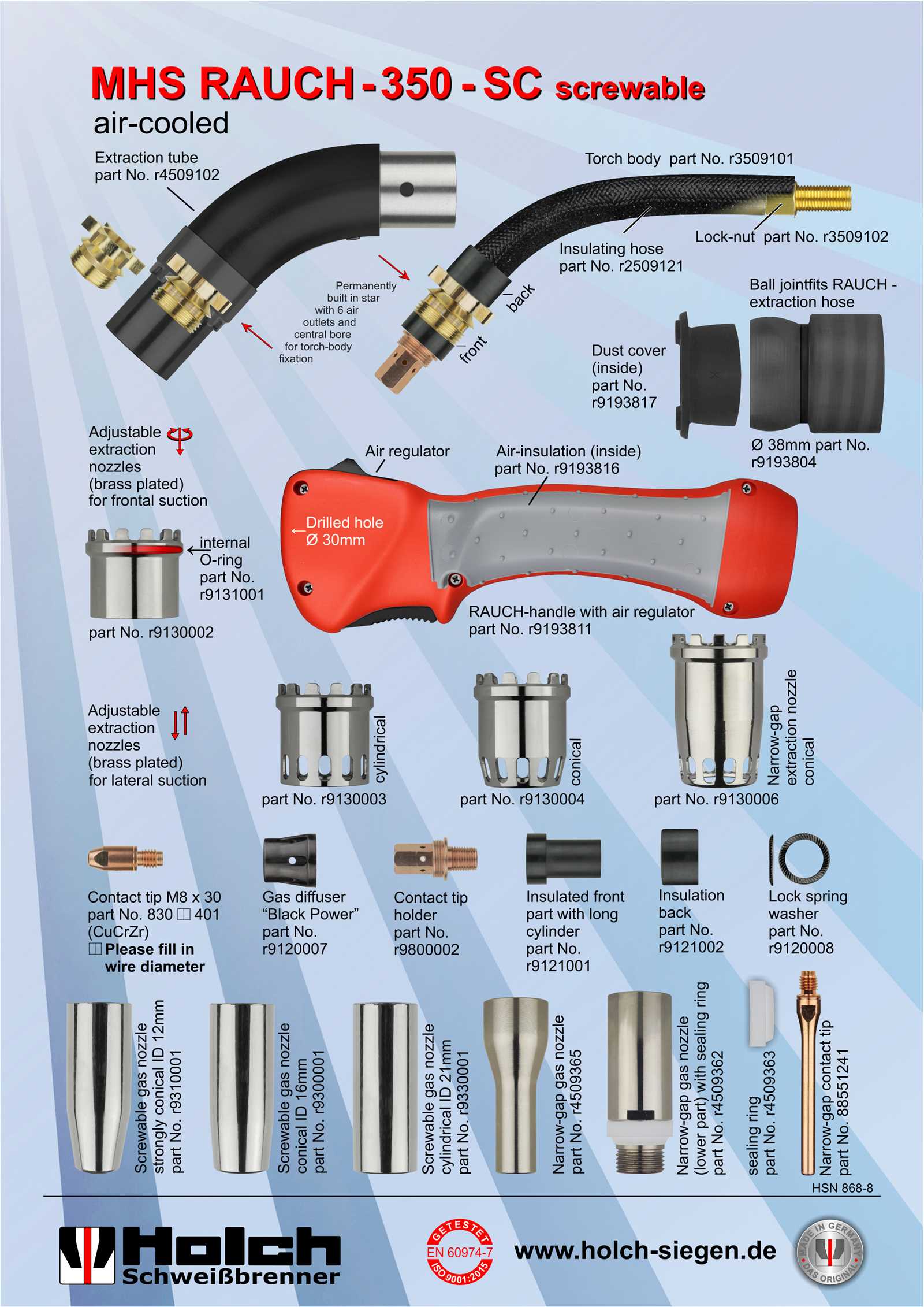

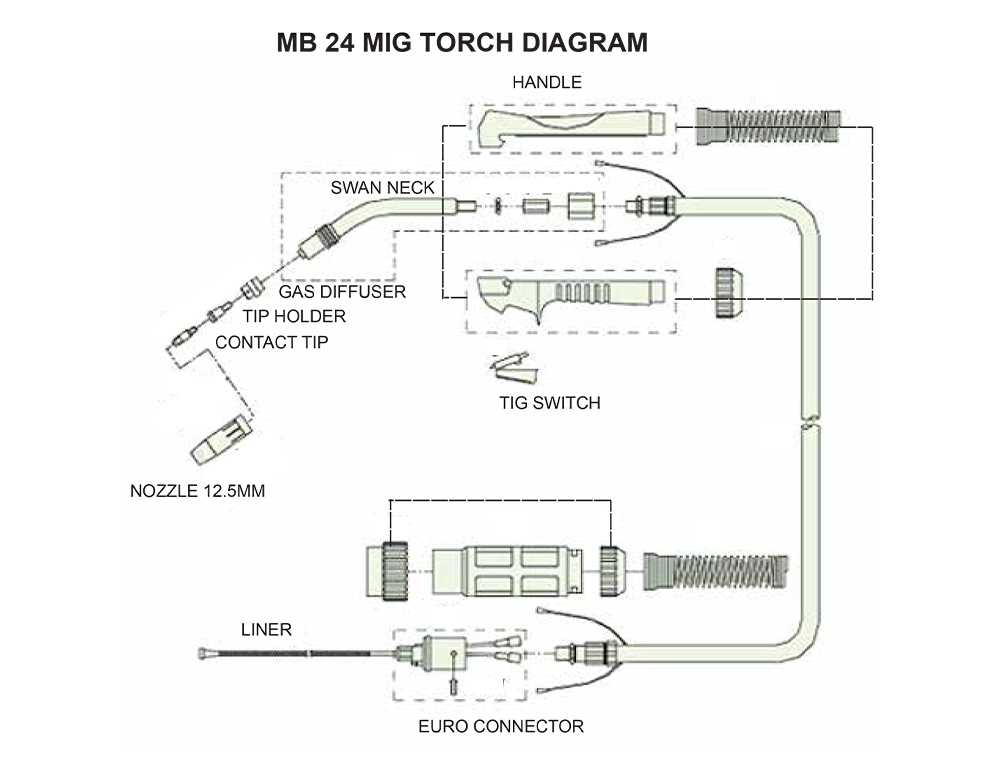

Mag-Torch Parts Diagram Overview

This section provides a comprehensive insight into the various components that make up the torch system. Understanding the individual elements is essential for effective operation and maintenance. Each segment plays a critical role in ensuring functionality and efficiency in various applications.

| Component Name | Description | |||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Handle | The part designed for holding and maneuvering the device comfortably. |

| Maintenance Activity | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Check for any visible signs of wear or damage. |

| Cleaning | After Each Use | Remove dirt and residues to maintain efficiency. |

| Lubrication | Quarterly | Apply appropriate lubricants to moving parts. |

| Functional Testing | Bi-Annually | Test all functionalities to ensure proper operation. |

By adhering to these practices, you can ensure that your equipment remains reliable and efficient over time. Consistent maintenance not only enhances performance but also minimizes the likelihood of unexpected failures.

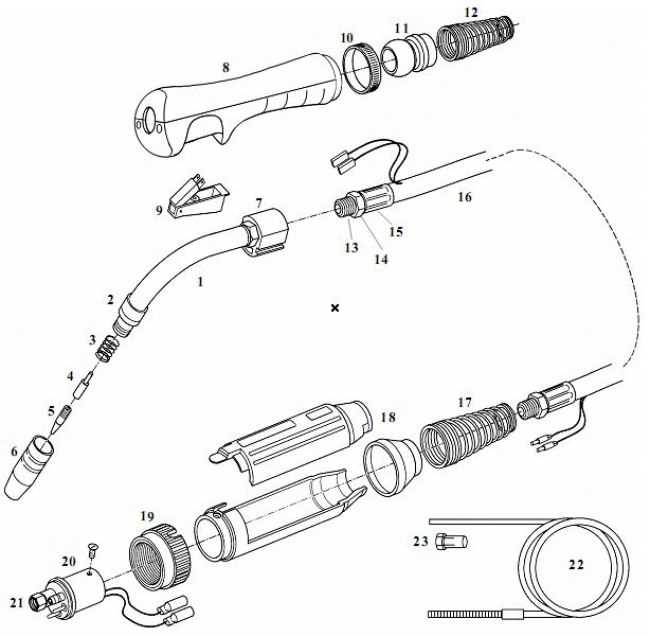

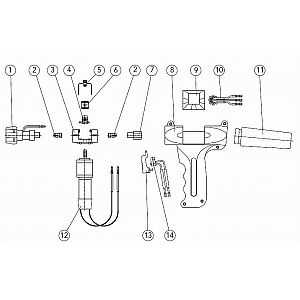

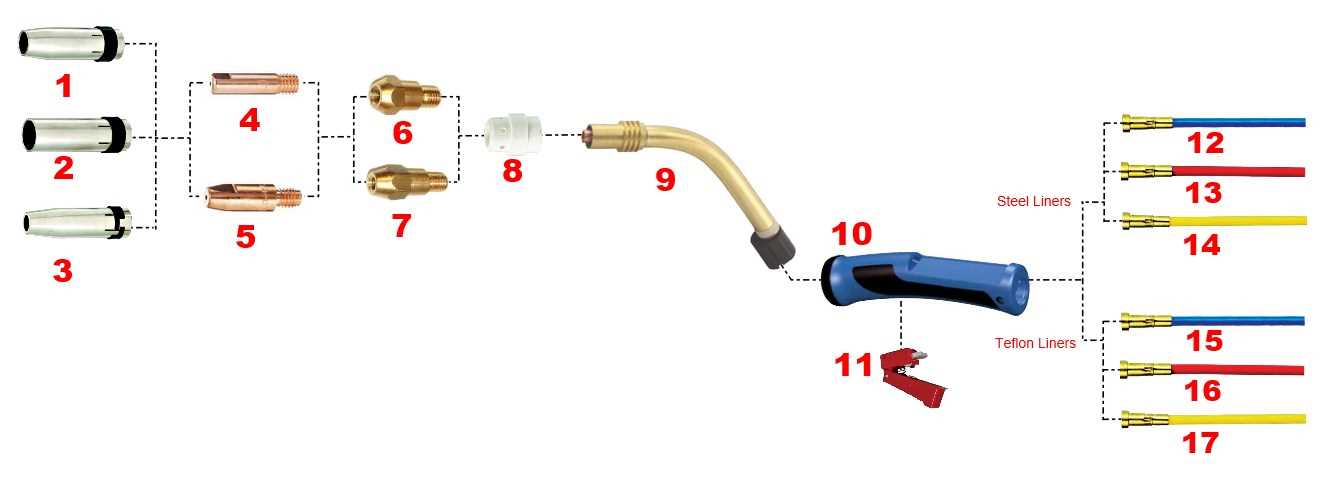

Identifying Parts in Diagrams

Understanding the components in visual representations is crucial for effective usage and maintenance. These illustrations provide a clear overview, allowing users to familiarize themselves with various elements and their functions. Recognizing the significance of each part enhances the overall efficiency and safety of operations.

Visual cues play a vital role in distinguishing different sections. Color coding, numbering, and labeling can significantly aid in identifying each element quickly. Additionally, becoming acquainted with the common symbols and shapes used in these representations will streamline the learning process.

To enhance comprehension, one should focus on the relationships between different sections. Observing how components connect or interact can provide insights into their functionality and importance. Careful analysis of these aspects fosters a deeper understanding, ultimately leading to improved performance and troubleshooting capabilities.

Comparative Analysis of Models

This section provides an overview of various models, emphasizing their unique characteristics and functionalities. By examining key specifications, performance metrics, and usability features, we aim to identify the strengths and weaknesses of each variant, aiding users in making informed decisions based on their specific needs.

Key Features Comparison

| Model | Power Output | Weight | Cooling System | Usage Duration |

|---|---|---|---|---|

| Model A | 200 W | 2.5 kg | Active | 120 mins |

| Model B | 250 W | 3.0 kg | Passive | 90 mins |

| Model C | 150 W | 2.0 kg | Active | 180 mins |

Usability and Performance Insights

When assessing usability, the ergonomics and handling characteristics play a significant role in user satisfaction. Performance metrics reveal how effectively each model meets its operational objectives, indicating suitability for various applications. Ultimately, this analysis helps users determine the best choice based on their specific preferences and requirements.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and lifespan. Various options exist for sourcing these necessary elements, catering to different preferences and requirements. Understanding where to look can streamline your search and ensure you acquire quality replacements.

Online Retailers

Numerous online platforms specialize in providing a wide range of components. These websites often feature detailed descriptions, customer reviews, and competitive pricing. Utilizing trusted online retailers can facilitate an efficient shopping experience while ensuring you find the right elements for your equipment.

Local Supply Stores

Visiting nearby supply outlets can be a practical approach to finding the required items. These stores typically offer a selection of components and knowledgeable staff who can assist you in identifying the correct options. Additionally, purchasing locally supports your community while allowing for immediate acquisition of necessary elements.

Safety Guidelines for Usage

Ensuring safety during the operation of equipment is crucial for both the user and the environment. Following recommended practices helps prevent accidents and injuries, while also maintaining the longevity of the device. Adhering to proper protocols fosters a secure working atmosphere.

1. Personal Protective Equipment: Always wear appropriate safety gear, including goggles, gloves, and protective clothing, to shield yourself from potential hazards. This minimizes the risk of injury from sparks or heat.

2. Ventilation: Ensure adequate ventilation in the workspace to prevent the accumulation of harmful fumes. Working in a well-ventilated area significantly reduces the risk of inhaling toxic substances.

3. Equipment Inspection: Regularly examine the device for any signs of wear or damage. Addressing issues promptly helps avoid malfunctions that could lead to unsafe conditions.

4. Safe Handling: Always handle the equipment with care. Avoid any abrupt movements or actions that could lead to accidents. Understanding the operational limits is essential for safe usage.

5. Emergency Procedures: Familiarize yourself with emergency procedures and the location of safety equipment. In the event of an incident, knowing how to respond can significantly mitigate risks.

Frequently Asked Questions on Parts

This section addresses common inquiries regarding the various components involved in torch systems. Understanding these elements can enhance user experience and ensure effective operation.

What are the common issues faced with torch components?

Users often encounter difficulties related to wear and tear, improper assembly, or compatibility with different setups. Regular maintenance and careful handling can mitigate many of these problems.

How can I identify a malfunctioning component?

Signs of malfunction may include inconsistent performance, unusual noises, or visible damage. Conducting routine inspections can help identify issues early and facilitate timely replacements.

Are replacement items readily available?

Most components are easily sourced from specialized suppliers or manufacturers, ensuring users can maintain their equipment without significant downtime.

What should I consider when replacing a component?

It is crucial to check compatibility with existing equipment, quality of the replacement, and proper installation to ensure optimal performance.

Upgrading Your Mag-Torch System

Enhancing your torch system can significantly improve its efficiency and functionality. This process often involves evaluating existing components and integrating new elements that better suit your needs. Whether you are looking to increase performance, enhance safety, or expand versatility, there are numerous options available to consider.

Benefits of Upgrading

- Improved Performance: New components can boost heat output and reduce energy consumption.

- Enhanced Safety Features: Modern upgrades often come with better safety mechanisms, reducing the risk of accidents.

- Increased Versatility: Adding new accessories allows for a wider range of applications, making your system more adaptable.

Key Upgrades to Consider

- Welding Tips: Upgrading to higher quality or specialized tips can improve precision and welding quality.

- Fuel Sources: Exploring alternative fuel options may enhance efficiency and reduce costs.

- Regulators and Hoses: Investing in better regulators and durable hoses can increase safety and ensure consistent performance.