When it comes to the intricate systems of outdoor machinery, having a clear overview of its individual elements is crucial for effective maintenance and repairs. This section delves into the various components that come together to form a cohesive unit, providing insights into their functions and interrelations.

Each segment of the machine plays a specific role, contributing to overall performance and efficiency. Understanding these segments not only aids in troubleshooting but also enhances the ability to optimize the equipment for better functionality. Whether you are a seasoned technician or a novice, familiarizing yourself with the various elements will empower you in your endeavors.

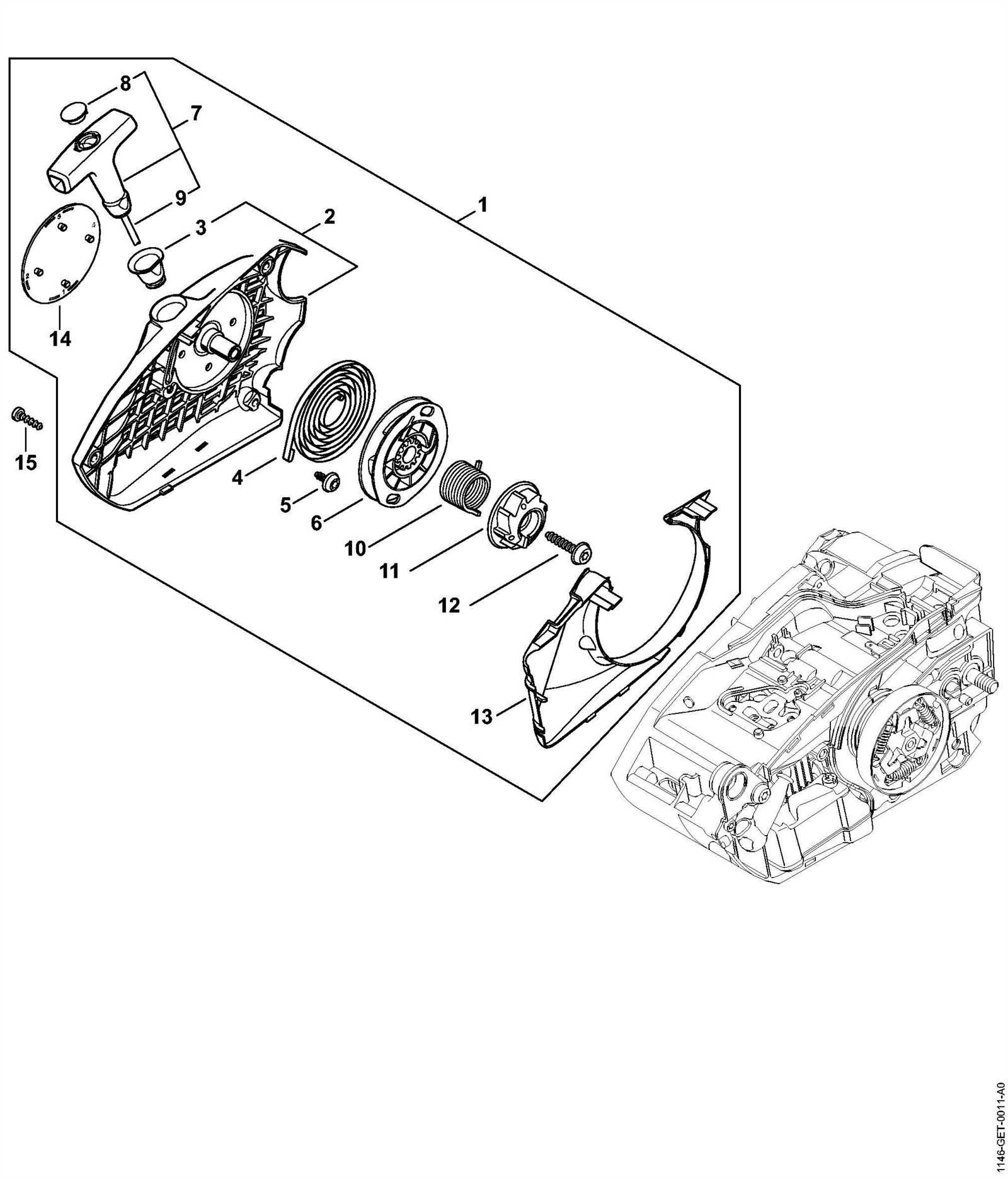

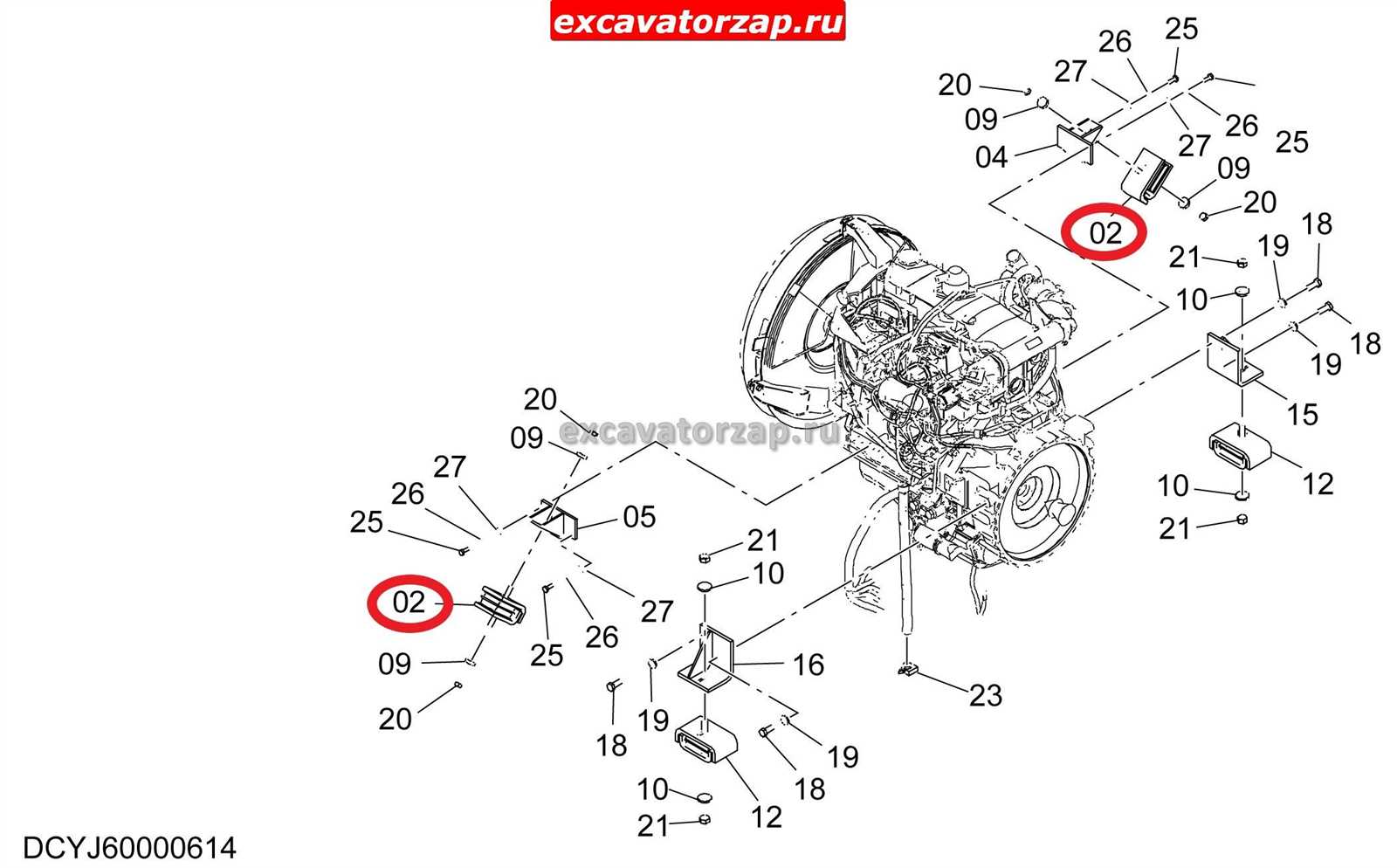

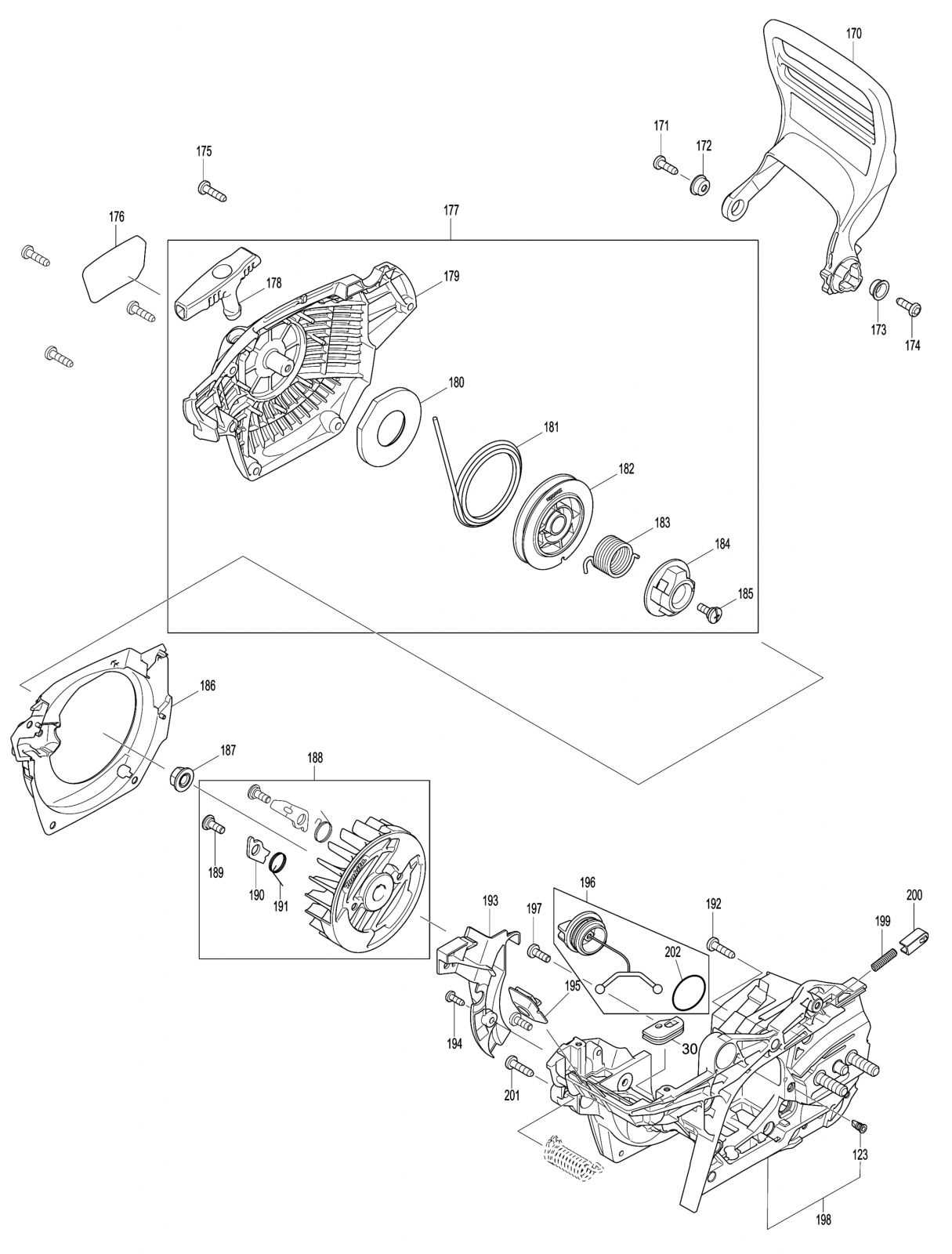

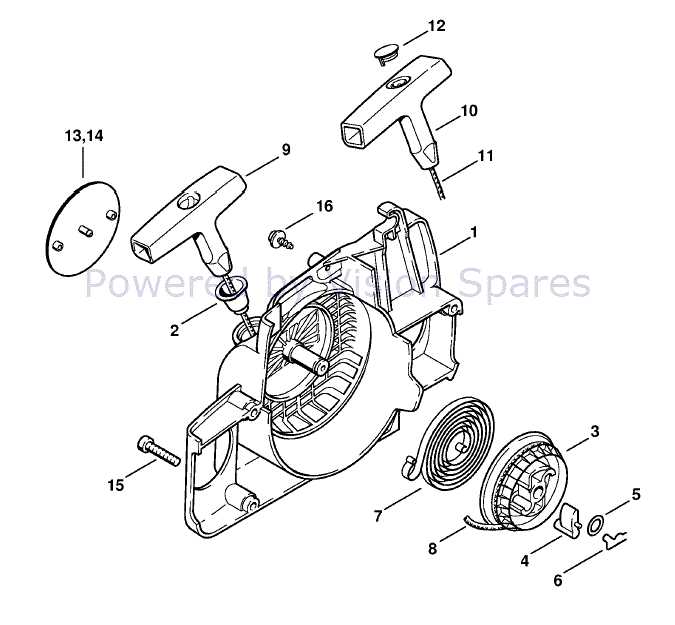

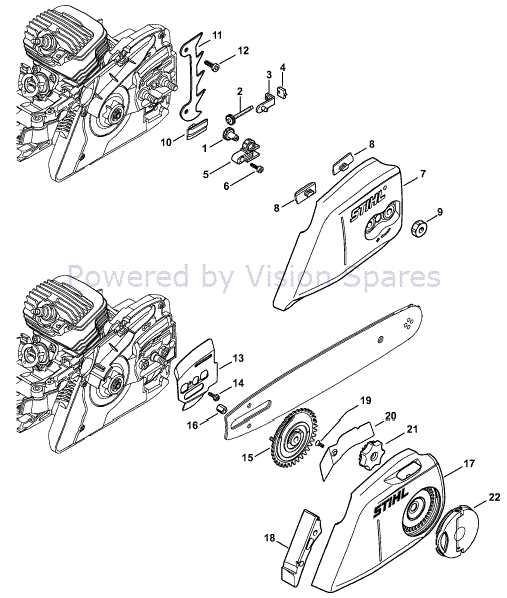

In the following sections, detailed visual representations and annotations will guide you through the essential constituents of this machinery. By examining the layout and configuration, you will gain a deeper appreciation for how these individual parts contribute to the machine’s operation and longevity.

Understanding MS271 Parts Diagram

Grasping the intricacies of the component layout is essential for effective maintenance and repair. This visual representation offers insights into the arrangement and functionality of various elements, aiding users in identifying parts and their interconnections.

Key Components

Each section of the schematic highlights specific elements, illustrating how they work together to ensure optimal performance. Familiarity with these components allows for efficient troubleshooting and replacement.

Navigation Tips

When examining the schematic, focus on the labels and identifiers for each part. Understanding these markings simplifies the process of locating the necessary components when conducting repairs or upgrades.

| Component | Description |

|---|---|

| Element A | Primary function in the system’s operation. |

| Element B | Supports connectivity and communication between units. |

| Element C | Facilitates energy distribution throughout the setup. |

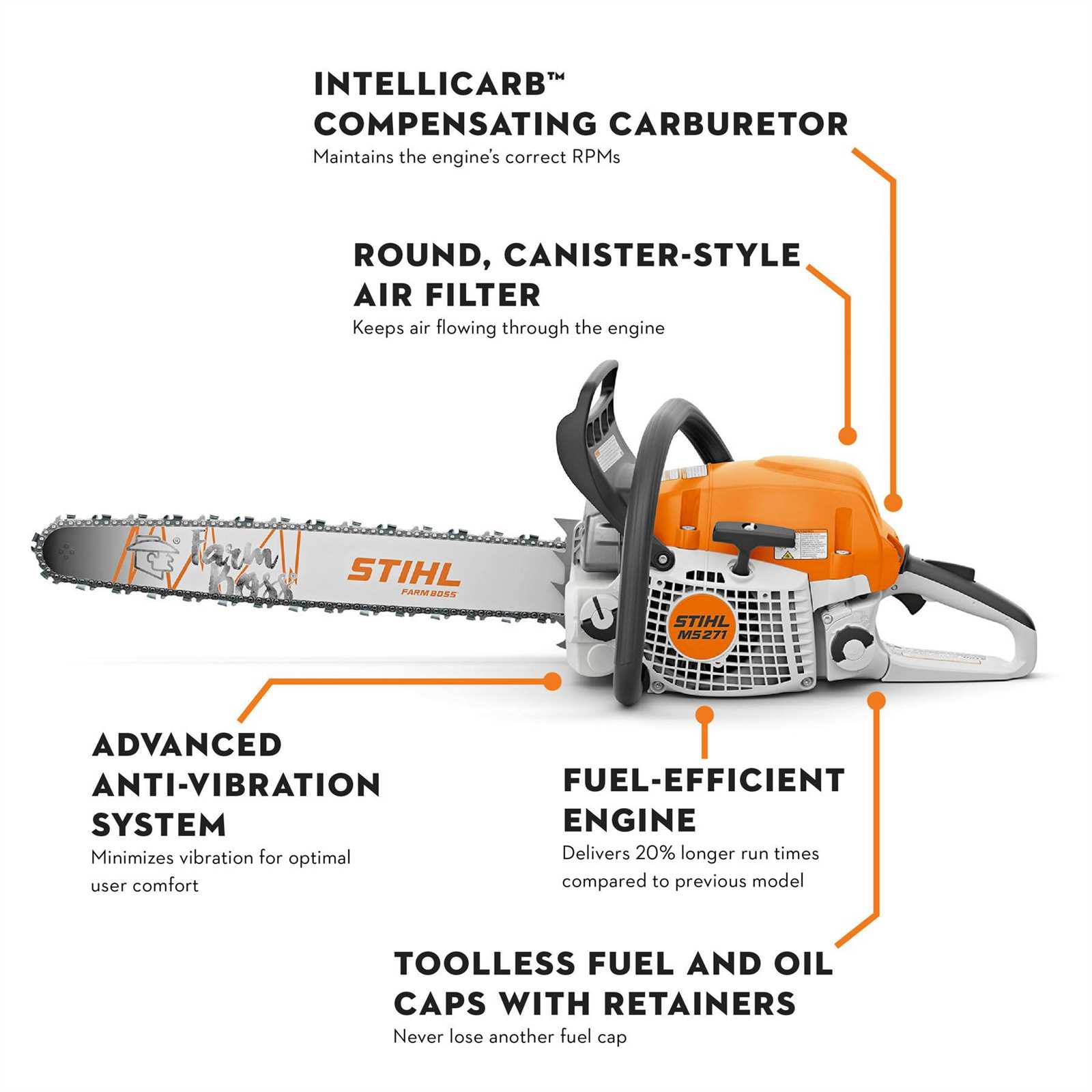

Key Components of MS271 Equipment

The efficient functioning of specialized equipment relies heavily on its essential elements, each contributing to the overall performance and reliability. Understanding these crucial components can enhance maintenance practices and ensure optimal operation.

Engine: The heart of the machinery, the engine provides the necessary power to operate various functions. Its design and specifications determine the efficiency and output capabilities of the entire system.

Control Unit: This component serves as the brain of the equipment, managing operations and facilitating user interactions. An intuitive interface allows for easy adjustments and monitoring of performance metrics.

Transmission System: Responsible for transferring power from the engine to the working parts, the transmission system plays a vital role in ensuring smooth operation and responsiveness under various conditions.

Hydraulic Components: These elements are crucial for enabling movement and providing force. They include pumps, valves, and cylinders that work in tandem to facilitate various tasks, from lifting to precise adjustments.

Chassis: The frame of the equipment supports all other components, providing stability and durability. A robust chassis design ensures longevity and the ability to withstand demanding environments.

Safety Features: Integral to the design, safety mechanisms protect users and the equipment itself from potential hazards. These features include emergency shut-off systems and protective guards.

By familiarizing oneself with these key elements, operators can better appreciate the complexity and functionality of the machinery, leading to improved performance and extended service life.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in ensuring the effective assembly, maintenance, and troubleshooting of complex machinery. They serve as essential references that guide users through various processes, minimizing errors and enhancing overall efficiency.

Clarity and Understanding

Clear representations help users comprehend the structure and functionality of various components. This understanding is vital for:

- Identifying individual elements and their relationships

- Facilitating effective communication among technicians and engineers

- Reducing the learning curve for new users

Efficiency in Maintenance

Accurate illustrations contribute significantly to the maintenance process by:

- Providing detailed information for troubleshooting

- Allowing for quick identification of wear or damage

- Streamlining the replacement of faulty components

In summary, well-crafted visuals are indispensable tools that enhance comprehension, support effective maintenance, and ultimately improve the performance of machinery.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visuals provide a comprehensive overview of components, helping users identify and locate each item with ease. By grasping the layout and notations, one can streamline the troubleshooting process and enhance overall efficiency.

First, familiarize yourself with the key that often accompanies these illustrations. This guide explains symbols and labels, enabling you to decode the information quickly. Components are usually marked with numbers or letters, which correspond to a list of items. This list typically details specifications and quantities, making it easier to order replacements or plan repairs.

Next, pay attention to the layout. Most illustrations present a bird’s-eye view or an exploded view, showcasing how parts interact. Identifying relationships between components can clarify assembly and disassembly procedures, preventing potential errors during maintenance. Additionally, note any special instructions or warnings highlighted within the visual to avoid common pitfalls.

Lastly, practice by using various illustrations to enhance your skills. The more you engage with these resources, the more adept you will become at interpreting them accurately, ultimately improving your maintenance outcomes.

Common Issues with MS271 Parts

Understanding frequent problems associated with components can significantly enhance maintenance and performance. Identifying these challenges early can prevent further complications and ensure longevity in operation.

1. Wear and Tear

Over time, certain elements may experience excessive degradation due to prolonged use. Regular inspection is vital, as friction and heat can lead to failures in essential functions. Routine checks can mitigate these risks.

2. Compatibility Concerns

Using non-original or incompatible elements can result in operational inefficiencies. Substitutes may not fit correctly or provide the necessary performance, leading to unexpected failures. Always ensure compatibility with original specifications to maintain optimal functionality.

Maintenance Tips for MS271 Models

Proper upkeep is essential for ensuring the longevity and efficient performance of your equipment. Regular maintenance not only enhances functionality but also helps prevent unexpected breakdowns. Here are some valuable suggestions to keep your machinery in optimal condition.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Inspect Filters | Every 25 hours | Check air and fuel filters for dirt and debris; replace if necessary to ensure proper airflow and fuel flow. |

| Clean Air Intake | Every 50 hours | Remove any dust or obstruction from the air intake to maintain optimal engine performance. |

| Check Oil Levels | Every 10 hours | Verify oil levels and top off as needed. Change oil based on the manufacturer’s recommendations. |

| Sharpen Blades | Every 50 hours | Inspect and sharpen blades to ensure a clean cut and reduce strain on the engine. |

| Inspect Belts and Cables | Every 100 hours | Look for wear or damage in belts and cables; replace if any signs of fraying or cracking are present. |

| Battery Maintenance | Monthly | Check battery terminals for corrosion and ensure connections are tight. Test battery performance regularly. |

By adhering to these maintenance recommendations, you can enhance the reliability and efficiency of your equipment, ensuring it operates smoothly for years to come.

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process if you know where to look. Understanding your options and resources is essential to ensure you get the right items without hassle.

Here are some effective strategies to simplify your search:

- Manufacturer Websites: Start with the official site of the manufacturer. They often provide detailed information about their products and a dedicated section for replacements.

- Authorized Dealers: Reach out to certified dealers who specialize in your specific equipment. They can offer genuine components and expert advice.

- Online Retailers: Utilize reputable online marketplaces. Filter your search using model numbers and specifications to find what you need.

- Community Forums: Join discussion groups related to your equipment. Members often share their experiences and can recommend reliable sources.

By exploring these avenues, you can streamline your search for components and enhance your maintenance efforts effectively.

Comparing MS271 to Other Models

When evaluating different machinery, it’s essential to consider how various models stack up against one another. Each unit brings its own set of features, specifications, and capabilities, which can influence performance and usability in diverse applications.

This particular model stands out for its balance of efficiency and functionality, making it a popular choice among users. However, when placed alongside similar devices, it becomes evident that some alternatives may offer enhanced power or specialized features tailored for specific tasks.

For instance, while some competitors may prioritize lightweight construction, this unit focuses on durability, making it suitable for rigorous use. Users seeking maximum versatility might find certain models that excel in adaptability, offering interchangeable components that cater to a wider range of tasks.

Ultimately, the decision should be guided by the specific requirements of the user. Understanding the strengths and weaknesses of each option will aid in making an informed choice that aligns with operational needs and preferences.

Benefits of Using Official Diagrams

Utilizing authorized illustrations offers numerous advantages for individuals seeking clarity and precision in their projects. These visual aids are meticulously crafted to ensure accurate representation of components and their interrelationships, providing a reliable reference for both novices and experienced users alike.

One significant benefit of official visuals is the assurance of authenticity and correctness. When relying on sanctioned resources, users can trust that the information is validated and reflects the latest updates, reducing the risk of errors that may arise from using unofficial or outdated materials.

Furthermore, these illustrations often come with comprehensive annotations that enhance understanding. Such details help users grasp complex configurations and facilitate troubleshooting, ultimately leading to more efficient assembly or repair processes.

In addition, engaging with official resources can promote a deeper familiarity with the equipment. Users can develop a better appreciation for the design and functionality of each element, empowering them to perform maintenance tasks with confidence and skill.

Overall, leveraging authorized illustrations not only streamlines the workflow but also enriches the user’s experience, making it an essential practice for anyone working with intricate systems.

Visualizing Assembly Process Effectively

To enhance the efficiency of any assembly procedure, a clear visual representation plays a crucial role. It helps in understanding the sequence of actions required and the relationship between different components. This clarity reduces confusion and ensures that each stage is executed with precision.

Utilizing illustrations can significantly simplify complex processes. When workers can see a detailed breakdown of the assembly steps, they are more likely to follow the correct order and utilize the appropriate tools. This visual aid fosters confidence, enabling individuals to focus on their tasks without second-guessing their actions.

Moreover, incorporating color coding and labels into these visuals can further enhance comprehension. By categorizing elements based on their function or assembly sequence, it becomes easier to identify parts and understand their roles. Ultimately, effective visualization leads to a smoother workflow and improved productivity.

Resources for Further Research

Exploring additional materials can greatly enhance your understanding of machinery and its components. Various platforms offer a wealth of information, including technical specifications, user manuals, and forums where enthusiasts share insights. These resources are invaluable for anyone looking to deepen their knowledge or troubleshoot issues effectively.

One excellent source is the manufacturer’s website, where you can find official documentation, including detailed specifications and service guides. Additionally, online retail platforms often provide user reviews and Q&A sections that can offer practical advice from those who have hands-on experience with similar models.

Industry forums and community groups are also fantastic places to gather insights. Members frequently share tips, tricks, and solutions to common problems, fostering a collaborative environment for learning. Furthermore, educational websites and YouTube channels dedicated to mechanical devices can provide visual aids and tutorials that simplify complex concepts.