The functionality of any agricultural vehicle relies heavily on its individual components. A comprehensive exploration of these elements not only aids in maintenance but also enhances overall performance. Familiarity with various sections and their specific roles contributes to the efficient operation of such machinery.

In this context, having access to a detailed visual representation of these components becomes invaluable. This type of resource allows users to identify each part easily and understand how they interconnect within the entire system. Whether for routine inspections or extensive repairs, grasping the layout of these elements ensures that users can effectively troubleshoot issues as they arise.

Furthermore, understanding the specific names and functions of each section fosters better communication when seeking assistance or ordering replacements. This clarity can significantly reduce downtime, enabling operators to maintain productivity on their farms. Thus, delving into the intricacies of these components empowers users to manage their equipment more proficiently.

Key Features of Ford 6640 Model

This agricultural machinery model is renowned for its robust design and versatility, making it a valuable asset for various farming tasks. With a combination of advanced technology and practical functionality, it caters to the needs of modern agriculture.

- Powerful Engine: Equipped with a reliable power unit, ensuring optimal performance for demanding tasks.

- Efficient Transmission: Features a smooth-shifting transmission system, enhancing ease of use and responsiveness.

- Durable Construction: Built with high-quality materials, offering longevity and resilience in tough working conditions.

- Comfortable Cab: Designed with operator comfort in mind, providing an ergonomic environment for extended use.

- Advanced Hydraulics: Incorporates a sophisticated hydraulic system, enabling effective attachment and implement management.

- Versatile Attachments: Compatible with a wide range of tools and implements, increasing its adaptability for various agricultural tasks.

The combination of these features allows for efficient operation, making it an excellent choice for farmers seeking reliability and performance.

Identifying Essential Parts in Diagrams

Understanding the components within technical schematics is crucial for efficient maintenance and repair. By recognizing the most important elements, users can quickly address issues and ensure proper functionality of equipment.

Main Components Overview

The key elements in any schematic can be categorized into several groups, which help in visualizing the full mechanism. These categories allow users to differentiate between mechanical, electrical, and fluid components.

- Mechanical elements – responsible for movement and structural support.

- Electrical components – powering the system and enabling automated functions.

- Fluid control systems – managing the flow of liquids essential for cooling or operation.

How to Locate Critical Components

When examining a technical schematic, specific symbols and labels indicate critical areas to focus on. Familiarizing yourself with these symbols simplifies

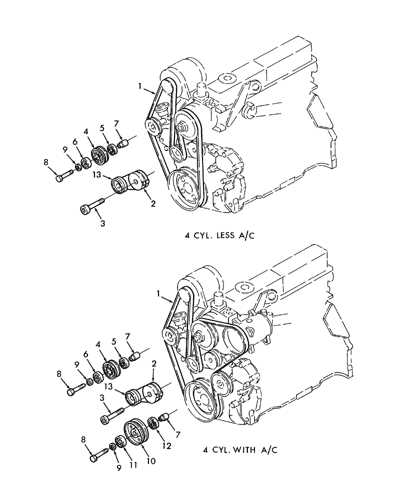

Understanding the Engine Assembly Layout

Comprehending the overall arrangement of the engine is crucial for maintaining and repairing mechanical systems. The structure of an engine involves several interconnected components working together to generate power and ensure smooth operation. Each part has a specific role, contributing to the efficiency and performance of the machinery.

- Block assembly: This is the main structure housing the cylinders, which is fundamental to the overall operation.

- Cylinder head: Located on top of the block, it contains important elements like valves and injectors that play key roles in combustion.

- Crankshaft: Converts linear motion from the pistons into rotational energy, essential for movement.

- Pistons: Positioned within the cylinders, they compress air and fuel

Transmission System and Related Parts

The transmission mechanism plays a crucial role in ensuring smooth operation and power transfer within the machinery. It consists of several components that work in unison to regulate speed, control direction, and distribute power to various moving parts. Understanding the layout and function of these components is essential for maintaining the efficiency and longevity of the entire system.

Main Components of the Transmission

The core elements of the transmission system include gears, shafts, and clutches, which are responsible for shifting between different speed ratios and transferring power from the engine to the wheels. Each component must be in optimal condition to avoid potential breakdowns or inefficiencies in performance.

Auxiliary Systems

In addition to the primary components, the transmission system relies on supplementary mechanisms such as filters, pumps, and coolers. These elements ensure that the transmission fluid is properly circulated and maintained at

Hydraulic Components and Their Functions

The hydraulic system is essential for the operation of many machines, allowing smooth and efficient control of various mechanical movements. Understanding the key elements of this system helps in diagnosing issues and maintaining optimal performance. Below, we explore the main components and their specific roles within the hydraulic mechanism.

Pumps and Fluid Circulation

Pumps are critical in creating the necessary pressure for moving fluid through the system. These devices ensure that hydraulic fluid is consistently circulated, driving the movement of actuators and other components. The type of pump used can vary depending on the machine’s requirements.

Cylinders and Actuators

Cylinders and actuators convert hydraulic energy into mechanical force. Cylinders provide linear motion, while actuators may create rotational movements. Their efficient operation depends on the proper regulation of hydraulic pressure and flow.

Component Electrical System Wiring and Connections

The electrical wiring and connections are crucial for the reliable operation of the machine’s systems. Properly maintained circuits ensure that all components, such as lights, sensors, and starters, function efficiently. This section outlines key aspects of the wiring layout, common issues, and best practices for maintenance.

Wiring Layout Overview

The layout includes various connections that distribute power to critical components. Ensuring all wires are properly insulated and routed helps prevent short circuits and electrical malfunctions.

- Main power supply routing to the control units

- Grounding points for stable connections

- Fuses and relays to protect circuits

Common Wiring Issues

Over time, wiring can degrade, leading to potential failures. Regular inspection helps catch common problems such as loose connections or worn insulation.

- Cor

Cooling System Elements Explained

The cooling system in any engine plays a critical role in maintaining the optimal temperature during operation. It ensures that the engine doesn’t overheat by circulating coolant, which absorbs excess heat. Understanding the key components of this system helps in maintaining its efficiency and diagnosing potential issues.

Main Components

The system primarily consists of the radiator, water pump, thermostat, and hoses. The radiator is responsible for dissipating heat into the air, while the water pump ensures the constant flow of coolant through the engine. The thermostat regulates the temperature by controlling the coolant flow, and the hoses connect all these elements.

Role of Coolant

Coolant, often a mix of water and antifreeze, plays a dual role. It absorbs the

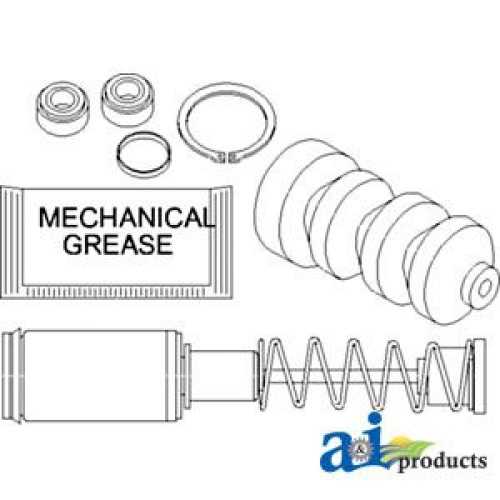

Common Wear Parts and Replacements

Machines and vehicles used in agriculture or heavy-duty tasks often experience wear on several key components over time. Regular usage in challenging environments can lead to the deterioration of specific elements, which require periodic inspection and replacement to maintain efficiency.

Hydraulic System Components

One of the most frequently affected areas is the hydraulic system. Seals, hoses, and pumps can degrade due to pressure and exposure to contaminants. Replacing these elements promptly ensures smooth operation and prevents more significant malfunctions.

Engine Components

The engine is another critical section that requires attention. Filters, belts, and bearings are prone to wear and should be regularly swapped out to keep the machine running at optimal performance. Ignoring these items can lead to costly repairs and prolonged downtime.

Maintenance Tips for Ford 6640

Ensuring the longevity and optimal performance of agricultural machinery requires regular upkeep and proper attention to various components. Routine check-ups and timely servicing help prevent breakdowns and improve overall efficiency.

Regular Fluid Checks

One of the most important tasks in maintaining any machine is to frequently inspect oil, coolant, and hydraulic fluid levels. Ensuring these are at appropriate levels can prevent overheating and ensure smooth operation. If fluid levels drop, top them up with the appropriate types, following manufacturer recommendations.

Inspecting the Electrical System

Regularly checking the battery and electrical wiring for corrosion or loose connections is essential to avoid any malfunctions. Cleaning the battery terminals and ensuring a strong connection will prevent starting issues and

Parts Diagram: Troubleshooting Guide

This guide provides an effective approach to identifying and resolving common issues with mechanical components. By following a visual reference and analyzing key areas, you can pinpoint malfunctions and determine the necessary steps for repair or replacement.

Common Problem Areas

Some frequent trouble spots include wear and tear on moving elements, fluid leaks, or loose connections. Checking these areas first can save time and help isolate the issue before moving to more complex diagnostics.

Step-by-Step Diagnostic Process

Begin by inspecting each section of the mechanism systematically. Ensure that all connections are secure, and no visible damage exists. If an issue persists, consult the visual reference to locate the specific area needing attention. Pay special attention

Aftermarket vs. OEM Parts Considerations

When choosing between alternative and original equipment components, there are several important factors to consider. Both options have their own strengths and drawbacks, which can affect performance, longevity, and cost. Understanding these differences is crucial for making an informed decision.

- Cost: Alternative options are typically more affordable, making them an attractive choice for budget-conscious buyers. However, the lower price may come at the cost of quality or durability.

- Quality: Original equipment components are manufactured to exacting standards, ensuring compatibility and long-lasting performance. On the other hand, aftermarket suppliers can vary in quality, so it’s important to research reputable brands.

- Warranty: Manufacturers often offer warranties for their original parts, providing peace of mind. Aftermarket components may not always come with the same level of coverage.

Where to Find Parts Diagrams Online

Locating visual references for machinery components is essential for maintenance and repairs. Numerous online platforms offer extensive collections of these resources, catering to various models and brands. By utilizing these resources, users can ensure they have accurate information to assist in their repair endeavors.

Official Manufacturer Websites

One of the most reliable sources for visual resources is the official website of the manufacturer. These sites often provide detailed illustrations along with specifications and part numbers, making it easier for users to find the exact items they need. Additionally, many manufacturers offer downloadable PDF manuals that include comprehensive visual aids.

Third-Party Retailers

Several online retailers specialize in equipment components and often feature detailed visual references. These platforms can be a great alternative for users seeking specific illustrations for various machinery. They may also provide user reviews and additional information about the components, enhancing the overall purchasing experience.