Understanding the intricate assembly of lawn care machinery is crucial for maintaining optimal performance. This section provides valuable insights into the various elements that contribute to the functionality of your gardening tools. By familiarizing yourself with these components, you can ensure efficient operation and longevity of your equipment.

Every model features a unique arrangement of critical elements that work in harmony to achieve precise cutting results. Identifying these individual pieces not only simplifies the repair process but also enhances your ability to troubleshoot common issues. Whether you’re replacing a worn-out item or performing routine maintenance, knowledge of the construction is invaluable.

In this guide, we will explore the specific features and arrangements of the essential components, offering detailed information that will empower you to make informed decisions. Dive into the intricacies of your equipment’s design and equip yourself with the expertise necessary for effective lawn management.

Understanding the John Deere 400 Mower

The equipment in question is designed for optimal performance and efficiency in maintaining landscapes. Its robust construction and innovative features cater to a variety of lawn care needs, making it a popular choice among homeowners and professionals alike.

Features play a crucial role in the functionality of this machine. Engine power, cutting width, and maneuverability contribute significantly to its effectiveness. Each element is engineered to enhance user experience while ensuring reliability in various conditions.

Moreover, maintenance is essential for longevity and peak performance. Familiarity with the components allows for timely replacements and repairs, ensuring that the device remains in top shape. Understanding how each part interacts can prevent issues and facilitate smoother operation.

Finally, knowing the accessories available for this machine can further enhance its capabilities. Attachments and additional tools can transform it to suit specific tasks, increasing versatility and productivity for users across different settings.

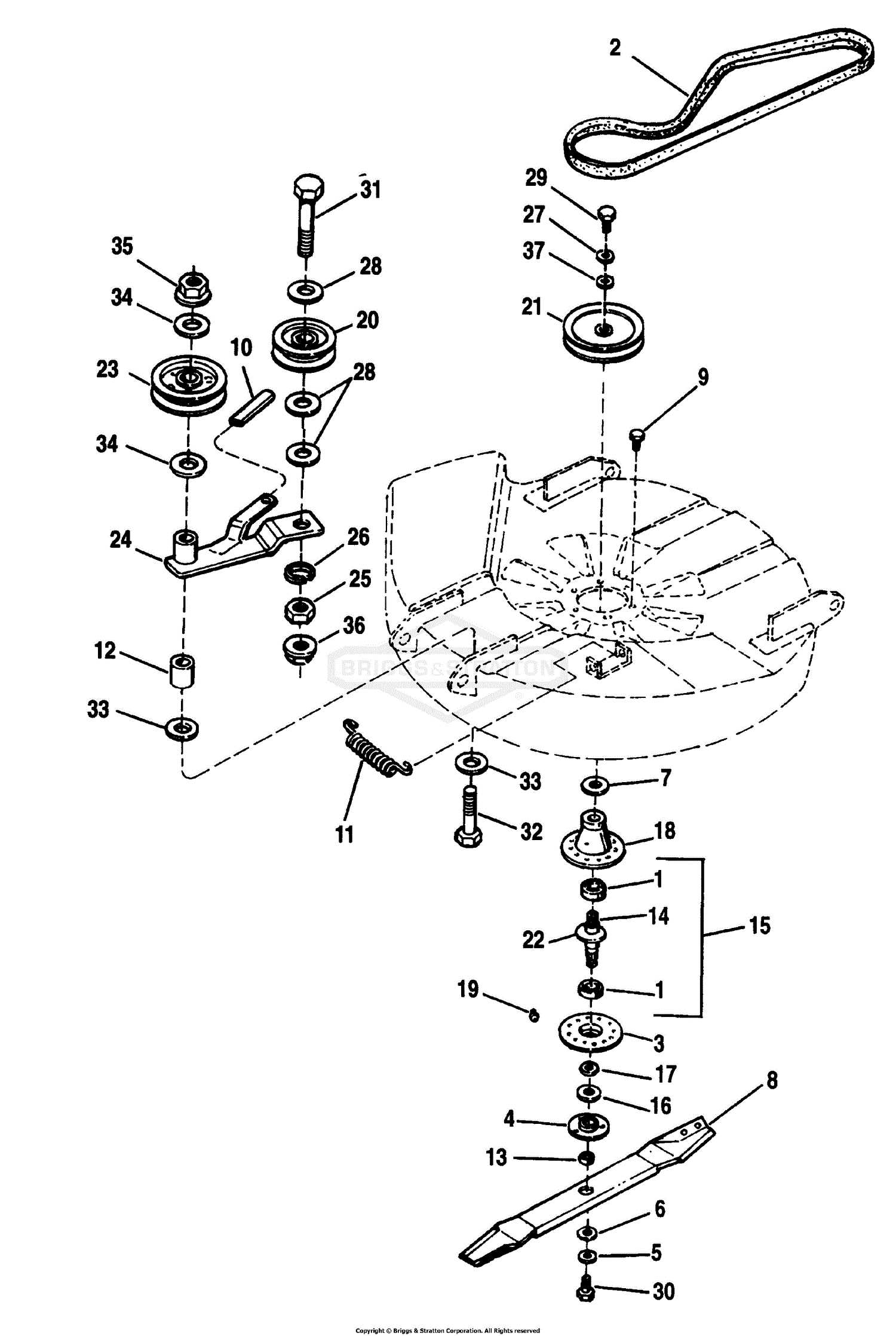

Key Components of Mower Deck

Understanding the essential elements of a cutting apparatus is crucial for effective maintenance and optimal performance. Each component plays a vital role in ensuring that the equipment operates smoothly and efficiently, contributing to a clean and precise cut. Familiarity with these elements enables users to identify potential issues and carry out necessary repairs or replacements.

Blades: The sharp, rotating elements are fundamental for achieving an even cut. Regular sharpening and replacement are necessary to maintain their effectiveness.

Spindle: This central component supports the blades and allows them to rotate. A well-functioning spindle ensures that the blades maintain proper speed and balance.

Housing: The protective casing around the cutting elements not only safeguards the internal components but also helps direct clippings away from the machine, promoting a tidy operation.

Belts: These flexible bands transfer power from the engine to the rotating blades. Proper tension and condition of the belts are crucial for maintaining cutting efficiency.

Wheels: These elements facilitate maneuverability, allowing the entire unit to glide smoothly over various terrains. Ensuring they are properly aligned and inflated is essential for optimal performance.

By comprehensively understanding these key components, users can enhance their equipment’s longevity and effectiveness, making maintenance more manageable and ensuring excellent results every time.

Common Issues with Mower Deck Parts

Maintaining the cutting apparatus of your lawn maintenance equipment is crucial for optimal performance. Various challenges can arise, leading to inefficiencies or malfunctions. Understanding these common problems can help in troubleshooting and ensuring that the machinery operates smoothly.

Worn Components

One of the frequent issues involves the deterioration of specific elements due to regular use. Worn-out blades, belts, and pulleys can significantly impact the cutting effectiveness, resulting in uneven grass height and additional strain on the engine.

Alignment Problems

Improper alignment of the cutting mechanism can lead to subpar performance. This issue may cause uneven cutting and premature wear of parts. Regular checks and adjustments are essential to maintain correct positioning.

| Issue | Symptoms | Solution |

|---|---|---|

| Worn Blades | Uneven cuts, grass tearing | Sharpen or replace blades |

| Loose Belts | Slipping noise, reduced power | Tighten or replace belts |

| Misaligned Components | Uneven cutting height | Realign parts as per specifications |

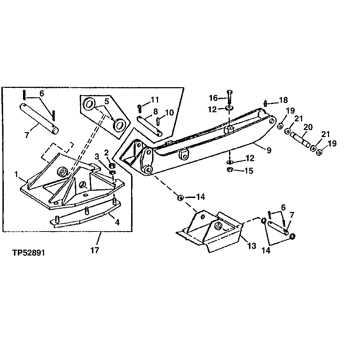

How to Identify Parts on Diagram

Understanding how to recognize components on a schematic is essential for efficient maintenance and repairs. Each element is represented in a way that conveys its function and relation to others, facilitating troubleshooting and replacement tasks.

Familiarize with Symbols

Start by learning the common symbols used in the representation. Each shape or line indicates a specific function or connection, providing crucial information about the machinery’s operation.

Cross-Referencing with Manuals

Utilize manufacturer manuals as a reference to match visual representations with actual components. This practice enhances accuracy and helps in making informed decisions during repairs or upgrades.

Replacement Parts for John Deere 400

When maintaining a specific model of outdoor equipment, finding the right components is crucial for optimal performance. This section focuses on various essential elements necessary for the upkeep and enhancement of your machine, ensuring longevity and efficiency in its operation.

Common Components Needed

Several components are frequently required to keep your equipment running smoothly. Identifying these can save time and enhance functionality.

| Component Name | Description | Part Number |

|---|---|---|

| Blade | High-quality cutting edge for effective trimming. | XYZ123 |

| Drive Belt | Durable belt ensuring power transmission. | ABC456 |

| Spindle Assembly | Critical for blade rotation and stability. | LMN789 |

Where to Find Quality Components

To obtain these crucial elements, consider authorized dealers or reputable online retailers that specialize in outdoor machinery. Ensuring the authenticity of components is essential for maintaining equipment integrity.

Maintenance Tips for Mower Deck

Proper care and attention to your cutting equipment are essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also ensures a clean cut and reduces the risk of breakdowns. Adopting a proactive approach to upkeep can save time and money in the long run.

Routine Inspections

Conducting frequent checks is vital. Look for any signs of wear or damage, such as cracks or rust. Ensuring that all components are securely fastened helps maintain stability during operation. Additionally, inspect the blades for sharpness; dull blades can lead to uneven cutting and stress on the engine.

Cleaning and Lubrication

Keeping the equipment clean is crucial for its functionality. Remove grass clippings and debris after each use to prevent buildup that can affect performance. Regularly lubricating moving parts minimizes friction and wear, promoting smoother operation. Always refer to the manufacturer’s guidelines for recommended cleaning and lubrication schedules.

Upgrading Your Mower Deck

Enhancing your cutting equipment can significantly improve its performance and efficiency. By replacing or upgrading certain components, you can achieve a cleaner cut, better durability, and a more enjoyable mowing experience. Understanding what options are available is key to making informed decisions about upgrades.

Benefits of Upgrading

- Improved Cutting Efficiency: High-quality blades can create a sharper, cleaner cut.

- Enhanced Durability: Upgraded materials can withstand wear and tear better.

- Better Maneuverability: Lighter components can make handling easier.

- Increased Versatility: Attachments can expand the functionality of your equipment.

Key Components to Consider

- Blades: Opt for advanced materials or specialized designs for specific grass types.

- Spindles: Upgrading spindles can lead to improved rotational efficiency.

- Belts: Reinforced belts enhance power transmission and longevity.

- Frame Support: A sturdier frame can improve stability during operation.

Investing in these improvements not only elevates the performance of your equipment but also extends its lifespan, providing long-term value and satisfaction. Researching available options and consulting with experts can guide you in selecting the best upgrades for your specific needs.

Tools Needed for Mower Repairs

Effective maintenance of lawn equipment requires a variety of instruments to ensure proper functionality and longevity. Familiarity with the necessary tools not only streamlines the repair process but also enhances safety during operation. Below are essential implements that every technician should have at hand.

Essential Tools

Having the right equipment is crucial for successful repairs. Here’s a list of key tools:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To handle various types of screws. |

| Socket Set | For reaching fasteners in tight spaces. |

| Pliers | To grip and manipulate small parts. |

| Grease Gun | For lubrication of moving components. |

Safety Equipment

In addition to repair tools, safety gear is vital. Always use gloves and goggles to protect against debris and sharp edges while working.

Finding OEM Parts for Your Mower

Locating original equipment manufacturer components for your machine is crucial for ensuring optimal performance and longevity. Genuine parts are specifically designed to fit and function seamlessly with your equipment, providing reliability that aftermarket options often cannot match. Understanding where to find these essential items will help you maintain the efficiency and safety of your machine.

To start your search for authentic components, consider the following avenues:

| Source | Description |

|---|---|

| Authorized Dealers | Visit local or online authorized dealers for a wide selection of genuine components and expert advice. |

| Manufacturer’s Website | Check the official website for a parts lookup tool, ensuring you find the correct items for your model. |

| Online Retailers | Reputable online platforms often stock genuine items, providing convenience and often competitive pricing. |

| Service Centers | Local service centers can help identify the parts you need and may also offer installation services. |

By exploring these options, you can confidently acquire the necessary original components to keep your equipment running smoothly.

Assembly Instructions for Mower Deck

Putting together the components of a cutting apparatus requires careful attention to detail and a systematic approach. Following the proper sequence ensures optimal performance and longevity of the equipment.

Preparation Steps

Before starting, gather all necessary components and tools. Verify that all elements are included and free of defects. A clean workspace will enhance efficiency during assembly.

Assembly Process

Begin by aligning the main frame with the corresponding brackets. Secure them using the provided fasteners, ensuring a tight fit. Next, attach the cutting blades, making certain they are oriented correctly for effective operation. Double-check all connections before proceeding to the final adjustments, which include checking the tension and alignment.

Remember: Proper assembly is crucial for achieving the ultimate cutting performance. Take your time and follow each step carefully.

Tips for Troubleshooting Mower Issues

Maintaining a healthy lawn care machine is crucial for achieving optimal performance. When challenges arise, understanding the underlying causes can help restore functionality effectively. This section provides practical advice for diagnosing and resolving common problems that may affect your equipment.

Start by checking the fuel system. Ensure that the tank is filled with fresh gasoline, as stale fuel can lead to starting difficulties. Inspect the fuel lines for any leaks or blockages that could hinder proper flow. Additionally, a clogged fuel filter may need replacement to ensure a smooth operation.

Next, examine the electrical components. A faulty battery can lead to starting issues, so confirm that the connections are secure and the battery is charged. Inspect the ignition system, including the spark plug, for wear and damage. Replacing a worn spark plug can significantly improve engine performance.

Don’t overlook the blades. Dull or damaged blades can affect cutting efficiency and result in uneven grass height. Regularly sharpen or replace blades as needed. Also, ensure that they are properly aligned to prevent unnecessary strain on the motor.

Finally, pay attention to the cooling system. Overheating can cause performance issues, so check for any debris blocking the cooling fins and clean them as necessary. Regular maintenance can prevent many common problems, allowing for a more enjoyable and effective lawn care experience.

Online Resources for Mower Owners

For enthusiasts and caretakers of lawn care equipment, the internet offers a wealth of information. Accessing reliable online platforms can significantly enhance the maintenance and operation of your machinery. Whether seeking instructional videos, community forums, or detailed guides, these resources can empower users to achieve optimal performance.

Interactive Communities

Participating in forums and social media groups dedicated to lawn care allows users to share experiences and solutions. These platforms often feature discussions that delve into troubleshooting common issues, which can be invaluable for both novice and experienced operators.

Guides and Manuals

Many websites provide comprehensive manuals and how-to articles. These resources can be the ultimate reference for understanding the intricacies of your equipment, ensuring that you have access to crucial information whenever needed. Additionally, video tutorials can visually demonstrate techniques, making learning more accessible.