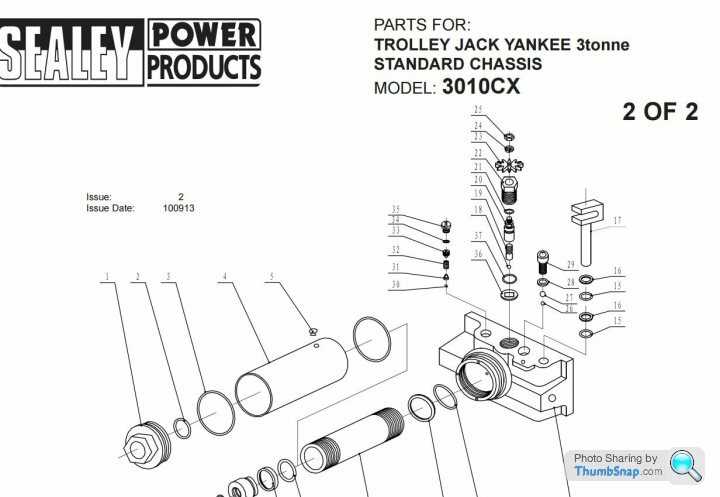

Maintaining and repairing a lifting tool often requires a detailed look at its individual elements. Whether you are trying to improve its performance or simply extend its lifespan, understanding the key components can significantly enhance your experience. By breaking down the structure into its core sections, you can gain a better grasp of how each part contributes to the overall functionality.

Each section within the device plays a crucial role in ensuring efficient operation. From the base, which provides stability, to the mechanism that allows smooth elevation, these elements work in unison to deliver reliable support during heavy-duty tasks. Identifying and familiarizing yourself with these sections will help you troubleshoot

Understanding the Components of a Floor Jack

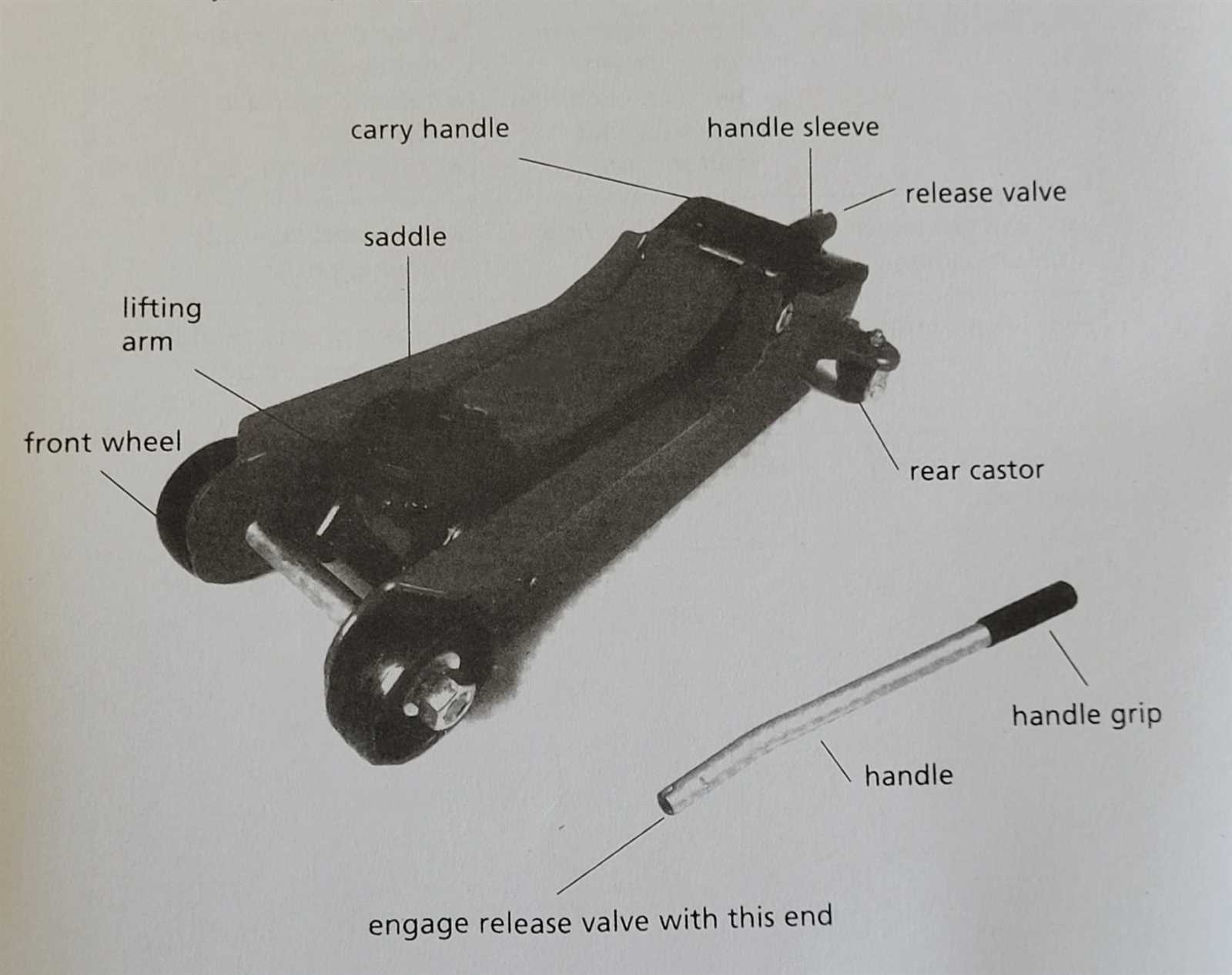

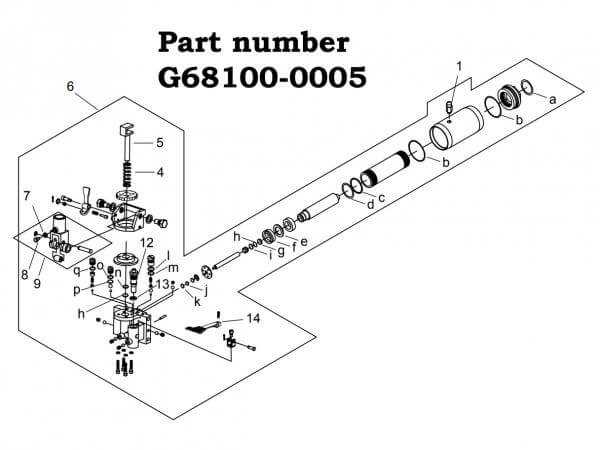

The lifting mechanism consists of several crucial elements that work together to elevate heavy objects safely and efficiently. Each piece plays a specific role, ensuring smooth operation and stability during use. Familiarizing yourself with these elements will help in proper maintenance and troubleshooting.

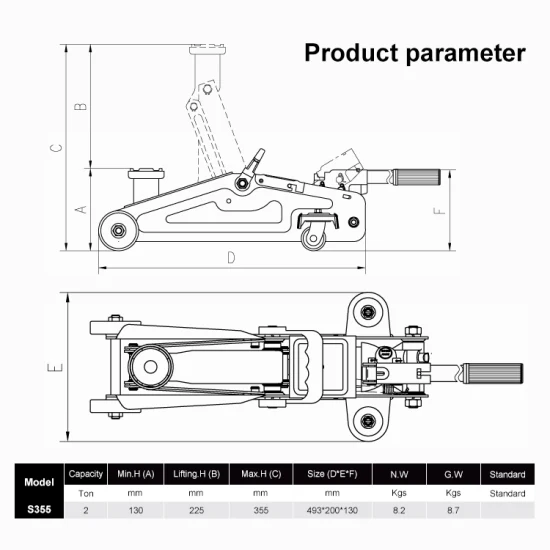

- Frame: This is the foundation, providing structural support and stability.

- Lifting Arm: The extension that raises the load, typically connected to the base.

- Handle: Used to control the lifting and lowering process, allowing for precise movement.

- Release Valve: A mechanism that controls the descent, ensuring a smooth lowering of the load.

- Wheels: These make it easier to move the equipment into position.

- Lever Action: The lever pivots around a fulcrum, allowing a small input force to create a larger output force.

- Ergonomics: The design of the handle ensures that the user can apply force comfortably and efficiently, reducing the risk of injury.

- Control: This system offers precise control over the lifting process, allowing for adjustments as needed.

- Regularly inspect for any signs of wear or damage to the handle and lever components.

- Lubricate moving parts to prevent friction and ensure smooth operation.

- Check the alignment of the lever and make adjustments if necessary to maintain efficiency.

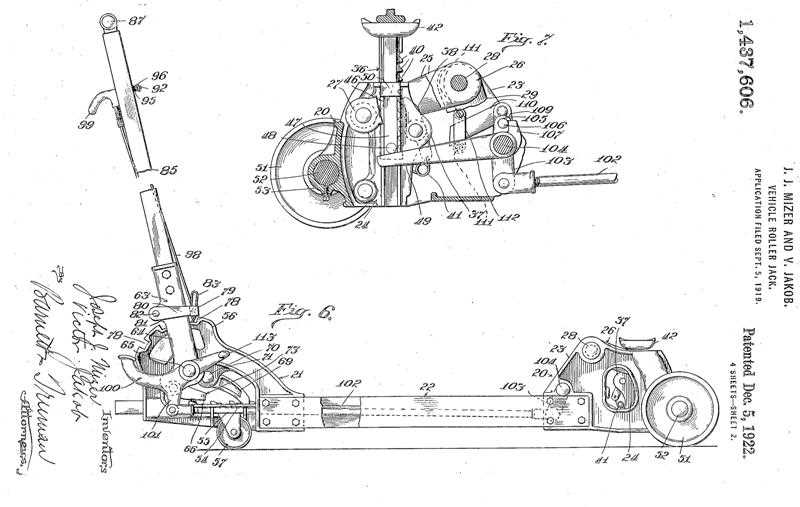

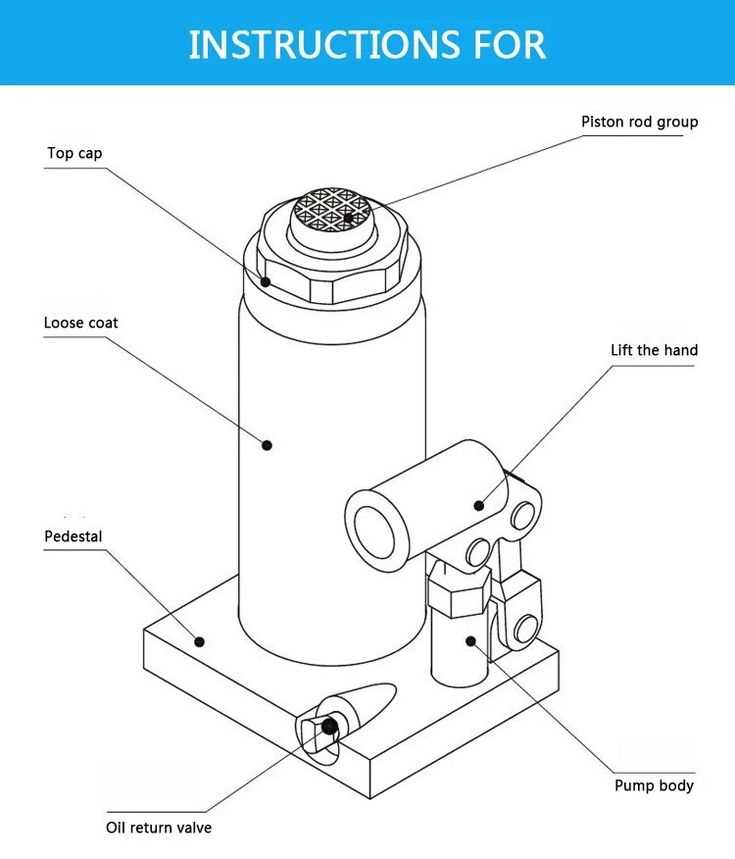

Main Structure of Hydraulic Jacks

The design of these lifting tools is based on a simple but effective framework, allowing users to raise heavy objects with minimal effort. The core components work in harmony to provide stability and precision during the lifting process. Understanding the layout of these elements is essential for ensuring safe and efficient operation.

Primary support elements

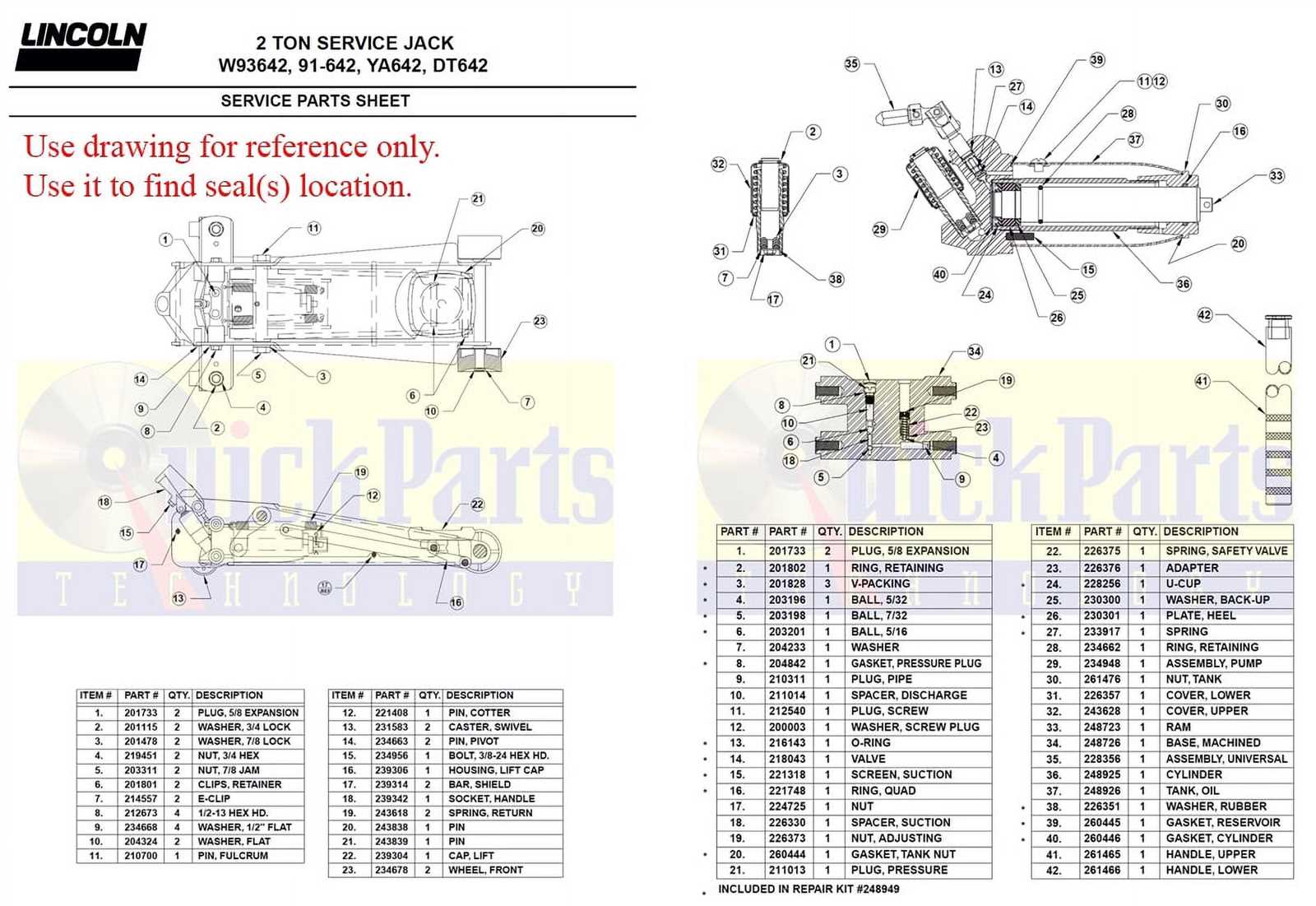

Pumping Mechanism: How Pressure is Created

The process of generating pressure relies on a carefully designed system that moves fluid in a controlled manner. This setup ensures that force is transferred efficiently through various internal components, resulting in the necessary energy to lift and hold objects. Understanding how pressure is built within this system is key to grasping its overall operation.

At the core of this mechanism is a pump that moves fluid from one chamber to another. As the handle is activated, it forces the liquid to shift, which gradually increases the internal pressure. This process allows the system to hold and sustain heavy loads. The movement is precise, ensuring that the system can control the amount of pressure needed for different applications.

Valves play a crucial role in maintaining the pressure within the system. They regulate the flow of liquid, allowing the buildup of force when necessary and releasing it when adjustments or lowering is required. These components ensure the proper balance of force throughout the system, making the lifting process both safe and effective.

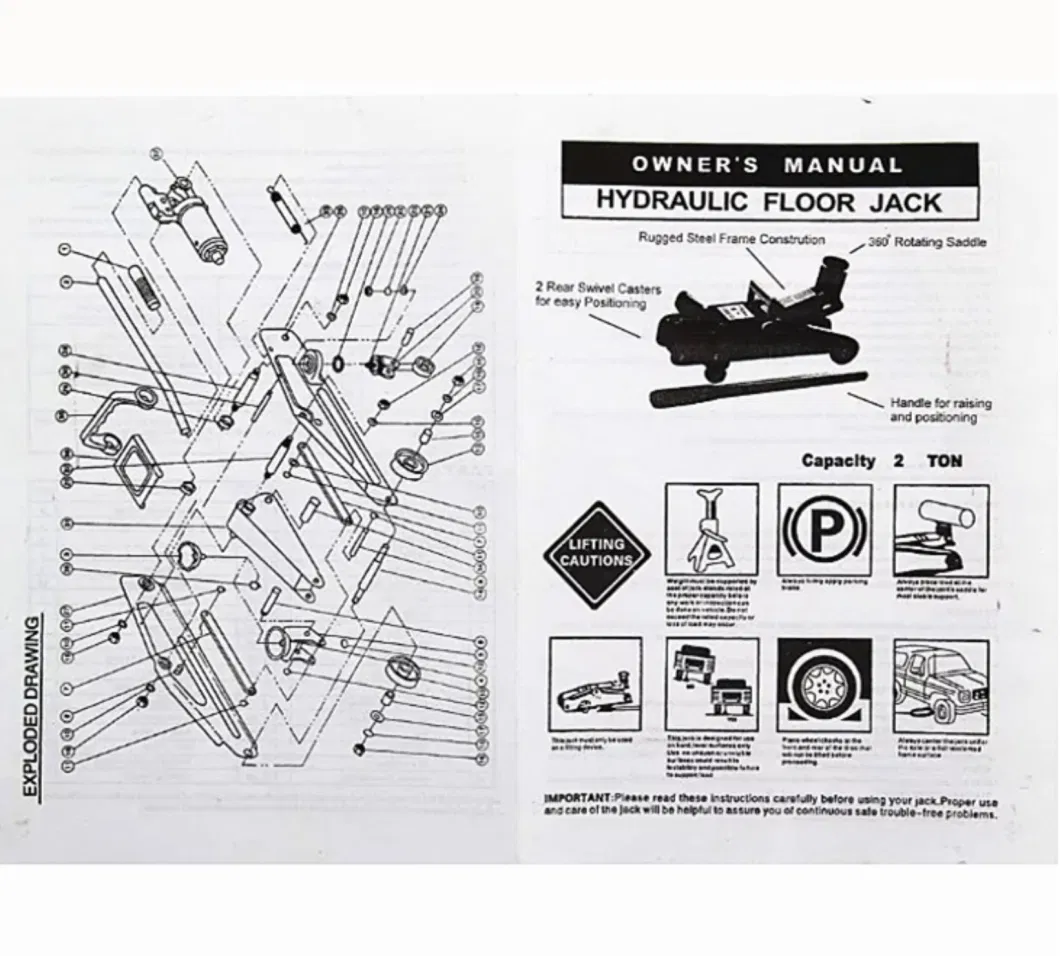

The Role of the Release Valve

The release valve plays a crucial part in ensuring the proper function and safety of lifting equipment. Its primary function is to control the lowering mechanism, allowing for smooth and precise adjustments during use. Understanding its role helps in maintaining balance and ensuring efficient performance during any lifting task.

Function and Importance

The release valve regulates the flow within the system, managing the descent of the load. By controlling this mechanism, it prevents sudden drops and provides the user with the ability to safely adjust the height. Proper operation of this valve is essential for preventing any damage or imbalance during lowering.

Key Considerations

| Aspect | Description | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Adjustment | Allows for gradual lowering of the load. | ||||||||||||||||||||||||||||||

| Maintenance | Regular cleaning and inspection prevent blockages and ensure smooth operation. |

| Issue | Description | Possible Solutions |

|---|---|---|

| Loss of Pressure | Inability to hold weight when lifted. | Check for fluid leaks, inspect seals, and refill hydraulic fluid. |

| No Lifting Action | Device does not raise when activated. | Examine the pump mechanism, ensure proper assembly, and test for blockages. |

| Uneven Lifting | Lifts are not level, causing instability. | Check ground surface, adjust foot pads, and verify alignment of the lifting arm. |

Maintenance Tips

Regular inspections and proper care can prevent many issues. It’s advisable to clean the device after use, check for any signs of wear and tear, and ensure that all components are functioning correctly. Following the manufacturer’s guidelines for maintenance can significantly reduce the likelihood of problems arising.

Maintaining Your Jack for Longevity

Regular upkeep is essential to ensure the extended life of your lifting device. By following a few simple practices, you can significantly enhance its performance and reliability, ultimately saving time and costs associated with repairs or replacements.

Here are some key maintenance tips:

| Task | Frequency | Description |

|---|---|---|

| Inspect for leaks | Monthly | Check all seals and connections for any signs of fluid loss. Addressing leaks promptly prevents further damage. |

| Clean the exterior | As needed | Remove dirt and grime from the surface to prevent corrosion. Use a soft cloth and mild detergent. |

| Check fluid levels | Monthly | Ensure that the lifting fluid is at the recommended level for optimal operation. |

| Examine the lifting mechanism | Every six months | Inspect the moving components for wear and tear. Lubricate any parts as needed to maintain smooth operation. |

| Store properly | Always | When not in use, keep your device in a dry, clean location to protect it from environmental damage. |

By adhering to these guidelines, you can ensure that your lifting tool remains in top condition, ready to perform when needed.