Maintaining high-performance cleaning equipment requires a clear understanding of its individual components and how they interact within the machine. Identifying and knowing the specific parts of the system is essential for effective troubleshooting, repairs, and upgrades. Each part serves a critical role in ensuring the equipment functions efficiently and lasts for years, even under constant use.

Proper maintenance starts with understanding how each element fits into the overall assembly. From the motor to the spray nozzle, every piece contributes to the machine’s ability to generate high pressure and deliver a powerful stream of water. For anyone looking to repair or replace parts, a clear overview of the layout can save time and help prevent costly mistakes.

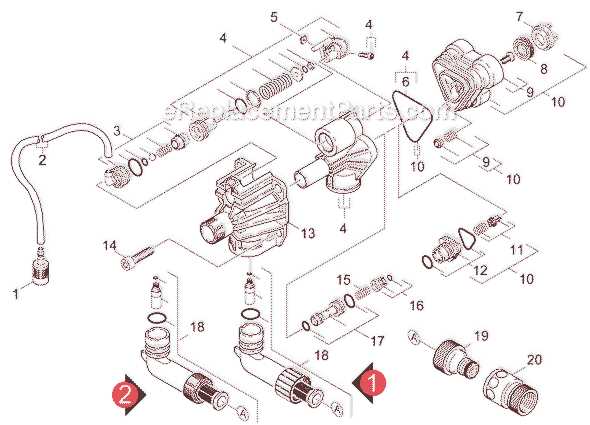

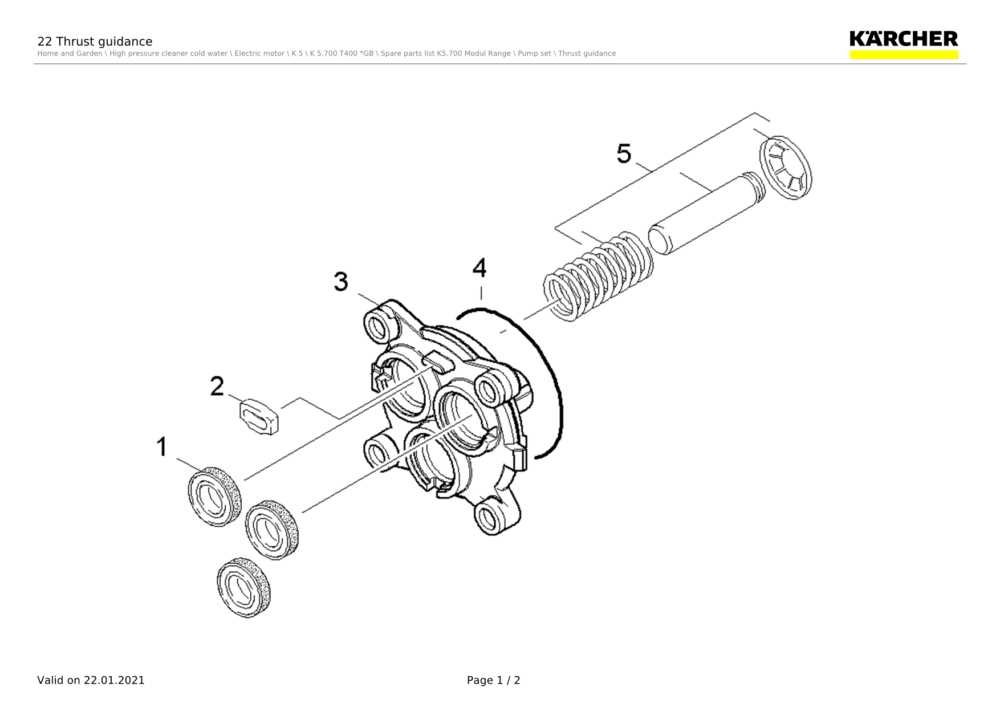

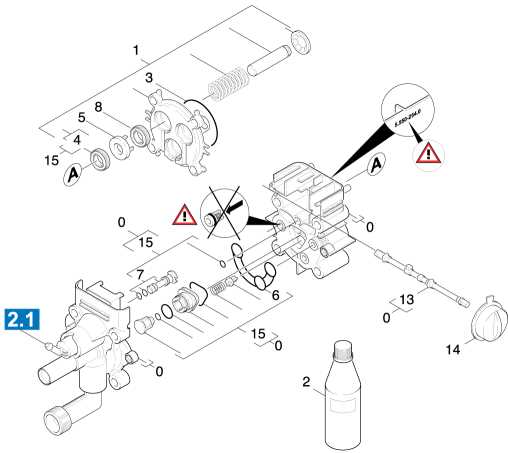

For those seeking to better manage their cleaning devices, reviewing a visual reference of these components provides an invaluable guide. This insight is not only useful for ensuring longevity but also for recognizing when parts may be wearing out or need adjustment. A comprehensive view of the internal structure can assist in the decision-making process, whether you are assembling a new device or restoring an older one.

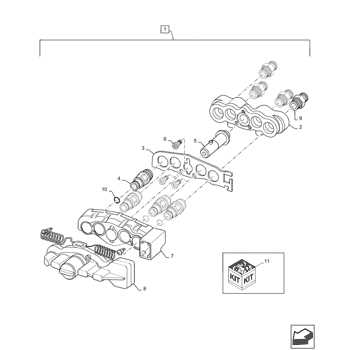

Karcher K1700 Parts Overview

Understanding the key components of a high-pressure cleaner is essential for efficient operation and maintenance. This overview covers the critical elements that make up this powerful cleaning machine, helping users identify and manage its various sections. Familiarity with the device’s structure allows for better troubleshooting, part replacement, and overall machine care.

Below is a breakdown of the main sections and elements that you will find in the machine, ensuring smooth performance and longer lifespan:

- Power Unit: Includes the motor and electrical components essential for operation.

- Water Pump: Responsible for pressurizing the water for effective cleaning.

- Hose and Nozzle Assembly: The system through which water is delivered to the surface being cleaned.

- Wheels and Frame: Ensures mobility and structural support of the device.

- Trigger Gun and Spray Wand: Controls water flow and directs the spray for targeted cleaning.

- Filter and Safety Valve: Protects the system from debris and controls pressure regulation.

By being familiar with these core components, users can ensure optimal functioning and quickly address any necessary repairs or replacements.

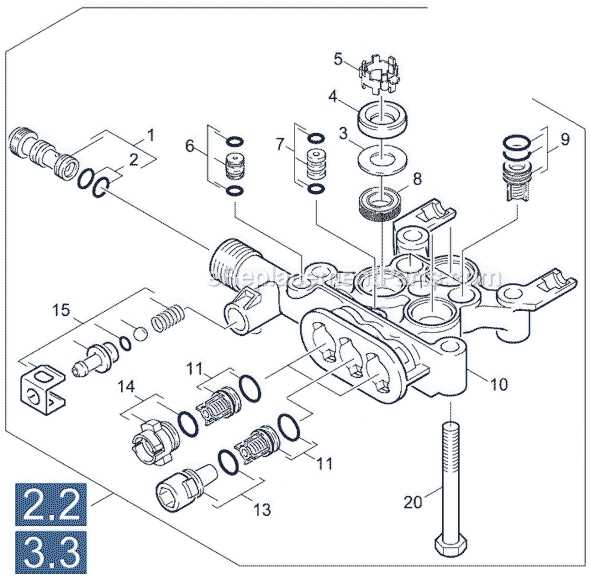

Understanding the Parts Diagram

When working with a pressure washer, it’s essential to have a clear understanding of the different components that make up the unit. Each element plays a crucial role in ensuring the device functions effectively and efficiently. By familiarizing yourself with the layout and structure of the machine, you can easily identify any areas that may need attention or replacement, helping to prolong the lifespan of the equipment.

Key Components and Their Functions

The machine consists of various interconnected parts that work together to provide high-performance cleaning. The motor, pump, and nozzle are some of the most important elements, as they directly influence the pressure and water flow. Other parts, such as the hose, filters, and connections, contribute to the overall functionality and ease of use. Understanding how each component interacts allows for better maintenance and troubleshooting.

Importance of Visual Guides

Having a visual reference, such as an illustration, allows for easier identification of parts when performing repairs or upgrades. A clear guide helps to locate specific components quickly, reducing downtime and preventing unnecessary damage. Knowing the exact positioning of each element also ensures that reassembly after maintenance is correct, minimizing the risk of malfunctions.

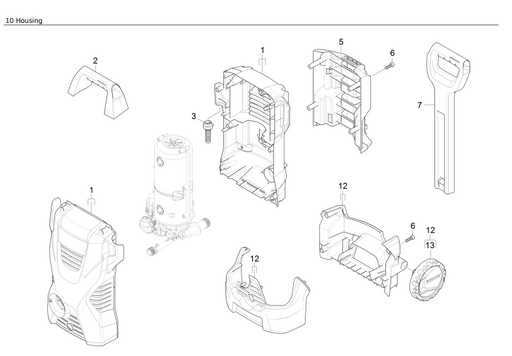

Essential Components of K1700

Understanding the key elements of a pressure cleaning machine is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance and longevity of the equipment.

- Motor: The heart of the machine, providing the necessary power to generate high-pressure water flow.

- Pump: Converts mechanical energy from the motor into hydraulic energy, responsible for creating pressure.

- Spray Gun: The interface for the user, allowing for precise control over water pressure and flow rate.

- Nozzles: Various attachments that modify the spray pattern, making it suitable for different cleaning tasks.

- Hoses: Essential for transporting water from the unit to the cleaning surface, with varying lengths and durability.

- Chassis: The frame that holds all components together, providing stability and support during operation.

Each of these elements works in harmony to deliver efficient cleaning results. Regular inspection and maintenance of these components will help ensure the machine operates smoothly and effectively over time.

Common Issues and Solutions

When utilizing pressure cleaning equipment, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their remedies can enhance the overall experience and prolong the lifespan of the device. Below are some frequent issues faced by users, along with effective solutions to address them.

Low Pressure

A frequent complaint is a decrease in pressure during operation. This can stem from several factors, including clogged nozzles or filters. To resolve this issue, inspect the nozzle for blockages and clean it thoroughly. Additionally, check the water supply for adequate flow and ensure that hoses are free of kinks or leaks.

Motor Not Starting

If the motor fails to start, it can be frustrating. Begin by examining the power source, ensuring that the electrical outlet is functioning. Check for any blown fuses or tripped breakers. If the power supply is intact, inspect the connections and wiring for any signs of damage. If the issue persists, it may be necessary to consult a professional for further diagnosis.

How to Read the Diagram

Understanding a schematic representation can greatly enhance your ability to identify and locate essential components within a device. This process involves familiarizing yourself with symbols and layouts, enabling you to navigate the information efficiently.

Familiarize Yourself with Symbols

Each element in the illustration corresponds to specific features or components. By recognizing common symbols, you can quickly interpret what each part represents, facilitating a deeper comprehension of the overall structure.

Follow the Flow of Information

Observe the connections and pathways shown in the representation. These lines often indicate the relationships between different elements, guiding you in understanding how they interact and function together. This flow is crucial for troubleshooting and maintenance.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the extended life of your equipment. Regular maintenance not only enhances performance but also helps prevent costly repairs. By following a few simple guidelines, you can keep your device in optimal condition.

1. Regular Cleaning: After each use, make sure to clean the exterior and any accessible components. This prevents dirt buildup and ensures smooth operation.

2. Check Fluid Levels: Regularly inspect and top off any necessary fluids. Maintaining the right levels is crucial for efficient performance.

3. Inspect for Wear: Frequently examine all parts for signs of wear or damage. Early detection can save you from more significant issues later.

4. Store Properly: When not in use, store the device in a dry, cool place. Proper storage conditions help prevent rust and degradation.

5. Follow Manufacturer Guidelines: Adhering to the manufacturer’s recommendations for maintenance and service intervals will ensure optimal performance and longevity.

Identifying Worn-Out Parts

Recognizing components that have lost their effectiveness is crucial for maintaining optimal performance. Regular inspection helps in early detection of wear, which can prevent further damage and costly repairs. Understanding the signs of degradation can extend the lifespan of your equipment and enhance its efficiency.

Common Indicators of Wear

Several signs indicate that a component may be nearing the end of its functional life. Look for cracks, discoloration, or unusual noises during operation. These symptoms often suggest that a replacement might be necessary. Additionally, leaks or reduced performance can also be significant red flags that should not be overlooked.

Regular Maintenance Checks

Implementing a routine maintenance schedule is essential for identifying worn components early. Regularly examine critical areas and use the manufacturer’s recommendations as a guideline. By staying proactive, you can ensure that your machinery operates at peak efficiency and avoid unexpected breakdowns.

Replacement Parts Availability

When it comes to maintaining high-performance cleaning equipment, accessibility to essential components is crucial. A well-stocked supply of replacement elements ensures that users can easily restore functionality and prolong the lifespan of their machines.

Sources for Components

There are various outlets where one can find these crucial items, ranging from online retailers to local hardware stores. Often, authorized dealers provide the most reliable options, ensuring compatibility and quality.

Importance of Quality

Choosing high-quality alternatives can significantly impact the effectiveness and durability of your equipment. Investing in superior replacements not only guarantees optimal performance but also contributes to the overall safety during operation. Remember to check for warranties or return policies to safeguard your purchase.

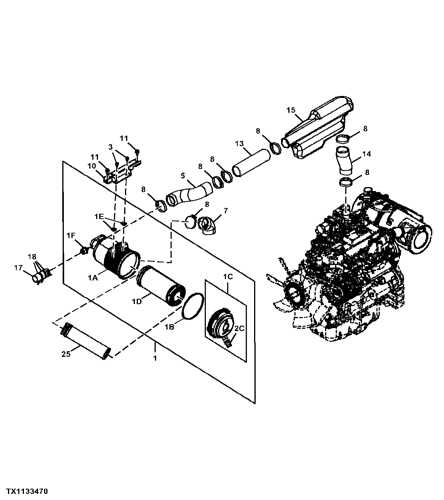

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing common issues found in pressure cleaning devices. By following a structured methodology, you can effectively troubleshoot and restore functionality to your equipment, ensuring it operates at peak performance.

| Step | Description |

|---|---|

| 1 | Disconnect the device from the power source to ensure safety before beginning any repairs. |

| 2 | Inspect all components for visible wear or damage; take note of parts that need replacement. |

| 3 | Gather necessary tools and replacement components to streamline the repair process. |

| 4 | Carefully disassemble the unit, keeping track of all screws and small parts to avoid loss. |

| 5 | Replace any damaged components with new parts, ensuring a proper fit and alignment. |

| 6 | Reassemble the device, making sure all connections are secure and the unit is properly sealed. |

| 7 | Reconnect to the power source and conduct a test run to verify that the repairs were successful. |

Upgrading K1700 Performance Parts

Enhancing the efficiency of your pressure washer can significantly improve its performance and longevity. By focusing on specific components that optimize functionality, you can achieve superior results in your cleaning tasks. This section explores the ultimate options for upgrades that will take your machine’s capabilities to the next level.

Firstly, consider investing in a high-quality nozzle. A precise nozzle can increase the pressure and improve the spray pattern, allowing for more effective dirt removal. Additionally, selecting a nozzle suited for your specific cleaning needs will maximize efficiency.

Secondly, upgrading the motor can provide more power and enhance durability. A robust motor can handle tougher jobs and reduce wear over time. Choosing an energy-efficient model also helps in reducing operational costs while maintaining high performance.

Lastly, inspecting and replacing worn hoses ensures that water flow remains unobstructed. A new, durable hose can withstand higher pressures and prevent leaks, which directly impacts cleaning efficiency. Combining these upgrades will ultimately lead to a more powerful and reliable machine.

Safety Precautions During Repairs

When undertaking maintenance or fixing equipment, ensuring safety is paramount. Proper precautions help prevent accidents and injuries, allowing for a smooth and efficient repair process. Familiarizing oneself with safety protocols is essential for both novice and experienced individuals in any repair scenario.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Ensure that the equipment is disconnected from any power source before beginning repairs.

- Keep the workspace organized and free of clutter to prevent tripping hazards.

- Follow the manufacturer’s instructions carefully to avoid improper handling.

Handling Tools and Components

- Use tools that are suitable for the specific task at hand to reduce the risk of accidents.

- Inspect tools for any signs of wear or damage before use.

- Store tools in designated places to prevent losing them and causing unnecessary distractions.

- Handle all components carefully, particularly those that are fragile or sharp.

By adhering to these guidelines, one can significantly reduce risks associated with repairs, ensuring a safer environment for all involved.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and repair of pressure cleaning equipment. Understanding the nuances of these devices can greatly enhance their performance and longevity.

What are the most common issues faced with pressure washers?

Common problems include loss of pressure, leaks, and starting difficulties. Regular inspection can help prevent these issues.

How can I identify the specific components needed for repair?

Referencing a detailed schematic can be immensely helpful in pinpointing the exact parts required for your device.

Are there any maintenance tips to extend the life of my cleaning equipment?

Routine cleaning, proper storage, and timely replacement of worn components are essential for maximizing lifespan.

Where can I find replacement parts?

Replacement components are typically available through authorized retailers, online marketplaces, or dedicated service centers.

What should I do if I can’t resolve an issue on my own?

Consulting a professional technician can provide the ultimate assistance in troubleshooting and repairs, ensuring optimal functionality.