When maintaining and repairing outdoor power tools, a comprehensive understanding of their assembly is crucial. Every machine comprises a multitude of intricate elements, each serving a specific purpose. By familiarizing oneself with the layout of these components, users can enhance both performance and longevity.

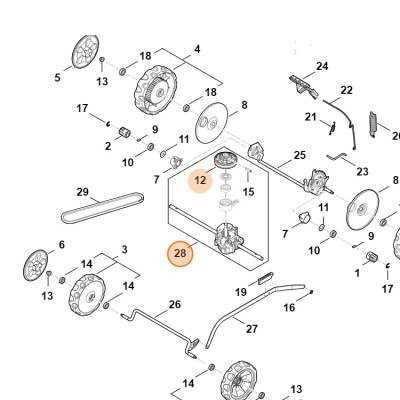

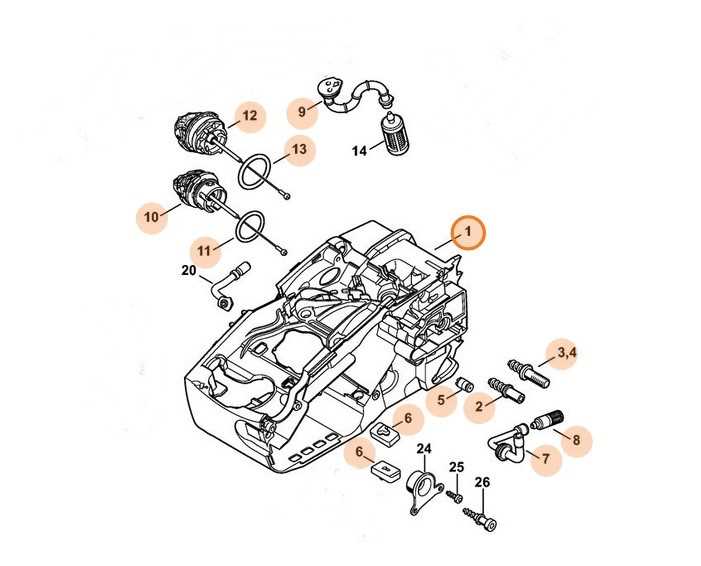

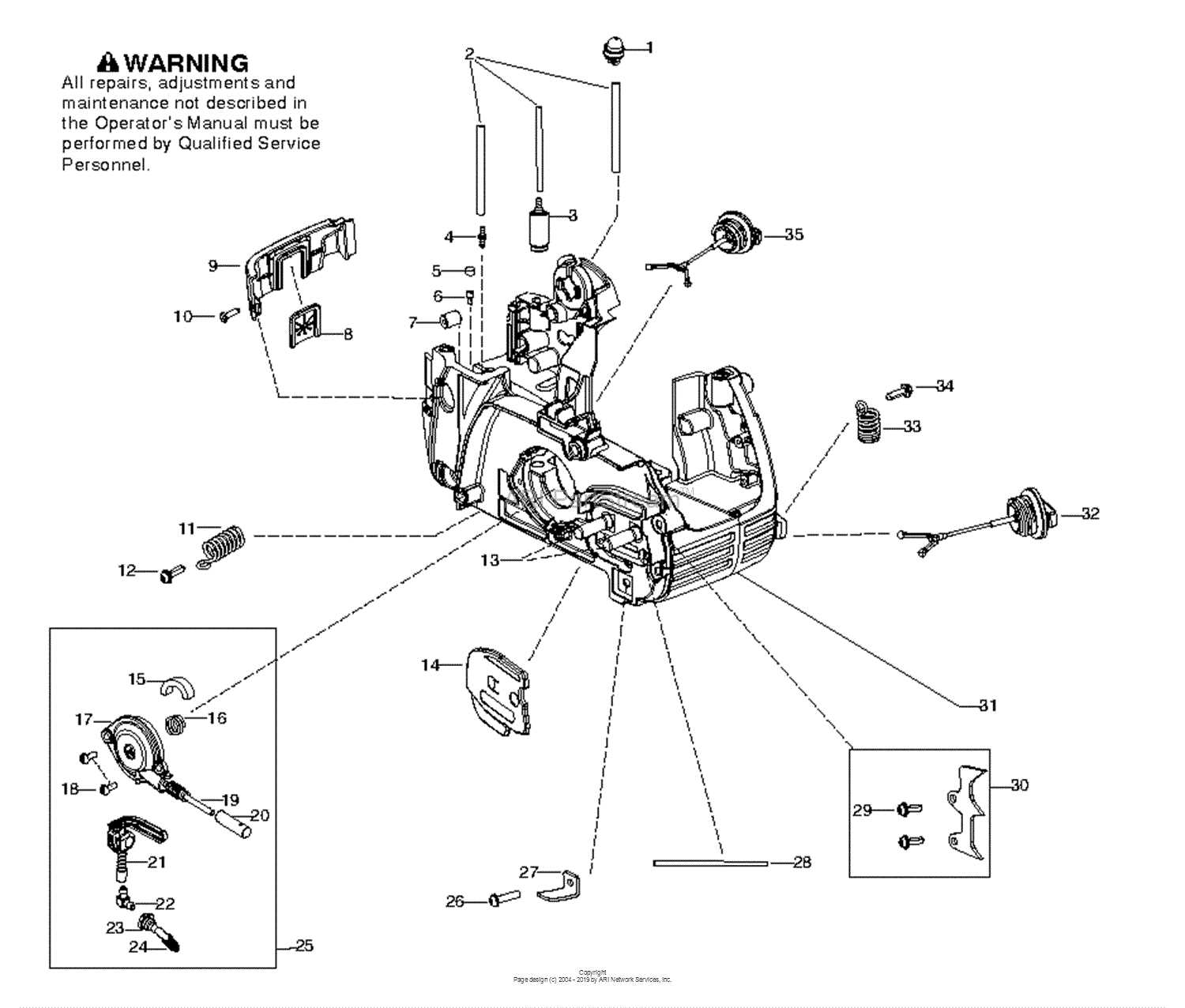

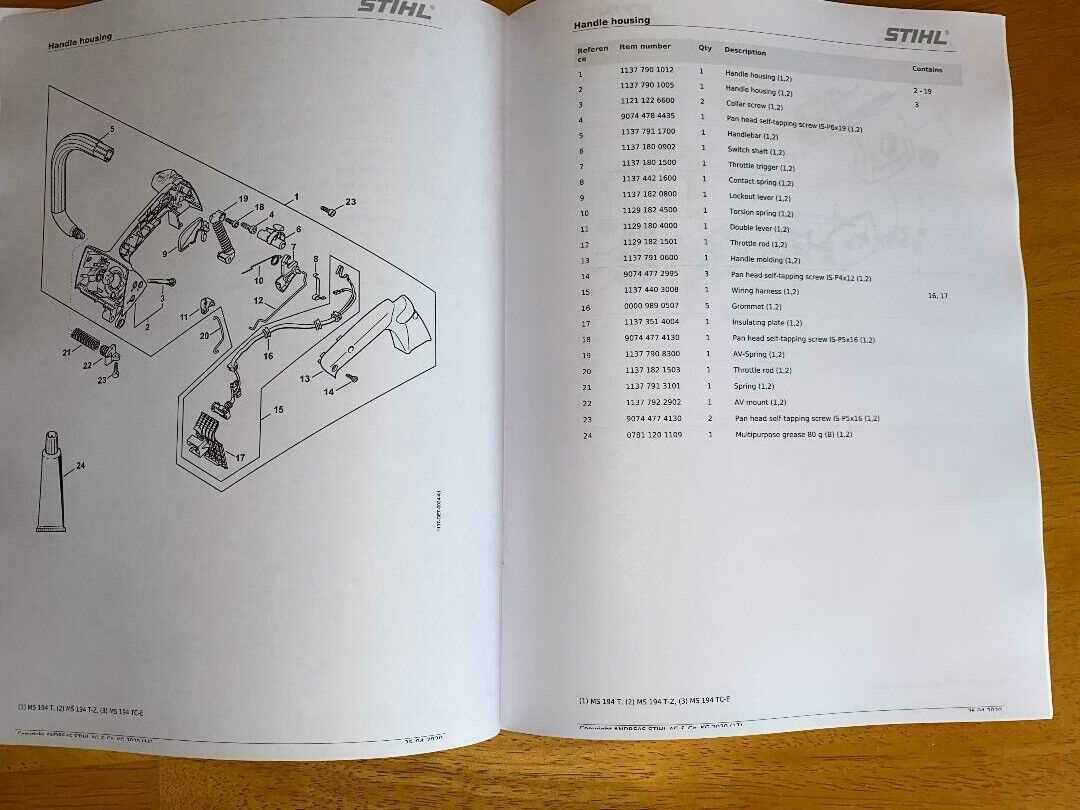

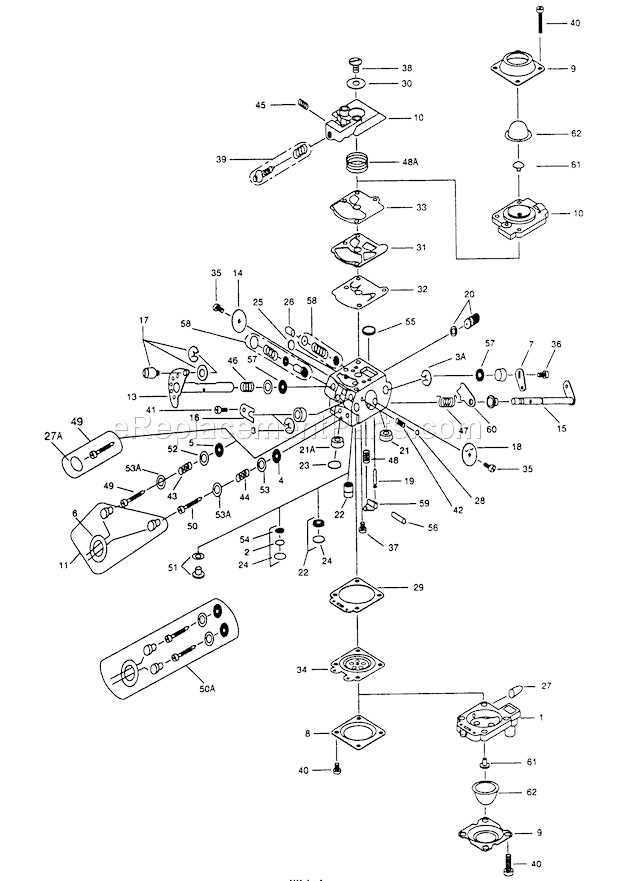

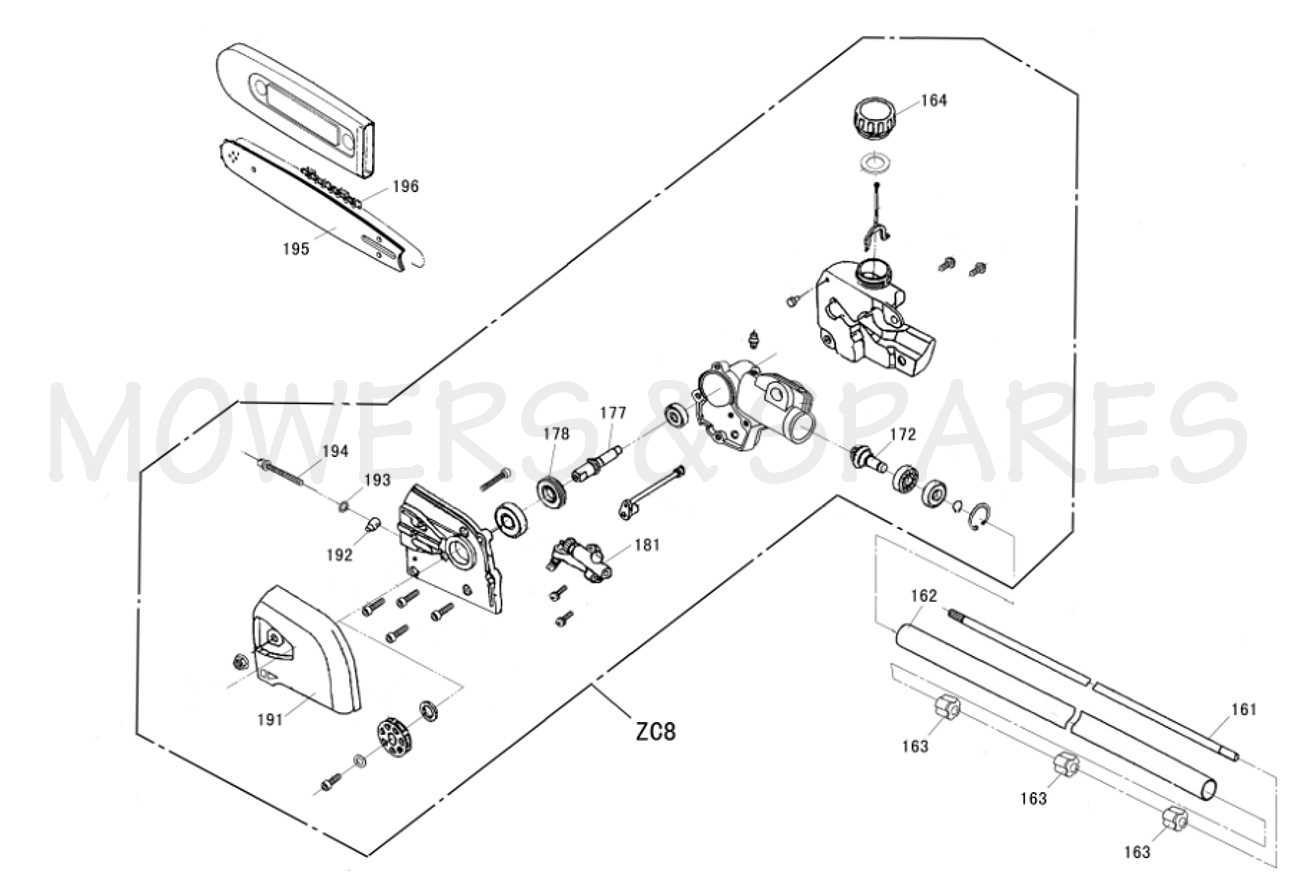

For those who wish to delve deeper into the mechanics of their equipment, visual representations of the internal configurations offer invaluable insight. These illustrations highlight the relationship between various sections and assist in identifying potential wear points or areas needing attention. Knowledge of such schematics is essential for efficient troubleshooting and effective maintenance.

Equipping oneself with this information empowers operators to make informed decisions, whether it’s about ordering replacements or performing upgrades. Understanding the synergy among different parts fosters a greater appreciation for the engineering that drives these powerful tools, ultimately leading to improved functionality and satisfaction in their use.

Understanding the Stihl 194t

This section explores the intricate design and functionality of a popular model in the power tool market. It emphasizes the importance of each component in ensuring optimal performance and longevity, making it essential for users to be familiar with their equipment.

| Component | Function |

|---|---|

| Engine | Powers the tool and determines efficiency. |

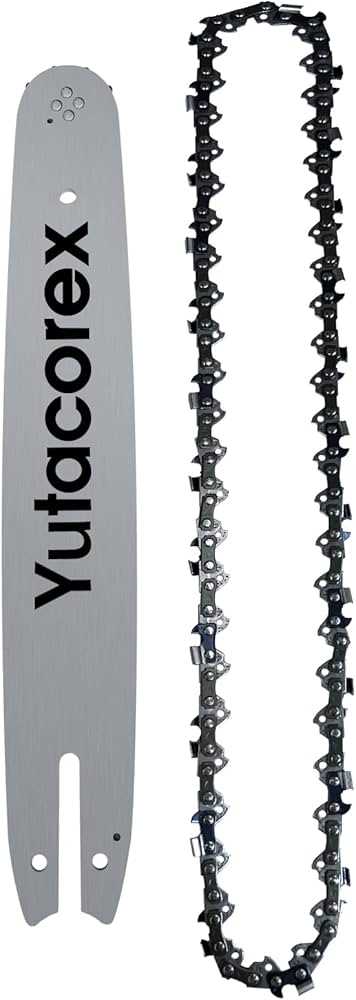

| Bar | Guides the cutting mechanism for precision. |

| Chain | Engages with the bar to perform cutting tasks. |

| Handle | Provides control and stability during operation. |

| Fuel Tank | Holds the fuel needed for engine operation. |

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations serve as valuable resources, allowing users to identify individual elements and their relationships within the system. This clarity enhances troubleshooting processes and ensures accurate reassembly after repairs.

Visual aids simplify complex information, making it accessible even to those with limited technical expertise. By breaking down intricate assemblies into manageable sections, these illustrations promote a better grasp of functionality and the role of each component. This, in turn, fosters greater confidence in handling equipment safely and effectively.

Moreover, having a clear visual reference can significantly reduce the time spent on repairs. By easily locating the necessary components, users can streamline their workflow and minimize the risk of errors. This efficiency not only saves time but also reduces potential costs associated with prolonged downtime.

In summary, these visual guides play a pivotal role in ensuring that maintenance and repair tasks are conducted with precision and ease. Their importance extends beyond mere convenience; they enhance overall understanding, efficiency, and safety in managing machinery.

Key Components of the 194t

This section delves into the essential elements that contribute to the efficiency and functionality of the equipment. Understanding these components is crucial for maintenance and optimal performance, allowing users to appreciate the intricate design and engineering involved.

Engine Assembly

The heart of the machine, the engine assembly, powers all operations. Its robust design ensures reliability and durability, providing the necessary torque and speed for various tasks. Regular checks and maintenance of this component are vital for sustaining performance and prolonging the lifespan of the equipment.

Cutting Mechanism

The cutting mechanism is fundamental to the device’s effectiveness. Comprising blades and drive components, it is engineered for precision and efficiency. Users should pay close attention to wear and tear, as maintaining sharpness and alignment can significantly impact cutting performance and safety.

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to maintain and repair equipment. These illustrations serve as invaluable tools for identifying various elements, their connections, and how they function together. Familiarizing yourself with the layout and symbols used in these graphics will streamline your repair process.

Key Components of Visual Representations

- Labels: Each item is often labeled with a unique number or letter, corresponding to a list of parts.

- Sections: Components are typically grouped by function or location, making it easier to locate specific items.

- Connections: Lines or arrows indicate how parts interact or connect, providing insight into assembly and disassembly.

Steps to Effectively Interpret Illustrations

- Start by reviewing the legend or key to understand the symbols used.

- Identify the main components in the graphic, focusing on their layout.

- Cross-reference the labeled items with the parts list to ensure accuracy.

- Follow the lines to grasp how parts are interconnected.

- Make notes on any components that require replacement or maintenance.

Common Issues with Stihl 194t

When operating power equipment, users may encounter a range of challenges that can affect performance and efficiency. Understanding these common problems can help in identifying and resolving issues effectively.

Frequent Problems

- Starting Difficulties

- Inefficient Fuel Consumption

- Overheating Issues

Solutions

- Check the ignition system for faults.

- Ensure the air filter is clean and unobstructed.

- Inspect the fuel lines for blockages or leaks.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring that your equipment remains in peak condition for years to come. Regular maintenance not only enhances performance but also significantly extends the lifespan of your machinery. Following a systematic approach to care can help you avoid costly repairs and downtime.

Routine Checks

Implementing a schedule for regular inspections can identify potential issues before they escalate. Focus on the following components during your checks:

| Component | Recommended Frequency | Notes |

|---|---|---|

| Air Filter | Every 10 hours of use | Clean or replace as necessary. |

| Fuel System | Monthly | Check for leaks and clean filters. |

| Blades | After every use | Sharpen and check for damage. |

| Cables and Hoses | Every 20 hours of use | Inspect for wear and tear. |

Cleaning and Storage

Keeping your equipment clean is crucial for optimal performance. After each use, remove debris and dirt. Additionally, proper storage is vital to protect against environmental damage. Store in a dry, cool place and cover if necessary to shield from dust and moisture.

Where to Find Replacement Parts

Finding the right components for your equipment can be essential for maintaining its performance and longevity. Various sources are available, each offering different advantages in terms of price, quality, and availability. Whether you are looking for original items or compatible alternatives, knowing where to search can save you both time and money.

One of the most reliable options is the official dealer network. Authorized retailers often stock genuine components, ensuring compatibility and performance standards. Additionally, many of these dealers provide expert advice and support, which can be invaluable when selecting the correct items.

Online marketplaces and specialty websites also present a wide selection of components. These platforms often feature competitive pricing and customer reviews, allowing you to compare different options easily. Be sure to check the seller’s reputation and return policy before making a purchase.

Local repair shops can be another resource. Many have access to a range of components and may offer installation services as well. This can be a convenient option if you prefer hands-on assistance or immediate access to the items you need.

Lastly, consider reaching out to community forums and groups focused on equipment maintenance. These platforms can provide recommendations for trustworthy sources and even direct connections to individuals selling spare components. Engaging with fellow enthusiasts can enhance your search and lead to valuable insights.

Comparing Original vs. Aftermarket Parts

The choice between genuine components and alternatives is a critical decision for any equipment owner. Each option carries its own set of advantages and disadvantages, influencing performance, durability, and cost-effectiveness. Understanding these differences can significantly impact maintenance strategies and overall equipment longevity.

Original components are manufactured by the original brand, ensuring a precise fit and compatibility. They often come with warranties and are made from high-quality materials, which can lead to improved performance and reliability. However, this quality often comes at a premium price.

On the other hand, alternative components can offer significant savings and may provide satisfactory performance for less demanding tasks. They are widely available and come from various manufacturers, allowing for a broader selection. However, the risk of lower quality and potential compatibility issues can lead to decreased performance or even damage over time.

Ultimately, the choice hinges on the user’s needs, budget, and willingness to compromise on quality for cost. Balancing these factors is essential for making an informed decision that aligns with maintenance goals and operational efficiency.

Assembly Instructions for 194t

This section provides detailed guidance for the assembly process of the specific equipment model. Proper assembly ensures optimal performance and longevity of the unit. Follow the steps carefully to ensure that each component is correctly fitted and secured.

Preparation Steps

Before beginning the assembly, gather all necessary tools and components. Verify that all parts are in good condition and free from damage. A clean and organized workspace will help facilitate the process.

| Step | Description |

|---|---|

| 1 | Start by placing the main body on a flat surface, ensuring stability. |

| 2 | Attach the handle securely, ensuring all screws are tightened. |

| 3 | Install the blade assembly, making sure it aligns with the guide. |

| 4 | Connect the power unit and check all electrical connections. |

| 5 | Final inspection: ensure all components are secured and functioning properly. |

Final Checks

Once the assembly is complete, perform a thorough check of all connections and fittings. Test the equipment in a safe environment to ensure everything operates smoothly. Regular maintenance after assembly will help prolong the lifespan and efficiency of the unit.

Safety Precautions During Repairs

Engaging in maintenance tasks on mechanical equipment necessitates a comprehensive understanding of safety measures. Ensuring a secure environment not only protects the individual performing the repairs but also extends the lifespan of the equipment itself. Adhering to safety guidelines mitigates the risks associated with potential hazards that may arise during servicing.

Essential Safety Gear

Wearing appropriate personal protective equipment (PPE) is crucial when undertaking repairs. This gear safeguards against various risks, including sharp objects, noise, and hazardous materials. Below is a list of recommended items:

| Protective Equipment | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris and chemical splashes. |

| Gloves | Prevents cuts and chemical exposure. |

| Ear Protection | Reduces noise levels and protects hearing. |

| Steel-Toed Boots | Offers foot protection from heavy objects. |

Work Environment Safety

Creating a safe workspace is equally important. A well-organized area can prevent accidents and enhance efficiency. Consider the following tips to maintain a safe environment:

- Keep the workspace tidy and free of clutter.

- Ensure adequate lighting to see all parts clearly.

- Use proper tools and equipment for the job.

- Be mindful of potential hazards, such as slippery surfaces.

Expert Recommendations for Users

Understanding the intricacies of your equipment is essential for optimal performance and longevity. Here, we provide insights to help you maintain and enhance the functionality of your machine, ensuring you get the most out of your investment.

Maintenance Tips

- Regularly inspect components for wear and tear.

- Keep all moving parts lubricated to prevent friction.

- Replace filters as recommended to ensure efficient operation.

Usage Guidelines

- Always follow manufacturer instructions for operation.

- Utilize appropriate safety gear to minimize risks.

- Store the machine in a dry, cool environment when not in use.

Community Resources and Forums

Connecting with fellow enthusiasts can greatly enhance your experience and knowledge. Online platforms provide valuable opportunities for sharing insights, troubleshooting issues, and discussing techniques related to equipment maintenance and repair. Engaging with a community not only fosters learning but also cultivates a sense of camaraderie among users.

Online Communities

There are numerous digital spaces where users can interact, exchange ideas, and seek assistance. Here are some popular options:

- Social Media Groups: Platforms like Facebook and Reddit host groups dedicated to equipment enthusiasts, allowing members to share experiences and tips.

- Specialized Forums: Websites focused on outdoor equipment often feature dedicated sections for discussions, advice, and support.

- YouTube Channels: Many creators share tutorials, reviews, and maintenance guides, providing visual aids for better understanding.

Local Workshops and Meetups

In addition to online resources, consider exploring local gatherings where enthusiasts can connect in person:

- Workshops: Local hardware stores or community colleges may offer classes on maintenance techniques and equipment handling.

- Meetup Events: Look for local clubs or organizations that host events focused on outdoor activities and equipment care.

- Trade Shows: Attend regional exhibitions to network with experts and discover the latest tools and technologies.