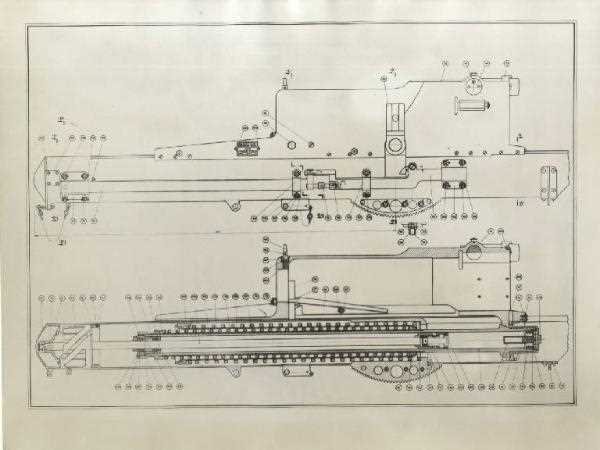

The design of vintage air-powered mechanisms has always fascinated enthusiasts and collectors alike. The intricate configuration within these models reflects the combination of craftsmanship and engineering precision that characterizes these timeless devices. Each component, from the smallest valve to the complex trigger system, plays a critical role in ensuring smooth operation and reliability.

Exploring the internal layout reveals a careful arrangement of interconnected elements, each contributing to the overall performance. By delving deeper into these arrangements, one can appreciate how every detail was meticulously planned to create an efficient and durable air-powered tool, often admired for its longevity and resilience.

For those who seek to maintain, restore, or enhance such models, understanding this layout becomes essential. Knowing the function and placement of each element helps ensure proper care and optimization, preserving the device’s functionality and historical value for years to come.

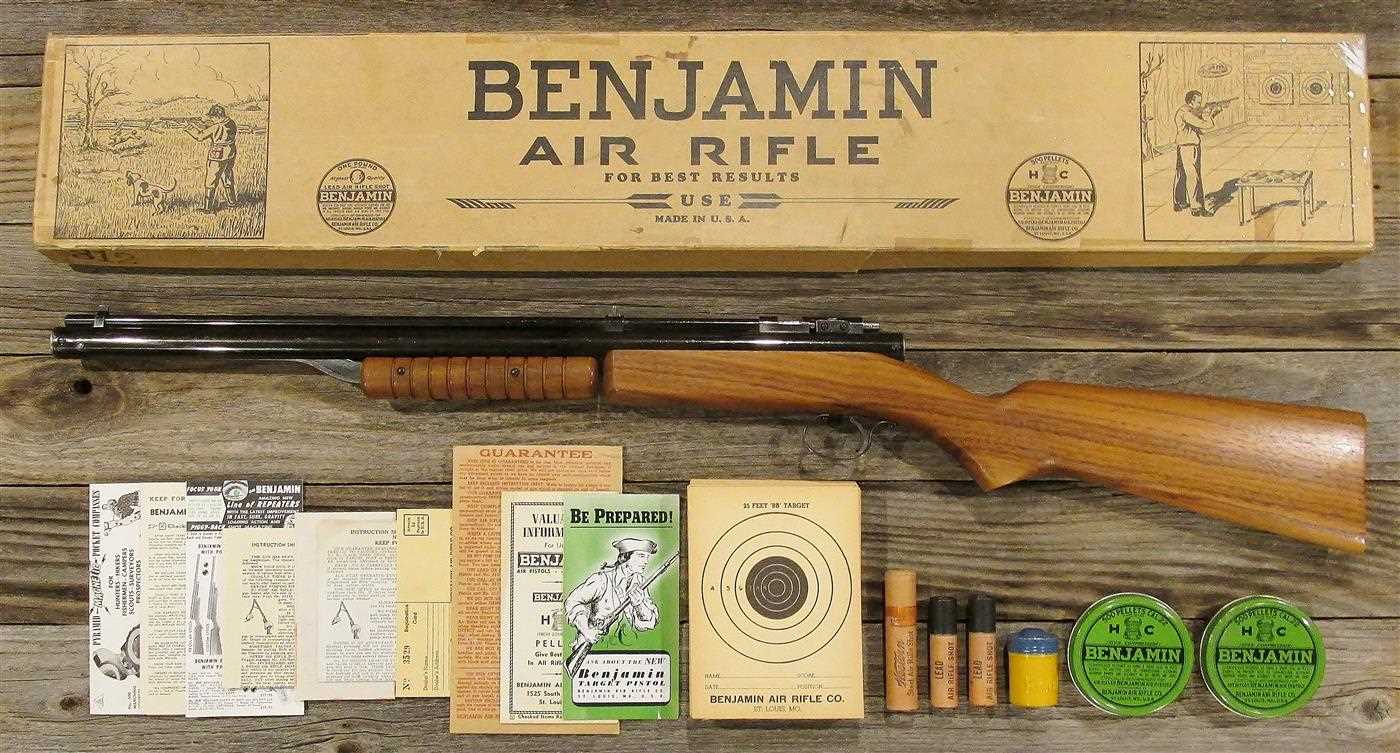

Overview of the Classic Air Rifle

The iconic model discussed here has been renowned for its durability and performance over the years. This particular air-powered firearm has a rich history and stands out due to its distinctive craftsmanship. Its design is a perfect blend of precision engineering and user-friendly functionality, making it a favored choice for both enthusiasts and collectors.

Durability and ease of use are key attributes of this model, ensuring a reliable experience for many users. Its robust structure and quality materials have contributed to its long-standing reputation, while the ease of maintenance makes it accessible even to novices. The combination of power and accuracy further adds to its appeal, particularly in various shooting scenarios.

One of the defining features of this air rifle is its smooth operation and ease of handling. With a mechanism designed for precision, it provides users with consistent performance, which

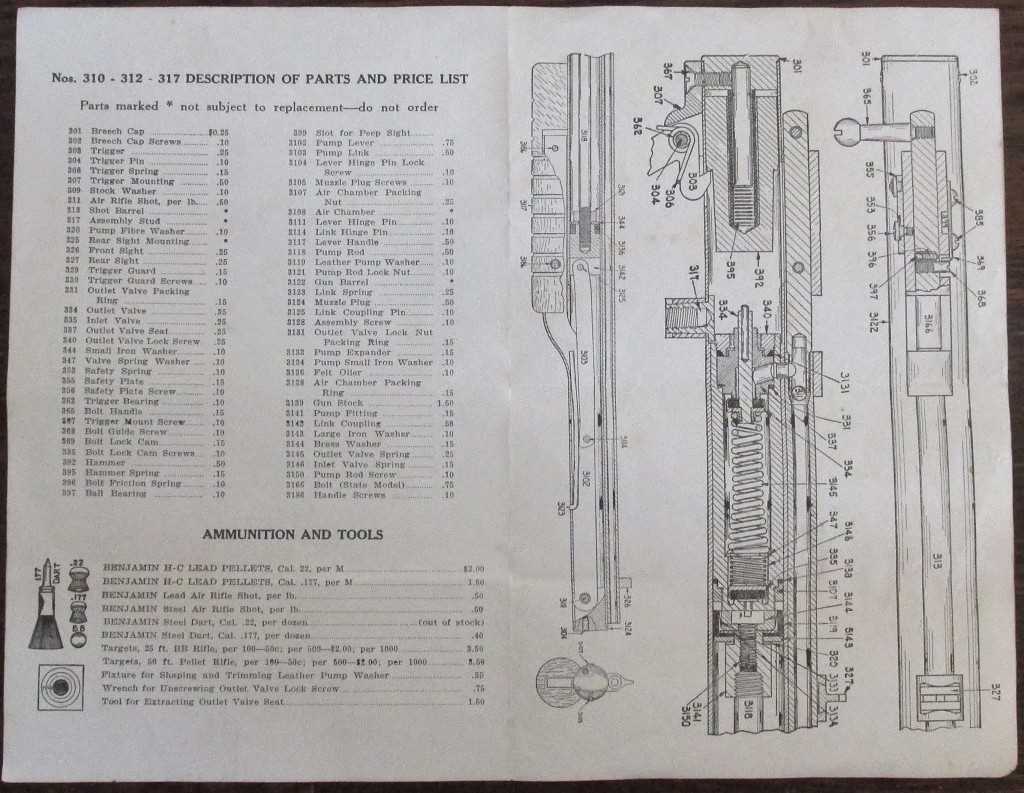

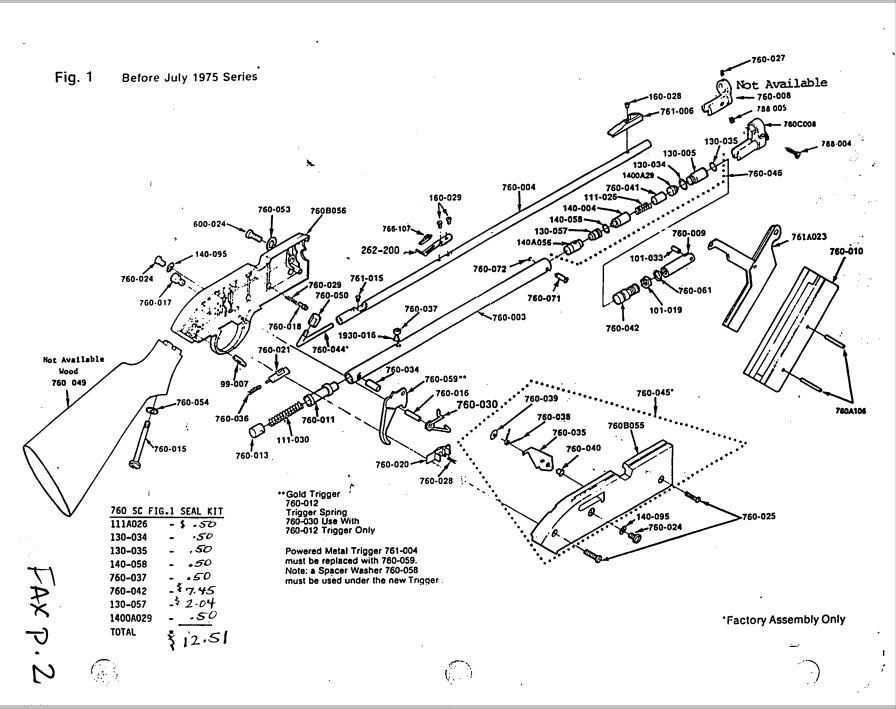

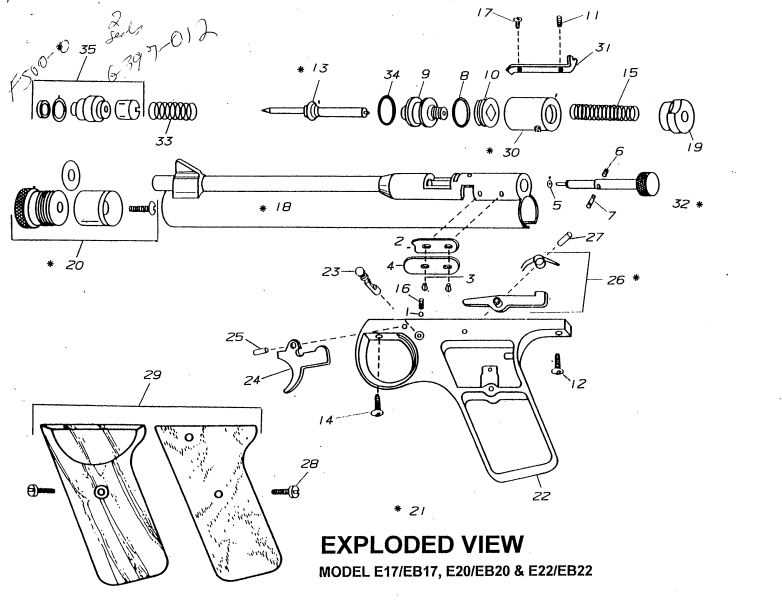

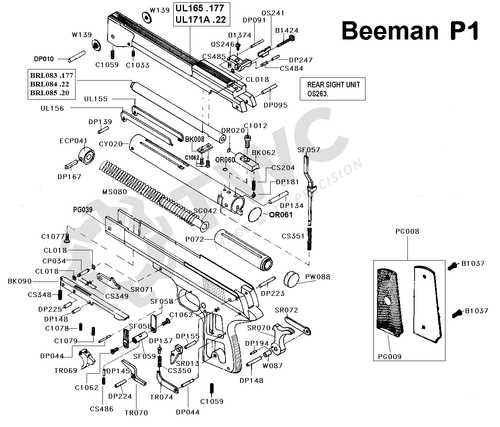

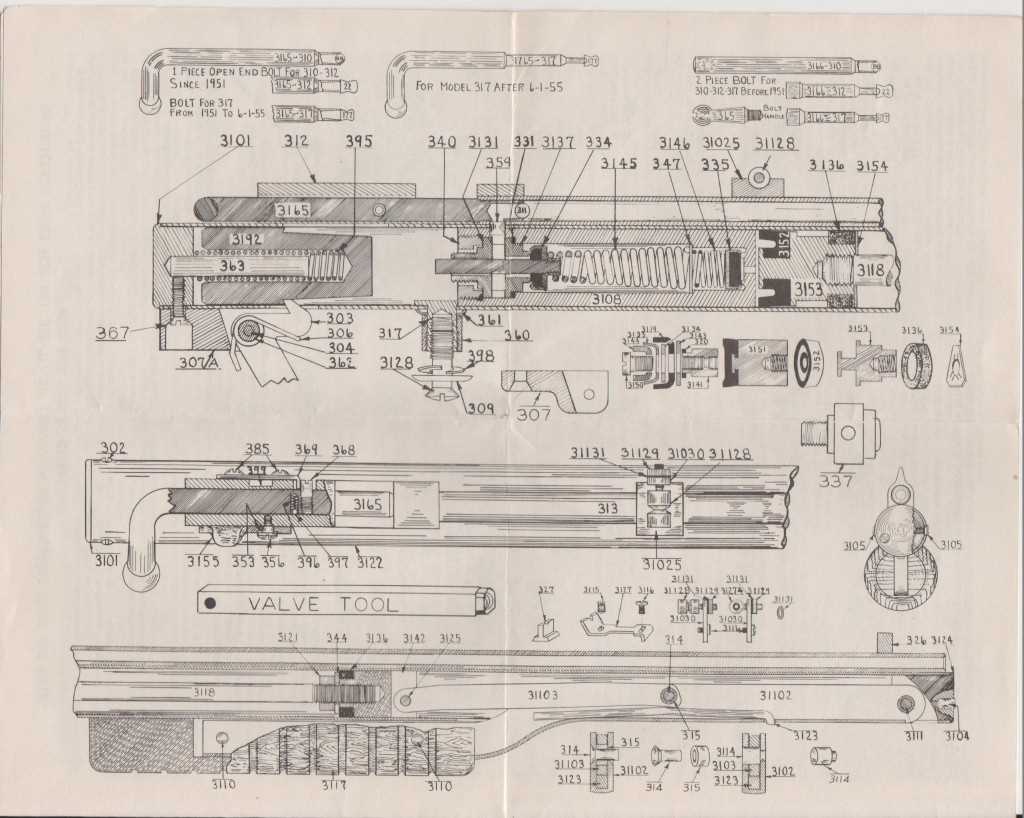

Key Components Breakdown

In this section, we will explore the essential elements that make up the inner workings of this mechanical design. Each individual piece plays a crucial role in the overall functionality, contributing to both performance and durability. Understanding how these parts interact is key to comprehending the overall assembly and maintenance of the system.

Core Structure: The foundational framework provides stability, ensuring all components are securely held in place. Its robust construction supports the entire mechanism, allowing other parts to function effectively without misalignment or excessive wear.

Movement Mechanism: At the heart of the system lies the intricate network of moving pieces. These are carefully calibrated to work in harmony, delivering precise motion. Each element is designed to interact smoothly, ensuring consistent performance under various conditions.

Understanding the Internal Mechanism

Exploring the inner workings of this precision device provides a comprehensive view of how its components interact to create a seamless operation. This section will delve into the essential elements of the system, explaining how each part contributes to overall functionality and performance.

- Main Components: The key elements form the backbone of the system. These include chambers, seals, and moving parts that work in unison to ensure efficient operation.

- Power Generation: The mechanism responsible for generating force is central to the device’s performance, relying on a sequence of interactions between springs, valves, and pressure systems.

- Sealing and Control: Tight sealing is crucial for maintaining the integrity of the system. Various gaskets and seals are employed to prevent any leaks, ensuring optimal function.

- Trigger Mechanism: The core of the system relies on delicate balance and timing, where each part contributes to the overall operation.

- Spring Tension: One of the key elements is the spring, which dictates the force required to activate the mechanism.

- Safety Features: Built-in safeguards ensure that the system only activates under specific conditions, preventing unintentional actions.

- Screwdriver set

- Wrenches

- Pliers

- Cleaning cloths

- Lubricant

- Ensure the device is unloaded and safe to handle.

- Remove any attachments or accessories from the assembly.

- Carefully unscrew and detach the outer casing, taking note of any screws or fasteners used.

- Inspect the internal components for any visible damage or wear.

- Gently separate the barrel from the main body, being cautious of any springs or mechanisms connected to it.

- Once removed, clean the barrel thoroughly to remove any debris or residue.

- Organize Your Workspace: A tidy and well-organized workspace can make a significant difference. Arrange all components and tools within easy reach to avoid unnecessary distractions.

- Follow a Logical Sequence: Reassemble parts in the order they were disassembled. This method helps prevent confusion and ensures that no pieces are overlooked.

- Utilize Reference Materials: Keep diagrams or photos of the original configuration handy. Visual aids can serve as invaluable references during the reassembly process.

- Check for Wear and Tear: Inspect each component for signs of damage or excessive wear. Replacing worn parts beforehand can save time and prevent issues later.

- Secure Fastenings Properly: Ensure that all screws, bolts, and fasteners are tightened appropriately. Loose fittings can lead to malfunction or misalignment.

- Take Your Time: Rushing can lead to mistakes. Approach the task with patience and care, taking breaks if needed to maintain focus.

Exploring the Trigger System

The trigger mechanism plays a crucial role in ensuring the smooth operation of the device. It governs the interaction between various internal components, allowing for precise and controlled actions. Understanding how this system functions can provide valuable insights into maintenance and customization.

By analyzing the various aspects of the trigger system, one can optimize its performance or troubleshoot potential issues with greater ease.

Air Pump Functionality

The air pump serves as a crucial element in the operation, converting mechanical energy into pressurized air, which is essential for efficient performance. Understanding how this mechanism works provides insight into the overall function of the device and helps ensure optimal pressure levels are maintained for consistent output.

The system operates through a series of interconnected components that work together to generate the necessary air flow. Below is a detailed overview of the key elements involved in this process.

| Component | Function |

|---|---|

| Piston | Moves up and down to compress air within the chamber. |

| Seals |

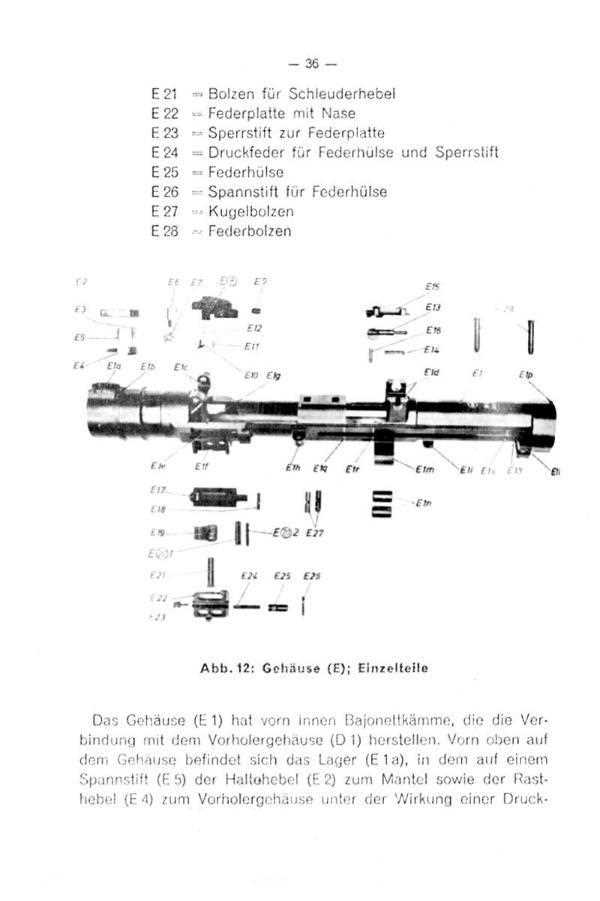

Disassembling the Barrel Section

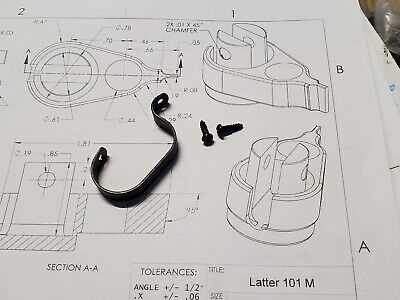

The process of dismantling the cylindrical component is crucial for maintenance and repair. This procedure allows for thorough cleaning, inspection, and replacement of worn parts, ensuring optimal performance. Understanding the steps involved can greatly enhance efficiency and safety during the task. Before beginning the disassembly, it’s important to gather the necessary tools and materials: Follow these steps for a successful disassembly: By following these guidelines, one can effectively disassemble the cylindrical component, paving the way for repairs or upgrades as needed. Maintaining the Valve Assembly

Proper care of the valve mechanism is crucial for ensuring optimal performance and longevity. Regular maintenance can help prevent issues that may arise from wear and tear, ensuring smooth operation and accuracy in function. Understanding the components involved and their interactions is essential for effective upkeep. Routine Inspection

Conducting periodic checks of the valve assembly is essential. Look for signs of wear, corrosion, or debris accumulation. Addressing these issues promptly can prevent more significant complications. Make it a habit to clean the assembly and inspect seals and gaskets for integrity. Cleaning and Lubrication

Cleaning the valve parts is vital to maintain their functionality. Use appropriate cleaning agents to remove dirt and residue without damaging the components. Additionally, applying suitable lubricants to moving parts can enhance their performance, ensuring they operate smoothly. Regular attention to these details will contribute significantly to the longevity of the entire mechanism. Replacement Guide for Worn Parts

When it comes to maintaining the functionality of your equipment, addressing degraded components is crucial. Over time, certain elements may lose their efficiency, leading to diminished performance. This guide serves to assist you in identifying and substituting these essential parts to ensure optimal operation. Identifying Worn Components: Regular inspections are vital for detecting signs of wear and tear. Look for any visible damage, such as cracks or excessive wear, which may indicate the need for replacement. Additionally, listen for unusual sounds during operation, as these can signal issues that require attention. Choosing Quality Replacements: Opt for high-quality substitutes that meet or exceed the original specifications. This not only enhances performance but also prolongs the lifespan of your equipment. Research reputable suppliers to ensure you acquire the best options available in the market. Installation Tips: When replacing a worn component, follow the manufacturer’s guidelines for installation. Ensure all connections are secure and that the new part is properly aligned. Take your time to avoid mistakes that could compromise the effectiveness of the repair. Regular Maintenance: After replacing worn components, establish a routine maintenance schedule to prevent future issues. Regularly check for signs of wear and perform necessary adjustments to keep your equipment running smoothly. Troubleshooting Air Leaks

Identifying and resolving air leaks is essential for ensuring optimal performance and efficiency in pneumatic systems. These leaks can lead to decreased functionality, increased operational costs, and potential damage if left unaddressed. By systematically examining components and connections, one can effectively pinpoint sources of air loss and implement necessary repairs. Common Symptoms: Recognizing the signs of air leaks is the first step in troubleshooting. Unusual hissing noises, reduced pressure readings, and inconsistent performance are typical indicators that warrant investigation. Pay attention to any sudden changes in operation, as these may signify an underlying issue. Inspection Techniques: Begin by visually inspecting all fittings, hoses, and seals for signs of wear or damage. Utilizing a soapy water solution can help identify leaks; apply the mixture to suspected areas and look for bubbling, which indicates escaping air. Additionally, using a sound detector or ultrasonic leak detector can aid in pinpointing hard-to-find leaks. Repair Strategies: Once a leak is identified, determine the best course of action for repair. This may involve replacing damaged hoses, tightening loose connections, or applying sealants to compromised areas. Regular maintenance and inspections can also help prevent future leaks and prolong the lifespan of the equipment. Reassembly Tips and Tricks

Reassembling complex mechanisms can be a rewarding yet challenging task. With the right approach, you can ensure that every component fits perfectly and functions as intended. This section provides essential guidance to streamline the reassembly process and enhance your efficiency. Implementing these strategies can significantly enhance your reassembly experience. By being methodical and attentive, you will achieve a successful outcome, ensuring that the mechanism operates smoothly and reliably. |