Maintaining outdoor equipment is essential for optimal performance and longevity. Familiarizing oneself with the various elements of a grass-cutting device can significantly enhance the user experience. This section delves into the intricate assembly of such machinery, providing insights into how each component contributes to its overall functionality.

By comprehending the layout and relationships between the different parts, users can efficiently troubleshoot issues and execute necessary repairs. Each segment plays a crucial role, from the motor that powers the unit to the cutting mechanisms that handle tough vegetation. A clear understanding of these elements can lead to more effective maintenance and improved operational efficiency.

For those seeking to enhance their knowledge, this overview serves as a valuable resource. It enables users to approach repairs and maintenance with confidence, ensuring that their equipment remains in peak condition. Whether you are a novice or an experienced user, grasping the essentials of your cutting tool is key to successful gardening and landscaping endeavors.

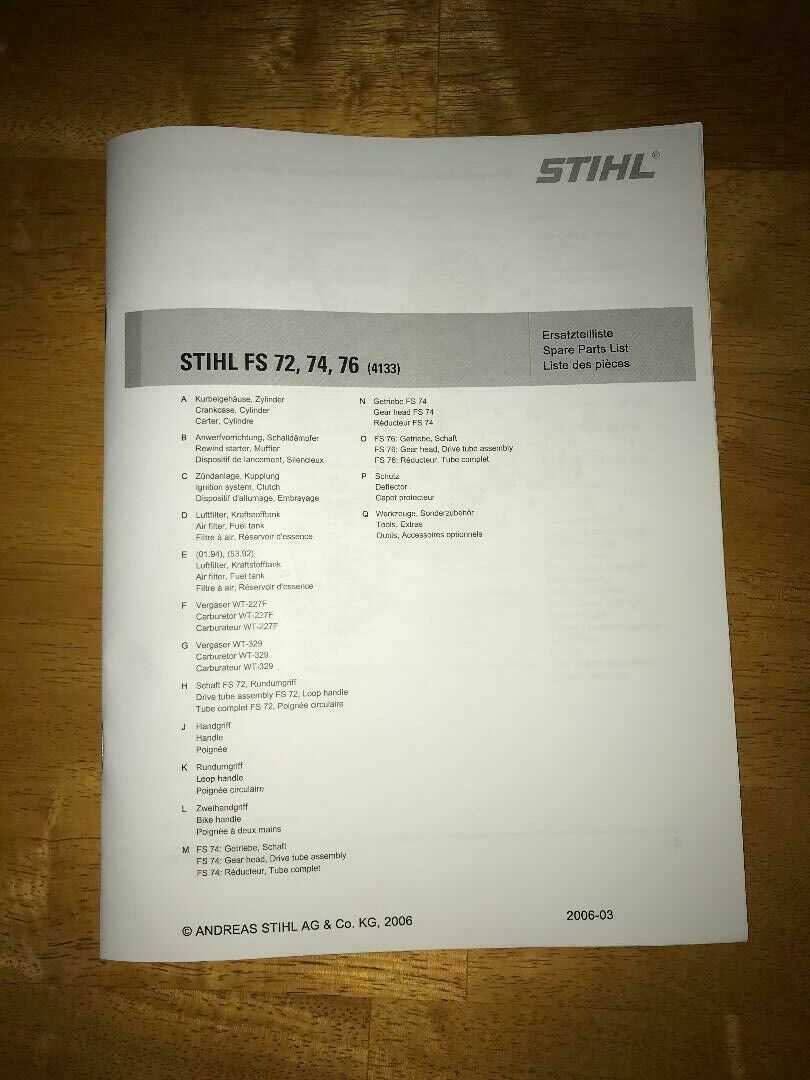

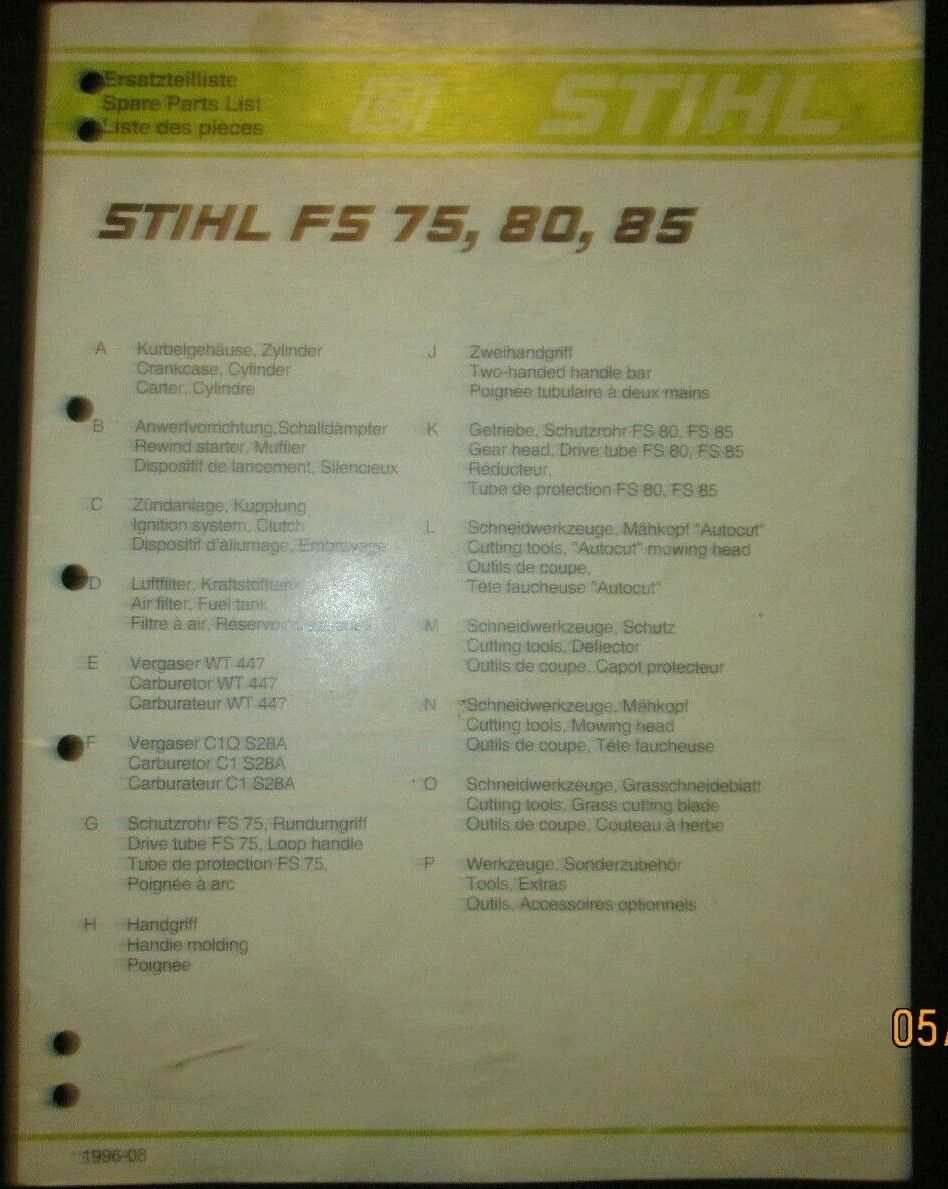

This section aims to provide a comprehensive overview of the essential elements found in a specific type of outdoor power equipment. Understanding these components is crucial for effective maintenance, repair, and operation. By exploring the various parts, users can gain insights into how each element contributes to the overall functionality and performance of the equipment.

Key Elements of the Equipment

- Engine: The heart of the machine, responsible for providing the necessary power.

- Fuel System: Ensures the proper delivery of fuel to the engine for efficient operation.

- Cutting Head: The component that performs the actual cutting action.

- Handle and Controls: Facilitates user interaction and control over the equipment.

- Safety Features: Designed to protect the user during operation.

Maintenance Tips for Optimal Performance

- Regularly inspect and clean the engine components.

- Check and replace fuel filters as needed.

- Ensure the cutting head is properly sharpened and aligned.

- Test all controls for proper functionality before use.

- Utilize safety gear during operation to minimize risk.

Importance of Understanding Parts Layout

Grasping the arrangement of components in any machinery is crucial for effective maintenance and troubleshooting. A well-organized layout allows users to identify individual elements quickly, facilitating smoother repairs and enhancing the overall performance of the equipment. Understanding how these elements interact with one another can significantly reduce downtime and improve efficiency during operations.

Enhanced Maintenance Efficiency

Comprehending the configuration of various components leads to better maintenance practices. Key benefits include:

- Quick identification of worn or damaged items.

- Streamlined repair processes.

- Improved safety during maintenance tasks.

Facilitating Troubleshooting

Being familiar with how parts are arranged aids in diagnosing issues effectively. This understanding helps in:

- Pinpointing the root cause of malfunctions.

- Reducing the time spent on repairs.

- Ensuring that replacements are accurate and compatible.

Common Issues with FS75 Parts

Understanding the frequent challenges associated with various components of outdoor power equipment can enhance the user experience and prolong the lifespan of the machine. Several factors contribute to the functionality of these mechanisms, and recognizing potential problems can facilitate timely maintenance and repairs.

Wear and Tear

Over time, certain elements may experience degradation due to regular use. This can lead to decreased performance or complete failure if not addressed promptly. Regular inspection is essential to identify signs of wear early.

Assembly and Fit Issues

Improper assembly or misalignment of components can result in inefficiency or operational difficulties. Ensuring that all parts fit together correctly is crucial for optimal performance. Regular checks can help prevent these issues from escalating.

| Issue | Symptoms | Recommended Action |

|---|---|---|

| Decreased Efficiency | Longer operation times, reduced power | Inspect and replace worn components |

| Noise and Vibration | Unusual sounds, excessive vibration | Check for loose or damaged parts |

| Difficulty Starting | Frequent starting issues, stalling | Examine the ignition system and fuel supply |

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular upkeep and attention to detail. By following a few essential practices, you can significantly enhance the lifespan of your tools while maintaining optimal performance.

Regular Cleaning: Keep your device free from debris and dirt. Cleaning after each use prevents buildup that can cause wear and tear. Pay special attention to the air filter and cooling fins, as these components are crucial for efficient operation.

Routine Inspections: Periodically check all moving parts for signs of wear or damage. Look for loose connections, frayed wires, or cracks in the casing. Addressing these issues early can prevent more significant problems later on.

Proper Lubrication: Ensure that all necessary components are adequately lubricated. Use the recommended lubricants to reduce friction and protect against corrosion, allowing for smoother operation and reducing the risk of breakdowns.

Storage Considerations: Store your equipment in a dry and secure location. Avoid exposure to extreme temperatures and moisture, which can lead to rust and deterioration. Additionally, consider using protective covers to shield against dust and debris.

Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations for maintenance schedules and procedures. Utilizing the correct tools and replacement parts will ensure your equipment operates efficiently and safely.

Finding Replacement Parts Easily

When it comes to maintaining outdoor equipment, locating suitable components can often be a challenge. However, with the right approach, you can streamline the process and ensure that you have access to all necessary items. By understanding how to effectively search for replacements, you can minimize downtime and keep your equipment running smoothly.

Utilizing Online Resources

One of the most effective ways to find suitable replacements is to leverage the power of online platforms. Numerous websites specialize in providing detailed catalogs that list various components along with their specifications. By inputting the model number or type of equipment, users can quickly access information about compatible parts.

Local Dealers and Repair Shops

Another valuable resource is your local dealers or repair shops. These establishments often have an array of components in stock and can offer advice on suitable replacements. They may also assist in placing orders for items that are not readily available, ensuring you receive the correct items in a timely manner.

| Resource Type | Description | Advantages |

|---|---|---|

| Online Retailers | Websites that specialize in replacement components. | Wide selection and often competitive pricing. |

| Local Dealers | Physical stores that sell equipment and components. | Personalized assistance and immediate availability. |

| Manufacturer’s Websites | Official websites that provide information and ordering options. | Guaranteed compatibility and original quality. |

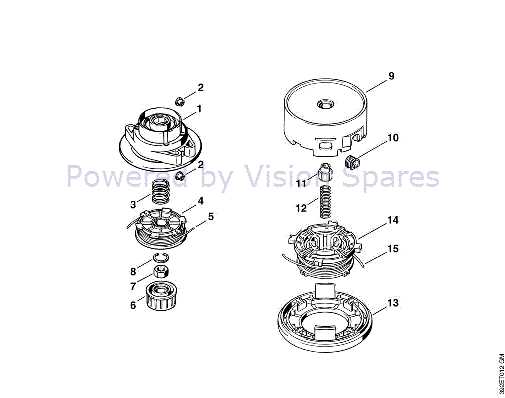

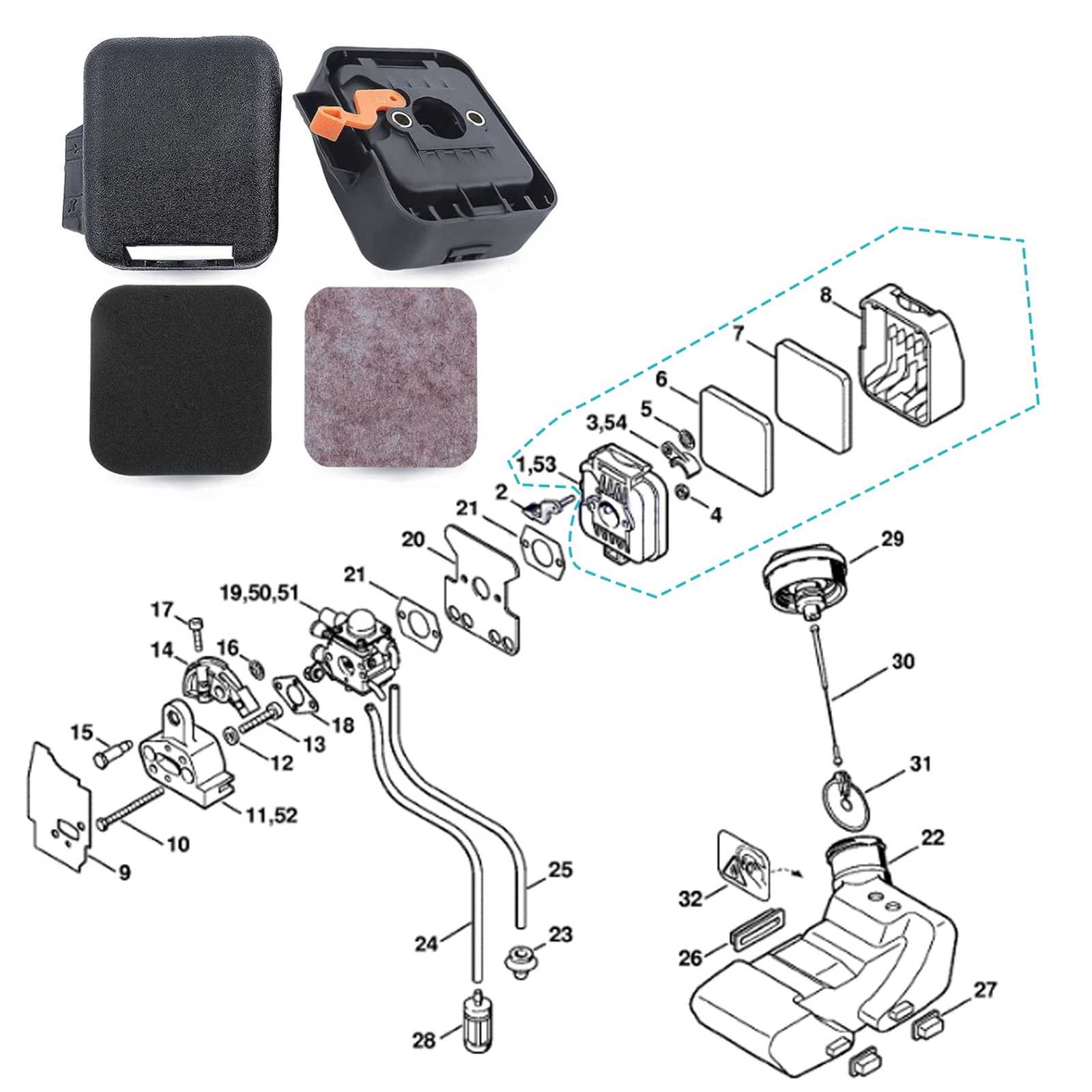

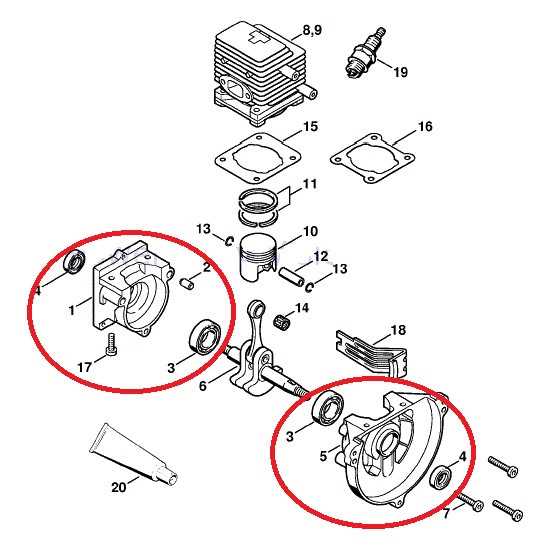

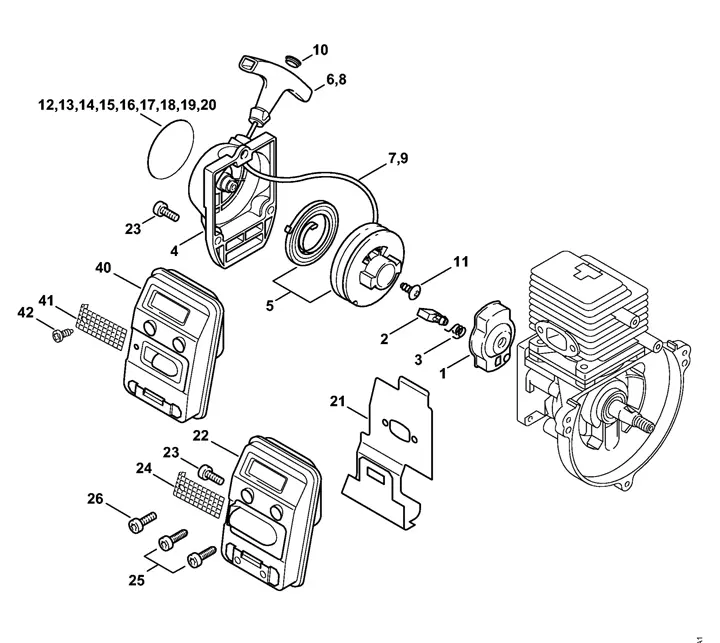

Visual Guide to Assembly Process

In this section, we will provide a comprehensive overview of the assembly process for your equipment. By following a step-by-step approach, you will gain a better understanding of how to efficiently put together the necessary components, ensuring optimal performance and longevity.

Essential Components for Assembly

- Handle and control mechanism

- Powerhead and engine assembly

- Cutting attachment

- Fuel system parts

- Safety features and guards

Step-by-Step Assembly Instructions

- Begin by securing the main handle to the powerhead, ensuring all bolts are tightened properly.

- Attach the cutting attachment to the shaft, making sure it is aligned correctly.

- Connect the fuel lines and ensure they are properly seated to avoid leaks.

- Install the safety guard, confirming it is securely in place to protect the user.

- Finally, conduct a thorough inspection of all connections and components to ensure everything is assembled correctly.

Following these guidelines will help you achieve a successful assembly, allowing for effective operation of your machine.

How to Identify Damaged Components

Recognizing damaged elements in your equipment is crucial for maintaining optimal performance. This process involves careful observation and assessment to ensure all parts function correctly. Below are some essential steps to help you identify any worn or broken components effectively.

Follow these guidelines for thorough inspection:

- Visual Inspection: Examine all parts for visible signs of wear, such as cracks, breaks, or corrosion.

- Listen for Unusual Noises: While operating the device, pay attention to any strange sounds that may indicate internal issues.

- Check for Leaks: Inspect for any fluid leaks, which can suggest compromised seals or gaskets.

- Assess Performance: Notice any decrease in efficiency or functionality, as this may point to underlying damage.

- Consult the Manual: Refer to the equipment’s user guide for specific signs of wear and troubleshooting tips.

By following these steps, you can effectively identify any damaged components, ensuring your equipment remains in peak condition.

Comparison of Genuine vs. Aftermarket Parts

When it comes to maintaining outdoor power equipment, choosing the right components is crucial for optimal performance. The market offers a variety of options, including original manufacturer items and alternatives produced by third parties. Understanding the differences between these choices can help users make informed decisions based on quality, cost, and compatibility.

Quality and Performance

One of the primary factors to consider is the quality of the components:

- Original Manufacturer Items: Typically engineered to meet strict quality standards, ensuring reliable performance and durability.

- Aftermarket Alternatives: While some may provide comparable quality, others can vary significantly, impacting efficiency and lifespan.

Cost Considerations

Pricing is another key aspect that often influences purchasing decisions:

- Original Manufacturer Items: Generally more expensive due to brand reputation and stringent manufacturing processes.

- Aftermarket Alternatives: Usually more affordable, appealing to budget-conscious consumers, but potential risks regarding quality may exist.

Ultimately, selecting between original and alternative options requires weighing factors such as reliability, cost, and the specific needs of the equipment.

Step-by-Step Repair Instructions

When it comes to maintaining your outdoor equipment, understanding the repair process can save you time and money. This guide provides a comprehensive approach to fixing common issues you may encounter with your device. Following these detailed steps ensures that you restore functionality efficiently.

Before starting any repair work, gather the necessary tools and replacement components. It is crucial to have everything on hand to avoid interruptions during the process. Below is a table outlining the essential tools and their respective purposes:

| Tool | Purpose |

|---|---|

| Wrench Set | Loosening and tightening bolts |

| Screwdriver Set | Removing and securing screws |

| Pliers | Gripping and manipulating components |

| Replacement Blades | Ensuring efficient cutting |

| Protective Gear | Safeguarding against injuries |

Once you have gathered your tools, begin by disconnecting the power source to ensure safety. Inspect the unit for any visible damage and consult the manufacturer’s manual for specific guidance related to your model. Step through the repair process methodically, checking off completed tasks to stay organized.

After the repair is finished, reassemble the unit and test it to ensure everything is functioning correctly. Regular maintenance will prolong the life of your equipment and enhance its performance.

Tools Required for Disassembly

To effectively dismantle the equipment, having the appropriate tools is crucial. The right instruments not only facilitate the process but also ensure that components remain undamaged during removal. Below is a list of essential tools needed for disassembly.

- Socket Wrench Set – Useful for loosening and tightening bolts.

- Screwdriver Set – Both flathead and Phillips types are needed for various screws.

- Adjustable Wrench – Ideal for gripping and turning nuts and bolts of different sizes.

- Pliers – Handy for holding or bending components as required.

- Torque Wrench – Ensures that bolts are tightened to the correct specifications upon reassembly.

- Utility Knife – Helpful for cutting through any bindings or straps.

Having these tools readily available will make the disassembly process smoother and more efficient.

Frequently Asked Questions on FS75 Parts

This section addresses common inquiries regarding components related to the specified model. It provides insights into compatibility, maintenance, and sourcing replacement items to ensure optimal performance.

What components are essential for maintenance?

Regular upkeep requires several key elements, including filters, trimmer lines, and cutting tools. Ensuring these items are in good condition is crucial for efficient operation.

Where can I find quality replacements?

Quality substitutes can be sourced from authorized dealers, online marketplaces, or specialty stores. Always check for compatibility with your specific equipment to avoid issues during installation.