In the realm of outdoor power equipment, comprehending the intricate layout of various elements is crucial for effective maintenance and repair. Each machine is a culmination of numerous individual parts, each playing a pivotal role in the overall functionality. By familiarizing oneself with these components, users can ensure their tools operate at peak performance and longevity.

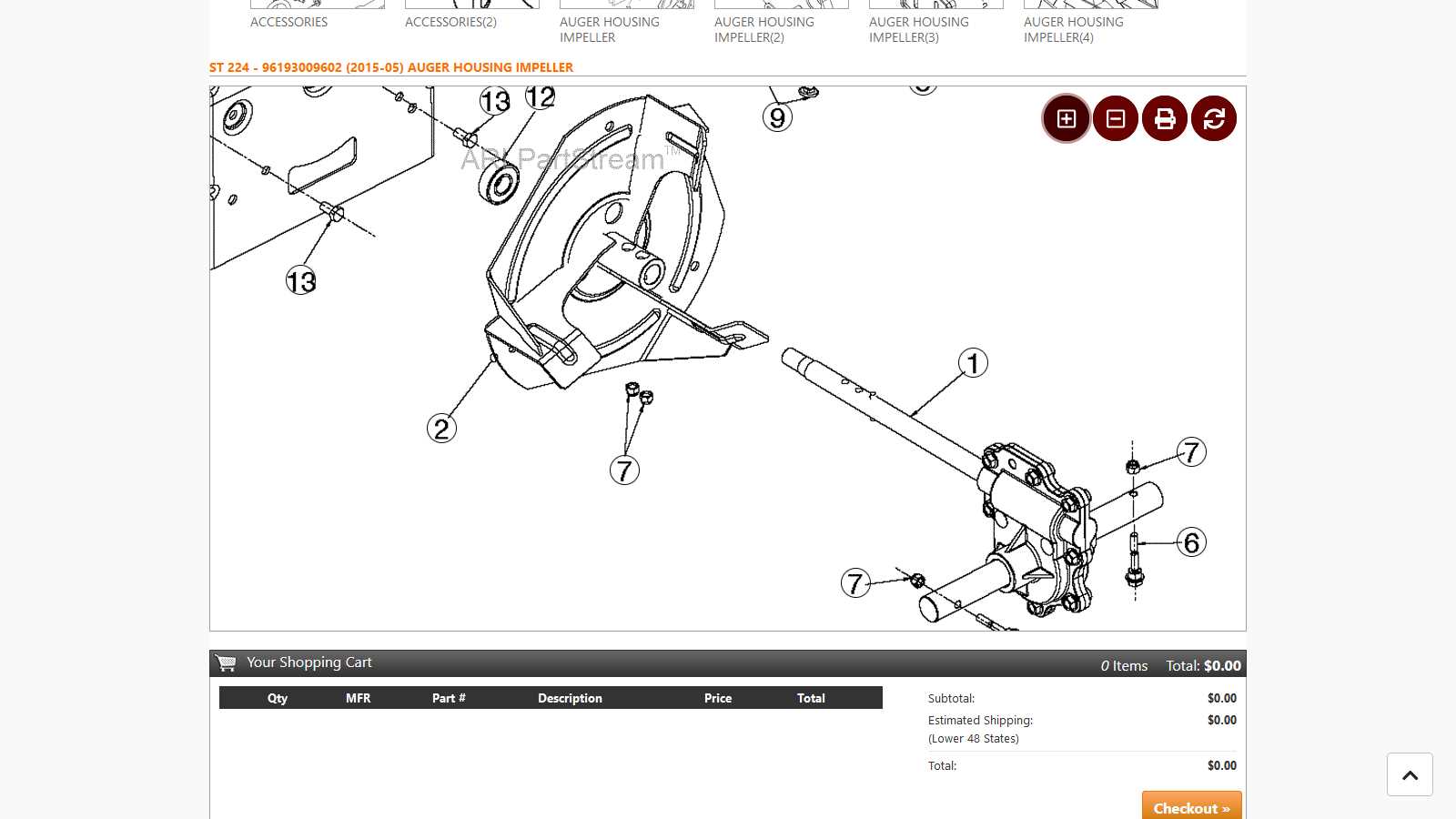

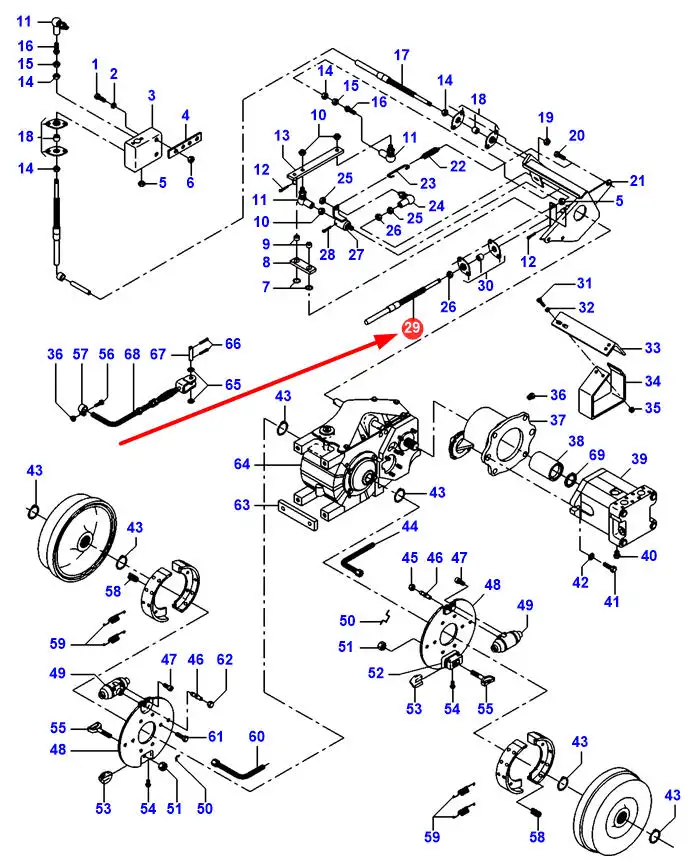

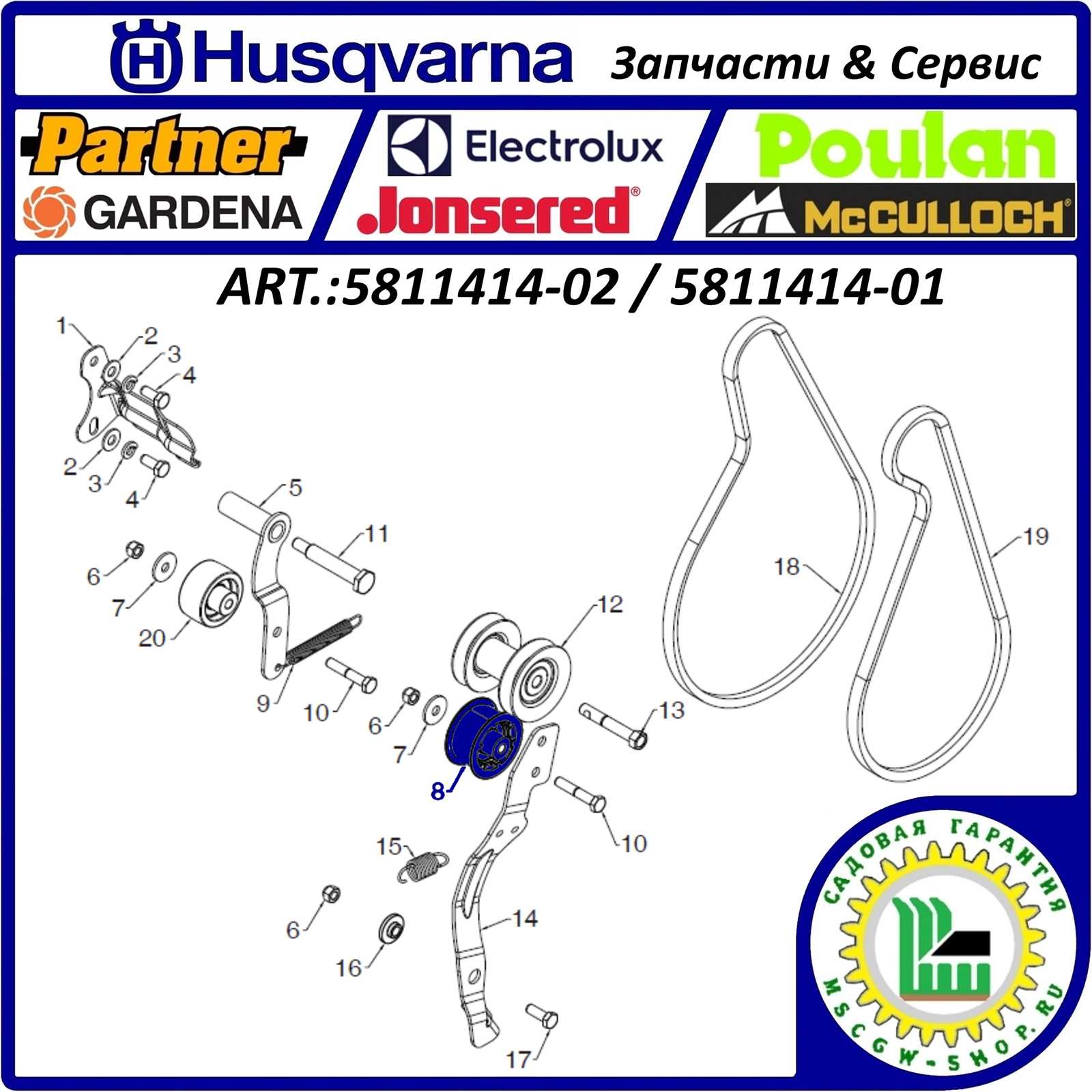

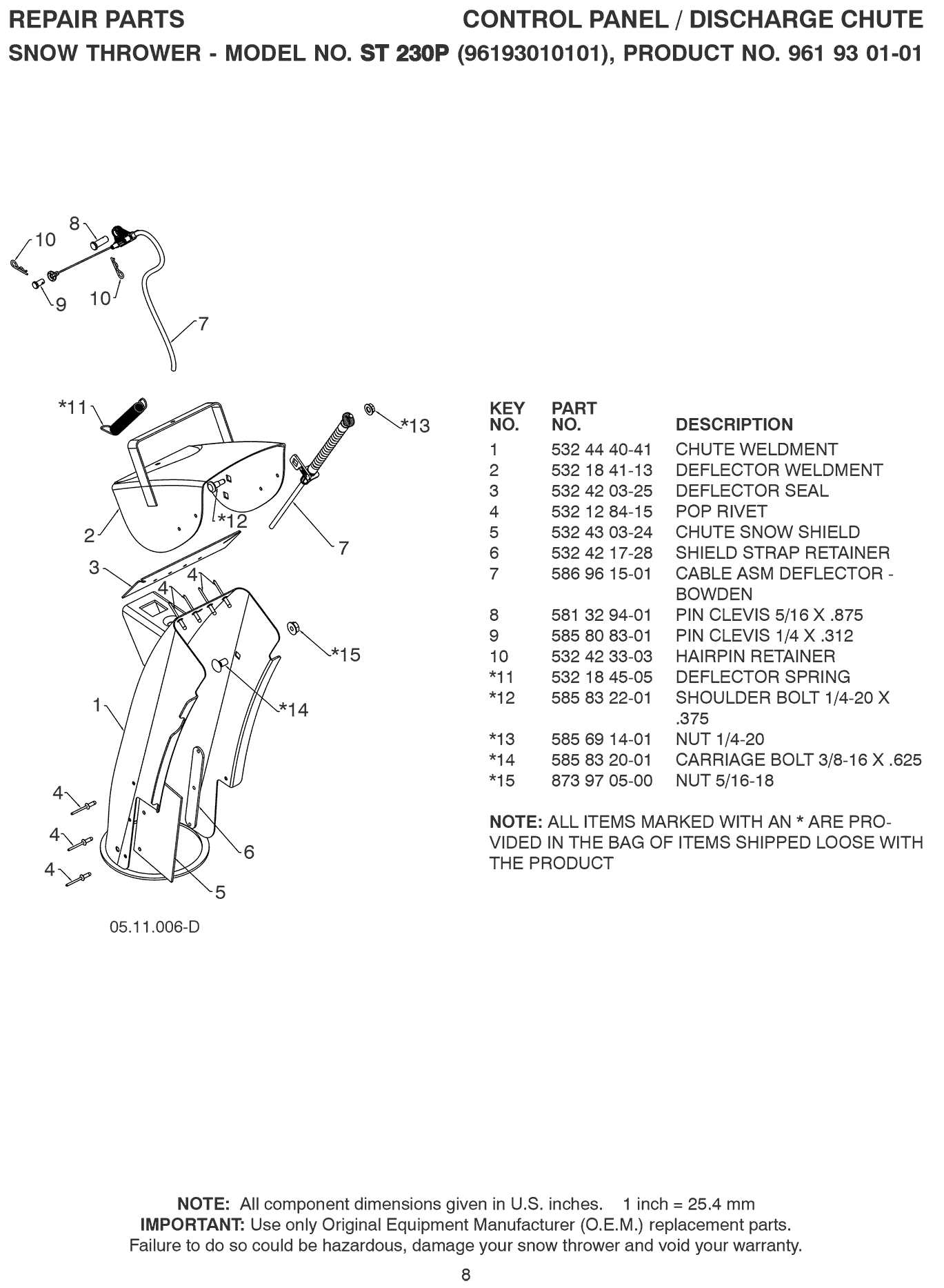

The visual representation of these elements can serve as an invaluable reference for both novice and experienced users. Such illustrations not only highlight the placement of each part but also aid in identifying potential issues that may arise during operation. Whether for troubleshooting or routine maintenance, understanding this layout can empower users to take charge of their equipment’s upkeep.

Moreover, detailed depictions can simplify the process of acquiring replacements when needed. Recognizing specific components enables users to efficiently locate and procure the necessary items, minimizing downtime and enhancing productivity. As such, having a clear grasp of the arrangement and function of these elements is essential for anyone invested in maintaining their machinery.

Understanding Husqvarna ST230P Components

Exploring the intricacies of a snow-clearing machine reveals a complex interplay of various elements that work together to ensure efficient operation. Each component plays a crucial role, contributing to the overall functionality and performance of the equipment. A comprehensive grasp of these elements allows users to troubleshoot issues effectively and maintain optimal performance.

The engine serves as the heart of the machine, providing the necessary power to drive other components. A well-maintained engine ensures smooth operation and enhances longevity.

The auger is responsible for breaking up and gathering snow, effectively aiding in the clearing process. Understanding its design and maintenance requirements can prevent blockages and improve efficiency.

The chute directs the expelled snow, allowing users to control where the snow is thrown. Familiarity with its adjustment mechanisms can significantly enhance maneuverability during use.

Controls and levers provide the operator with the ability to adjust speed and direction, making them vital for user-friendly operation. Regular inspection ensures they function properly and respond as expected.

Finally, the chassis supports all components, contributing to stability and balance. Awareness of its structure and potential wear can aid in prolonging the machine’s life and maintaining its performance.

Key Features of Husqvarna ST230P

This model stands out in its category, offering an impressive blend of performance and user-friendly design. With advanced engineering, it provides excellent efficiency in various winter conditions, making snow clearing tasks easier and more effective for homeowners and professionals alike.

Powerful Engine

Equipped with a robust engine, this equipment delivers exceptional power and torque. The high-performance motor ensures reliable operation, even in heavy snow, allowing users to tackle challenging weather conditions without hassle. Efficiency and durability are hallmarks of this design, making it a reliable choice for many seasons.

Ergonomic Design

The ergonomic layout enhances comfort during use. Features such as adjustable handles and easy-to-reach controls enable smooth operation and reduce fatigue. Additionally, the built-in headlights improve visibility, ensuring safe and efficient work during early mornings or late evenings. Safety and convenience are prioritized in every aspect of its construction.

Importance of Parts Diagrams

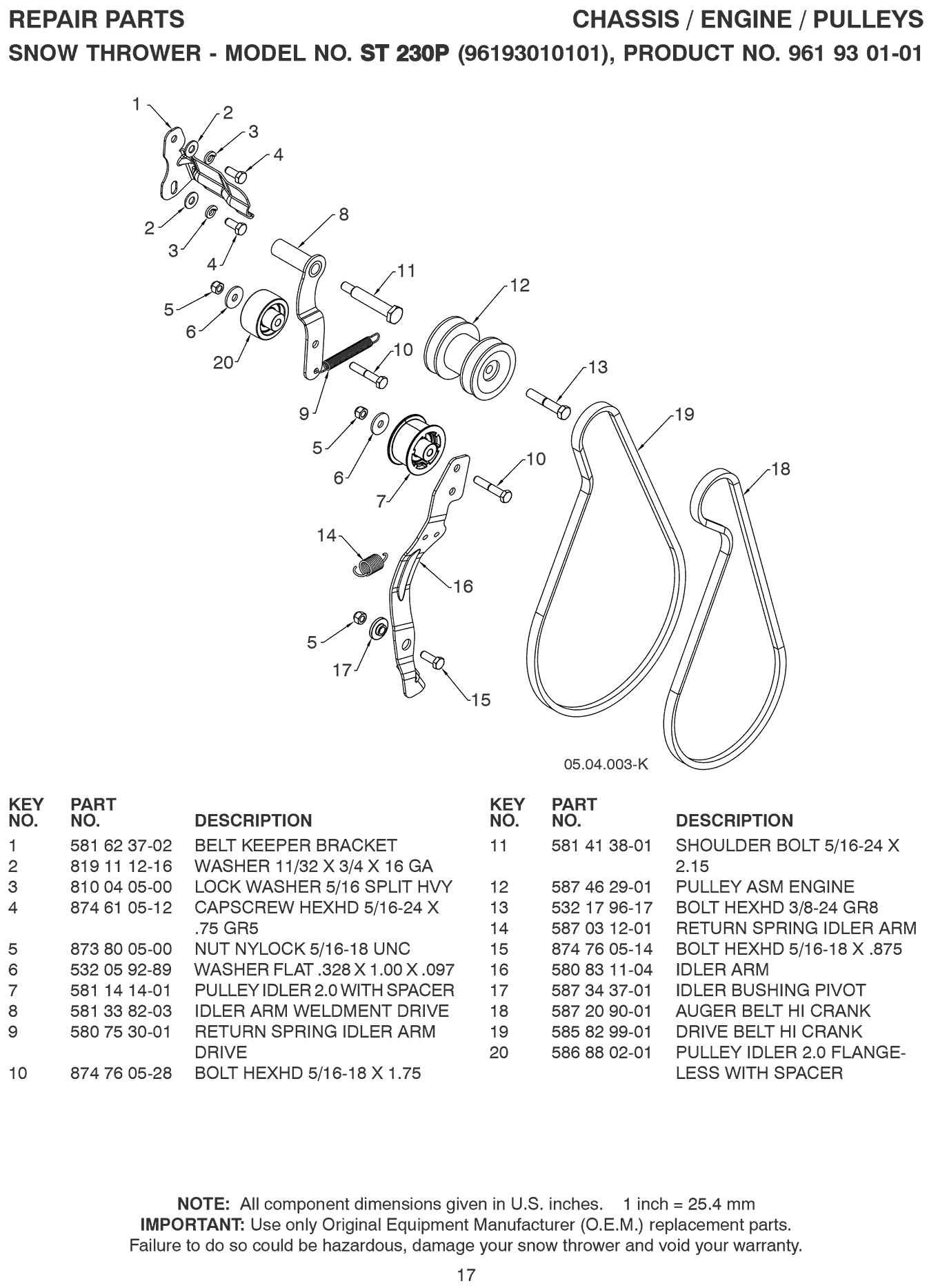

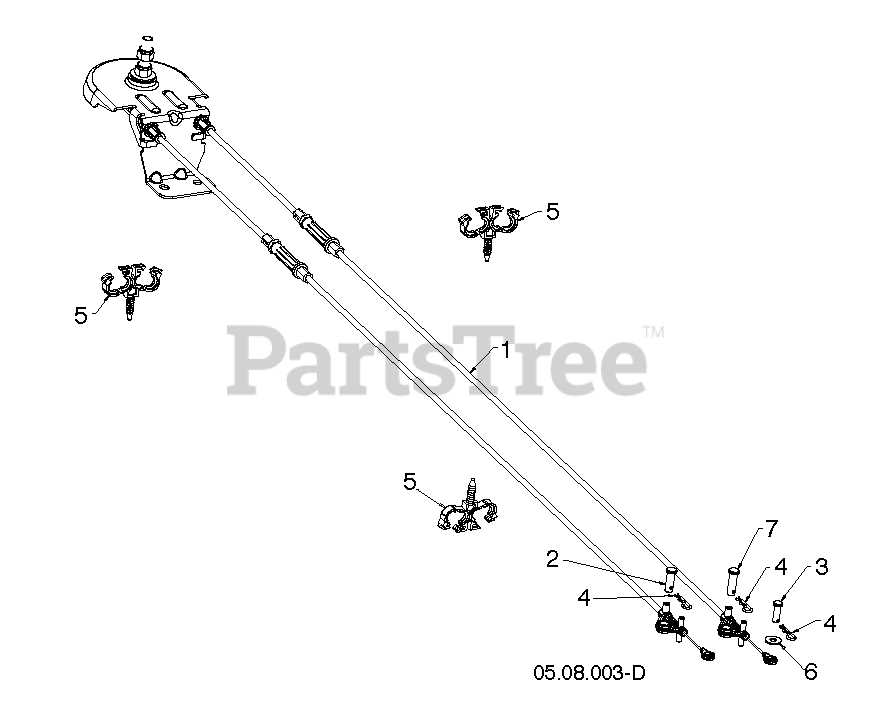

Understanding the layout and components of any machinery is crucial for effective maintenance and repair. Visual representations that illustrate each element play a significant role in ensuring proper functionality and longevity. They not only facilitate easier identification of parts but also enhance the overall efficiency of repair processes.

Enhancing Maintenance Efficiency

When technicians have access to visual aids, they can quickly locate and assess the condition of individual components. This expedites troubleshooting and minimizes downtime. Furthermore, a clear overview aids in understanding how various pieces interact, which is essential for diagnosing issues accurately.

Streamlining Replacement Processes

Detailed visual guides simplify the process of replacing worn or damaged elements. By providing a comprehensive view, these resources ensure that the correct items are chosen and installed properly. This reduces the risk of errors that could lead to further complications, thereby saving both time and resources.

In summary, visual representations are indispensable tools in the realm of equipment maintenance and repair, promoting efficiency and precision.

Common Issues with ST230P Parts

When maintaining outdoor power equipment, users often encounter various complications that can hinder performance and efficiency. Understanding these common challenges is essential for ensuring reliable operation and prolonging the lifespan of your machine. Frequent wear and tear, as well as occasional malfunctions, can lead to the need for replacement components or adjustments.

Wear and Tear

Over time, certain components may experience significant degradation due to regular use. This wear can manifest as decreased efficiency, unusual noises, or even complete failure. It’s crucial to routinely inspect these elements to catch issues early and maintain optimal functionality.

Installation Errors

Another frequent problem arises from incorrect installation of replacement items. Misalignment or improper attachment can lead to a cascade of complications, ultimately resulting in decreased performance or further damage. Ensuring that every part is installed according to manufacturer specifications is vital for preventing such issues.

How to Interpret Parts Diagrams

Understanding the visual representations of components is essential for effective maintenance and repair. These illustrations provide a detailed overview of each element within a machine, allowing users to identify specific parts and their functions. By mastering the interpretation of these graphics, individuals can streamline their repair processes and ensure accurate replacements.

To effectively decode these visuals, follow these key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout and numbering system used in the illustration. |

| 2 | Identify the main components and their relationships to one another. |

| 3 | Refer to the accompanying list for detailed part names and numbers. |

| 4 | Cross-reference the information with your equipment to confirm compatibility. |

| 5 | Take notes on any special instructions or warnings related to specific elements. |

By following these steps, you can enhance your understanding of the components and ensure you have the right items for your repair tasks.

Where to Find Replacement Parts

Locating components for your equipment can sometimes feel daunting, but there are numerous reliable sources available. Understanding where to look can make the process smoother and ensure you get the right items for your needs.

Online Retailers

Many websites specialize in outdoor equipment and machinery components. Here are a few options to consider:

- Dedicated machinery websites

- Major e-commerce platforms

- Manufacturer-authorized online stores

Local Suppliers

In addition to online options, visiting local suppliers can be beneficial. They often have a selection of components on hand, and knowledgeable staff can assist you:

- Hardware stores

- Specialty outdoor equipment shops

- Garden centers with a focus on tools

Whether you choose to shop online or visit a local store, ensuring compatibility with your machinery is crucial. Always verify specifications before making a purchase to avoid any inconvenience.

Tools Needed for Maintenance

Proper upkeep of your equipment requires a specific set of instruments to ensure optimal performance and longevity. These essential tools enable you to effectively address routine tasks, troubleshoot issues, and replace worn components, contributing to the overall efficiency of your machine.

Essential Tools

Here is a list of the fundamental instruments you will need for maintenance:

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening or loosening bolts and nuts. |

| Screwdriver Set | For assembling or disassembling components. |

| Oil Can | To lubricate moving parts and prevent wear. |

| Filter Wrench | For removing and replacing oil filters. |

| Safety Goggles | To protect your eyes during maintenance activities. |

Additional Recommendations

In addition to the basic tools listed, consider having a few extra items on hand. A multimeter can be invaluable for electrical diagnostics, while a cleaning brush will help maintain optimal cleanliness of components. Keeping these tools organized will facilitate quicker and more efficient maintenance sessions.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues associated with your equipment. By following a structured method, you can effectively identify problems and apply the necessary repairs, ensuring optimal performance and longevity.

Preparation

- Gather essential tools: screwdriver, wrench, pliers, and replacement components.

- Refer to the user manual for specific guidelines relevant to your model.

- Ensure a clean, well-lit workspace to facilitate your repair process.

Troubleshooting Steps

- Identify the symptoms: Note any unusual noises, leaks, or performance issues.

- Inspect visible components: Check for wear, damage, or loose connections.

- Test functionality: Conduct basic tests to isolate the problem area.

- Replace or repair faulty parts: Utilize the appropriate replacement parts to address issues.

- Reassemble and test: Ensure all components are securely reattached before powering on.

By adhering to this guide, you can tackle repairs confidently, restoring your equipment to peak condition.

Safety Precautions During Repairs

When undertaking maintenance tasks on outdoor equipment, ensuring personal safety is paramount. Proper precautions not only protect the individual performing the work but also prevent damage to the machinery. By adhering to specific guidelines, one can mitigate risks associated with mechanical repairs.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) to shield yourself from potential hazards. This includes gloves to protect your hands, goggles to safeguard your eyes from debris, and sturdy footwear to prevent injuries from falling objects. Consider using ear protection if the machinery produces high noise levels.

Work Environment Safety

Maintain a clean and organized workspace. Clear away any unnecessary tools or materials that could pose tripping hazards. Ensure adequate lighting to prevent accidents while working. Additionally, make sure that the equipment is powered off and disconnected from any power sources before beginning any repair tasks. This precaution helps avoid accidental startups, which could lead to serious injuries.

Comparing ST230P with Other Models

When evaluating various snow removal machines, it’s essential to consider their features, performance, and overall usability. Each model brings unique strengths and weaknesses, making it crucial for potential buyers to understand how they stack up against each other. This comparison will highlight key aspects that differentiate one model from another, helping users make informed decisions.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 200 cc | 250 cc | 220 cc |

| Clearing Width | 24 inches | 30 inches | 26 inches |

| Weight | 85 lbs | 110 lbs | 95 lbs |

| Drive System | Single-stage | Two-stage | Single-stage |

| Headlight | No | Yes | Yes |

Understanding these differences allows users to identify which machine best fits their specific needs. Whether prioritizing power, clearing width, or additional features like headlights, each option caters to different requirements in the snow removal process. Thus, it’s essential to carefully assess these models based on individual preferences and local conditions.

Tips for Prolonging Lifespan

Ensuring the longevity of your equipment requires a combination of regular maintenance, careful operation, and timely repairs. By following certain practices, you can significantly extend the life of your machine and improve its performance. These steps are essential for preventing wear and tear and ensuring that your investment remains reliable for years to come.

Regular Maintenance

Implementing a consistent maintenance schedule is crucial. This includes routine inspections, cleaning, and lubrication of moving parts. Check for signs of wear, replace filters, and ensure that all components are functioning correctly. Regular maintenance not only helps in identifying potential issues early but also keeps the machine operating at optimal efficiency.

Proper Usage

Using your equipment according to the manufacturer’s guidelines is essential. Avoid overloading and be mindful of the conditions in which you operate the machine. Proper handling and usage can prevent unnecessary strain and damage. Additionally, storing the equipment in a safe, dry place will protect it from environmental factors that could lead to deterioration.

Customer Reviews and Feedback

This section aims to provide insights from users regarding their experiences with the product. Collecting feedback helps potential buyers make informed decisions and understand the strengths and weaknesses from a practical standpoint.

Positive Experiences

Many users have expressed satisfaction with the overall performance and reliability. Durability and ease of use are frequently highlighted, making it a preferred choice for various tasks. Customers appreciate the powerful engine and efficient design, which contribute to a smooth operation even under challenging conditions.

Areas for Improvement

While the feedback is largely positive, some users have noted areas that could benefit from enhancement. A few have mentioned the need for clearer assembly instructions and better customer support options. Addressing these issues could further elevate user satisfaction and make the experience more seamless for newcomers.