In the realm of heavy machinery, the effective operation of specialized lifters hinges on a well-organized assembly of various elements. These machines are designed to streamline material handling processes, ensuring that goods are transported safely and efficiently. A thorough comprehension of their structure is essential for maintenance and troubleshooting, enabling users to optimize functionality and longevity.

Each element within these lifters plays a crucial role, contributing to the overall performance and reliability of the system. By examining how these components interconnect, operators can identify potential areas for improvement or repair. This knowledge empowers individuals to make informed decisions, fostering a more productive work environment.

As we delve into the intricate layout of these mechanisms, we will explore the significance of each segment and its contribution to the machine’s efficiency. Understanding these details not only enhances operational capabilities but also facilitates effective upkeep, ultimately leading to enhanced productivity in various industries.

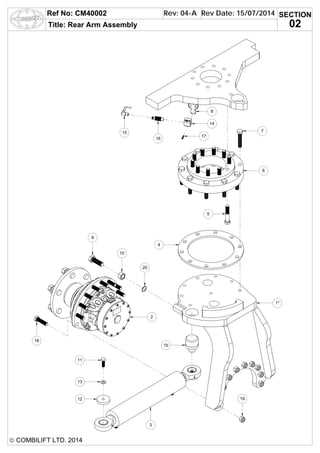

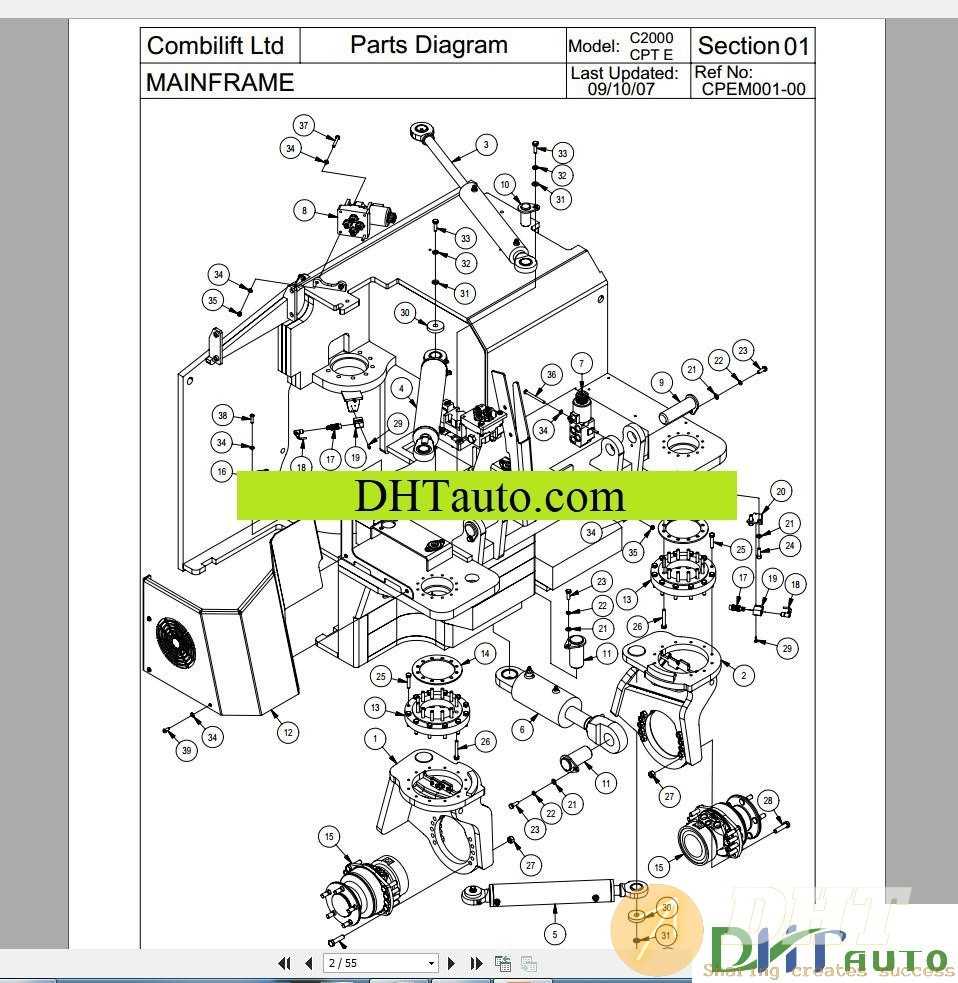

Overview of Combilift Parts

This section provides a comprehensive look at the various components that contribute to the functionality and efficiency of these specialized machines. Understanding the intricate relationships between different elements is crucial for optimal performance and maintenance.

Each component plays a significant role in the overall operation, ensuring seamless movement and handling of goods in tight spaces. From the robust frames to the sophisticated hydraulic systems, every element is designed with precision and purpose.

Familiarity with these integral components not only aids in troubleshooting but also enhances the ability to carry out effective repairs and upgrades. This knowledge empowers operators and technicians alike to ensure longevity and reliability in their equipment.

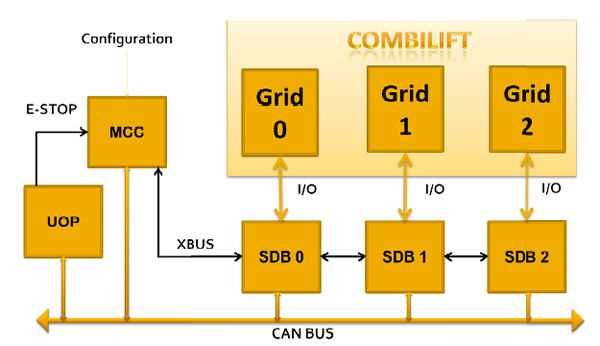

Understanding the Functionality of Components

Every machine relies on an intricate system of individual elements working together in harmony. These elements, each with its own role, contribute to the overall operation, ensuring the system runs smoothly. Understanding how each component interacts with the others is essential to grasp the full functionality of the entire setup.

The Role of Mechanical Elements

Mechanical units serve as the backbone, providing the necessary physical movement and structural support. They work in sync to transfer motion, power, or force, often converting one form of energy into another. Whether it’s enabling precise rotations or stabilizing load distribution, these elements form the foundation of operational efficiency.

The Importance of Electrical Connections

Electrical connections act as the nerve center, coordinating the various functions. Through wires, sensors, and circuits, they communicate signals, monitor performance, and ensure safety. Without these essential links, the system could not respond to commands or adapt to changing conditions, making electrical components critical for maintaining control and reliability.

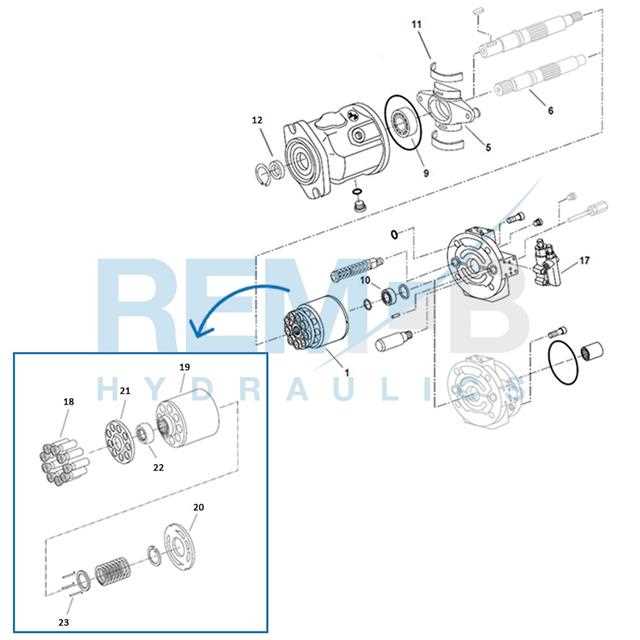

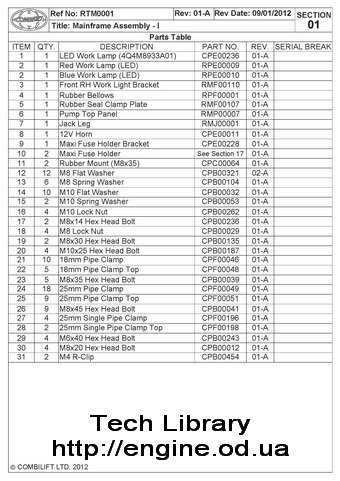

Importance of Accurate Diagrams

Precise visual representations play a crucial role in the effective maintenance and repair of machinery. They serve as essential tools for technicians, ensuring that all components are correctly identified and handled. A clear illustration enhances understanding, facilitating efficient troubleshooting and assembly processes.

Benefits of Clarity

When illustrations are accurate, they minimize the risk of errors during repairs. Technicians can quickly locate parts, reducing downtime and increasing productivity. Furthermore, well-crafted visuals can significantly improve training for new staff, allowing them to grasp complex systems more rapidly.

Impact on Efficiency

Utilizing detailed visuals leads to streamlined operations. A clear reference can help in planning maintenance schedules, ensuring that every component is regularly checked. This proactive approach can prevent costly breakdowns and extend the lifespan of the machinery.

| Advantage | Description |

|---|---|

| Reduced Errors | Accurate representations minimize mistakes during assembly or repair. |

| Improved Training | New personnel can learn systems quickly through clear visuals. |

| Enhanced Efficiency | Streamlined processes save time and resources in maintenance. |

Identifying Key Elements in Diagrams

Understanding the visual representations of machinery components is crucial for effective maintenance and repair. These illustrations provide valuable insights into the arrangement and function of different elements, facilitating a clearer comprehension of the system as a whole. Recognizing the significant parts and their connections is essential for troubleshooting and optimizing performance.

Common Symbols and Annotations

Visual representations often utilize various symbols and annotations to convey information efficiently. Familiarity with these icons can significantly enhance the interpretation process.

| Symbol | Description |

|---|---|

| ⚙️ | Represents a gear or mechanical component |

| Indicates electrical connections or terminals | |

| Signifies adjustment or maintenance points |

Analyzing Relationships and Connections

Examining how different elements interact is vital for understanding functionality. Connections often indicate the flow of energy or information, revealing how components work together to achieve specific tasks. By focusing on these relationships, users can identify potential issues and streamline their problem-solving approaches.

Common Issues with Combilift Parts

In the realm of specialized machinery, certain challenges frequently arise that can hinder optimal performance. Understanding these prevalent concerns can significantly enhance the longevity and efficiency of your equipment. This section delves into the typical complications users may encounter, offering insights into maintenance and troubleshooting.

Mechanical Wear and Tear

Over time, various components may experience significant wear due to regular usage. This deterioration can lead to decreased functionality and increased risk of failure. Regular inspections and timely replacements are essential to prevent unexpected breakdowns.

Electrical Malfunctions

Electrical systems are often susceptible to faults, including short circuits and connection issues. Such malfunctions can disrupt operations and cause inefficiencies. Proper wiring checks and using quality connections can mitigate these risks, ensuring smoother functionality.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your equipment involves a combination of regular care and strategic practices. By following a few essential guidelines, you can significantly extend the lifespan and efficiency of your machinery.

Regular Inspections: Conduct periodic assessments to identify any signs of wear or potential issues before they escalate. Look for unusual sounds, leaks, or vibrations that may indicate underlying problems.

Proper Lubrication: Maintaining adequate lubrication is crucial. Ensure all moving components are adequately greased according to the manufacturer’s recommendations, as this reduces friction and wear.

Cleanliness: Keep the machinery clean from dust, debris, and other contaminants. Regular cleaning not only improves performance but also prevents corrosion and damage over time.

Correct Usage: Always operate the equipment within its specified limits. Overloading or improper handling can lead to premature failure and costly repairs.

Routine Maintenance Schedule: Establish a consistent maintenance routine that includes tasks like oil changes, filter replacements, and system checks. Documenting these activities helps track the history and performance of the machinery.

By implementing these strategies, you can maximize the efficiency and longevity of your equipment, ensuring it remains a reliable asset for years to come.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair tasks. These illustrations provide a comprehensive overview of various elements, helping users identify and locate specific items within a complex system. By familiarizing oneself with the structure and symbols used in these visuals, individuals can streamline their troubleshooting and ordering processes.

Here are some key points to consider when interpreting these visuals:

- Familiarize with Symbols: Each illustration uses unique symbols to represent different elements. Recognizing these will aid in quick identification.

- Check the Legend: Many illustrations include a legend or key, explaining the meaning of various symbols and lines.

- Follow the Flow: Understand how components interact with one another by following the pathways indicated in the visual.

- Identify Groups: Look for clusters of elements that serve specific functions, as these may indicate assembly or operational groupings.

By mastering these techniques, individuals can enhance their understanding of the visual representations and improve their efficiency in handling related tasks.

Comparison of Different Models

When evaluating various types of lifting equipment, it’s essential to consider the unique features and specifications that distinguish each model. Different designs cater to specific operational needs, making it vital to understand their capabilities and limitations.

Here are some key factors to consider when comparing models:

- Load Capacity: Each model supports different weight limits, affecting its suitability for various tasks.

- Dimensions: The size and shape can significantly impact maneuverability and storage capabilities.

- Power Source: Options include electric, diesel, or hybrid systems, influencing operational costs and environmental impact.

- Stability: Design features that enhance stability can be crucial for safety, especially in high-lift scenarios.

Understanding these aspects allows operators to make informed decisions based on their specific operational requirements. The choice of model can affect efficiency, safety, and overall productivity in the workplace.

Where to Find Quality Diagrams

Locating high-quality visuals that illustrate complex machinery can significantly enhance understanding and maintenance efforts. Reliable sources for these visuals are essential for professionals and enthusiasts alike, ensuring accuracy and clarity in interpreting technical information.

Online Resources

- Manufacturer Websites: Many companies provide comprehensive resources, including detailed visuals on their official sites.

- Technical Forums: Communities of users often share invaluable resources and personal experiences, making them a great place to find quality visuals.

- Online Marketplaces: Websites specializing in machinery and equipment frequently offer downloadable materials for purchase, featuring extensive collections.

Printed Materials

- Service Manuals: Official manuals usually contain detailed illustrations that are invaluable for troubleshooting and repairs.

- Industry Publications: Journals and magazines dedicated to machinery often include articles with high-quality visuals and diagrams.

- Workshops and Training Sessions: Attending industry workshops can provide access to printed materials that are not available online.

Role of Diagrams in Repairs

Visual representations play a crucial part in the maintenance and restoration of machinery. They provide a clear blueprint that aids technicians in identifying components and understanding their interconnections. This clarity is essential for efficient troubleshooting and effective repairs.

Understanding layouts through these visuals enhances the technician’s ability to pinpoint issues swiftly. With a comprehensive overview, one can assess the relationships between various elements, ensuring that no critical aspect is overlooked. Such insight is invaluable when addressing complex systems that require precise interventions.

Moreover, these illustrations serve as an educational tool. They help less experienced individuals grasp the intricacies of machinery. By utilizing visual aids, teams can streamline their workflow and minimize downtime, ultimately leading to more successful outcomes in repair efforts.

Expert Insights on Component Durability

Understanding the longevity of machine elements is crucial for maximizing efficiency and minimizing downtime. The resilience of these components directly impacts overall performance, making it essential to explore the factors that contribute to their durability. Industry experts emphasize the importance of material selection, manufacturing processes, and maintenance practices in extending the lifespan of essential elements.

Material Selection and Its Importance

Choosing the right materials is fundamental to ensuring that components can withstand various operational stresses. High-quality alloys and composites are often preferred for their enhanced strength and resistance to wear. Experts suggest that investing in superior materials not only improves performance but also reduces the frequency of replacements.

Maintenance Practices for Longevity

Regular upkeep is vital for maintaining the integrity of machine elements. Implementing a routine inspection schedule allows for the early detection of wear and tear, preventing potential failures. Industry professionals advocate for adherence to recommended service intervals to ensure optimal functionality and durability over time.

Upgrades and Modifications to Consider

Enhancing the functionality and efficiency of your equipment can significantly improve performance and productivity. Exploring various enhancements can lead to better operation, increased safety, and extended lifespan of your machinery. Below are several modifications that can make a substantial difference.

Performance Enhancements

Improving the operational capabilities of your machinery can streamline processes. Consider the following upgrades:

- Upgrading the engine for higher torque and better fuel efficiency.

- Implementing advanced hydraulic systems for smoother lifting and lowering.

- Integrating modern control systems for enhanced maneuverability and precision.

Safety Features

Prioritizing safety can protect operators and prolong equipment lifespan. Here are some modifications to enhance safety:

- Installing additional lighting for improved visibility in low-light conditions.

- Adding backup alarms to alert personnel during operation.

- Implementing ergonomic improvements to reduce operator fatigue.

Resources for Further Learning

Expanding your knowledge in the field of industrial machinery can greatly enhance your understanding of various components and their functions. Numerous educational materials are available to assist enthusiasts and professionals alike in mastering this area. Engaging with these resources will deepen your insights and improve your practical skills.

Online platforms offer a wealth of articles, tutorials, and video content that cater to different learning styles. Many organizations also provide workshops and seminars, allowing for hands-on experience and expert guidance. Additionally, technical manuals and industry publications serve as invaluable references for anyone looking to delve deeper into machinery configurations and maintenance techniques.

Participating in forums and community discussions can further enrich your learning journey. Networking with peers and industry experts fosters knowledge exchange and opens doors to new opportunities. Embracing these resources will ultimately equip you with the tools necessary to navigate the complexities of this field effectively.