Efficient water treatment is crucial for maintaining a safe and enjoyable swimming environment. In this section, we will explore the essential elements involved in the process of automated sanitation for swimming pools. By understanding these components, users can optimize the functionality and longevity of their systems.

The intricate assembly of various units plays a vital role in ensuring the effective disinfection of pool water. Each component serves a specific purpose, contributing to the overall efficiency of the system. This overview will highlight the relationships between these elements and their impact on water quality management.

Gaining insight into these key units enables pool owners to perform regular maintenance, troubleshoot potential issues, and make informed decisions regarding upgrades or replacements. By familiarizing oneself with the layout and functionality of these elements, users can ensure their aquatic environment remains clean and safe for all.

Overview of the Chlorination System

This section provides an insight into the system designed to maintain water quality in pools and spas. By utilizing advanced technology, it effectively sanitizes the water, ensuring a clean and safe environment for users. Understanding its components and functionality is essential for proper maintenance and operation.

Key Components

- Electrolytic Cell

- Control Module

- Flow Switch

- Power Supply

Functionality

The system operates by converting salt into chlorine through a process known as electrolysis. This continuous generation of chlorine eliminates harmful bacteria and algae, providing a safe swimming experience. Users can adjust the settings to suit their specific needs, optimizing the balance between sanitation and chemical use.

Regular maintenance of the components is crucial for optimal performance. Checking for any signs of wear and ensuring proper water chemistry will prolong the life of the system and enhance its efficiency.

Understanding Chlorinator Functionality

The operation of saltwater sanitizing systems plays a crucial role in maintaining water quality. These systems facilitate the transformation of salt into a powerful disinfectant, ensuring that swimming environments remain clean and safe for users. By comprehending how these systems work, users can optimize their performance and extend their lifespan.

At its core, this system utilizes a series of components that work together seamlessly. The primary functions include:

- Electrolysis: The process by which salt is converted into chlorine, effectively killing bacteria and algae.

- Flow Regulation: Ensures that the water circulates properly through the unit, allowing for consistent sanitation.

- Monitoring: Incorporates sensors to detect levels of disinfectant, providing feedback for adjustments.

- Cell Maintenance: Requires regular cleaning to prevent buildup, which can hinder efficiency.

By understanding these key functions, users can troubleshoot issues and perform necessary maintenance. Familiarity with the workings of these systems leads to better management and enhanced user experience.

In conclusion, recognizing how these water treatment systems function is essential for maintaining clean and healthy water. By mastering their operation, users can ensure optimal performance and longevity.

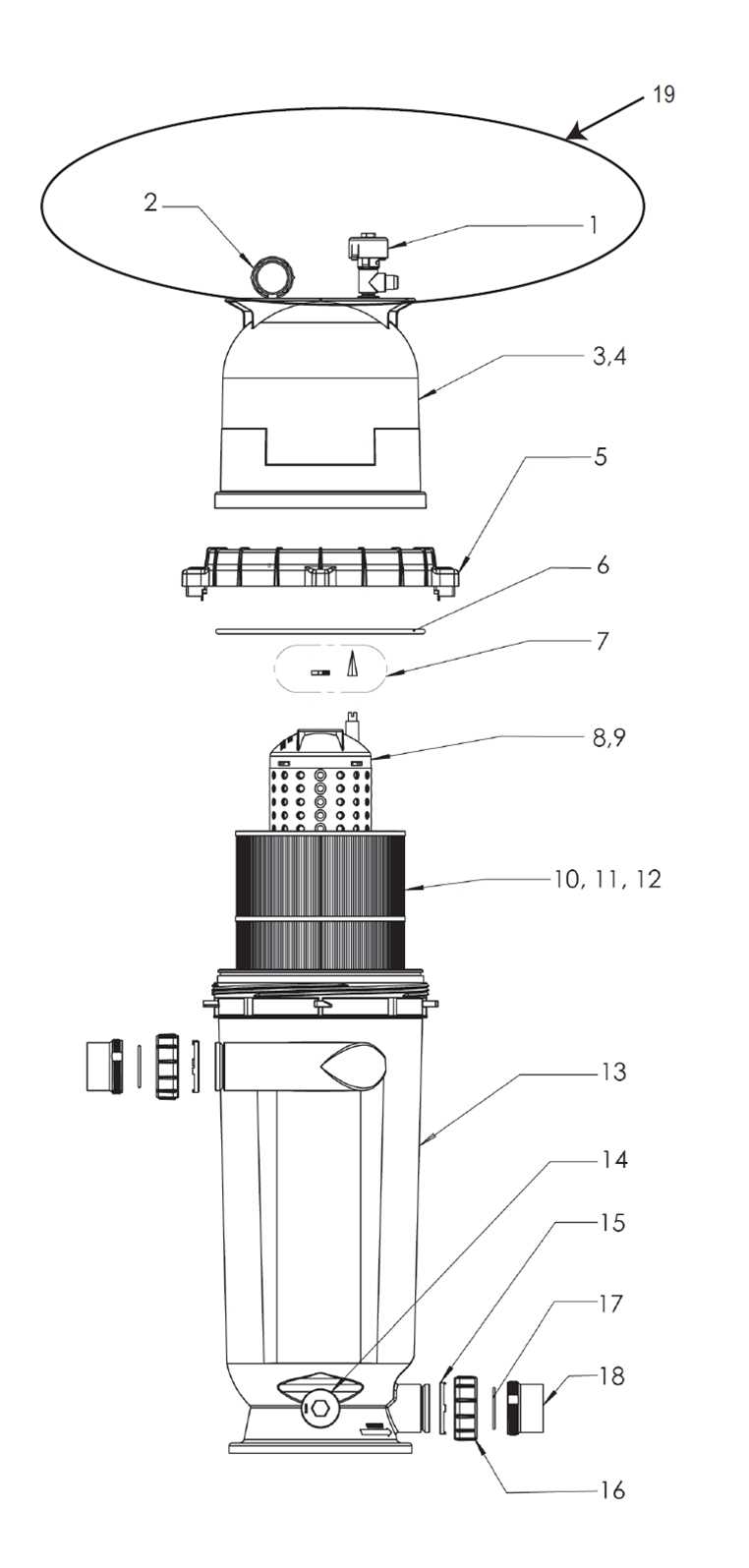

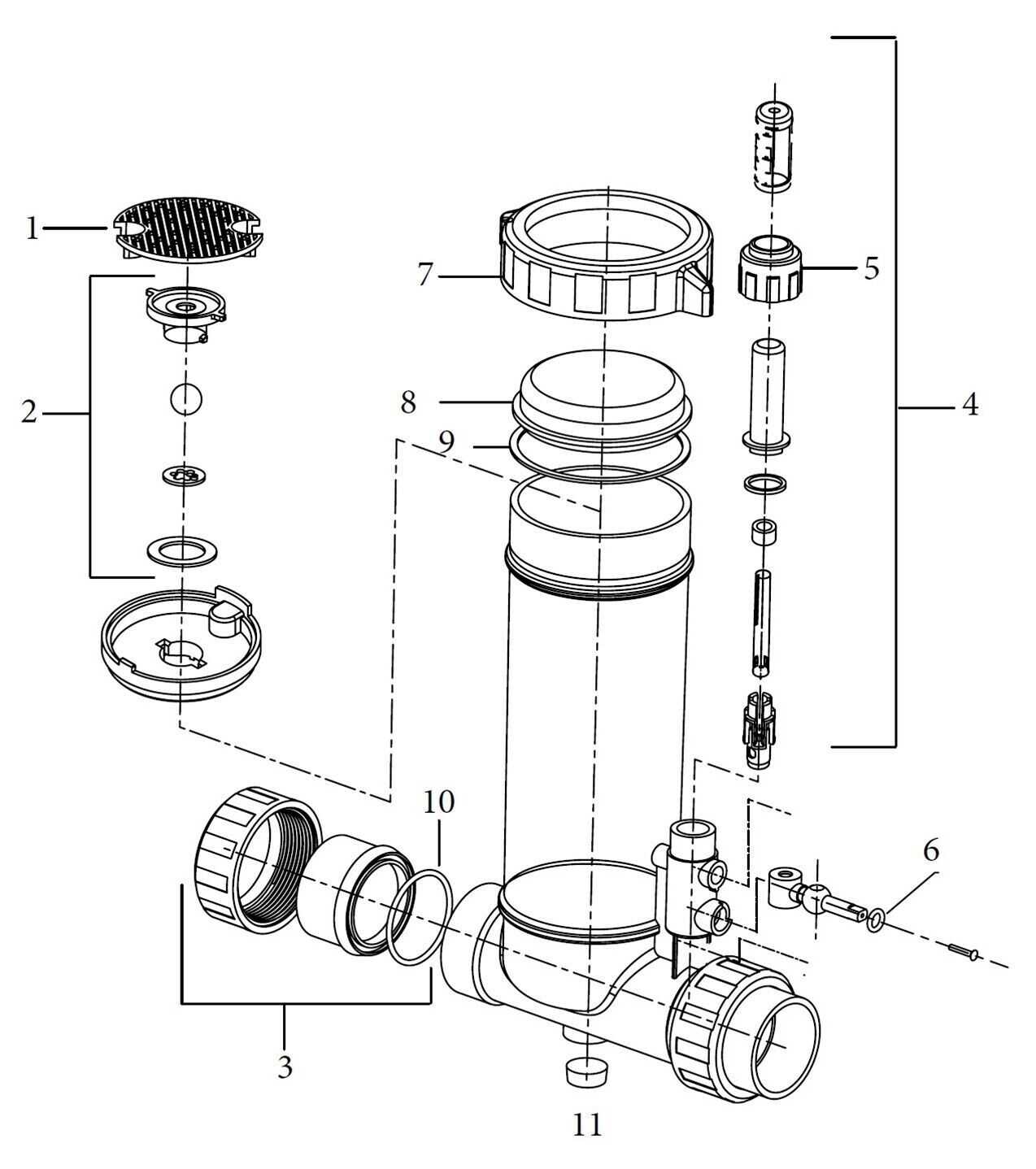

Key Components of Pentair Systems

The effectiveness of pool maintenance systems relies heavily on various essential elements that work in harmony to ensure optimal performance. Understanding these integral components can significantly enhance the efficiency and longevity of the entire setup.

Control Unit: This component serves as the brain of the system, managing the operation and settings to maintain the desired chemical balance and sanitation levels.

Electrolytic Cell: An important part of the system, this element converts salt into chlorine through a chemical reaction, providing continuous sanitation without the need for manual chemical additions.

Flow Switch: This device ensures that the system operates only when water is flowing, preventing damage and promoting safe operation.

Transformer: A critical component that provides the necessary voltage for the electrolytic cell, enabling it to perform efficiently.

Display Panel: The user interface allows for easy monitoring and adjustment of system settings, providing feedback on performance and maintenance needs.

Each of these elements plays a pivotal role in the overall functionality and effectiveness of water treatment systems, contributing to a cleaner and healthier swimming environment.

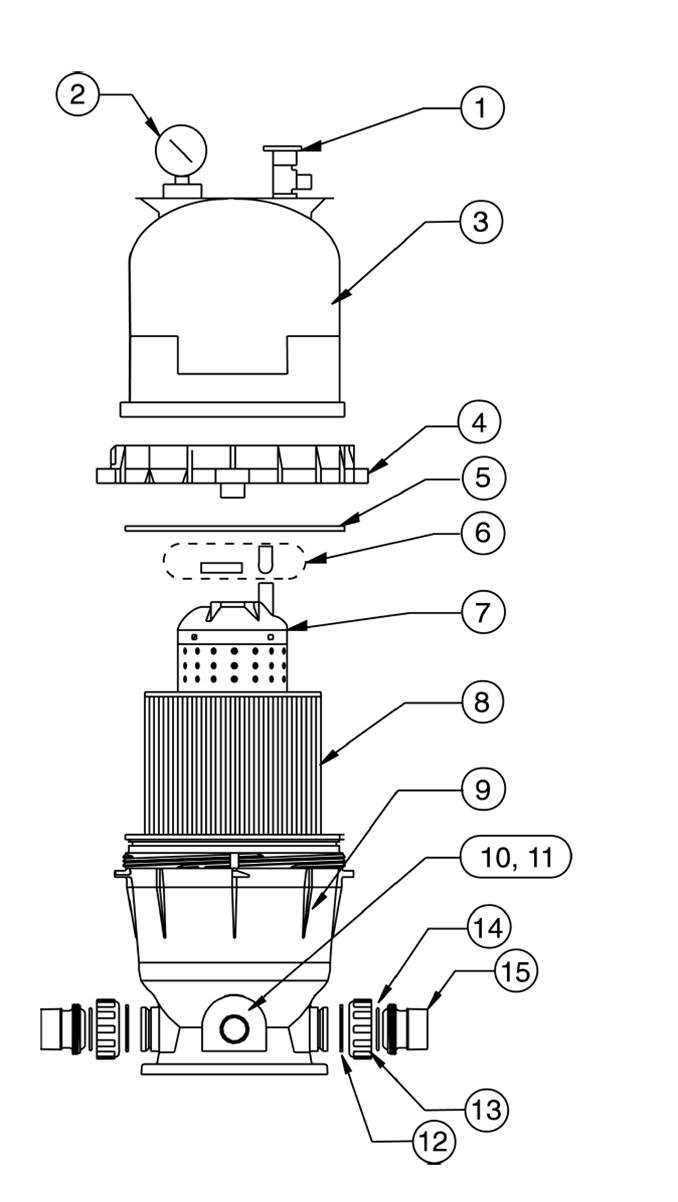

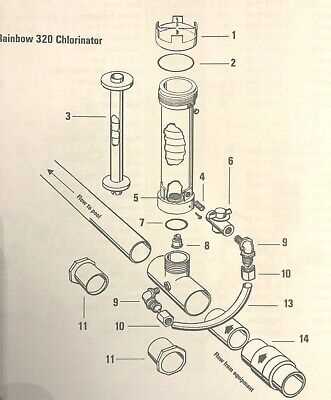

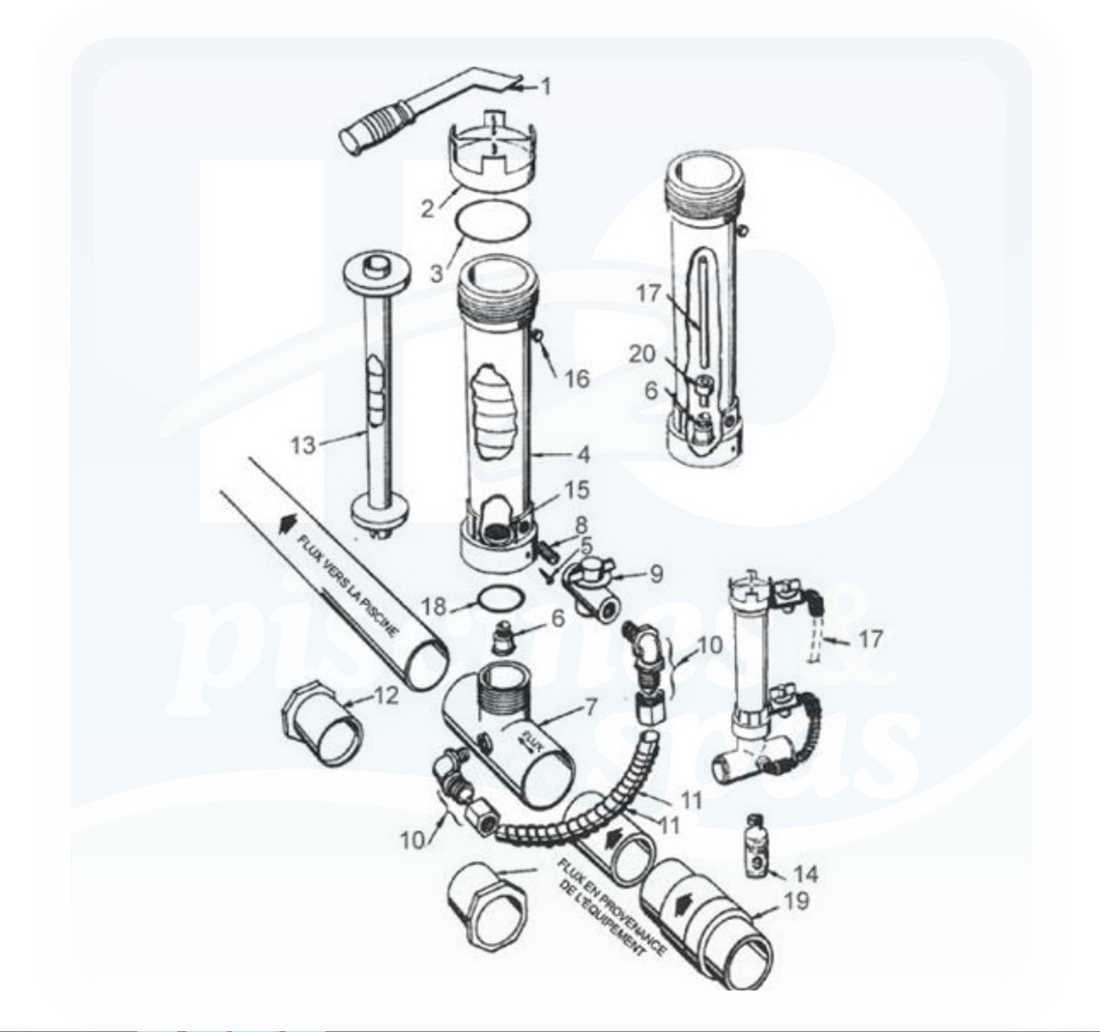

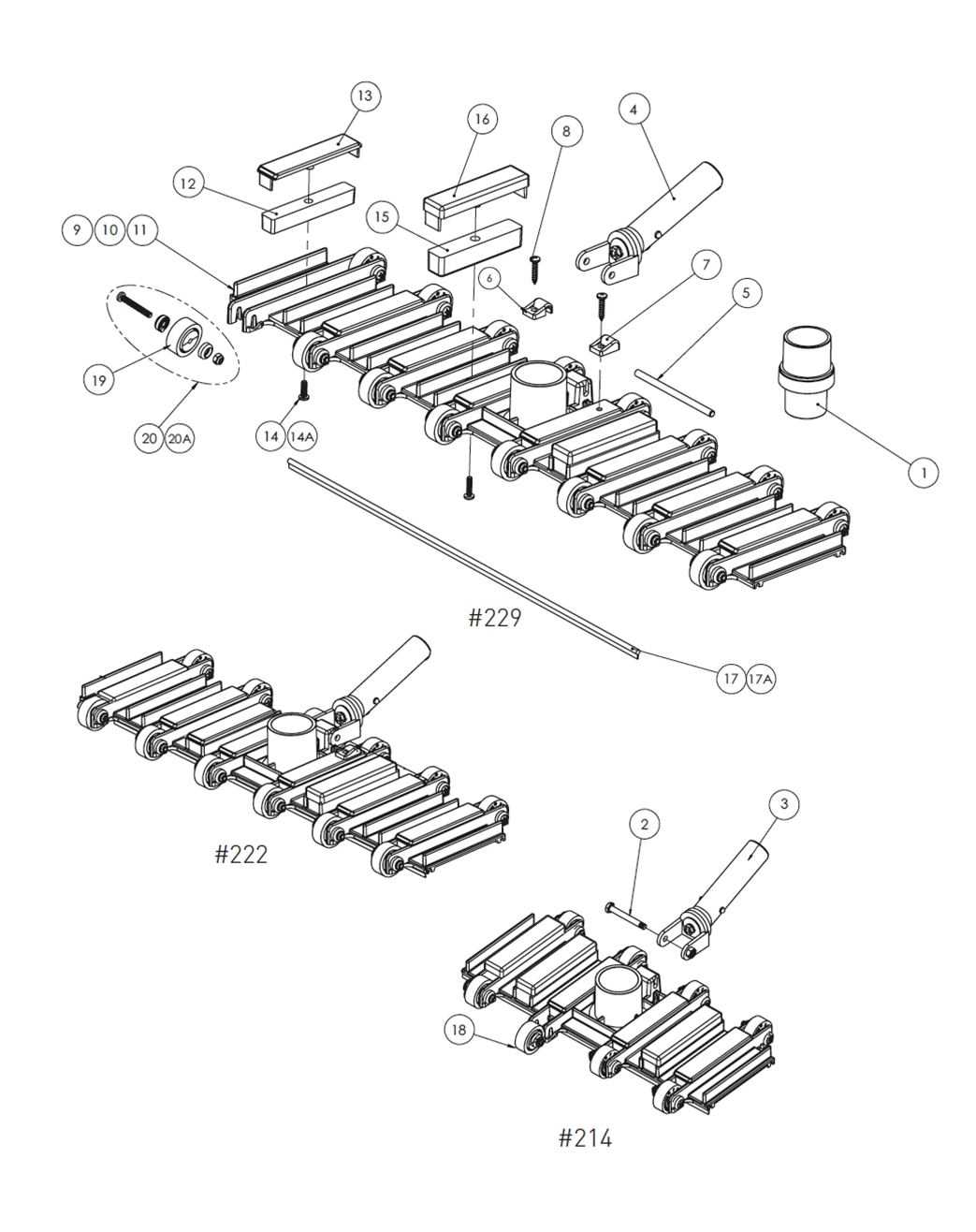

Parts Identification for Chlorination Units

Understanding the components of sanitizing systems is essential for efficient operation and maintenance. Proper recognition of these elements enables users to troubleshoot issues effectively and ensure optimal performance. This section provides insights into the various components commonly found in these units, helping users familiarize themselves with each part’s function and significance.

Common Components Overview

The main components of sanitizing units include several vital elements that work together to maintain water quality. Each element has a specific role, contributing to the overall functionality of the system.

| Component | Description |

|---|---|

| Electrode Cell | Generates sanitizing agents through electrolysis, critical for effective disinfection. |

| Control Module | Monitors and regulates the system’s operation, ensuring consistent performance. |

| Flow Switch | Detects water flow and activates the sanitizing process, preventing damage when flow is insufficient. |

| Chamber | Holds the electrode cell and facilitates the reaction process, allowing for efficient agent generation. |

| Power Supply | Provides the necessary voltage and current for the electrode cell, essential for its operation. |

Importance of Component Recognition

Recognizing each element’s role is vital for effective maintenance and repair. Users can quickly identify which components require attention, ensuring the longevity and reliability of the sanitation system. Regular inspections and understanding of these elements facilitate proactive maintenance and prevent unexpected failures.

Maintenance Tips for Longevity

Ensuring the durability of your water treatment system requires regular upkeep and attention. By implementing a few straightforward practices, you can extend the lifespan of the equipment and maintain its efficiency. These guidelines will help you safeguard your investment and ensure optimal performance over time.

Regular Cleaning

Consistent cleaning of components is vital to prevent the buildup of debris and mineral deposits. Make it a habit to inspect and clean the system periodically, using appropriate cleaning solutions. This practice not only enhances performance but also reduces the risk of malfunction.

Monitor Chemical Levels

Maintaining proper chemical balance is essential for the effective operation of your system. Regularly check and adjust the levels of sanitizers and other necessary substances to ensure that the equipment functions as intended. This will help prevent wear and tear, ensuring longevity.

Remember: investing time in maintenance will yield long-term benefits, keeping your water treatment system in excellent working condition.

Common Issues with Chlorinator Parts

Maintaining a reliable sanitation system can often lead to various challenges that users may face. Understanding the common problems that can arise with these systems is essential for effective troubleshooting and upkeep. Identifying these issues early can help prevent more significant complications and ensure optimal performance.

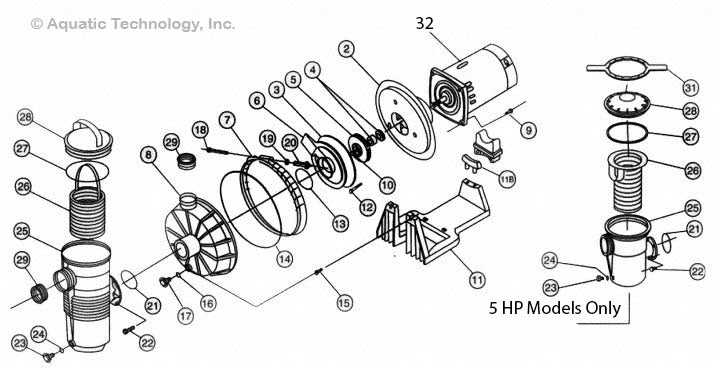

Frequent Mechanical Failures

One of the primary concerns involves mechanical components failing to function as intended. This can result from wear and tear over time, leading to inefficient operation. Regular inspection and timely replacement of these elements can help avoid unexpected interruptions.

Inconsistent Chemical Output

Another common problem is the irregular delivery of sanitizing agents. Factors such as clogs, malfunctions in regulation mechanisms, or incorrect settings can contribute to this issue. Regular maintenance and monitoring of system settings can help ensure a steady release of chemicals, maintaining water quality.

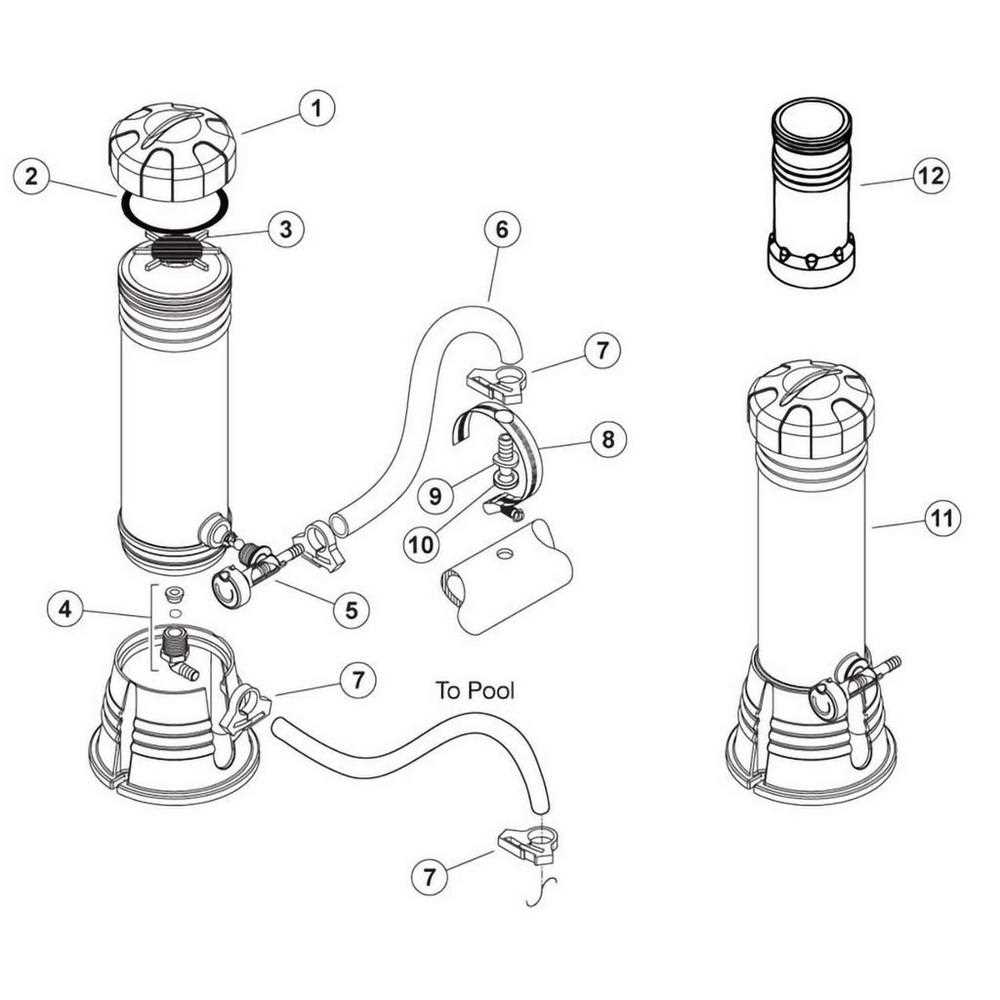

Replacement Parts and Accessories

When it comes to maintaining your water sanitization system, having the right components and supplementary items is essential for optimal performance. Ensuring that all elements are functioning properly not only extends the life of the equipment but also enhances its efficiency in keeping your water clean and safe for use.

Essential Components

Key components play a crucial role in the overall operation of the system. These include items like cell assemblies, which generate the necessary sanitation elements, and connectors that facilitate seamless integration with existing plumbing. Regular inspection and timely replacement of these elements can prevent system failures and ensure consistent operation.

Additional Accessories

In addition to core components, there are several accessories designed to enhance functionality. These may include cleaning kits, which help maintain the efficiency of the system, and monitoring devices that provide real-time feedback on water quality. Utilizing these accessories can significantly improve the overall user experience and prolong the lifespan of your system.

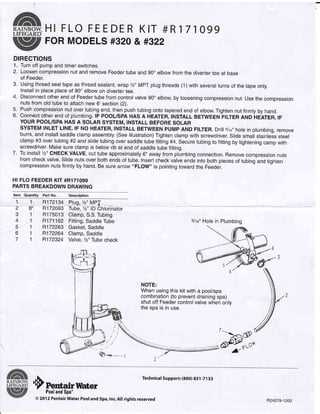

Installing New Components Safely

Ensuring the safe installation of new elements in a water sanitation system is crucial for optimal performance and longevity. Proper handling and adherence to guidelines not only safeguard the equipment but also enhance the overall efficiency of the system.

Preparation and Safety Measures

Before beginning the installation process, it is essential to prepare adequately. Ensure that the power supply is turned off to prevent any electrical hazards. Gather all necessary tools and components to avoid interruptions during the installation. Wearing appropriate personal protective equipment, such as gloves and goggles, will help minimize risks during handling.

Step-by-Step Installation Process

Follow a systematic approach while installing the new components. Begin by reviewing the manufacturer’s instructions to understand the specific requirements for your system. Carefully position the new parts, ensuring a secure fit. Double-check all connections for tightness and proper alignment. After completing the installation, restore power and perform a test to confirm that everything operates as expected. Regular maintenance checks will help to identify any issues early, ensuring continued efficiency.

Troubleshooting Chlorination Problems

Maintaining effective sanitation in water systems is crucial for safety and comfort. However, issues may arise that hinder the performance of disinfection units, affecting the overall quality of water. Identifying and addressing these problems promptly can help ensure optimal functionality and longevity of the equipment.

Here are common issues and their potential solutions:

- Insufficient Chlorine Levels:

- Check the unit’s settings to ensure they are appropriate for your water volume.

- Inspect for any clogs in the flow system that might reduce chlorine output.

- Test the water regularly to monitor chlorine concentration.

- Excessive Chlorine:

- Adjust the control settings to lower chlorine production.

- Inspect the chemical feeder for malfunctions.

- Perform a shock treatment to balance chlorine levels if needed.

- Cloudy or Discolored Water:

- Test the water for pH and alkalinity; imbalanced levels can affect clarity.

- Examine filtration systems for clogs or damage that may lead to contamination.

- Ensure proper circulation throughout the water system.

- Equipment Leaks:

- Inspect all connections and seals for wear and tear.

- Tighten loose fittings and replace any damaged components.

- Consult a professional for significant leaks or structural issues.

Regular maintenance and careful monitoring are key to avoiding common issues. Keeping detailed records of performance can also aid in troubleshooting and preventing future problems.

Importance of Regular Inspections

Routine evaluations of equipment are crucial for ensuring optimal performance and longevity. These assessments help identify potential issues before they escalate, thus preventing costly repairs and maintaining efficiency. Regular check-ups are an essential aspect of proactive maintenance strategies, allowing for timely interventions.

Frequent inspections not only enhance reliability but also contribute to the overall safety of the system. By thoroughly examining components and functionality, users can detect wear and tear, corrosion, or other deterioration signs. This vigilance minimizes the risk of unexpected breakdowns, ensuring that the equipment operates smoothly.

Additionally, systematic evaluations can lead to improved energy efficiency. Identifying and addressing inefficiencies during inspections can reduce energy consumption, resulting in lower operational costs. Ultimately, prioritizing regular inspections supports sustainability efforts and promotes responsible resource usage.

How to Read Diagrams Effectively

Understanding visual representations can greatly enhance your ability to grasp complex systems. By interpreting symbols and connections correctly, you can uncover the relationships between different elements, making it easier to analyze the overall functionality.

Key Components to Focus On

When examining these visual aids, pay close attention to the various symbols and their meanings. Each shape often represents a specific component or function, and lines indicate how these parts interact. Familiarizing yourself with common symbols will facilitate a quicker comprehension of the information presented.

Tips for Efficient Interpretation

Approach the visual representation methodically. Start by identifying the main components and their connections. Break down the information into manageable sections, and refer to any accompanying legends or keys to clarify any uncertainties. This structured approach will help prevent confusion and enable a clearer understanding of the overall picture.

| Symbol | Description |

|---|---|

| Circle | Represents a connection point or junction. |

| Square | Indicates a major component or device. |

| Arrow | Shows direction of flow or action. |

| Dotted Line | Represents a secondary or optional connection. |

Upgrading Your Chlorination Equipment

Enhancing your sanitization system can lead to improved efficiency and water quality. When considering an upgrade, it’s essential to evaluate your current setup and identify components that could be replaced or enhanced to meet modern standards. An updated system can reduce maintenance efforts and improve overall performance.

Key factors to consider during the upgrade process include compatibility with existing equipment, ease of installation, and the potential for automation. Investing in high-quality components can lead to long-term savings and better water management.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Electrolytic Cell | Higher efficiency models | Increased output and reduced energy costs |

| Control System | Smart technology integration | Improved monitoring and remote access |

| Flow Sensor | Advanced flow measurement devices | Enhanced accuracy and performance |

| Injection System | Upgraded injection pumps | Better distribution and reduced chemical usage |

Upgrading your sanitization system not only enhances performance but also contributes to a safer and more enjoyable aquatic environment. By carefully selecting components, you can ensure that your system operates at its best.

Resources for Further Information

For those seeking to enhance their knowledge about pool maintenance equipment and its components, numerous resources are available. These materials can help individuals understand the functionality, repair, and optimal usage of various systems designed for water treatment.

Online Guides and Manuals

Many manufacturers and suppliers provide detailed manuals and guides on their websites. These documents often include information about installation, maintenance, and troubleshooting of different systems, which can be invaluable for both beginners and seasoned users.

Community Forums and Support Groups

Engaging with community forums and support groups can offer insights and solutions from experienced users. Participants often share their experiences, tips, and advice, making these platforms a great source for practical knowledge and real-world applications.